Translate this page into:

Effect of tungsten content on the structure, physical and mechanical properties of silicon bronze (Cu-3 wt%Si)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

This research investigated the effect of tungsten content on the structure, physical and mechanical properties of silicon bronze (Cu-3 wt%Si). Tungsten was added in concentrations of 0.1, 0.3, 0.5, 0.8, 1 and 1.5 wt%. The samples were produced using permanent die casting technique, machined and stored for the structural analysis, physical and mechanical tests. The microstructural analysis of the control sample (Cu-3 wt%Si) revealed the presence of dendrite of intermetallic compounds which could be primary silicon and copper silicide (Cu3Si) phases while the alloy doped with tungsten consisted of fine grains of intermetallic compounds evenly dispersed in the copper matrix. The mechanical tests results showed that addition of tungsten to silicon bronze significantly increased the percentage elongation, ultimate tensile strength, hardness and electrical conductivity of the alloy by 174.5%, 741.2%, 98.9% and 14.9% respectively. Maximum percentage elongation, electrical conductivity, ultimate tensile strength and hardness of 25.8%, 61.25% IACS, 286 MPa and 358 BHN respectively were obtained.

Keywords

Silicon bronze

Electrical conductivity

Mechanical properties

Dendrite

1 Introduction

Copper based alloys for automotive, building and electrical components such as electrical conduits, valve stems, tie rods, fasteners, nuts, bolts, screws, rivets and nails are required to have good combination of tensile strength, ductility, hardness and electrical conductivity. Various silicon bronzes with nickel as the major alloying element have been investigated however; these alloys though of high strength have low ductility, hardness and electrical conductivity. Hence there is need to obtain silicon bronze that has good combination of ductility, hardness, strength and electrical conductivity.

Li et al. (2009) investigated the microstructure and properties of Cu-1.8Si-8.0Ni-0.6Sn-0.15Mg alloy. The study indicated maximum hardness, average tensile strength, elongation and average electrical conductivity of 345Hv, 1180 MPa, 2.75%, and 26.5% International Annealed Copper Standard (IACS) respectively at ageing time of 30mins. Study by Eungyeong et al. (2011) on the effect of titanium addition on the structure and mechanical properties of Cu-Ni-Si alloys indicated that addition of titanium has significant effect on the tensile strength, percentage elongation and electrical conductivity of the alloy at different ageing time with maximum values of 837 MPa, 28.8% and 51% IACS respectively. Huang et al. (2003) in their study of the precipitation in Cu-Ni-Si-Zn alloy for lead frame revealed maximum hardness value of 250Hv after cold rolling to 78% and ageing at 450 °C for 1 h. Maximum electrical conductivity of 31% IACS was also obtained at ageing time of 0.5 h. Ketut et al. (2011) established in their study of the effect of silicon content on the mechanical and acoustical properties of silicon bronze alloys for musical instruments that the mechanical properties and damping capacity of Cu-xSi were higher than Cu-20 wt%Sn bronze alloys. Mattern et al. (2007) reported the presence of different meta-stable phases such as η, σ and κ on rapidly quenched silicon bronze. The study also established that room temperature phase, ε was suppressed by rapid quenching. Lei et al. (2013) indicated that addition of aluminium to Cu-Ni-Si alloy has significant effect on the hardness, electrical conductivity, tensile strength and percentage elongation of the alloy with maximum values of 343Hv, 28.1% IACS, 1080 MPa and 3.1% respectively. The effect of thermo-mechanical treatments (TMT) on the microstructures and properties of Cu-1.5Ni-0.3Si-0.03P-0.05 Mg lead frame alloy was investigated by Ho et al. (2000). The study revealed maximum tensile strength and percentage elongation of 640 MPa and 15% with corresponding electrical resistivity of 1.475 × 10−8 Ωm by reducing the size of Ni2Si precipitates to 4 nm. Study on the effect of cold working on the structure and mechanical properties of high strength silicon bronze (C65500) by Kulczyk et al. (2012) revealed that application of cumulative hydrostatic extrusion route caused a substantial grain size refinement which was accompanied by increase in the alloy strength. Puathawee et al. (2013) in their study of the effect of silicon and tin addition on the microstructure and micro-hardness of Cu-Si-Zn alloy revealed maximum hardness of 123.4Hv. Božić et al. (2008) revealed that the rapidly solidified Cu-1.2Ti-3TiSi2 powder microstructure was characterized by the presence of fine, dispersed primary TiSi2 particles and high super saturated solid solution. The study also indicated that Cu-1.2Ti-3TiSi2 powder yielded much higher micro-hardness values compared with the Cu-1.2Ti powder, owing to primary TiSi2 dispersoides formed during atomization. Study by Xiao et al. (2013) on the effect of thermo-mechanical treatments on the microstructures and properties of Cu–2.1Ni–0.5Si–0.2Zr alloy indicated peak strength and electrical conductivity of 665 MPa and 47% IACS at ageing temperature of 450 °C for 2 h and 8 h respectively.

The effect of tungsten on the physical and mechanical properties of silicon bronze has not been investigated. Therefore, this research investigated the effect of tungsten content on the structure, physical and mechanical properties of silicon bronze with the sole aim of developing silicon bronze of good combination of ductility, tensile strength, hardness and electrical conductivity suitable for automotive, building and electrical applications.

2 Materials and method

In this experimental study, the base alloy (999% pure copper and silicon) with and without tungsten were melted in a bailout crucible furnace and cast using permanent die casting technique. The tungsten was added in concentrations of 0.1, 0.3, 0.5, 0.8, 1 and 1.5 wt%. The cast alloy samples were machined and stored for the mechanical and physical tests such as percentage elongation, ultimate tensile strength, hardness and electrical conductivity. The tensile strength and hardness of the developed alloy were determined using an automated 100KN JPL tensile strength tester (Model: 1,30,812) and portable dynamic hardness testing machine (Model: DHT-6) respectively. Standard Ohm’s experiment was adopted in determining the electrical conductivity of the developed alloy. The samples for structural analysis were subjected to filing, grinding, polishing and etching, after which the surface morphology was examined using an optical metallurgical microscope (model: L2003A) and scanning electron microscopy (SEM) equipped with energy dispersive spectroscopy (EDS).

3 Results and discussion

3.1 Mechanical and physical properties of the studied alloy

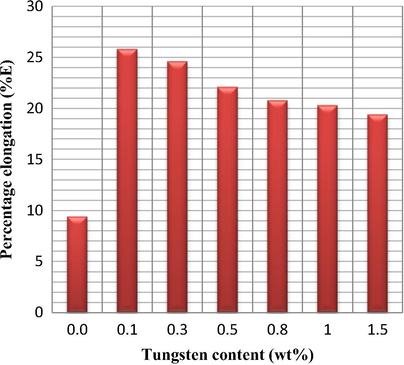

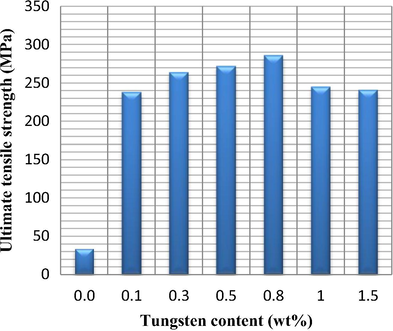

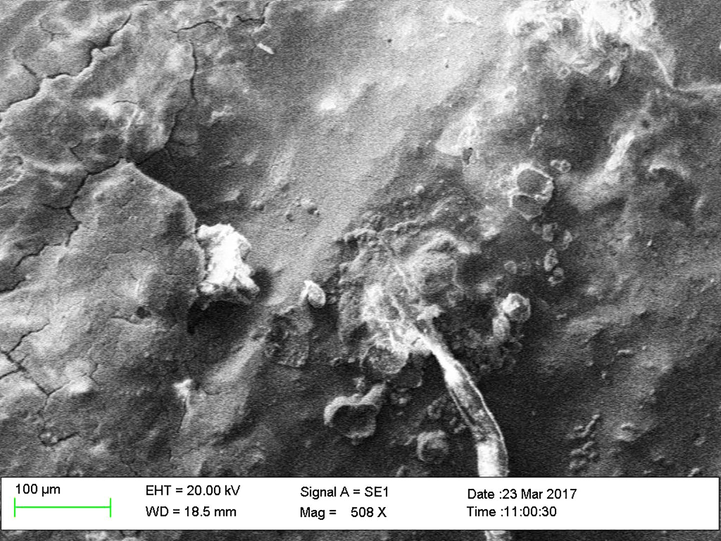

The effect of tungsten content on the percentage elongation, ultimate tensile strength and hardness of silicon bronze (Cu-3 wt%Si) is presented in Figs. 1–3. Analysis of Figs. 1–3 showed that addition of 0.1 wt% tungsten to silicon bronze significantly increased the percentage elongation, ultimate tensile strength and hardness of the alloy. No significant change in mechanical properties was observed in Cu-3 wt%Si alloy when tungsten content is below 0.1 wt%. It was noted in Figs. 1–3 that the percentage elongation of Cu-3 wt%Si-W alloy decreased with increase in tungsten content while the ultimate tensile strength and hardness increased with increase in tungsten content up to 0.8 wt% tungsten addition. Further increase in tungsten content in excess of 0.8 wt% caused a decrease in ultimate tensile strength and hardness of Cu-3 wt%Si-W alloy. This trend in mechanical properties was probably as a result of the presence of coarsened intermetallic compound in the alloy structure (Fig. 9).

Effect of tungsten content on the percentage elongation of silicon bronze (Cu-3 wt%Si).

Effect of tungsten content on the ultimate tensile strength of silicon bronze (Cu-3 wt%Si).

Effect of tungsten content on the hardness of silicon bronze (Cu-3 wt%Si).

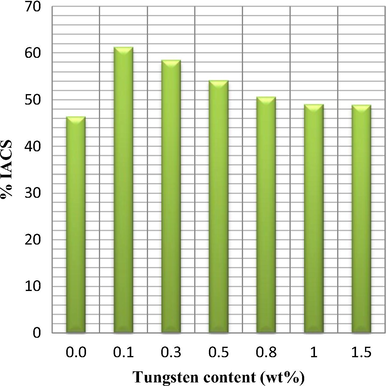

Fig. 4 shows the effect of tungsten content on the electrical conductivity of silicon bronze. Analysis of Fig. 4 indicated that addition of 0.1 wt% of tungsten to silicon bronze increased the electrical conductivity of silicon bronze significantly by 14.9%. No significant improvement in electrical conductivity of Cu-3 wt%Si alloy was observed when the tungsten content is below 0.1 wt%. It was evidenced in Fig. 4 that the electrical conductivity of Cu-3 wt%Si-W alloy decreased with increase in tungsten content with maximum value of 61.25% International Annealed Copper Standard (IACS).

Effect of tungsten content on the electrical conductivity of silicon bronze (Cu-3 wt%Si).

3.1.1 Scanning electron microscopy and energy dispersive spectroscopy (EDS) of the developed alloy

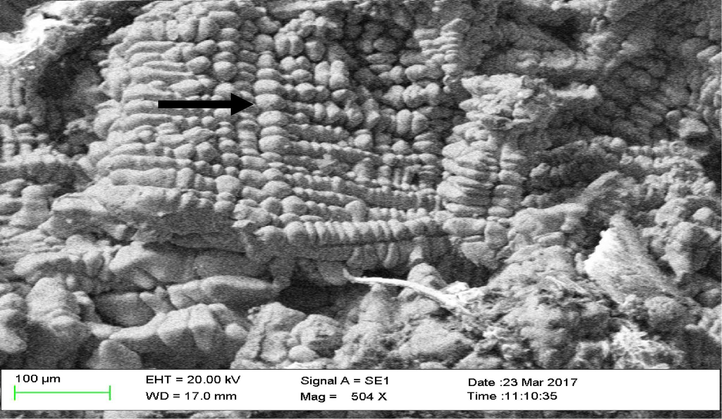

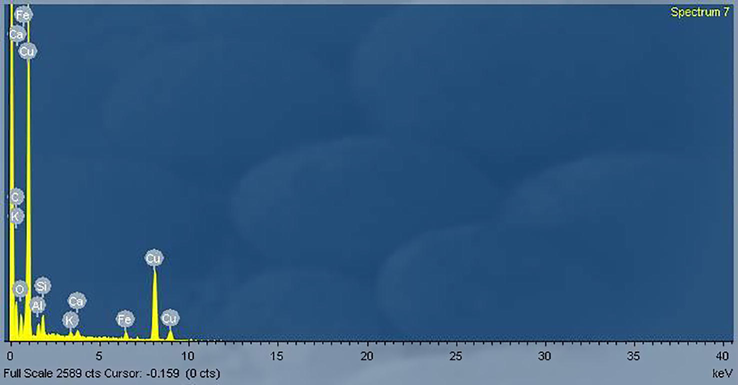

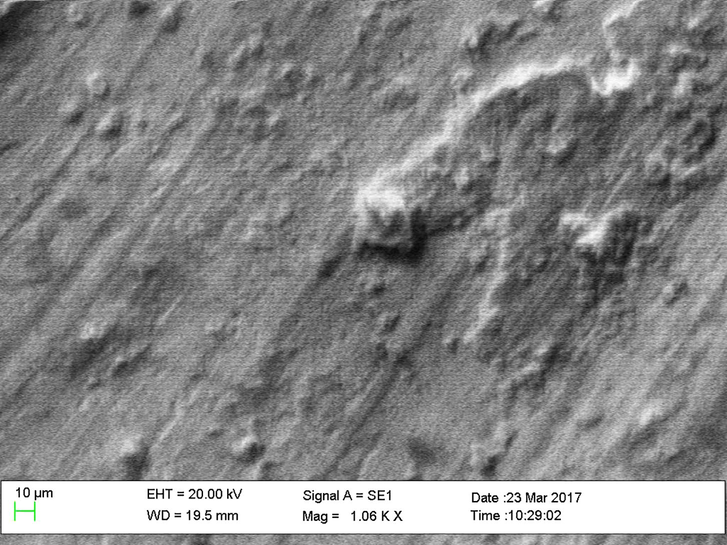

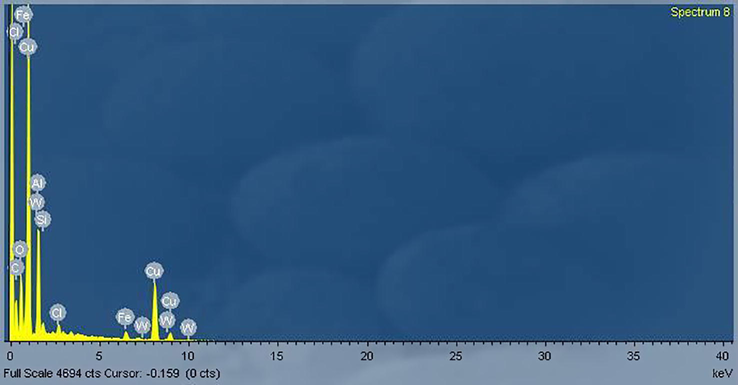

The scanning electron microscopy and energy dispersive spectroscopy analyses of silicon bronze (Cu-3%wt.Si) is presented in Figs. 5 and 6 respectively. The micrograph revealed dendrite of intermetallic compounds which could probably be the primary silicon and copper silicide (Cu3Si) phases as reported by Li et al. (2009). The energy dispersive spectroscopy spectrum indicated the presence of six major elements such as Cu, Si, Al, Fe, K, Ca and contaminants such as C and O etc. A detailed analysis of the scanning electron microscopy and energy dispersive spectroscopy analyses of Cu-3 wt%Si-W alloy are presented in Figs. 7–9. Figs. 7 and 9 revealed grains of spherical pattern unlike the dendritic grains revealed in Fig. 5. Fig. 7 revealed the presence of fine grains of intermetallic compounds evenly distributed in the alloy structure. Fig. 8 showed more large grains when compared with the grains revealed in Fig. 7. These intermetallic compounds could be Cu3Si and WSi2 intermetallic phases. The change in the morphology of the intermetallic compounds from dendritic to fine spherical pattern systematically improved the percentage elongation, ultimate tensile strength and hardness of the alloy. The EDS spectrum indicated the presence of Cu, Si, W, Al, Fe, O, Cl and C elements etc.

Scanning electron microscopy (SEM) of Cu-3 wt%Si silicon bronze.

EDS spectrum of Cu-3 wt%Si silicon bronze.

Scanning electron microscopy of Cu-3 wt%Si-0.8 wt%W silicon bronze.

EDS spectrum of Cu-3 wt%Si-0.8 wt%W silicon bronze.

Scanning electron microscopy of Cu-3 wt%Si-1.5 wt%W silicon bronze.

4 Conclusion

The effect of tungsten content on the physical and mechanical properties of silicon bronze (Cu-3 wt%Si) has been studied in details. The following conclusions were drawn from the results of the study.

-

Addition of tungsten to silicon bronze significantly increased the percentage elongation, ultimate tensile strength and hardness of the alloy by 174.5%, 741.2% and 98.9% respectively.

The percentage elongation of Cu-3 wt%Si-W alloy decreased with increase in tungsten content. Maximum percentage elongation of 25.8% was obtained.

-

The ultimate tensile strength and hardness of the Cu-3 wt%Si-W alloy increased with increase in tungsten content up to 0.8 wt% with maximum values of 286 MPa and 358 BHN respectively. Further increase in tungsten content caused a decrease in ultimate tensile strength and hardness of the alloy.

-

The significant increase in mechanical properties of the alloy was attributed to the change in the morphology of the intermetallic compounds from dendritic to spherical pattern.

-

The decrease in ultimate tensile strength and hardness of Cu-3 wt%Si-W alloy with tungsten content above 0.8 wt%W was attributed to the increase in grain size of the intermetallic compound.

-

Addition of tungsten to silicon bronze significantly increased the electrical conductivity of the alloy by 14.9%.

References

- The combination of precipitation and dispersion hardening in powder metallurgy produced Cu–Ti–Si alloy. Mater. Charact.. 2008;5(9):1122-1126.

- [Google Scholar]

- Effect of Ti addition on tensile properties of Cu-Ni-Si alloys. Met. Mater. Int.. 2011;17(4):569-576.

- [Google Scholar]

- Effect of thermo-mechanical treatments on microstructure and properties of Cu-base lead frame alloy. J. Mater. Sci.. 2000;35(14):3641-3646.

- [Google Scholar]

- Precipitation in Cu–Ni–Si–Zn Alloy for lead frame. Mater. Lett.. 2003;57:2135-2139.

- [Google Scholar]

- Mechanical and damping properties of silicon bronze alloys for music applications. Int. J. Eng. Tech. IJET-IJENS. 2011;11(06):81-85.

- [Google Scholar]

- High strength silicon bronze (C65500) obtained by hydrostatic extrusion. Arch. Metall. Mater.. 2012;57(3):859-862.

- [Google Scholar]

- Effect of aluminium on microstructure and property of Cu–Ni–Si alloys. Mater. Sci. Eng., A. 2013;572:65-74.

- [Google Scholar]

- Microstructure and properties of high-conductivity, super-high-strength Cu-8.0Ni-1.8Si-0.6Sn-0.15Mg alloy. J. Mater. Res. Soc.. 2009;24(6):2123-2129.

- [Google Scholar]

- Phase formation of rapidly quenched Cu–Si alloys. J. Alloy. Compd.. 2007;429:211-215.

- [Google Scholar]

- Microstructure and properties of Cu–Ni–Si–Zr alloy after thermomechanical treatments. Rare Meals. 2013;32(2):144-149.

- [Google Scholar]