Translate this page into:

Processing and formulation technology of nutritional and functional food products by utilizing cheese and/or paneer whey: A critical review

⁎Corresponding authors. rajadkv@rediffmail.com (Deepak Kumar Verma), cristobal.aguilar@uadec.edu.mx (Cristobal Noe Aguilar)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Abstract

Whey is an excellent source of proteins, with a high biological value and essential elements in addition to the proteins it contains. Additionally, it possesses a number of characteristics that are exclusive to it. Whey has been “rediscovered” in recent years and is now being used in a wider variety of food recipes as a result of the features discussed here in the present review paper. It’s possible that using whey instead of the “nutrient goldmine” will be more “economical.” Consumers who are educated on the role that whey plays in human nutrition and are aware of its significance are more likely to be interested in purchasing food products that include whey. Due to the nutritional and functional features that whey possesses, it has been included into a wide variety of food compositions, such as dairy-based products, biofunctional components, confectionary products, and beverages that are both refreshing and nutritious. In this review, several types of food products and beverages containing whey that have been produced so far by researchers from all over the world are described, along with their processing characteristics, sensory attributes, and commercial potential. Moreover, this paper delves into the potential applications of probiotic and functional whey-based products within the realms of biofunctional and therapeutic relevance.

Keywords

Paneer whey

Nutrients

Beverages

Cost-effective

Dairy products

Food products

1 Introduction

At first, whey was seen as a byproduct of the dairy industry with little value, and it was destined for disposal. However, due to increasing environmental regulations in the late twentieth century, the practice of disposing of whey in the drains was no longer allowed (Panghal et al., 2017; Adesra et al., 2021; Amiri et al., 2021). At this point, the importance of whey components became apparent (Dinika et al., 2020; Tsermoula et al., 2021). As per a previous report, global whey production exceeds 180–190 million tons annually (Flinois et al., 2019). With a projected annual increase of 1–2 %, the estimated amount is expected to reach approximately 203–241 million metric tons by 2030. Moreover, out of this overall amount, as indicated by Zotta et al. (2020), 40 million metric tons are generated solely within the European Union, with 13 million metric tons constituting the yearly excess of cheese whey. India produces approximately 3 million tonnes of whey annually, leading to a substantial loss of about 2 lakh tonnes of crucial milk nutrients (Naik et al., 2009). Based on research report published by IMARC in 2023, the global paneer market size reached an impressive US$ 10.1 Billion. In the future, IMARC Group predicts that the market will achieve a value of US$ 18.1 Billion by 2032, with a growth rate of 6.5 % between 2024 and 2032 (IMARC, 2024). The worldwide cheese market had a valuation of approximately USD 119.7 billion in 2020 and is projected to achieve USD 155.5 billion by 2026, with a growth rate of 4.2 % during the forecast period (Balasubramanian, 2024). Europe holds the position of being the largest consumer and producer of cheese, with North America following closely behind. The combination of different regional tastes and cuisines leads to the widespread use of paneer and cheese globally, consequently boosting whey production (Parekh et al., 2017; Raghavendra et al., 2017; Raj et al., 2017; Kakan et al., 2018; Ahmed and Bajwa, 2019; Kaur et al., 2019; Pandey et al., 2019; Ranavaya et al., 2019).

During the production of paneer, channa, and cheese, a significant volume of greenish water known as whey is often leftover (Kumar et al., 2014; Johnson, 2017; Panghal et al., 2018; Dinika et al., 2020). Because of the significant biochemical oxygen demand (BOD) of whey, it is considered the most polluting among all dairy wastes (Algirdasl et al., 2016; Bacenetti et al., 2018; Panghal et al., 2017, 2018; Adesra et al., 2021). This has led to serious environmental worries regarding its global disposal. Subsequently, this byproduct of the paneer industry is identified as a valuable source of nutrients (Table 1). In the early 17th century, whey was utilized for treating jaundice-infected skin sores, gonorrhea, and epilepsy (Gandhi and Dixit, 2008; Bounous and Kongshavn, 2018; Panghal et al., 2018). This collection consists of a wide range of proteins that are produced and possess various chemical, physical, and functional characteristics. This source contains a wide variety of amino acids (AAs), both essential and non-essential (Ahmed et al., 2015; Sharma, 2019; Choudhary et al., 2023; Satpute and Swami, 2023). Source: Darade and Ghodake (2012) and Gupta (2000). *obtained during manufacturing of fresh acid cheeses (ricotta or cottage cheese), paneer & chhanna; **obtained during manufacturing of cheese.

Parameter

Acid whey*

Rennet whey**

Total solids (%)

6.06

6.87

Fat (%)

0.13

0.34

Protein (%)

0.30

0.98

Lactose (%)

4.40

4.60

Ash (%)

0.60

0.54

pH

5.60

6.40

Lactic acid (%)

0.21

0.14

Calcium (ppm)

710.65

501.50

Phosphorus (ppm)

560.50

441.50

From a different perspective, whey proteins contain a higher amount of essential AAs and branched-chain AAs compared to many other dietary proteins. Consequently, they impact insulin responses in humans in a positive way (Marshall, 2004; Deeth and Bansal, 2019; Sharma, 2019; Lagrange and Clark, 2019; da Rosa Camargo et al., 2020). Studies have shown that incorporating whey proteins into meals can enhance insulin release and decrease postprandial blood glucose levels (Frid et al., 2005; Adams and Broughton 2016). The product is composed of milk solids, lactose, proteins, a wide range of water-soluble vitamins, and vital minerals (Table 2). Several chronic conditions, including diarrhea, biliary sickness, skin issues, urinary system scales, hypertension, and cardiovascular disorders, can be addressed by utilizing whey's biological components (Ashoush et al., 2013; Kerasioti et al., 2014; Deeth and Bansal, 2019; Lagrange and Clark, 2019; Kelly 2019; Rosa et al., 2020). The role of nutritional and bioactive components of whey has been discussed in Table 3. It can be inferred that the nutritional and bioactive components provide a diverse array of health advantages, especially for chronic conditions. The published research reports highlight the ability to maximize the therapeutic benefits of whey by utilizing different delivery methods such as supplements, functional foods, and topical applications. In addition, continuous research and clinical studies will play a vital role in improving these applications and guaranteeing their effectiveness and safety. The proteins found in whey possess antimicrobial properties that can aid in the management and alleviation of diarrhea, particularly in children. They have the ability to hinder the proliferation of harmful bacteria and viruses. Whey is known to contain helpful bacteria that can help restore the balance of gut flora, an important factor in the treatment and prevention of diarrhea. Whey can assist in restoring electrolyte levels that are depleted during periods of diarrhea, facilitating a faster recovery. Whey proteins have the ability to stimulate bile production, which can be beneficial for digestion and provide relief for individuals with biliary diseases. These findings have the potential to enhance fat digestion and alleviate symptoms commonly linked to biliary disorders. Whey components, such as lactoferrin, possess anti-inflammatory properties that can aid in the management of inflammation within the biliary system. Whey proteins possess antioxidants that have the potential to mitigate oxidative stress, a prevalent contributor to skin aging and damage. Whey components possess anti-inflammatory properties that can effectively alleviate inflammation and enhance skin conditions such as acne and eczema. Whey contains a high concentration of amino acids that are essential for the synthesis of collagen, which plays a crucial role in maintaining and repairing skin health. Whey contains growth factors and immunoglobulins that have the potential to enhance wound healing and tissue repair. Whey contains calcium and citrate, which have the ability to prevent the formation of specific kidney stones by binding to oxalates and reducing their crystallization. The abundant water content in whey plays a crucial role in promoting hydration and detoxification. This aids in flushing out the urinary system, thereby reducing the chances of stone formation. Whey can assist in maintaining a urine pH that is alkaline, which can lower the chances of developing uric acid stones. Whey contains peptides that function as ACE inhibitors, which can assist in reducing blood pressure levels. Whey is an excellent source of potassium, which plays a crucial role in counteracting the impact of sodium and lowering hypertension. Whey peptides have the ability to enhance vasodilation, resulting in improved blood flow and a decrease in blood pressure. Whey proteins have been found to have a positive impact on cholesterol levels, specifically by lowering LDL cholesterol and increasing HDL cholesterol. This can lead to improved lipid profiles and a decreased risk of cardiovascular issues. The presence of antioxidants in whey helps to decrease oxidative stress and inflammation, both of which play a significant role in the development of cardiovascular disease. Peptides found in whey have been shown to have a positive impact on blood flow and blood pressure by promoting vasodilation. Certain elements found in whey have the potential to lower the likelihood of blood clots, which in turn can decrease the risk of strokes and heart attacks. Sources: Chavan et al. (2015), Yadav et al. (2015), Liutkevičius et al. (2016), Gupta and Prakash (2017), Kelly (2019), Lagrange and Clark (2019), Sharma (2019), Rosa et al. (2020) and Solanki et al. (2023)

Nutrients

Ingredients

References

Proteins

More than half of the proteins and peptides in milk are β-lactoglobulin (65 %), α-lactalbumin (25 %), serum albumin (8 %), glycomacropeptide (GMP), bovine serum albumin, lactoferrin, immunoglobulin, and phospho lipoproteins, respectively.

Fox and McSweeney (1998); Deeth and Bansal (2019)

Minerals

There is a concentration of calcium (Ca), magnesium (Mg), and phosphorus (P) in the solution, and some of these elements are partially attached to proteins. Zinc (Zn) can be found in small concentrations. The absorption of Zn and Mg ions has been promoted by lactose.

Zadow (1992); Lagrange and Clark (2019)

Vitamins

Amounts of vitamin-B12 (cobalamin) range from 40 to 70 %; vitamin-B6 (pyridoxine, pyridoxal, and pyridoxamine) and vitamin-B5 (pantothenic acid) range from 55 to 75 %; vitamin-B2 (riboflavin) and vitamin-B7 (biotin) range from 70 to 80 %; and vitamin-B1 (thiamine), vitamin-B3 (nicotinic acid), vitamin-B9 (folic acid) and vitamin-C (ascorbic acid) range from 80 to 90 %. When rennet coagulation was utilized instead of acid coagulation for cobalamin, more of it was transported into the whey.

Zadow (1992)

Lactose

About 70 % of the total solids in whey are made up of lactose.

Jelen (1992); Deeth and Bansal (2019)

Chronic Conditions

Observation and Remarks

Diarrhea

Biliary Sickness

Skin Issues

Urinary System Stones

Hypertension

Cardiovascular Disorders

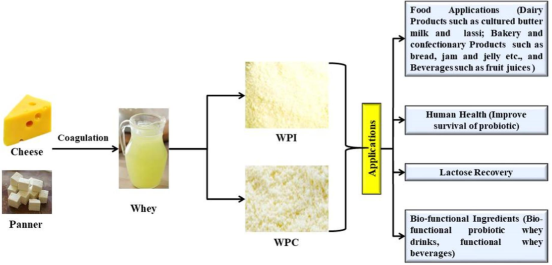

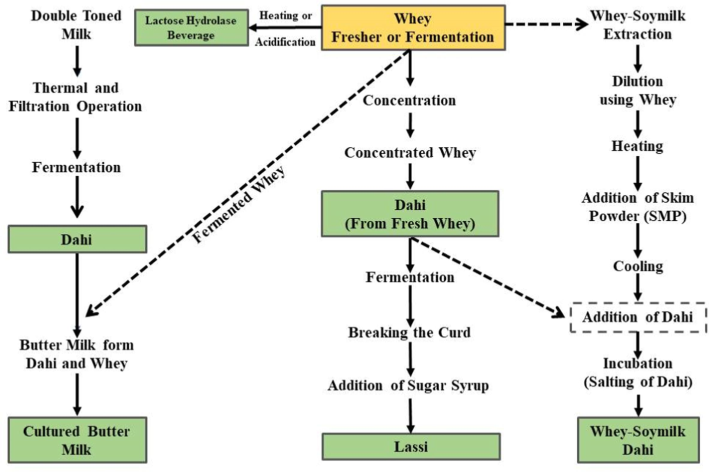

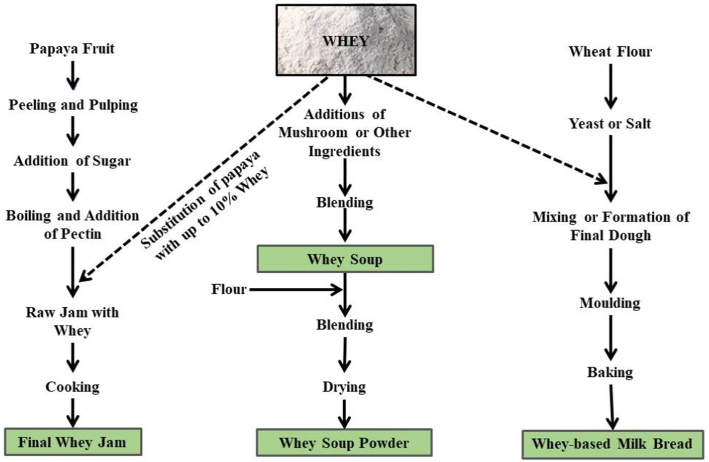

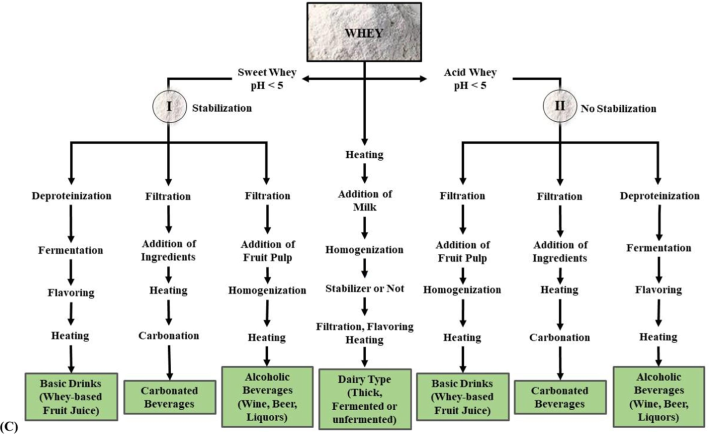

An effective solution to the ecological challenge is utilizing whey to develop nutritious and therapeutic foods and products, as suggested by Marshall (2004), Gupta and Prakash (2017), and Lagrange and Clark (2019). Whey protein extracts have been extensively promoted and used as a dietary supplement, as evidenced by various studies (Marshall, 2004; Dąbrowska et al., 2017; Gupta and Prakash, 2017; Anand and Awasti, 2020; Minj and Anand, 2020). In addition to their nutritional and medicinal advantages, whey components offer a variety of positive functional traits such as solubility, foaming, emulsifying, gelling, water binding, and more (Methews, 1984; Patel and Kilara, 1990; Yadav et al., 2015; Pereira et al., 2015; Parekh et al., 2017; Raj et al., 2017; Doost et al., 2019; Minj and Anand, 2020). The compounds found in whey are extremely valuable for human nutrition. Whey is commonly used in beverages, nutrition for the elderly, and sports nutrition because of its high nutritional value, as supported by various studies (Baljeet et al., 2013; Saxena et al., 2015; Villarreal, 2017; Shah and Patel, 2019; Minj and Anand, 2020). Using whey to formulate a range of dairy and food products with excellent sensory qualities is a highly effective and successful approach (Figs. 1-3).

Schematic representation of processing and formulation technology of whey-based dairy products.

Schematic representation of processing and formulation technology of whey-based bakery and confectionery products.

Schematic representation of processing and formulation technology of whey-based beverages.

Therefore, the present article discusses different whey-based food products and beverages developed by researchers worldwide, including their processing parameters, sensory attributes, and commercial feasibility. Furthermore, one section delves into the potential use of probiotic and functional whey-based products in terms of their biofunctional and therapeutic significance. In addition, the article paves the way for researchers, scientists, and industry professionals involved in the field to explore new opportunities and innovative work.

2 Whey-based dairy products

Dairy products, including liquid, powdered, and fermented milk, are not just an excellent source of nourishment but also a vital part of a nutritionally balanced diet (Fan et al., 2023). Elements such as lactose, lipids, and protein are crucial components present in milk that act as important indicators of dairy quality. Dairy products are consumed all around the world because of their outstanding nutritional value (Beermann and Hartung, 2013; Suh, 2022). There is an in-depth analysis of key dairy food products developed with cheese as well as paneer whey, along with an exploration of the technologies involved in their production and processing (Fig. 1). These aspects are covered in the subsequent sections.

2.1 Cultured buttermilk and lassi

Buttermilk is produced as a byproduct and is considered a functional food because of its emulsifying power, which is attributed to the polar lipids and milk fat globule membrane components (Gebreselassie et al., 2016; Rose et al., 2023; Jakopović et al., 2023). There are different ways to categorize buttermilk, such as traditional or conventional buttermilk, or cultured buttermilk. Churning is a process that effectively separates the white butter from the curd, leaving behind a liquid known as cultured buttermilk. This technique has been extensively studied and documented by various researchers (Gebreselassie et al., 2016; Mudgil et al., 2016; Rose et al., 2023; Jakopović et al., 2023). Manufacturing curd, homogenizing curd, and diluting with water are all essential steps in the commercial production of cultured buttermilk in India. Buttermilk is a highly nutritious and beneficial beverage due to its rich content of phospholipids and essential nutrients (Gebreselassie et al., 2016; Rose et al., 2023; Jakopović et al., 2023). Consuming cultured buttermilk in the diet has been found to have several benefits, including improved digestion, increased immunity, and reduced cholesterol levels in the blood (Devi, 2010; Nirgude et al., 2013; Rose et al., 2023). Cultured buttermilk is a widely recognized fermented dairy product that has been studied for its potential health benefits. It is known by various names, such as “Chhash” in South Asian countries and certain states in India (Devi, 2010; Pushpangadan et al., 2012; Ghanshyambhai et al., 2015; Rose et al., 2023). With its delightful flavor and impressive array of health advantages, buttermilk has gained significant popularity among consumers and is an essential ingredient in various Ayurvedic formulations (Devi, 2010; Pushpangadan et al., 2012; Rose et al., 2023; Jakopović et al., 2023).

Lassi is a well-known and widely enjoyed fermented milk beverage that is often consumed during the summer months for its refreshing qualities. It is made from dahi, as described in several studies (Kedaree et al., 2021a, b; Datir et al., 2022). This beverage is widely consumed during the summer season in cold drink shops and restaurants across India, especially in the northern region (Kedaree et al., 2021a, b). Lassi is a fermented milk product prepared using specific strains of lactic acid bacteria (LAB) as starter cultures. It is then mixed with water, sugar, salt, and optional flavoring ingredients, along with spices like cumin seeds and coriander leaves (Betoret et al., 2011; Kedaree et al., 2021a, b; Datir et al., 2022). Lassi can be categorized into two types: salty Lassi and sweet Lassi, depending on the ingredients used (Mollet and Rowland, 2002). In addition to the regular classification of lassi, there exists a unique variation known as Bhang lassi. This particular type of lassi is made utilizing the plant leaf extract of Cannabis spp., and is commonly consumed during the Holi and Shivaratri festivals in India (Kedaree et al., 2021a, b; Datir et al., 2022). Lassi offers numerous health benefits similar to yogurt or curd. It aids in reducing acidity in the stomach, promoting the growth of advantageous bacteria in the gastrointestinal (GI) tract, boosting immunity, aiding digestion, and maintaining internal organ temperature during hot summers (Mollet and Rowland, 2002; Betoret et al., 2011). Therefore, there has been a shift in consumer perceptions regarding foods and dietary habits. Many peoples now recognize the significant impact that these foods can have on their health (Mollet and Rowland, 2002; Betoret et al., 2011).

Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus were combined in equal proportions (i.e. 1:1) to produce cultured buttermilk. Half of the milk in this preparation was replaced with paneer whey for curd production. To enhance the sensory quality, salt (0.5 %) and spices (0.4 %) were incorporated into the buttermilk production process. The resulting buttermilk had a shelf life of up to 4 days, as reported by Maheta et al. (2015). In 2003, researcher prepared lassi by using dahi made from neutralized fresh paneer whey and buffalo milk (Mittal, 2003). Yogurt was made by adding a specific amount of stabilizer at 60 °C, mixing, and pasteurizing at 80 °C. Following cooling to 30 °C, the mixture received a 1 % starting culture and was left to incubate for 14–16 h. The lassi was produced by mixing sugar syrup and flavoring, followed by homogenizing and cooling the mixture to 4 °C before consumption. After a sensory assessment by a panel of expert judges, the product scored 7.83 out of 9.0 on the Hedonic scale, indicating a high level of acceptability. The suitability of lassi depends on the interplay of environmental factors and chemical processes that take place during its making. Undesirable flavors in food, like milk, were caused by processes involving different unit operations. Factors such as heat and solids transfers, oxidable compounds, and oxygen exposure have been associated with causing off-flavoring in foods (Zhang et al., 2012; Park et al., 2016; Smith et al., 2016; Amit et al., 2017). The bitterness and metallic taste are a result of proteolysis in cheese whey, involving proteases and chymosin in fluid whey necessary for coagulating the curd (Amiri et al., 2021; Ardö, 2021). Eliminating chymosin and proteolysis in dairy processing can assist in minimizing off-flavoring. For instance, lassi, a cultured milk product, includes carbohydrates, fat, minerals, and organic acids, especially lactic acid from the curdling process. This typically leads to acid whey, known for its sour aroma and taste (Smith et al., 2016). However, by incorporating syrup and low methoxy pectin as a protein stabilizer during processing, the sour attribute can be masked effectively. Consequently, paneer whey-based lassi, in its current formulation, is not only a feasible way to reduce environmental pollution caused by whey, but it also provides an opportunity to generate economic value and provide consumers with an end-product that is of good quality and has a minimal off-flavor.

2.2 Dahi

Earlier, dahi (i.e. Curd) was made by fermenting boiled milk of cow or buffalo with lactic cultures like L. lactis spp. lactis, L. lactis spp. cremoris, and L. diacetylactis. These cultures could be used alone or in combination (Rathi et al., 2015). Curd, also known as Indian dahi, is manufactured by fermenting milk with LAB. The milk undergoes a series of specific processes, including heat treatment, homogenization, and cooling, to create the ideal conditions for the introduction of bacteria or starter culture. Under optimal conditions of temperature and moisture, the bacteria have the ability to undergo lactose fermentation, resulting to the formation of lactic acid. The milk proteins undergo a process of coagulation and solidification, resulting in the formation of curd, commonly known as Indian dahi. During fermentation, a clear liquid known as acetaldehyde is also made, which adds to the distinctive taste of the curd (Indian dahi). It is commonly included in daily diets due to its potential to provide vitamin B-complex including riboflavin (vitamin B2) and folic acid (vitamin B9) (Sarkar et al., 2015). Dahi contains a high amount of LAB and has been found to have a probiotic effect. This can be beneficial for maintaining intestinal health and managing diarrhea in children (Sharma and Lal, 1997; Sarkar et al., 2015). In addition, misti dahi is referred to by other names such as misti doi, payodhi, and lal dahi. This is a conventional sweetened fermented milk product that is quite popular in the eastern region of India, particularly in West Bengal, Bihar, and Assam. The product is made through a process known as lactic acid fermentation, which involves the fermentation of sweetened milk. Misti dahi is considered a significant dessert during ceremonial events in both rural and urban Bengal. The product is typically found in a variety of sizes, contained within earthen pots. A high-quality misti dahi exhibits distinct visual attributes such as a rich brown color, a solid yet yielding texture, a velvety smoothness, and a delightful caramelized taste. Misti dahi is best made using buffalo milk because of its high fat content, resulting in a rich and creamy product with a delightful texture. Due to its high protein content, buffalo milk forms a firm coagulum that effectively prevents whey separation during storage and transportation.

2.2.1 Whey soymilk dahi

“Whey Soymilk Dahi” prepared using paneer whey is a fascinating blend of age-old Indian yogurt-making methods and contemporary, plant-derived components (Rathi et al., 2015; Han et al., 2021). This cutting-edge product merges the healthful advantages of whey, obtained from dairy processing, with the velvety indulgence of soymilk, resulting in a lactose-free and protein-rich dairy substitute (Gupta and Prakash, 2017; Minj and Anand, 2020; Han et al., 2021; Solanki et al., 2023; Nguyen et al., 2024). This versatile product offers a tangy flavor that brings to mind traditional dahi. It can be enjoyed on its own, used as a base for smoothies, or incorporated into savory dishes such as curries and marinades (Rathi et al., 2015; Smith et al., 2016; Solanki et al., 2023). If one has dietary restrictions or is seeking a more nutritious alternative, whey soymilk dahi provides a delicious solution to enhance the food quality that endeavors (Rathi et al., 2015; Han et al., 2021; Solanki et al., 2023).

People allergic with milk protein can turn to soy as a protein alternative, as supported by various studies (Zhang et al., 2012; Rathi et al., 2015; dos Santos et al., 2019; Han et al., 2021). Furthermore, fermentation can not only preserve food but also modify or improve its taste, consistency, and nutritional value (dos Santos et al., 2019; Han et al., 2021). Prebiotics that occur naturally and enhance the growth of Bifidobacterium in the large intestine can be found in soy yogurt. According to the time it takes for the dahi to set, a whey-soymilk blend with a paneer whey: soybean ratio of 5:1 and a total solids content of 20 % was selected (5 h) (Rathi et al., 2015). A study discovered that paneer whey and soybeans, when consumed individually, may not be very tasty, but when mixed together, the resulting dish is not only flavorful but also provides a combination of nutrients from both paneer whey and soybean (Rathi et al., 2015). Combining whey and soybean can enhance palatability by adding whey to dahi, which increases total solids like protein, total sugar, and milk solids (Zhang et al., 2012). This helps reduce the beany/grassy or astringent flavor often found in soymilk. Regarding this matter, Routray and Mishra (2012) examined the sensory evaluations of four distinct dahi beverages. These included Sample-1 (dahi powder and water), Sample-2 (dahi powder, guar gum, locust beans, and water), Sample-3 (dahi powder, guar gum, locust beans, and water), and Sample-4 (commercially available drink). Their findings indicated that Sample-3 outperformed Samples-2 and 1. Probably, the variation in samples Sample-3 and Sample-2 (which had the same texture) was caused by the inclusion of vanilla essence in Sample-3. Based on this observation, it can be inferred that incorporating flavor or additional solids into regular yogurt enhances its taste, increases its nutritional content, and reduces the environmental impact of whey discarding (Routray and Mishra, 2012).

2.2.2 Dahi from concentrated whey

“Dahi from Concentrated Whey” is an innovative yogurt alternative made from the concentrated whey obtained during cheese or paneer production (Raghavendra et al., 2017; Veena et al., 2017; Gandhi et al., 2022).This cutting-edge procedure not only minimizes waste but also yields a smooth, high-protein dahi with a unique flavor profile (Adesra et al., 2021; Tsermoula et al., 2021). The concentrated whey enhances the flavor profile of the dahi, giving it a distinct tanginess and richness (Park et al., 2016; Smith et al., 2016; Veena et al., 2017; Gandhi et al., 2022). This makes it a highly adaptable ingredient that can be used in a wide range of sweet and savory dishes. Whether savored as a refreshing complement to zesty curries or incorporated into baking and dessert recipes, dahi made from concentrated whey provides a delectable and eco-friendly variation of conventional yogurt (Mudgal and Prajapati, 2017).

Blending dairy milk with 11.5 % total solids in different ratios (1:1, 2:1, and 3:1) with concentrated paneer whey with 11.5 % total solids was studied by Raghavendra et al. (2017). This blend was utilized in producing dahi, which underwent testing to evaluate its sensory, physicochemical, and textural properties. The yogurt produced by combining milk and concentrated whey in a 3:1 ratio was determined to be satisfactory in terms of sensory perception and texture. According to the results of this study, it was noted that paneer whey can be used as a viable replacement for 25 % of the milk in the production of high-quality dahi (Raghavendra et al., 2017). By incorporating whey, a byproduct of the dairy industry, the nutrient content of dahi can be significantly improved.

2.3 Lactose fermented beverage

It is worth noting that lactose is the main carbohydrate found in dairy products. This particular disaccharide is a unique combination of glucose and galactose, exclusively present in the milk of mammals (Schaafsma, 2008; Kanurić et al., 2018). Lactose plays a vital role in the formation of the neural system and the growth of skin, bone skeleton, and cartilage in infants. In addition, it aids in the prevention of conditions like rickets and saprodontia (Emmett and Rogers, 1997; Kanurić et al., 2018). The process of lactose fermentation by LAB is a frequent happening in the production of different fermented dairy products. Specifically, lactose serves as the primary energy source for the bacteria in the starter culture (Kanurić et al., 2018).

Utilizing a cost-effective and simple fermentation method, along with enriching with fruit juices and carbonation, cheese or paneer whey can be effectively used to produce beverages, as demonstrated by various studies (Dilipkumar and Yashi, 2014; Patel et al., 2017; Rizzolo and Cortellino, 2018; Silva e Alves et al., 2018; Ahmed and Bajwa, 2019; Kaur et al., 2019). From an economic standpoint, producing whey as a beverage on a large scale is beneficial. The findings from the research demonstrate that whey can be successfully used to produce fermented carbonated beverages (Pereira et al., 2015; Panghal et al., 2017; Ranavaya et al., 2019). Transforming the entire paneer whey into a refreshing carbonated health drink with a sensory score above 8.01 for overall acceptance can help address environmental pollution concerns (Kakan et al, 2018; Pandey et al., 2019). According to reports, the beverage has been stated to have a shelf-life of one week (Shaik, 2013; Baba et al., 2016). Utilizing paneer whey in manufacturing fermented milks might also help to minimize the adverse environmental impact of whey (Raghavendra et al., 2017). When it comes to dairy products, incorporating whey and stabilizing ingredients in yogurt, dahi, cultured buttermilk, or lassi can enhance texture and minimize whey syneresis while the product is stored (Mittal, 2003; Kelly, 2019).

3 Whey-based bakery and confectionery products

In recent years, the use of whey proteins and whey as a food ingredient has gained significant popularity in the bakery and confectionery industry (Board, 2013; Mathuravalli, 2021; Jagarlamudi, 2022). Its unique ability to enhance flavors resulting in tender products has made it a sought-after ingredient (Jagarlamudi, 2022). Whey-based bakery and confectionery products have become increasingly popular across the globe, because of their nutritional advantages and adaptability in various dishes (Board, 2013; Królczyk et al., 2016; Mathuravalli, 2021; Britchenko and Mickiewicz, 2022; Jagarlamudi, 2022). As whey contains a high amount of protein, vitamins, and minerals, which makes it a great addition to baked products and sweets to boost their nutritional value. Protein bars, cookies, muffins, and cakes can all benefit from the addition of whey, which enhances their protein content and enhances their texture (Board, 2013; Sharma, 2019; Britchenko and Mickiewicz, 2022; Chaven, 2023). Whey protein isolate is commonly utilized in dishes to enhance protein content while minimizing fat and carbohydrate intake (Sharma, 2019). Whey is commonly used in confectionery products such as protein-enriched chocolates, truffles, and fudge (Board, 2013; Sharma, 2019; Britchenko and Mickiewicz, 2022; Chaven, 2023). These treats provide consumers with a guilt-free indulgence while also offering added nutritional value. Additionally, whey powder has applications as a coating for candies or as a binding agent in chewy treats (Board, 2013; Chaven, 2023). Thus, the inclusion of whey proteins in bakery and confectionery products seems to be an appropriate option for improving the convenience and sensory experience of consuming these proteins (Radzymińska et al., 2018). Their positive influence on the physicochemical and sensory properties of bakery and confectionery products as a whole has been well-documented (Chavan et al., 2015; Britchenko and Mickiewicz, 2022). Incorporating whey protein concentrates and isolated whey proteins into baked and confectionery products can enhance their functionality and nutritive value, leading to improved quality and overall appeal (Radzymińska et al., 2018).

Each day, an increasing number of peoples purchase products from bakeries and confectioneries, while their standards continue to rise. Striving for perfection has elevated this sector into a fiercely competitive specialized market. When producing bread, wheat flour, yeast, water, salt, and sugar are combined to develop the most sought-after product in bakeries. Bread is produced using these components. Other baked products like cakes and cookies are considered top-tier confections. There is an in-depth evaluation of some of the most prominent bakery and confectionery foods that are based on whey that has been provided in the following sections, along with a discussion of the technologies that are employed in the processing and formulation of these foods (Fig. 2).

Therefore, with the increasing demand for healthier choices among consumers, whey-based bakery and confectionery products are expected to maintain their popularity. They are appealing to fitness enthusiasts, health-conscious individuals, and those with dietary restrictions. In addition, bakery and confectionery products made with whey exhibit a range of flavors, textures, and presentations that differ from country to country. These variations reflect the unique local tastes and culinary traditions, highlighted in Table 4. The process of making of whey-based bakery and confectionery products is influenced by the culinary traditions and preferences of each country, leading to a wide variety of delectable offerings found across the globe. Indian cuisine often includes whey-based sweets like barfi or peda. These delectable treats are made by combining whey solids with sugar, nuts, and spices, resulting in a decadent and fudgy dessert. Whey is incorporated into bakery products such as naan bread or savory snacks like mathri to increase protein content and improve texture. Whey has been seamlessly integrated into classic confections such as ricotta cheesecake or cannoli filling, imparting a delightful richness and creaminess to these cherished treats. Whey powder is also incorporated into biscotti or panettone, adding a protein boost to these traditional delicacies. Whey is utilized in creative ways within the realm of bakery and confectionery products. For instance, it is incorporated into protein-enriched mochi or served as a delectable filling for dorayaki pancakes. Whey powder is also used to enhance the texture of fluffy Japanese cheesecakes, making them light and airy. Bakeries in Brazil are served pão de queijo, a type of cheese bread made with tapioca flour and whey. This combination gives the bread a chewy texture and a delicious cheesy taste. Sources: Board (2013); Radzymińska et al. (2018); Mathuravalli (2021); Britchenko and Mickiewicz (2022); Jagarlamudi (2022); and Chaven (2023).

Country

Bakery and Confectionery Products

Remarks

India

Sweets (such as barfi or peda), naan bread and savory snacks (like mathri)

Italy

Traditional sweets desserts (like ricotta cheesecake or cannoli), biscotti and panettone

Japan

Mochi, dorayaki pancakes, and fluffy Japanese cheesecakes

Brazil

Pão de queijo, cheese bread, brigadeiros, and traditional chocolate truffles

3.1 Paneer whey supplemented milk bread

“Paneer Whey Supplemented Milk Bread” combines the technical aspects of paneer whey with the scientific benefits of milk in a delightful bread recipe (Kakan et al., 2016, 2018). This cutting-edge loaf combines the residual whey from paneer production with fresh milk, resulting in a tender and delectable bread with a subtle tang (Kakan et al., 2018). The addition of paneer whey enhances the nutritional composition of the bread, enriching it with essential protein, vitamins, and minerals (Kakan et al., 2016, 2018; Dobhal et al., 2024). Indulge in the warmth of this bread, mixed perfectly with butter or transformed into delectable sandwiches and toast. Not only does it satisfy the way it tastes, but it also helps minimize food waste and provides a wholesome homemade essential (Kakan et al., 2018). People try it for a unique twist on traditional bread recipes that are celebrated for sustainability and flavor.

Adding paneer whey to bread led to a slight rise in total solids, ash, and total protein content. As the level of paneer whey was elevated, the moisture and pH values showed a decrease (Kakan et al, 2018; Paul et al, 2019). When 300gm of flour was used, various amounts of paneer whey were added, ranging from 45 to 180 mL. It was observed that as the quantity of paneer whey increased, the moisture and pH values decreased. The overall solid, ash, and protein content of the bread remained relatively stable. In a study by Paul et al. (2019), they explored the utilization of paneer whey as a diluent in the production of multigrain bread. Their findings revealed that incorporating whey led to enhanced crust browning along with a higher total solid content. Adding whey did not impact the texture quality due to the high temperature of over 160 °C and the total solids content of 15 %. The results remained largely consistent with the control multigrain bread; however, incorporating whey into the process resulted in the characteristic browning linked to the Maillard reaction. When adding paneer whey to milk bread, it's crucial to closely monitor the baking temperature to achieve the desired properties in the final product. According to Paul et al. (2019), milk bread enriched with paneer whey can be produced with a creamy hue to avoid the Maillard reaction above 180 °C. Technologically, the multigrain dough made by adding concentrated paneer‐whey (15, 20, and 25 % TS) was found to have a firmer and stickier texture, but less gummy compared to dough made with water. Concentrated whey was discovered to slow down the proofing rate of dough (Paul et al., 2019).

As per a study by Iuga and colleagues (2020), the dough's elasticity decreased when acid whey was used, while an increase in elasticity was noted when milk was used, compared to the control. In addition, the study by Iuga et al. (2020) discovered that the samples with up to 25 % acid whey exhibited an increase in resistance to dough deformation. However, this resistance decreased when water was substituted with more than 25 % milk. Using paneer whey instead of water not only enhanced the nutritional properties of the milk breads, but it also had economic benefits for dairy plants. It helped reduce the expenses of treating effluent and played a role in addressing pollution problems resulting from whey drainage (Kakan et al, 2018).

3.2 Jam and jelly with the addition of paneer whey

Paneer whey-based jam and jelly provide a fascinating variation on conventional fruit preserves, delivering a combination of unique flavors and health advantages (Wasnik, 2016; Raj et al., 2017). Paneer whey adds a delicate tanginess to jams and jellies, elevating their flavor with a touch of acidity (Wasnik and Changade, 2015; Wasnik, 2016). The distinct flavor profile of this product enhances the sweetness of the fruits, resulting in a harmonious blend of flavors (Raj et al., 2017). In addition, paneer whey contains a high amount of protein, vitamins, and minerals, which can enhance the nutritional value of jams and jellies. Integrating whey into these preserves not only elevates their flavor but also boosts their nutritional content, providing a healthier choice for consumption (Raj et al., 2017; Kumari and Rani, 2019). Furthermore, the addition of paneer whey in the production of jam and jelly contributes to the reduction of food waste by repurposing a byproduct of cheese-making (Raj et al., 2017; Kumari and Rani, 2019; Tsermoula et al., 2021). This practice emphasizes the importance of optimizing resources and reducing environmental impact, which ultimately leads to a more sustainable and environmentally-friendly food system. In addition, paneer whey-based jam and jelly have a wide range of culinary uses. They can be spread on toast, used as a topping for pancakes or waffles, filled into pastries, or even added to salad dressings and marinades (Wasnik and Changade, 2015; Wasnik, 2016; Raj et al., 2017; Kumari and Rani, 2019). Their adaptability makes them a flexible ingredient for both sweet and savory dishes.

Proteins undergo denaturation during jam processing, leading to the removal of whey proteins (Brodkorb et al., 2016). Considering the lower protein levels in fruit pulps used in jam, whey can be incorporated as an economical protein source to enhance its nutritional content. Replacing papaya jam with 10 % whey led to a satisfactory formulation with improved texture, suitable for a jam-like product (Raj et al., 2017). By incorporating paneer whey, there was a noticeable rise in the acidity (pH), total solids, and ash levels. The water content of the jam contained a significant amount of protein and reduced sugar levels. Protein concentrations in different samples were 0.92 %, 3.15 %, and 4.23 % for T0 (control jam), T1, and T2, respectively (Raj et al., 2017). Moreover, a study showed that whey can be successfully substituted in jam, enhancing its nutritional, physiochemical, and textural properties while maintaining its sensory attributes. Moreover, the research paved the way for effectively utilizing paneer whey, a plentiful byproduct of the Indian dairy industry.

The jelly confection was developed using paneer whey, offering a promising alternative for utilizing 100 % of the whey, particularly during the manufacturing process (Wasnik and Changade, 2015). Several combinations of paneer whey and water that were developed in various ratios: 00:100 (T1), 25:75 (T2), 50:50 (T3), 75:25 (T4), and 100:00 (T5). They were then heated to 77–82 °C with color, flavor, and citric acid added at 0.1, 0.2, and 1.0 %, respectively. High methoxyl pectin at 1.5 % and ground sucrose at 47.5 % were combined and concentrated to 65 °Brix to produce a jelly confection (Wasnik and Changade, 2015). As the paneer whey content increased, the total protein content also increased. Following a 30-day storage period, the moisture content reduced with the rise in paneer whey volume. Based on the research by Wasnik and Changade (2015), paneer whey has the potential to fully substitute water in making jelly confections without significantly altering the sensory attributes, as indicated by the non-significant changes in sensory scores. As the levels of paneer whey increased, the nutrient contents in the treatments showed improvement. This will help dairy plant operations reduce costs by lowering the expense of effluent treatment and will contribute to solving pollution issues caused by whey drainage (Wasnik and Changade, 2015). The addition of whey to sweetened formulation not only increases the protein and mineral contents, but it also reduces the amount of other sugar that is required to be added in the product because it also contains some amount of sugar in its composition. This is despite the fact that there are not enough studies in the literature that address the employment of whey in the production of jelly and jam. de Almeida Marques et al. (2016) developed cookies without added sugar that matched the taste of regular cookies by replacing wheat with whey protein concentrate. To preserve the sensory qualities of traditional cookies with acceptance rates of 70 % or higher, a combination of 54.0 g of WPC/100 g and 33.4 g of margarine/100 g is recommended (de Almeida Marques et al., 2016). Moreover, the limited solubility of acidic whey proteins combined with conjugation in the presence of reducing carbohydrates could lead to the development of heat-stable networks, solid gelification, viscosity increase, and turbidity to maintain desirable textural characteristics (Wijayanti et al., 2014; Brodkorb et al., 2016).

In a nutshell, paneer whey-based jam and jelly provide a tasty and healthy choice that embraces the exploration of new flavors, sustainable practices, and culinary ingenuity.

3.3 Rusk and soup with the addition of paneer whey

Paneer whey concentrated to 30 % total solids can be utilized instead of water as a diluent in making rusks and soup sticks. These products remained unchanged at 30 °C for 9 days without any loss in sensory qualities (Mallik and Kulkarni, 2010). After analyzing the costs, it was found that whey-incorporated Rusks were priced at Rupees 44.24 per kg, whereas the control was priced at Indian Rupees 46.70 per kg. Similarly, whey-incorporated Soup sticks were priced at Rupees 46.18 per kg compared to Rupees 48.50 per kg for the control. Concentrated paneer whey can effectively substitute water in the production of rusks and soup sticks without compromising the sensory characteristics. In a study conducted by Parjane et al. (2010), a tomato soup was developed using a ratio of 1:3 tomato pulp to chhana whey. The soup received a satisfactory rating of 7.73 on a 9-point Hedonic scale for overall acceptance. Various studies have explored the utilization of liquid whey in different soup recipes. For instance, corn flour soup, vegetable soup, and mushroom whey soup powder have been developed using liquid whey as an ingredient (Singh et al., 2003; Verma et al., 2010; David and Prashant, 2014; Rai et al., 2014). An ice candy was produced successfully by utilizing direct liquid whey (Raval, 2014; Chavan et al., 2020). Additional information about the studies can be found in Table 5.

Type of Whey

Name of Novel Product and Probiotic Strain(s)

Major Outcomes

Country of Product Origin

Reference

Paneer whey

Ice candy

The whey candy may be kept refrigerated for up to 60 days. Approximately 58 % of consumers regarded experimental candy as great (scoring 5), while 20.5 % ranked it as very good.

India

Chavan et al. (2020)

Paneer whey

Apple-whey blended RTS beverage

The beverage containing 75 % sweetos (a blend of sucralose and fructooligosaccharide) was determined to be the most acceptable, with an overall acceptability score of 8.59 ± 0.26 and a higher score after 60 days of refrigerated storage.

India

Sharma et al. (2020)

Cheese whey

Whey beverage with beetroot juice & Kluyveromyces lactis

The phenolic content of the yeast fermented cheese whey beverages ranged from 102.75 to 291.61 μg EAG/mL and DPPH inhibition ranged from 38.69 to 81.02 % after 21 days of storage.

Brazil

Oliveira et al. (2019)

Recomposed whey

Whey beverage with Lactobacillus plantarum AA1–2 and Saccharomyces boulardii

The best sensory qualities of beverages were obtained with a % inoculation of L. plantarum AA1–2. According to the GC/MS-SPME results, the aroma component with the highest concentration in whey was acetate isopropyl.

Turkey

Saglam et al. (2019)

Cheese whey

Probiotics carbonated whey beverage

Culture of probiotic bacteria During product storage, Bifidobacterium animalis demonstrated high vitality, with counts ranging from 7.45 to 6.87 log CFU/mL. During the 0-28th day of storage, the pH and titratable acidity were increased from 3.98 to 4.07 and 0.52 to 0.58 %, respectively.

Brazil

Silva e Alves et al. (2018)

Whey

Probiotic guduchi whey beverage with Lactobacillus acidophilus

The beverage containing 10 % Guduchi leaves extract (G1A) and 1.5 % probiotic culture was stable at refrigerator temperature for one month without significantly altering its sensory qualities.

India

Kamble et al. (2017)

Skim milk paneer whey

Low fat probiotic (Lactobacillus acidophilus) whey and sorghum beverage

Sample LAC1P3 was found highly acceptable: color and appearance; flavor and taste; consistency and overall acceptability scores were 8.3 ± 0.15, 8.1 ± 0.32, 8.2 ± 0.25, and 8.3 ± 0.28 respectively.

India

Morya et al. (2017)

Cheese whey

Probiotic whey beverages

After assessing the sensory parameters acquired from a panel of 11 judges, the probiotic whey beverage samples were scored in the following order: Sample-3 > Sample-2 > Sample-1 > Sample-4, with Sample-4 was being the standard market whey beverage sample.

India

Faisal et al. (2017)

Liquid whey protein concentrates

Fermented Kefir drink

Fermented kefir beverages exhibited satisfactory sensory and physicochemical qualities; after 14 days of refrigeration, they contained more than 7 log CFU/mL lactococci and lactobacilli and 6 log CFU/mL yeasts.

Portugal

Pereira et al. (2015)

Lactose hydrolyzed whey

Ice candy

For the orange-flavored candy, the overall acceptance rating was much higher (8.70). Jaljira (8.40) was statistically equal to orange (8.40) in terms of overall quality.

India

Raval (2014)

Concentrated Paneer/cheese whey

Lassi

The addition of concentrated whey resulted in a thinning effect, as shown by the results for consistency, viscosity, and index of viscosity.

India

Patel (2013)

Liquid whey

Yogurt

Yogurt made from 70 % milk and 20 % milk whey, then enzymatically treated, had identical features to conventionally made yogurt, with no modification in syneresis (p > 0.05) and similar textural parameters to the control sample.

Brazil

Gauche et al. (2009)

Concentrated liquid whey

Yogurt

More syneresis index and less apparent viscosity were seen when supplementing milk-retentant-based yogurts with whey retentant, compared to milk-retentant-based milk-retentant yogurts.

Brazil

Magenis et al. (2006)

4 Utilization of whey in beverages

Paneer whey is produced using a high-temperature process that eliminates proteins from the whey, resulting in a valuable ingredient for various beverages (Baba et al., 2016; Özer and Evrendilek, 2022). By substituting paneer whey with cheese whey, the longevity of whey-based beverages can be extended. With the inclusion of minerals, lactose, and highly absorbable whey proteins, whey-based beverages offer the opportunity to enhance the nutritional content of the end products (Baba et al., 2016; Villarreal, 2017; Özer and Evrendilek, 2022). There are two primary categories of whey beverages: fermented and non-fermented. Extensive research has been carried out using clinical data, revealing a multitude of advantages associated with fermented whey products (Guimarães et al., 2018; Keith, 1994; Sharma, 2019).

In the following sections, we will undertake a study of some of the most notable beverages that are derived from whey, as well as a comprehensive explanation of the technology that is utilized in the processing and formulation of these beverages (Fig. 3).

4.1 Acido whey

The whey from the paneer is utilized to produce this beverage, which is both invigorating and delicious. Paneer whey was pasteurized at 72 °C for 15 min, and then cooled before adding a culture of L. acidophilus (1 %) and fermenting at 37 °C for 24 h. Flavoring the food with sugar and citrus enhances its appeal during refrigeration. The end result exhibited an acidity level of 0.8–0.9 % (L. acidophilus). When stored in refrigerated conditions, the product's shelf life was approximated to be two to three weeks. A patent was granted for the process of producing Acidowhey by Gandhi D.N. in 1989 (Gandhi, 1989). Acidowhey is a non-alcoholic whey beverage produced by fermenting whey with the beneficial bacteria L. acidophilus and L. bulgaricus, as described by Hati et al. (2013). Additional whey-derived beverages were also documented by Hati and colleagues, including whevit, soups made from whey, whey-based lassi, and more (Hati et al., 2013).

4.2 Electrolyte whey drink

Paneer whey contains lower lactose content and higher concentrations of minerals like chloride (Cl), salt, calcium (Ca), and magnesium (Mg) compared to cheese whey (Goyal and Gandhi, 2009). To produce a top-notch electrolytic drink, it is essential to keep mineral and lactose levels at a minimum (Gandhi, 1989). It has been demonstrated that paneer whey is better suited for producing beverages or electrolyte drinks to replenish lost minerals in the body.

4.3 Whey-based fruit juice

Researchers have formulated a variety of fruit juice-based whey beverages, including fermented, nonfermented, and carbonated, prepared either utilizing paneer whey or cheese whey. For the production of Whey-based Kinnow juice concentrate (WKJP), a specific formula was utilized which included 40 % kinnow juice, 53 % paneer whey, 7 % sugar, 0.05 % pectin, and 0.15 % carboxymethylcellulose. The concentrate obtained showed a pH of 4.5. For over six months, the metalized polyester pouches were kept at a temperature of 25 °C (Khamrui and Pal, 2003). Acid whey, whey powder, and whey protein concentrate are different types of whey that can be effectively incorporated into beverages. Storing whey-based mango juice led to a significant increase in the juice's acidity (0D 0.405 % and 30D 0.435 %). After 30 days of refrigerator storage, the acceptance ratings of the whey protein concentrate-based mango beverage dry mix (WPCMB) were found to be satisfactory (Chavan et al., 2015). The optimal combination was 77.24 g of whey/mango pulp, 8.65 g of fructose (totaling 100 g). Singh and Kumar (1997) found that a blend of 15 % mango pulp (25 °Brix), 77 % paneer whey concentrate (37 %, TS), and 8 % sugar was the most suitable for producing whey-mango concentrate. Over a period of 90 days in storage, a kinnow-whey beverage that was sonicated for 15 min at 20 kHz showed better acceptability and lower microbial growth compared to samples that were thermally treated or contained preservatives (Siddique et al., 2023).

4.4 Carbonated whey-based lemon beverages

Paneer whey is a key element in a lemon-based beverage developed by Singh et al. (2014). When developing this beverage, a combination of sugar, lemon juice, and lemon flavoring was used to achieve a total acceptability score of 7.8 on the 9-point Hedonic scale. Whey, lemon juice (4.5 %), sugar (10.1 %), ginger juice (1 %), and salt were mixed to produce a carbonated lemon whey beverage of acceptable quality (0.6 %). The whey beverage can be stored in the refrigerator for a maximum of 49 days at a temperature of 4 ± 1 °C. The price was Rupees 5.33 for every 200 mL of whey beverage (Patel et al., 2017). Utilizing this product in the dairy sector, particularly in the production of chhana and paneer, can help decrease waste disposal and increase revenue from whey. Famous fermented milk dish popular in India, Shrikhand, has acidic whey which was used to make carbonated whey fruit beverages (Dilipkumar and Yashi, 2014).

4.5 Whey-based alcoholic beverage

Utilizing Kluyveromyces fragilis and Saccharomyces lactis, whey has been employed in the production of beer, wine, and sparkling “whey champagne” with specific yeast strains (Oliveira et al., 2019). These food products are characterized by their low alcohol concentration, which is less than 1.5 %. Whey provides a rich source of lactose, minerals, and nutrients. Nevertheless, fat negatively affects beer foam and is considered an unwanted element (Jeličić et al., 2008). When incorporating whey into a beverage, it is crucial to maintain a balance between clarity, stability, shelf life, and protein content to ensure its market success and effectiveness in enhancing human performance and recovery upon consumption (da Rosa Camargo et al., 2020). Typically, whey is used in two main types of beverages: those with acidified and neutral pH levels. The beverage's quality and stability depend on the pH level and type of whey utilized in the formulation. Consider this: when developing an acidified whey-based beverage, the pH typically falls between 2.8 and 4.0. Interestingly, incorporating whey with a high protein content does not affect the drink's clarity or turbidity negatively. This is due to the remarkable stability and solubility of whey proteins at a pH of around 3.0.. Processing at a neutral pH, specifically with an end-product pH between 4.6–7.5, necessitates specialized processes and stabilization techniques like carboxymethylcellulose, lecithin, dextran, pectin, heat, and more to address protein aggregation, turbidity, and short shelf life issues in this beverage type (Kelly 2019). For instance, the investigation by Singh et al. (2014) reported that incorporating carboxymethylcellulose in carbonated paneer whey-based lemon beverages, along with acidification, produced a high-quality product with a shelf life of 49 days when stored at 4 ± 1 °C. A comparable approach was utilized in the development of acid whey, whey-based fruit juice, and alcoholic beverages.

There is a wide range of whey-based spirits available for consumption worldwide, all emphasizing the dairy or whey relationships. This information is typically provided on the product label and in descriptions that highlight the creamy flavors (Hughes et al., 2018). There is a potential for smaller-scale cheese manufacturers to enhance their products by fermenting and distilling whey to produce ethanol. This process could facilitate the production of a premium end product, like ethanol or spirits. On an industrial scale, the Carbery method is employed to transform whey or whey permeates from dairy manufacturing into ethanol. The process starts with the fermentation of sugars within a substrate by microorganisms to produce ethanol, which is then concentrated through distillation to separate it from other volatile components (Ling 2008; Hughes et al., 2018). According to these findings, dairy whey may be more suitable than other forms of whey for use in the production of alcoholic drinks derived from whey and meant to supply consumers with whey nutrients.

5 Whey as a biofunctional ingredient

In a previous study, Goyal and Gandhi (2009) examined the nutritional composition of paneer whey and cheese whey. They found that paneer whey has a greater amount of minerals such as calcium (Ca), chloride (Cl), potassium (K), and sodium (Na). Furthermore, whey proteins play a crucial role as a substantial source of bio-functional peptides that aid in the regulation of multiple bodily systems, including the nervous, digestive, cardiovascular, and immune systems. Moreover, various biological and speculative impacts of consuming whey proteins have been documented (Horton, 1995; Rolim et al., 2020). Whey beverages with added functionality are a popular choice for incorporating whey nutrients into one's diet. Enhancing fruit juices, beverages, and other specialty foods can take advantage of the superior nutritional qualities of whey proteins, including their high protein efficiency ratio (PER)-3.6, biological value (BV), net protein utilization (NPU), and protein digestibility corrected AA score (PDCAAS). Paneer whey is the sole origin of biologically active compounds.

5.1 Biofunctional probiotic whey drinks

Research has shown that fermented whey drinks are an effective way to deliver probiotics, prebiotics, and other beneficial components (Kumari and Vij, 2015; Cordeiro et al., 2019). Thakkar and their team developed a beverage using paneer whey, probiotic bacteria, and orange juice (Thakkar et al., 2018). This unique combination helped to maintain the survival of the probiotic bacteria at specific levels during refrigeration for 28 days. The control group (A) had a survival rate of 6.10 log CFU/mL, while group B2 (60F:40 W) had a survival rate of 7.25 log CFU/mL, which was significantly different (p < 0.05) (Thakkar et al., 2018). A fermented beverage was formulated utilizing paneer whey and L. acidophilus NCDC195, a strain with potential biofunctional properties. The production process started by filtering fresh paneer whey through a muslin cloth to eliminate any leftover casein particles. Damaged particles could reduce solubility and make the beverage more turbid. Typically, the pH was maintained to 6.5 with 0.1 N NaOH, followed by transferring the neutralized whey to designated containers for sterilization (at 121 °C for 10 min) and storage at room temperature. During the preparation of the beverage, it is inoculated with the starter culture (specifically 1 % L. acidophilus NCDC195 in this study) and then incubated at a precise time and temperature (39 °C for 18 h) to undergo fermentation. Upon sensory evaluation, it was found that the whey-based fermented beverage scored above 7.0 on a 9-point Hedonic scale, indicating high acceptability.

Based on a study conducted by Panghal et al. (2017), increasing the concentration of whey in the papaya-based whey drink had a positive effect on its nutritional value. However, it had a negative impact on the taste and microbial quality of the drink. A study conducted by Shende et al. (2022) explored the digestion of an enhanced paneer whey beverage. The researchers discovered that the complex form of zinc (Zn+2) in the beverage exhibited significantly higher bio-accessibility (p < 0.05) compared to its free form. According to the study conducted by Shende et al. (2022), it was observed that the concentration of complexed Zn+2 showed a significant increase with decreased salt levels, elevated pH, and higher spices concentration.

The use of whey proteins in food formulation is motivated by their high levels of bioactive proteins such as β-lactoglobulin (β-Lg), α-lactalbumin (α-La), bovine serum albumin (BSA), immunoglobulins (Igs), glycomacropeptide (GMP), and proteose peptone (Sharma, 2019). When utilized as a food additive, β-lactoglobulin has been found to have beneficial impacts on human health. According to a study conducted by Tai et al. (2016), it was discovered that when β-Lg is folded correctly, it can boost human immune responses through a pathway that involves receptors. α-lactalbumin comprises approximately 22 % and 3.5 % of the protein content in human milk and bovine milk, respectively. It has a significant impact on lactose synthesis, which plays a crucial role in determining milk volume. Furthermore, it offers bioactive peptides and essential AAs such as tryptophan, lysine, branched-chain AAs, and sulfur-containing amino acids that are crucial for infant nutrition (Layman et al. 2018). In addition, whey containing bioactive proteins has the potential to act as an antibacterial agent. A study conducted by Kumari and Vij (2015) discovered that the permeate, which contained peptides of 10 and 5 KDa, showed activity against a range of pathogens. These included Gram-negative bacteria such as Salmonella typhi, Shigella dysentriae and Escherichia coli, as well as Gram-positive bacteria like Bacillus cereus, Listeria monocytogenes, and Staphylococcus aureus. The zones of inhibition observed ranged from 17 to 23 mm. In 2015, the quality and shelf life of probiotic drinks formulated with whey and Aloe vera juice were assessed by Sasi Kumar (Sasi Kumar, 2015). Several other researchers have conducted comparable studies (Castro et al., 2013; Kamble et al., 2017).

5.2 Functional whey beverage

The fortification of whey-based beverages with calcium phosphate (Ca3(PO4)2), calcium lactate (C6H10CaO6), vitamin D3, and prebiotic dietary fiber was investigated in studies conducted by Algirdasl et al. (2016) and Liutkevičius et al. (2016). A study conducted by Liutkevičius et al. (2016) revealed that the presence of Ca3(PO4)2 resulted in a more significant decline in the overall acceptability of the beverages over time in comparison to C6H10CaO6. Upon comparing Ca3(PO4)2 to lactate, researchers found that lactate proved to be more suitable for the food matrix. Consequently, this formulation was chosen for additional investigation (Algirdasl et al., 2016). Following a 21-day period of consuming C6H10CaO6, vitamin D3, and prebiotic dietary fiber, there was a notable decrease in LDL-cholesterol and triglyceride concentrations (p < 0.01). According to the study findings, it was expected that these modifications would improve the overall welfare of the individuals involved (Algirdasl et al., 2016).

Exploring the incorporation of prebiotics and fruit flavor into whey-based drinks opens up exciting possibilities for developing novel functional food products on a large scale (Shah and Patel, 2019). In addition, the inclusion of prebiotics enhances the physical, chemical, and functional properties of the whey-based beverage. Furthermore, it also promotes the proliferation of beneficial bacteria. In strawberry-flavored whey-based beverages, researchers have found that the addition of 1.25 g/100 mL of a prebiotic xylooligosaccharide (XOS) can have interesting effects on diabetes, hypertension, and antioxidant properties (Souza et al., 2019).

When developing paneer whey-based iced tea, it was found that samples with 80 % and 100 % whey scored significantly (p < 0.05) better in sensory metrics compared to samples with 50 % whey (Shah et al., 2019). Even more fascinatingly, the enhanced product showed a 25 % antioxidant activity based on the DPPH test and contained 0.6 % protein. In contrast, Baba and colleagues developed a paneer whey beverage by adjusting the ratio of paneer whey (10 % to 30 %) in pineapple juice (Baba et al., 2016). The protein content in both drinks was 0.61 % and 0.86 %, respectively, and both beverages achieved an overall acceptability score of over 8.0 on a 9-point Hedonic scale. The paneer whey-based beverages showed higher levels of protein and minerals compared to the control, suggesting their potential to help address protein-energy malnutrition in children living in underprivileged nations (Baba et al., 2016). In addition, scientists have developed herbal beverages using whey, such as green and black tea (Perasiriyan et al., 2013). A new study presented spicy water made from paneer whey known as Hajma Hajam, containing mint (Mentha aquatica L.) (often known as mentha or pudina, is a member of the Lamiaceae family of plants) along with other ingredients (Ranavaya et al., 2019). When compared to other mixtures, the product with a 50:50 blend of whey and water (pH 3.8–4.2) received the top sensory ratings. Mixing whey with natural herbs like mint or tea within a suitable range, can produce a nutritious drink packed with antioxidants like polyphenols and other beneficial components (Ranavaya et al., 2019; Shah et al., 2019). This enables individuals to enjoy whey without changing its original qualities or increasing expenses.

5.3 Cultured butter milk with biofunctional properties

Angiotensin-converting enzyme (ACE) inhibition, antioxidant potential, and antimicrobial properties were discovered in beverages developed from different combinations of dahi and fermented paneer whey, as compared to a control sample made from dahi and water (Parekh et al., 2017). The cultured buttermilk produced from fermented paneer whey and dahi (blended with different ratios i.e. 40 % and 60 %, respectively) exhibited enhanced biofunctional properties compared to buttermilk made from different blend fermented paneer whey and dahi (blended with 30 % and 70 %, respectively). Paneer whey was discovered to be useful in the production of cultured buttermilk when combined with fermented paneer whey (Suneeta et al., 2014; Maheta et al., 2015; Paraffin et al., 2019). A study conducted by Parekh et al. (2017) discovered that incorporating fermented paneer whey into cultured buttermilk had a significant positive impact on its biofunctional characteristics. This included improvements in antioxidant and antimicrobial activities.

In addition, the combination of whey-based beverages and fruit fermentations has the potential to be a unique and functional drink option in the market (Pereira et al., 2015). Several compounds found in fruits are commonly combined with whey to enhance their beneficial properties (Baba et al., 2016; Liutkevičius et al., 2016; Raj et al., 2017; Thakkar et al., 2018). Modifying the fruit juice in this whey-based juice beverage can have an effect on its functional properties. Various compounds present in fruits like strawberries (Fragaria ananassa) and blueberries (Vaccinium corymbosum) have shown protective effects against oxidative stress. These compounds include flavanols, catechins, anthocyanins, and phenolic acids (Dhalaria et al. 2020; Kim et al. 2020). Studies conducted by Dhalaria et al. (2020) and Kim et al. (2020) have found that certain substances have the ability to counteract the harmful effects of free radicals and other reactive oxygen species (ROS). Minimizing the development of oxidative stress can help prevent illnesses such as cancer and obesity. The presence of polyphenols, phenolic acids, and flavonoids in apple juice has been found to have a positive impact on cells, potentially reducing the risk of chronic illness (Dias et al., 2021; Guiné et al., 2021; Sobhani et al., 2021). Studies by Dias et al. (2021), Guiné et al. (2021), and Sobhani et al. (2021) have demonstrated the antiproliferative and antioxidative effects of these compounds.

According to a study conducted by Ferreira Wessel and colleagues, it was found that pear juice contains various compounds such as quercetin, hydroxy-cinnamic acids (HCAs), catechins, and other polymeric units (Ferreira Wessel et al., 2016). These compounds possess antioxidant properties and are capable of counteracting free radicals. Various experiments have played a significant role in the advancement and production of whey-based beverages that incorporate a variety of fruit combinations. Several studies have investigated the combined use of sweet rennet-based whey and acid whey, as documented by Smith et al., (2016), Rizzolo and Cortellino (2018), Skryplonek et al. (2019), and Anand and Awasti (2020). A recent study found that Ricotta-Cheese whey has the potential to replace whey in pectin-free beverages like apple, blueberry, and pear (Rizzolo and Cortellino, 2018).

Consumers have a wide range of choices when it comes to finding a nutritious and cost-effective beverage, with energy drinks being one of them. Various flavors are often used to conceal the taste and aroma of energy drinks made from whey. According to a study by Naik et al. (2009), refrigerated watermelon-flavored whey-based energy drinks showed favorable texture, flavor, and color. As per a study conducted by Divya andArchana (2009), it was discovered that a guava-flavored drink containing paneer whey remained safe for consumption even after being stored for 45 days. A study conducted by Kumar and colleagues in 2017 resulted in the development of a nutritious drink made from whey and pineapple juices (Kumar et al., 2017). The drink showed impressive stability over a two-month period. Whey-based fruit beverages and drinks provide a valuable source of energy, nutrition, and beneficial therapeutic properties, making them suitable for a wide range of consumers, from children to seniors. Several studies have also investigated the degree of polymerization (DP) of prebiotic oligosaccharides. In a recent study, Guimaraes and colleagues examined the effects of inulin DP on the physical stability of a soursop-flavored whey beverage (Guimaraes et al., 2020). The aim was to develop a novel prebiotic food product. The researchers observed that samples with inulin DP ≥ 23 demonstrated superior physical stability in comparison to samples with DP ≥ 10.

6 Beneficial effects of whey proteins on probiotics and human health

Probiotic bacteria have been incorporated into various dairy products like cheeses, yogurts, ice cream, and desserts (Sperry et al., 2018; Turkmen et al., 2019; Rolim et al., 2020). It is essential for probiotics to endure GI conditions in order to develop beneficial properties (Rabah et al., 2017; Cordeiro et al., 2018; Banwo et al., 2021). The digestive systems, such as stomach acidity and tolerance to bile salts, play a role in limiting the survivability of these beneficial microbes (Huang et al., 2016; Banwo et al., 2021). The food used as a protective medium is crucial in enhancing microorganism tolerance to these conditions and improving their bioavailability (Cordeiro et al., 2018; Banwo et al., 2021). Whey plays a crucial role in sustaining habitat for these microbes (Felicio et al., 2016; Rolim et al., 2020). When combined in paneer with different amounts of sweet buttermilk, whey proteins have been shown to maintain moisture (Suneeta et al., 2014; Masotti et al., 2017). Due to their chemical and physical properties, whey proteins have been linked to the levels of essential and non-essential AAs, and have been studied for a range of technical and nutritional factors (Yadav et al., 2015; Cordeiro et al., 2018). Cysteine, a crucial AA involved in accelerating glutathione fusion, is a vital element of whey proteins. This is involved in human body processes like protein synthesis, tissue healing, and immune system activity (Sharma, 2019).

Numerous investigations have shown that whey has the potential to improve the viability of probiotic bacteria throughout the manufacturing and storage processes (Huang et al., 2016; Baruzzi et al., 2017; Dąbrowska et al., 2017; Cordeiro et al., 2018). In a study conducted by Cordiero et al. (2018), the advantages of whey protein as a shield for probiotic microorganisms, L. casei BL23 and Propionibacterium freudenreichii 138, were investigated. These microorganisms were utilized in the production of beverages that proved to be successful in preventing mucositis in BALB/c mice induced by 5-Fluorouracil. One approach to guarantee the safety and longevity of these strains in foods like paneer whey is encapsulation (Ningtyas et al., 2019). By utilizing the Maillard process in whey proteins, researchers demonstrated the effectiveness of encapsulation in preserving L. rhamnosus 6134, a probiotic strain in brined cheese (Liu et al., 2017; Doost et al., 2019; Rolim et al., 2020). Whey proteins offer specific health benefits, including enhanced mental performance in stressed individuals, immune system regulation, weight management linked to feelings of fullness, and cancer prevention, and have been incorporated into the production of different functional foods (Sharma, 2019). In a study by Cordeiro et al. (2019), they investigated the protective impact of co-supplementing L. casei 01 with a fermented whey dairy beverage against Salmonella enterica ssp. enterica serovar typhimurium infection in mice. According to the study, the traditional treatment (FWB; starter culture) showed better results in terms of animal survival (70 %), pathogen translocation to the liver (2 out of 10 animals), histopathology (fewer lesions), and inflammation compared to the probiotic treatment (PFWB; starter and probiotic cultures), which had a 50 % animal survival rate, pathogen translocation in 5 out of 10 animals, and increased lesions (Cordeiro et al., 2019).

Various nutrients found in whey can be utilized to enhance human health. Probiotic products are currently highly sought after due to their potential health advantages. Owing to this, plain whey beverages can be used in innovative ways. Probiotic microorganisms, bioactive peptides, proteins, and other functional components can be incorporated into this procedure. Developing whey-based beverages with probiotic bacteria offers numerous health benefits. Adding probiotic bacteria to whey-based beverages could offer additional health benefits due to their various health-promoting properties. Buttermilk, sour milk, flavoring milk, and milk smoothies are all examples of probiotic whey-based drinks. There are two main varieties of whey used in the production of probiotic whey drinks: acid whey and sweet whey. Probiotic-fermented beverages have benefitted from the use of acid whey (Skryplonek et al., 2019). A probiotic acid whey beverage can be prepared using Bifidobacterium animalis ssp. lactis BB-12 or L. acidophilus LA-5 cultures. Research has demonstrated that the acid whey beverage effectively transports probiotic bacteria, with their viability remaining high at 8 log CFU/mL throughout storage. These materials can also be used for medicinal purposes (Skryplonek et al. 2019). In a study conducted by Drgalić and coworkers, they utilized rennet whey that was fermented with B. animalis BB-12 and L. acidophilus LA-5, yielding comparable results (Drgalic et al., 2005). Enhancing whey-based beverages with probiotics improves their health benefits, texture, and taste. There is a variety of whey-based probiotic drinks available for consumers to purchase, including Actimel, Activia, Chamyto (Nestlé), Danito (Danone), Sofyl (Yakult), Vigor-Club (Vigor), Yakult, and more. Additionally, fruit-based whey drinks like ProWhey, Latella, frucht-molke, frusighurt, Taksi, and others are also on the market.

Sweet whey is produced using rennet coagulation. Whey with added sugar has lower acidity compared to whey without sugar, which has higher acidity. Due to this, it possesses a sweeter taste compared to acid whey. The acidifying capability of whey-based beverages made from milk rennet whey, probiotic bacteria, and yogurt bacteria was enhanced (Smith et al., 2016; Anand and Awasti, 2020). In a study by de Castro et al. (2009), it was observed that fermenting 30–40 % of milk and rennet-treated whey with Bifidobacterium spp., L. acidophilus, and S. thermophilus did not have a significant impact on the viability of the cultures or the fermentation process. Another investigation utilized yogurt bacteria and the probiotic bacterium L. helveticus to develope a rennet whey-based probiotic beverage (Bulatović et al., 2014a). According to the researchers, an ideal fermentation temperature of 42 °C was documented. Throughout a 22-day shelf life testing, the recently developed product demonstrated superior performance thanks to its high cell viability and long-term stability. In order to enhance the nutritional content of the beverage, researchers incorporated probiotic L. johnsonii and prebiotic inulin (Bulatović et al. 2014b). In 2014, Bulatović and colleagues conducted a study that examined the texture, sensory qualities, and stability of probiotic bacteria in a fermented whey-based beverage (Bulatović et al. 2014c). A fermented beverage was developed by combining L. rhamnosus, a probiotic bacterium, with 30 % skim milk. The texture and flavor of the product were perfectly matched for its intended purpose. Upon opening, the probiotic whey beverage maintained a significant level of active probiotic bacteria for a period of 20 days (Bulatović et al. 2014c). A beverage developed from whey and strengthened with probiotics provides a range of nutritional and therapeutic benefits.