Translate this page into:

Performance of full-scale slaughterhouse effluent treatment plant (SETP)

⁎Corresponding authors. obaidqamar@yu.ac.kr (Mohd Obaid Qamar), farooqi.cv@amu.ac.in (Izharul Haq Farooqi),

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

This paper studied the effectiveness of a slaughterhouse wastewater treatment plant. The purpose of this study is to evaluate the slaughterhouse effluent treatment plant (SETP) in eliminating impurities, as well as the variables that affect performance. The SETP consisted of a dissolved air floatation (DAF) system with an up-flow anaerobic sludge blanket (UASB) reactor followed by two activated sludge processessing (ASP) stages. The removal efficiencies of chemical oxygen demand (COD), biochemical oxygen demand (BOD), and total suspended solids (TSS) were 74.7%, 76.8%, and 90.14%, respectively. The study proposes constructing a tertiary treatment facility, installing two dung squeezers, and commissioning the UASB.

Keywords

Full-scale

Slaughterhouse

Wastewater treatment

Dissolved-air floatation (DAF)

UASB reactor

- ASP

-

activated sludge process

- BOD

-

biochemical oxygen demand (mg l−1)

- COD

-

chemical oxygen demand (mg l−1)

- DAF

-

dissolved air floatation

- SETP

-

slaughterhouse effluent treatment plant

- HRT

-

Hydraulic retention time (h)

- ICMR

-

Indian Council of medical research

- PST

-

primary settling tank

- SWW

-

slaughterhouse wastewater

- TSS

-

total suspended solids (mg l−1)

- UASB

-

up-flow anaerobic sludge blanket

- WWTP

-

wastewater treatment plant

Abbreviations

1 Introduction

The worldwide production of meat doubled folded in the past three decades (Bustillo-Lecompte and Mehrvar, 2015), expected to replicate the progress of meat production up until 2050. Moreover, In India, beef production has been growing due to increased income and the shift toward a western-like protein-rich diet. Meat is a significant source of protein and a valuable commodity; it is only available at roughly 15 g/person/day, despite the Indian Council of medical research (ICMR) recommendation of 30 g/person/day (Islam et al., 2016). A brief note on slaughterhouses, they are facilities where animals are slaughtered for consumption as food locally and abroad (Hilares et al., 2021). There are approximately 3600 registered slaughterhouses in India, with 56 of them located in the state of Uttar Pradesh alone. All the major Indian cities have central slaughterhouses that date back to the British period (>70 years old) (Singh et al., 2014). Among them, Uttar Pradesh is the highest producer of meat products with a 19.1% share in the state, which produced around 7.515*103 tonnes of buffalo meat. The data from the state’s animal husbandry department shows that in the year 2014–15, industrial and structural slaughterhouse improvements have been highly subsidized, which has contributed to the sector’s growth. The Uttar Pradesh meat processing industry accounts for 50% of India’s exports, which makes it one of the leading meat producers and exporters in the country (Meiramkulova et al., 2020). The procedure of treatment, management, and disposal or recycling of organic solid and liquid wastes generated from slaughterhouses are intimidating works because of the massive volumes of waste material generated every day in solid and liquid forms (Ahmad et al., 2014).

The meat processing wastes have high carbon-based and inorganic compositions (Xiang et al., 2019). The high suspended solids content, the dark color, and the offensive odor are responsible for poor bacteriological standards (Martínez et al., 1995). The waste from slaughterhouses contains high-strength complex wastewater with about 45% soluble and 55% abrasive suspended organics. The organics originate from blood and offal (Ahmad et al., 2014). The lion's share of the uncleanness is produced by the blood and by intestinal and abdominal secretions. Additionally, Organics, pathogenic and non-pathogenic bacteria, and cleaning detergents and disinfectants are all found in high concentrations in slaughterhouse wastewater (SWW) (Kreutz et al., 2014). Nutrients, heavy metals, color, and turbidity are also present. Moreover, disinfectants, cleaning chemicals, and veterinary medications can be found. Preliminary treatment of SWW can include grit chambers, screens, settling tanks, and dissolved air floatation (DAF) systems, which are widely utilized before biological processes. The removal of suspended solids, oil, and grease is required to avoid sludge flotation, and components overload (Johns, 1995; Massé and Masse, 2000; Wang and Banks, 2003; Sayed and de Zeeuw, 1988; Lettinga and Hulshoff Pol, 1991; Petruy and Lettinga 1997; Halalsheh et al., 2005). Subsequently, the SWW flow is intermittent, and an equalization tank is compulsory to reduce the consistency variations and the carbon-based load. As an initial biological treatment, most abattoir wastewater treatment plants (WWTP) use activated sludge processes, stabilization ponds, and anaerobic reactors (Vilvert et al., 2020). The high demand for energy for aeration and the extensive generated sludge increase the operating expenses of the treatment system (Gude, 2015). Consequently, aerobic biological treatment is not recommended for use on high-strength industrial wastes by experts (Del Pozo et al., 2000; Parawira et al., 2005). Energy can be reserved, and sludge production can be decreased by anaerobic digestion of the SWW (Rasapoor et al., 2020). The typical limits of discharge of slaughterhouse wastewater for COD, BOD, and SS are 250 mg/l, 30 mg/l, and 50 mg/l, respectively. The efficient performance of the treatment system is the most critical factor that directly impacts the cost, treatment, and disposal of wastewater (Lyu et al., 2020). This research aims to evaluate the performance and examine the factors that improve the quality of slaughterhouse effluent treatment plants (SETP). In addition, the work will suggest solutions to provide stable and efficient operation of full-scale SETP.

2 Materials and methods

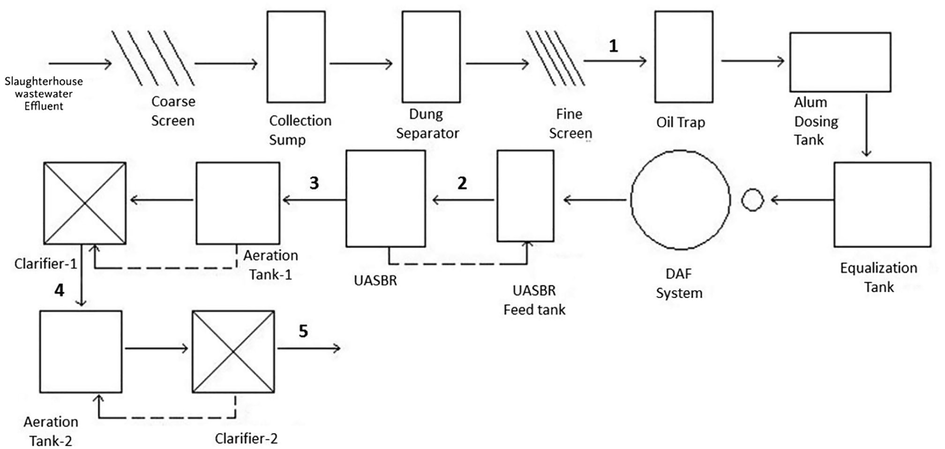

The study was conducted at a SETP of 800 m3/day in Aligarh, Uttar Pradesh, India. The SETP consisted of static screens, an oil skimmer, an equalization tank, a DAF system, an up-flow anaerobic sludge blanket (UASB) reactor, followed with two activated sludge processes (Fig. 1). The coarse screen removed solids larger than 20 mm, and the fine screen removed solids larger than 5 mm. Before entering the DAF unit, 30% effluent was recycled and mixed with the liquid fraction of the blood that passes through the static screens, and then coagulation was homogenously mixed in a 175 m3 equalization tank. The waste water after passing through the skimming tank, it goes into the alum dosing tank where coagulation and flocculation leads to the settlement of pollutants and the effulent of alum tank goes to the equalization tank. The rectangular 857 m3 UASB reactor with 33% recycling was constructed after the DAF unit. Furthermore, Aeration Tank −1 and Aeration Tank −2 of volumes 321 m3 and 412 m3, respectively, with 40% recycled effluent. Followed by clarifier-1 and clarifier-2 of volumes 101 m3 and 171 m3, respectively.

Simplified layout of the SETP: 1, 2, 3, 4 and 5 are the sample collection points.

The pH was controlled in the biological systems by adding an alkalinity buffer in the influent of the reactors. The hydraulic retention time (HRT) of the effluent varied from 10 to 15 h daily, rendering to the work managing. The design and operating parameters are listed in Table 1 for the DAF unit, UASB reactor, aeration tanks, and secondary clarifiers.

Parameter

Parameter

Collection Tank

PST

Retention (h)

7.14

Retention (h)

4.28

Volume (KL)

250

Volume (KL)

150

Dimensions (m)

7.7Ø x 3.3

DAF feed Tank

DAF

Retention (h)

5

Volume (KL)

78

Volume (KL)

175

Dimensions (m)

5.5Ø × 3.3

UASBR Feed Tank

UASB reactors

Retention (h)

4

No. of units

1

Volume (KL)

140

Depth (m)

6

Dimensions (m)

8 × 5 × 3.5

Area (m2)

143

Air Blower

Volume (m3)

858

Quantity

2 Nos 100 Hp

Retention Time (h)

24.3

Volume (KL)

850

Aeration Tank-1,2

Secondary Clarifier-1,2

Depth (m)

4.5, 4.5

Depth (m)

3, 3

Area (m2)

71.3, 91.45

Area (m2)

33.64, 56.95

Volume (m3)

320.8, 411.5

Volume (m3)

100.92, 170.85

Retention Time (h)

9.14, 11.71

Retention Time (h)

2.85, 4.85

Volume (KL)

320,410

Volume (KL)

100, 170

Influent samples of the SETP followed by effluent of different treatment units have been collected onsite wastewater treatment plant throughout the employed hours. The average calves slaughtered on each day are 500 heads. Slaughtering process wastewater samples from different units were collected on 3 alternate days each week over a period of 17 weeks i.e. 2nd January 2017 to 1 May 2017, between 10 a.m. and 1 p.m. Samples in bottle were stored in deep freezer in the lab for analysis on the same day.

Acidity (pH), total suspended solids (TSS), biological oxygen demand (BOD), and chemical oxygen demand were all measured in samples collected from various locations (COD). All of the tests were carried out using the following standard procedure for water and wastewater testing.

The acidity (pH): After standardizing the instrument at pH 4 and 7 with the calibration solution of pH 4 and 7, the collective movable meter (Type HI 8424) was used for testing.

The biochemical Oxygen Demand (BOD): The samples were incubated at 20 °C for 5 days using the OxiTop measurement device. Following mixing, the samples were placed into OxiTop bottles and diluted to the machine's test range as recommended by the manufacturer's instructions.

The chemical oxygen demand (COD): Chemical oxygen demand is measured to determine the total oxygen required to oxidise the complex organic matter content of a sample by strong oxidants (2KCrO2 27/H2SO4 at 145 °C) due to the multifaceted content of the slaughterhouse's wastewater and the presence of uneasy biodegradable organic matter.

2.1 Suspended solid (SS)

The material was filtered through a weighted standard glass fiber filter, and the filter residue was dried at 105 °C. The suspended solids are defined as the difference in weight between the filter and the filter with the leftover solids, according to the 2540 D technique.

3 Results and discussion

3.1 Slaughterhouse wastewater characterization

The effluent shows biodegradable appearances (BOD/COD < 0.6). Table 2 listed appearances of wastewater generated from slaughtering process. The distinctive levels of COD for abattoir waste series from 18,000 mg/l to 43,000 mg/l (Ho and Tan, 1989). Though, it has been experiential that the COD can possibly be reach at the levels as high as 100,000 mg/l, contingent on the alignment and dilution of the waste (Kreutz et al., 2014).

3.2 Performance of the effluent treatment plant (SETP)

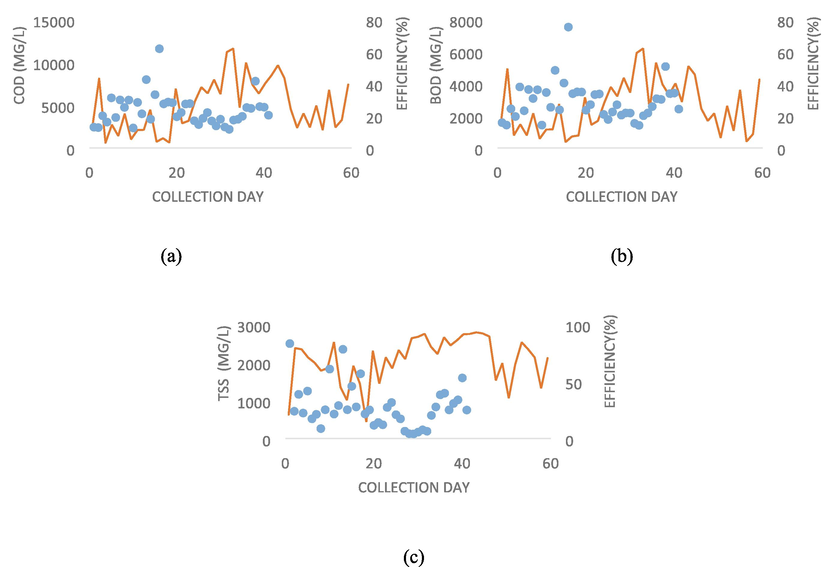

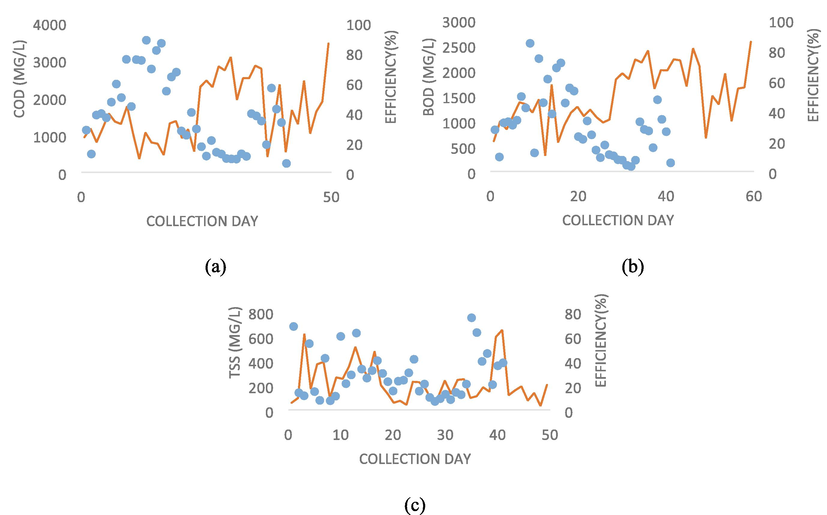

The purpose of installing the DAF unit before the UASB reactor was to adapt wastewater to the UASB process. COD, BOD, and SS removal efficiencies in the DAF unit were 29%, 28.58%, and 71.13%, respectively (Fig. 2), screening differences in the unit’s routine over the operating period (Table 3). In the pre-treatment food industry, chemical-DAF units remove SS ranging between 80 and 99% (Woodap et al., 1977; Ho and Tan, 1989; Rusten et al., 1990; Schneider et al., 1995; Núñez et al., 1999; Azbar and Yonar, 2004; Alam et al., 2021; Akhtar et al., 2019; Akhtar et al., 2021). Adjusting the operating condition and chemical treatments can improve the instability of dissolved air floatation effluent quality. Industrial process management can also help in improving the further efficiency.

Parameter monitoring of the DAF unit during the study period. (a) COD, (b) BOD and (c) TSS. ‘—’ represents Chemical-DAF removal efficiency, ‘●’ denotes DAF effluent.

Parameter

Na

Industrial Effluent

Unit effluent

Removal efficiency (%)

Average

Min

Max

Average

Min

Max

Average

Min

Max

DAF

COD

BOD

TSS

pH41

41

41

416172 ± 528

4009 ± 436

2813 ± 182

6.82835

1860

1252

4.313,950

9062

5615

7.6

4380 ± 238

2863 ± 145

834 ± 90

7.22170

1405

125

6.611,596

7538

2500

7.5

29 ± 5

28.58 ± 6.2

71.13 ± 7

–3.2

3.6

55.48

–68

62

90

–

UASBR

COD

BOD

TSS

pH41

41

41

41

3414 ± 460

2380 ± 319

521 ± 175

7.21020

690

113

6.87320

4826

1754

7.7

22 ± 8

16.86 ± 7.5

37.57 ± 4

–1.36

1.76

1.79

–58

54.90

75.56

–

Clarifier-1

COD

BOD

TSS

pH41

41

41

41

2519 ± 117

1720 ± 234

371 ± 109

7.5390

273

92

7.15225

3611

925

8

26 ± 3

27.7 ± 5

28.6 ± 2

–2.96

2.16

1.52

–62

60.43

60.12

–

Clarifier-2

COD

BOD

TSS

pH41

41

41

41

1559 ± 212

930 ± 163

285 ± 95

7.5234

95

69

6.43523

2533

749

8.4

38 ± 6

45.8 ± 4

23.12 ± 3.8

–8.77

10.27

3.23

–77

85.43

65.06

–

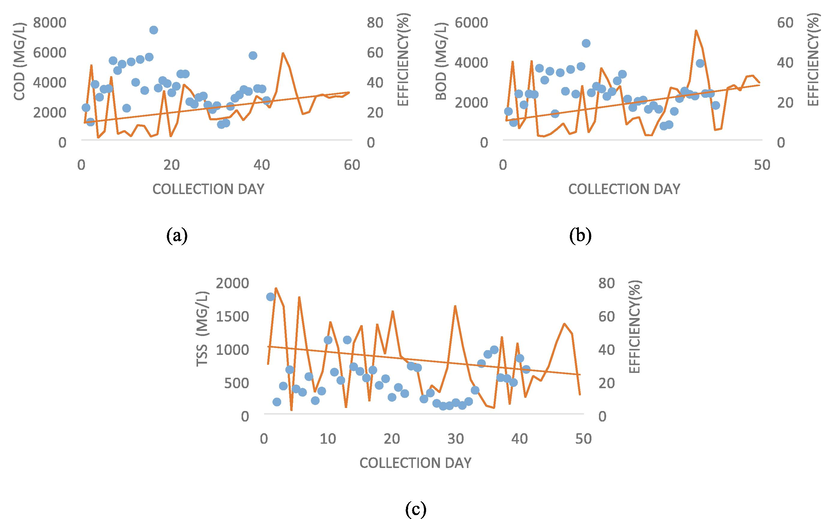

The adequate performance and stability of the reactors made adopting the UASB process as a fundamental technology at the WWTP unsatisfactory (Table 3). COD removals efficiency of UASB reactor showing poor performance. Similar results were also observed in the removal efficiency of BOD and TSS of UASB reactors treating slaughterhouse wastewater. Over the study period, very little improvement in the removal efficiency of COD and BOD of the UASB reactor was achieved (Fig. 3). Furthermore, the results of TSS removal efficiency of the reactor decreased with time.

Monitoring parameter of the UASB during the study period. (a) COD, (b) BOD and (c) TSS. ‘—’ represents UASB removal efficiency, ‘●’ denotes UASB effluent.

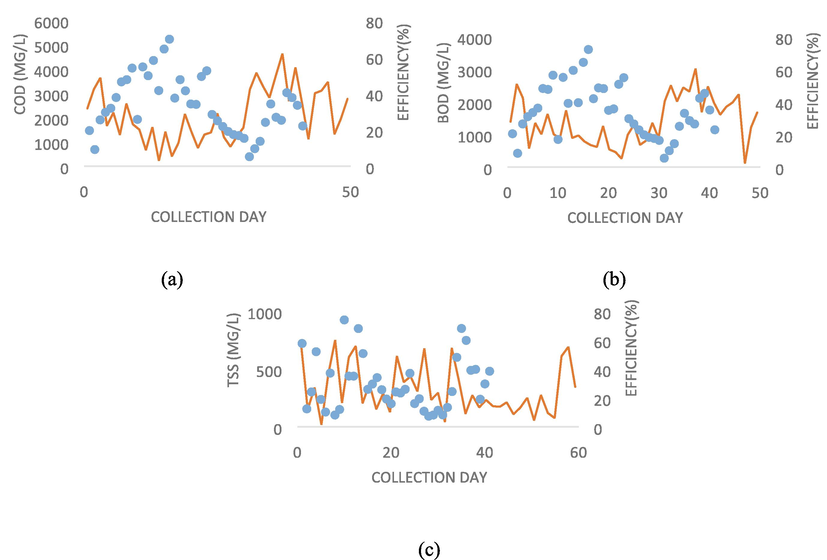

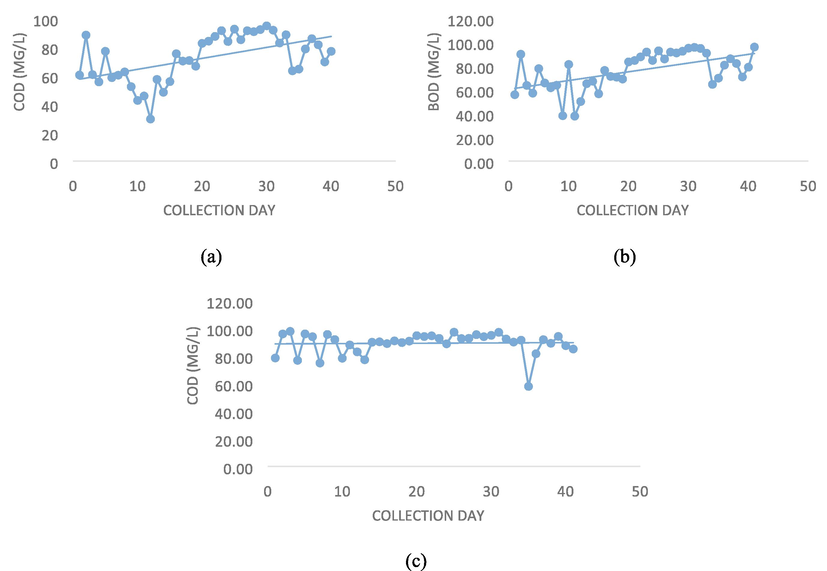

The Suspended Growth Activated Sludge process, Aerobic system-2 shows better results in removal of the COD and BOD as reported in Table 3 and Figs. 4 and 5. The performance was affected by poor performance of the UASB. Moreover, dissolved oxygen was found to be less than 1 mg/l in Aeration tank-1 and Aeration tan-2 on an average, may also be the reason for inadequate performance. The maximum 95% of COD removal can be obtained with 40% of sludge return, HRT 8 h, DO 3.5 mg/l and pH stable at 7.65 with the sludge aged and the bio solids retention time 23 days (Ebrahimi and Najafpour 2016).

Monitoring parameter of the Clarifier-1 during the study period, (a) COD, (b) BOD and (c) TSS. ‘—’ represents Clarifier-1 removal efficiency, ‘●’ denotes Clarifier-1 effluent.

Monitoring parameter of the Clarifier-2 during the study period. ‘—’ represents Clarifier-2 TSS removal efficiency, ‘●’ denotes Clarifier-2 effluent TSS.

Overall performance of wastewater handling plant was assessed rendering to the value of monitoring limits. The Average COD, BOD, and TSS removal efficiency of SETP was found to be 74.7 ± 1%, 76.8 ± 1%, and 90.14 ± 1% (Table 3, Fig. 6). In Table 2, the average COD, BOD, and TSS of wastewater from the industrial slaughtering process are given along with the minimum and maximum values of Industrial effluent during the study period. A graphical presentation of the overall performance of the SETP is given in Fig. 6 for the COD-total, BOD-total, and TSS.

Parameter monitoring of the SETP during the study period. (a) COD, (b) BOD and (c) TSS. ‘—’ represents SETP removal efficiency, ‘●’ denotes SETP effluent.

3.3 Wastewater treatment system operating costs

Wastewater treatment plant operating costs are consisting of Staff wages, electricity for pumping, chemicals and analytical monitoring. The cost of operation can vary plant to plant (Bustillo-Lecompte and Mehrvar, 2015). The use of diffused aeration to remove organic matter are the most expensive constituents of the WWTP and correspond to 45% of the total costs, followed by staff (24%), chemicals (22%), and analytical monitoring (7%) (Table 4). In a wastewater treatment system in a slaughterhouse with simply a UASB reactor as a biological treatment, a smaller percentage of electric power (20%) was associated to running expenses (Del Nery et al., 2007). The addition of chemicals to improve the DAF unit's effectiveness could result in a significant increase in running costs (Del Nery et al., 2007).

Items

Cost (Rs)

Cost($)

Staff

3,00,000

4687

Electric power

5,50,000

8590

Analytical monitoring

92,000

1440

Chemicals

2,76,000

4312

Total

12,18,000

19,029

3.4 Operational problems

Coarse screen installed in the SETP were irregular in space, vertical and round in shape. Large pieces of animal parts like fats etc. coming into the collection tank passes through coarse screen, chokes the cutter pump supplying wastewater to dung squeezer. The wastewater bypasses through the other pump via fine screen chamber without dung separation. Mechanical problem was observed on the horizontal motion of the skimmer. Moreover, due to heavy load of dung the movement of oil skimmer was affected. Problem in the UASB accounts for the sludge which remains floating atop. This is because of the entry of fatty materials in the UASB. The sludge coming out of UASB along with the wastewater into aeration tank. Sludge collected from bottom of the UASBR forms 3 layers when placed for 30–60 min in cylinder. Dissolved Oxygen level in the aeration tank-1 and tank-2 was found less than 1 mg/L throughout the monitoring. Since, UASB is not performing efficiently, the load on the aeration unit’s increases. As a result, aeration becomes limited.

4 Conclusions

The DAF is showing considerably good performance; however, it can be further enhanced by taking some corrective measures in pretreatment. UASB reactor showing poor performance. The imperfect performance of the reactor hence resulting in inadequate performance of the Activated Sludge Process (ASP). For the efficient performance of the SETP; i) Proper pretreatment has to be installed and the existing units needs to be rectified. ii) It has been proposed to install a drum screen for removing dung. iii) The industry should have two dung separators. iv) Oil skimmer needs to be rectified. v) UASB needs commissioning again and the excessive sludge needs to be drained. vi) New high-power aeration system should be installed which to improve the performance of the aeration systems. vii) The company should install tertiary treatment which is essential to reduce the concentration of the pollutants to the desired limit.

Acknowledgement

“The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for its funding this Research Group No. (RG-1441-371)”.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Iranica journal of energy & environment biological treatment processes: suspended growth vs. attached growth. Iran. J. Energy Environ.. 2016;7(2):114-123.

- [Google Scholar]

- Environmental and health impacts from slaughter houses located on the City Outskirts: A case study. J. Environ. Prot. (Irvine, Calif). 2014;05(06):566-575.

- [Google Scholar]

- Physiochemical characterization and dematerialization of coal class F flyash residues from thermal power plant.. 2019;5(5):1041-1051.

- Performance of sustainable sand concrete at ambient and elevated temperature. Elsevier; 2021.

- Coagulation as pretreatment of food industry wastewater. Water Sci. Technol.. 1990;22(9):1-8.

- [Google Scholar]

- Comparison of chemical flocculation and dissolved air flotation of anaerobically treated palm oil mill effluent. Water Res.. 1989;23(4):395-400.

- [Google Scholar]

- Slaughterhouse wastewater characteristics, treatment, and management in the meat processing industry: A review on trends and advances. J. Environ. Manage.. 2015;161:287-302.

- [Google Scholar]

- Performance of an anaerobic-aerobic reactor and kinetic study of organic matter removal of cattle slaughterhouse effluent. Eng. Agric.. 2014;34(2):341-351.

- [Google Scholar]

- Characterization of wastewater from hog slaughterhouses in Eastern Canada and evaluation of their in-plant wastewater treatment systems. Can. Biosyst. Eng.. 2000;42(3):139-146.

- [Google Scholar]

- Processing Wastes. 1977;I:1-5.

- USAB-process design for various types of wastewaters. Water Sci. Technol.. 1991;24(8):87-107.

- [Google Scholar]

- Energy positive wastewater treatment and sludge management. Edorium J. Waste Manage.. 2015;1:10-15.

- [Google Scholar]

- Primary treatment of a soybean protein bearing effluent by dissolved air flotation and by sedimentation. Water Res.. 1995;29(1):69-75.

- [Google Scholar]

- Promising physicochemical technologies for poultry slaughterhouse wastewater treatment: A critical review. J. Environ. Chem. Eng. 2021105174

- [Google Scholar]

- Slaughterhouse wastewater treatment using ferric and aluminium salts and organic polyelectrolites. J. Environ. Sci. Heal. - Part A Toxic/Hazardous Subst Environ. Eng.. 1999;34(3):721-736.

- [Google Scholar]

- Exploring the cost of wastewater treatment in a chemical industrial Park: Model development and application. Resources, Conserv. Recycl.. 2020;155:104663

- [Google Scholar]

- The effect of scale on the performance of an integrated poultry slaughterhouse wastewater treatment process. Sustainability. 2020;12(11):4679.

- [Google Scholar]

- Treatment of strong domestic sewage in a 96 m 3 UASB reactor operated at ambient temperatures: Two-stage versus single-stage reactor. Bioresour. Technol.. 2005;96(5):577-585.

- [Google Scholar]

- Anaerobic digestion of waste from a slaughterhouse. J. Environ Chem. Eng.. 2014;2(3):1317-1320.

- [Google Scholar]

- Scenario of livestock and poultry in India and their contribution to national economy. Int. J. Sci. Environ. Technol.. 2016;5(3):956-965.

- [Google Scholar]

- Developments in wastewater treatment in the meat processing industry: A review. Bioresour. Technol.. 1995;54(3):203-216.

- [Google Scholar]

- Comparative evaluation of a laboratory and full-scale treatment alternatives for the vegetable oil refining industry wastewater (VORW) Process Biochem.. 2004;39(7):869-875.

- [Google Scholar]

- Recognizing the challenges of anaerobic digestion: Critical steps toward improving biogas generation. Fuel. 2020;261:116497

- [Google Scholar]

- Anaerobic pre-treatment of slaughterhouse wastewater using fixed-film reactors. Bioresour. Technol.. 2000;71(2):143-149.

- [Google Scholar]

- The performance of a continuously operated flocculent sludge UASB reactor with slaughterhouse wastewater. Biol. Wastes. 1988;24(3):199-212.

- [Google Scholar]

- Shamshad Alam, Assefa Weldu Gebremedhin, Hika Wachila Atomsa, Afzal Husain Khan, 2021. A comparative study between strength and durability of bentonite and natural gum stabilised sand, Geomech. Geoeng.

- Long-term operating performance of a poultry slaughterhouse wastewater treatment plant. Resour. Conserv. Recycl.. 2007;50(1):102-114.

- [Google Scholar]

- Minimization of energy demand in slaughterhouses: Estimated production of biogas generated from the effluent. Renew. Sustain. Energy Reviews. 2020;120:109613

- [Google Scholar]

- A study of industrial anaerobic treatment of opaque beer brewery wastewater in a tropical climate using a full-scale UASB reactor seeded with activated sludge. Process Biochem.. 2005;40(2):593-599.

- [Google Scholar]

- Carbon-based materials as adsorbent for antibiotics removal: mechanisms and influencing factors. J. Environ. Manage.. 2019;237:128-138.

- [Google Scholar]

- Evaluation of a two stage anaerobic digester for the treatment of mixed abattoir wastes. Process Biochem.. 2003;38(9):1267-1273.

- [Google Scholar]