Translate this page into:

An Intuitionistic fuzzy approach to modeling the drivers to promote Energy-Efficient textile Manufacturing: Implications for sustainable development

⁎Corresponding author. mainul.ipe@gmail.com (A.B.M. Mainul Bari)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

The textile manufacturing sector plays a vital role in the economic growth of many emerging economies. Hence, achieving energy efficiency and sustainability is crucial for this sector to cope with the ongoing energy crisis, rising fuel prices, and economic inflation. Previous studies on energy efficiency focused on various industrial sectors. However, none focused on assessing the driving forces to encourage the energy-efficient textile manufacturing sector in emerging economies. This study, therefore, addresses the gap in existing studies by determining and evaluating the factors and their interrelationships that encourage energy-efficient textile manufacturing in a developing economy like Bangladesh. This study utilizes a novel hybrid Interval-Valued Type 2 Intuitionistic Fuzzy (IVT2IF) theory-based decision-making trial and evaluation laboratory (DEMATEL) framework. After expert validation, sixteen factors were analyzed in this study. The findings suggest “Implementing effective in-house energy management measures (F4)” to be the most eminent factor for promoting energy efficiency. Again, “Adopting renewable energy (F2)” was found to be the most important causal group factor, and “Adopting alternative waterless dyeing technology (F3)” was found to be the most affected effect group factor. This study is expected to aid industrial managers and policymakers in promoting energy efficiency in the textile manufacturing sector and thus contribute to the sustainable development of emerging economies like Bangladesh.

Keywords

Energy efficiency

Textile manufacturing

Sustainable development

Interval-valued type 2 intuitionistic fuzzy set theory

DEMATEL

1 Introduction

As an intangible yet fundamental resource, energy supports a complex web of interconnected systems and processes. Energy forms the bedrock of a nation's economy, acting as a catalyst for societal and economic advancement while exerting the most significant influence on sustainable development. It is commonly understood that energy plays a critical role in poverty eradication, economic prosperity, long-term infrastructure development, and national security (Kanwal et al., 2022). Energy is fundamental to existence, and its constant and omnipresent supply provides a region with much-needed economic growth and prosperity (Abbas et al., 2018). A rise of 1% in economic growth in developing nations results in a concomitant escalation of energy consumption (Raihan & Bari, 2024). A higher investment-to-gross domestic product (GDP) ratio is significantly associated with an increase in the growth rate of energy use (Raihan & Bari, 2024). Beyond its economic implications, energy also influences other important aspects such as the environment, sustainability, health and well-being, energy security, technological innovation, and geopolitical considerations. With the rapid economic development of emerging economies, the acceleration of industrialization and urbanization, expanding industrial energy consumption, and increasing reliance on energy, there are growing concerns about resource scarcity, supply insufficiency, and disruption (Raihan & Bari, 2024). Energy inefficiency, especially in industries, negatively impacts the achievement of Sustainable Development Goals (SDGs) 7, 8, and 12, which deal with access to affordable and clean energy, decent work and economic growth, and sustainable production and consumption patterns, respectively. As outlined in SDGs 7, 8, and 12, ensuring equitable access to cost-effective, dependable, and environmentally friendly energy sources is critical to relieving poverty, stimulating economic expansion, and promoting sustainable patterns of resource consumption (Alam et al., 2024b).

The textile industry is a traditional pillar industrial sector in emerging economies like Vietnam, India, and Bangladesh, with distinct international competitive advantages (Swazan & Das, 2022). This industry is often critical to economic development in these regions. The industry significantly contributes to boosting the market, absorbing labor, empowering women, hastening urbanization, and supporting harmonious social development (Zhao & Lin, 2019). Energy is an essential resource for textile manufacturing, permeating every process stage and substantially impacting operational efficiency, cost structure, and environmental sustainability (Debnath et al., 2024). The exponential expansion of both population and economy will lead to a significant upsurge in textile manufacturing and consumption (Lin & Bai, 2020). The intricate interplay of complex processes in textile manufacturing necessitates a significant amount of energy to power the complicated machineries involved, allowing the transformation of raw materials into high-quality textiles via processes such as spinning, weaving, and dyeing. Energy-intensive machines are crucial in smoothly converting fibers into fabrics with diverse compositions and textures. Furthermore, the thermal energy supplied from fossil fuels or renewable sources used in the dyeing process assures vivid pigmentation and colorfastness of textiles, making them both visually pleasing and commercially successful. Several finishing processes, such as drying, curing, and heat-setting, also use a substantial amount of energy (Nunes et al., 2018). Additionally, energy is also consumed in the manufacture of apparel, where electricity is required by the cutting, sewing, and other machines to stitch fabrics together and in utility services and supply chain and logistics for the transportation of raw materials and finished good. According to the China Energy Investment Corporation (CEIC) database, the Chinese textile industry's specific energy consumption was 16.67 million tons of oil equivalent (Mtoe) in 1985, rising to 21.14 Mtoe in 2000. Following that, it quickly increased to 51.07 Mtoe in 2016. Energy usage has increased by 67.36% since 1985 (Lin & Bai, 2020).

Emerging economies are striving to raise both their economic and living standard in line with the demands of their rapidly growing populations. However, some issues are refraining them from achieving the goal, such as less diversified energy policies and inefficient energy consumption (Mancheri et al., 2019). Against the backdrop of the ongoing conflict between Russia and Ukraine, inflationary pressures, and the post-COVID disruption situation, the need for energy conservation becomes even more pronounced, with complex ramifications for economic stability, geopolitical dynamics, and environmental sustainability (Orhan, 2022). The COVID-19 pandemic has exerted profound disruptions on the global textile industry, manifesting in supply chain disturbances and a significant shift in consumer demand (Debnath et al., 2024). The war has already put nations that depend on Russia or Ukraine at risk for energy, minerals, fertilizers, and agricultural products (Alam et al., 2024b). Energy resources, particularly natural gas, have become critical geopolitical instruments and economic leverage. Large textile establishments in Bangladesh face a delicate situation due to various challenges. Due to the strong dollar exchange rate, the crisis of electricity shortage and rising production costs, including increased expenditure on importing fossil fuels, coals, etc., have put financial pressure on the textile manufacturing sector (Kanwal et al., 2022). Additionally, natural gas use in Bangladesh has been substantially higher in the last 15 years than that of natural gas discovery. The total amount of recoverable natural gas was anticipated to be around 27 trillion cubic feet (TCF) by the end of 2017, with 15.22 TCF previously consumed (Shetol et al., 2019). As a result, the remaining amount of gas is 12 TCF, only enough to cover the country's demand for the next 10–12 years (Shetol et al., 2019). In addition, the scarcity and higher prices of textile raw materials in the international market have further compounded these difficulties. The impact of the Ukraine-Russia war has led to a decline in purchasing power in the main buyer markets, namely the United States and Europe, resulting in a 50% reduction in orders (Liadze et al., 2023). These groups' dependency on imported raw materials necessitates maintaining a six-month stock, which incurs significant financial and insurance costs (Debnath et al., 2024). Additionally, the recent 250% increase in gas prices has affected these groups' production costs, while the availability of gas and consistent power supply remains unreliable, causing disruptions and increased expenses (Milewska & Milewski, 2022). These energy challenges, along with decreased demand in the international market, pose a risk to the overall economic sustainability of the business. Furthermore, the combination of inflationary pressures and the COVID-19 epidemic mandates a strategic emphasis on energy saving.

Due to the severe condition of scarce energy resources and environmental difficulties, achieving energy efficiency has become increasingly critical for textile manufacturing in emerging economies. Accounting for the lack of energy sources in the country and the economic implications of the textile manufacturing sector, improving energy efficiency is an important means for effectively alleviating the disparity between energy demand and energy supply, as well as an effective way of promoting economic and environmental sustainability (Zhao & Lin, 2019).

Hence, it is obvious that energy-efficient strategies should be executed in the textile sector, reducing consumption to move towards a more sustainable business and reducing the country's reliance on energy imports (Costa et al., 2019). Many studies have already been carried out regarding energy efficiency in various aspects. Traditional energy efficiency was measured and decomposed using data envelopment analysis, while the Biennial Malmquiste Luenberger (BML) productivity index (Zhao & Lin, 2019) and dynamic energy performance evaluation were done by non-radial direction distance function (NDDF) (Lin & Bai, 2020). Very few studies are centered on exploring the driving factors and barriers to energy efficiency (Hasan et al., 2019), using only statistical methods. However, the overall factors to promote energy efficiency considering every stage of textile manufacturing in the context of emerging economies to achieve sustainable consumption remain unexplored in the existing literature. The consequences of the Russia-Ukraine war on energy have not yet been investigated much. There has been no investigation into the driving factors that can help overcome the impact of the energy crisis arising from the COVID-19 pandemic and the Russia-Ukraine conflict on energy, particularly for emerging economies like India and Bangladesh. To ensure the smooth functioning of all textile-related industries, achieve sustainability, and ensure the country’s economic security, correctly identifying and evaluating the interactions of these driving factors is pivotal. The principal objective of this study is to fill the above-mentioned research gaps by investigating the following research questions (RQs):

RQ1: What are the driving factors promoting energy-efficient textile manufacturing in the context of an emerging economy like Bangladesh?

RQ2: How are these factors interrelated with each other?

RQ3: How will assessing factors benefit industry managers and policymakers in achieving energy efficiency and sustainability?

To address these RQs, past research has been reviewed to identify the driving factors for energy-efficient textile manufacturing, and interviews have been conducted with several Bangladeshi textile manufacturing companies to refine the identified driving factors. Before having these criteria validated by specialists, preliminary systematic literature research has been conducted to discover the initial driving factors from the literature. The respondents have then finalized the factors. Therefore, this research endeavor will contribute to two sectors of the existing literature, including sustainability and energy-efficient textile manufacturing, by accomplishing the underscored research objectives (ROs):

RO1: Identifying driving factors that encourage energy efficiency in emerging economies' textile industries.

RO2: Proposing an appropriate analytical framework to examine and assess the drivers.

RO3: Looking into how the factors affect each other and helping lawmakers to emphasize and promote environmentally friendly and energy-efficient textile manufacturing practices.

A combination of the Interval Valued Type 2 Intuitionistic Fuzzy (IVT2IF) set theory and the Decision-making trial and evaluation laboratory (DEMATEL) have been used in this study to evaluate the significant factors (overall prominence) and uncover the causal interrelationships and hierarchy of relevance of the resulting driving factors in pursuit of the defined ROs. Integrating Interval-Valued Type 2 Intuitionistic Fuzzy Numbers (IVT2IFN) with DEMATEL presents a versatile approach to addressing uncertainty and vagueness in decision-making (Zulqarnain et al., 2022). By combining the IVT2IFN theory with DEMATEL, the imperfect and unpredictable features of human perceptions can be effectively managed by integrating the IVT2IFN theory with DEMATEL. This allows one to overcome the limitations of the DEMATEL method and enhances the precision of the interrelationships among various driving factors (Zulqarnain et al., 2022).

This study facilitates the existing literature by empirically exploring the driving factors for production methods that use less energy in the textile manufacturing industry of a developing economy. This expands the body of knowledge since it allows us to identify a wide range of driving factors and their corresponding causal interrelationships. Additionally, this research can aid policymakers and practitioners in better planning by helping them understand the interdependence and reliance among the driving variables for boosting energy efficiency in the textile industry. The study also allows policymakers and practitioners to implement more efficient production processes in the textile industry by identifying the priority factors that should receive the most investment and attention.

2 Related Works, research gaps, and research contributions

The textile sector is widely recognized as being highly energy-intensive. Numerous studies have investigated energy efficiency measures that can be adopted in textile manufacturing. The production processes involved in textile manufacturing, such as spinning, weaving, knitting, dyeing, and finishing, require substantial energy (Hasan et al., 2019). However, incorporating energy-efficient processes in textiles will lead to a sustainable future. Efficient energy management is essential for reducing costs, minimizing environmental impact, and enhancing overall sustainability in the textile sector. Hence, this study conducted a comprehensive review of existing literature spanning from 2018 to 2023. The objective was to assess the relevant works on energy efficiency and identify various factors contributing to adopting energy-saving production processes in the textile sector. Furthermore, the review exposed a research void in this field, prompting the current study. A research approach incorporating databases, temporal resolution, keywords, inclusions, exclusion criteria, etc., was developed during the literature review process, as shown in Table 1. A cross-referencing analysis was executed, and pertinent literature on the efficacy of resource utilization was delved into.

Research protocol

Detailed depiction

Databases

Google Scholar, Scopus

Language

English

Temporal resolution

2018 to 2023

Search terms and keywords

“Energy consumption,” “Energy efficiency in textile,” “Energy Security,” “Energy sustainability”

Inclusion criteria

(i) Articles saliant to RQ1, RQ2, and RQ3 that provide proper relevance to the topic.

(ii) Scientific journals that are pertinent to the variables and factors to support energy utilization and efficiency.

Exclusion Criteria

(i) Articles that are disseminated in languages other than English.

(ii) Articles that emphasize quantitative methodologies while downplaying the qualitative findings.

(iii) Articles that are not indexed in reputed databases, such as Scopus and Google Scholar.

Data extraction

The relevant paper with variables and factors of interest was extracted for the proposed framework.

Christensen (2021) proposed a circular economy model for textile recycling. Ahmed et al. (2020) and Hasan et al. (2018) conducted their research in Bangladesh to assess energy consumption and perform energy evaluations. In another study, Islam & Khan (2017) accomplished a review of energy scenarios in Bangladesh. These studies collectively provide valuable insights into the potential for sustainable practices and energy efficiency improvements in the textile and manufacturing sectors. Table A1, Appendix A of supplementary materials presents the summary of the recent literature on energy efficiency.

After studying the previous relevant literature, the following research gaps were revealed:

-

Though unearthing the consequences of energy efficiency approaches has been popular among researchers, very few studies have identified the driving factors for promoting energy efficiency in the textile manufacturing sector.

-

There has been no investigation into the driving factors that can help overcome the impact of the energy crisis arising from the COVID-19 pandemic and the Russia-Ukraine conflict.

-

No study has been found to explore the driving factors in the context of emerging economies.

-

The existing literature falls short of uncovering the mutual relationships among the driving factors to promote energy efficiency and how they contribute to sustainability.

This study aims to address these gaps and offer valuable insights into energy efficiency in textile sectors of emerging economies by considering multiple perspectives. By combining the IVT2IF theory and DEMATEL method, this study intends to evaluate the findings (overall prominence to learn how the resulting causative factors are connected to one another and rank in importance. Furthermore, the IVT2IF DEMATEL technique produces more robust findings when taking decisions in perplexing condtions, deriving both priority and causal linkages concurrently. By implementing the recommended suggestions in this study, the proposed framework will assist managers in making proactive and reactive decisions to enhance energy effectiveness in emerging economies. Such a strategic stand will retrieve emerging economies from energy loss and waste, enabling energy security and establishing sustainable textile manufacturing.

2.1 Driving factors for promoting energy efficiency in textile manufacturing

This section aims to explore existing studies that shed light on the various factors influencing energy efficiency in the textile industry within emerging economies. Several authors have highlighted the importance of leveraging advanced tools and technologies to digitize energy efficiency in the textile sector (Rahman et al., 2020). These technological advancements are expected to enhance the sector's capabilities in addressing energy consumption challenges and improving overall efficiency. While the utilization of electricity, steam, or hot air as energy sources may initially seem intricate, it is important to recognize their significance as catalysts in fostering a sustainable energy paradigm (Siwal et al., 2020). Additionally, Lawrence et al. (2019) proposed the implementation of efficient energy management practices at the department level to enhance cost-effective internal operations and augment energy efficiency within the textile industry. Hossain et al. (2018) addressed a noteworthy alternative to traditional dyeing processes, which is the waterless dyeing method that not only ensures sustainability but also brings about a substantial reduction in energy demands. Moreover, the integration of variable frequency drives (VFDs) in textile manufacturing plants, as advocated by Hasan et al. (2019), contributed significantly to improved energy efficiency. To ensure energy security, it is of paramount importance to strengthen human behavioral aspects (Soepardi & Thollander, 2018). Furthermore, the establishment of an Energy Efficiency Network (EEN) assumes a crucial role in surmounting significant barriers to energy efficiency, ultimately unlocking the full potential for energy savings (Jalo et al., 2021). Following the research protocols, the initial driving factors in addressing the energy efficiency in textiles are identified likewise from the literature and presented in Table A2, Appendix A of supplementary materials. Subsequently, the list of initial factors thus identified was sent to relevant field experts for validation in the form as shown in Table A2. The final factors extracted through the validation process are represented in Table 2, and their brief description is depicted in Table A3, Appendix A of supplementary materials.

Code

Driving factors

Reference

F1

Incorporating circular economy in the production process

Christensen (2021)

F2

Adopting renewable energy

Alam et al., (2024b)

F3

Adopting alternative waterless dyeing technology

Hossain et al. (2018)

F4

Implementing effective in-house energy management measures

Lawrence et al. (2019)

F5

Employing nano-filtration effluent treatment plant (ETP)

Dash & Kumar (2017)

F6

Adopting advanced machinery & total productive maintenance

Achamu et al. (2018); Chen & Lin (2020)

F7

Establishing an energy audit system

Johansson & Thollander (2018)

F8

Reduction and control of compressed air leaks

Costa et al. (2019)

F9

Installing IoT devices to manage gas combustion and minimize excess steam generation

Manglani et al. (2019)

F10

Insulation of machinery, boilers & transmission system

Saha et al. (2021)

F11

Appropriate production planning

Özer & Güven (2021)

F12

Strengthening government support

Hasan et al. (2018)

F13

Rising energy prices

Abbas et al. (2018)

F14

Raising consumer awareness about energy efficiency

Soepardi & Thollander (2018)

F15

Adoption of green emerging technologies

Expert feedback

F16

Employing motion and occupancy sensors and a timer-based power control system

Expert feedback

The remainder of the paper follows this outline: Methods are outlined in Section 2, and results are offered in Section 3. The outcomes and discoveries pertaining to the causal and consequential aspects are elaborated upon in Section 4. Implications for theory, policymaking, and practice are discussed in Section 5, followed by a conclusion and various avenues for further research in Section 6.

3 Methodology

3.1 Survey Design and Data Collection

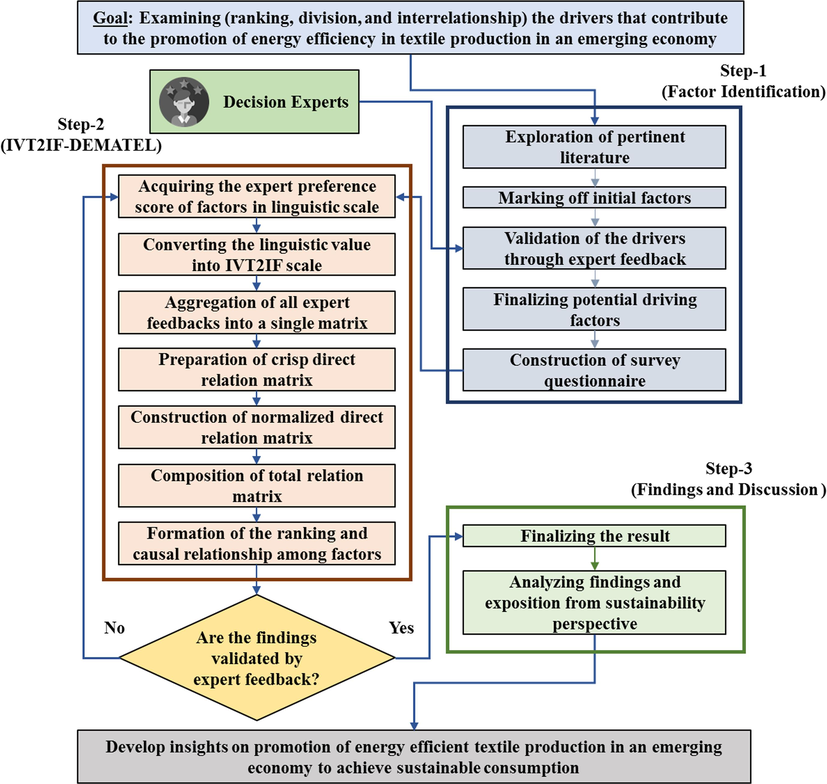

A detailed and acute survey is performed for an in-depth investigation of the literature to identify potential driving factors and examine their interrelationships that promote energy-efficient manufacturing processes in the textile sector of an emerging economy to attain sustainable development. The survey has been accomplished in several distinct stages. However, as depicted in Fig. 1, the study's framework starts with defining the research goal of systematically analyzing the drivers to promote energy-efficient textile manufacturing in emerging economies. Firstly, the snowballing technique, a randomly selected sequential sampling method, was used to identify initial driving factors to increase energy efficiency in textile manufacturing (Debnath et al., 2024). As outlined in Table 1, the research protocol was utilized to initially skim through more than 120 papers chosen from a rigorous literature assessment using the keywords with a timeline from 2018 to 2023. After careful full-text screening and appropriate application of the study protocol, the 55 most pertinent publications, projects, and documents were finally reexamined in order to determine the contributing elements and respond to the particular RQs.

Study design and the methodological framework.

Utilizing the application of the afore-mentioned elaborate research technique, 18 potential driving factors promoting energy efficiency in textile manufacturing in a rising economy were unveiled. Table A1, located in Appendix A associated with the supplementary materials, provides a preliminary list of the factors examined in the literature study. The list was then sent to appropriate field decision experts (DEs) for confirmation. A total of 12 responses were collected from the DEs during the validation stage to finalize the list of factors for further evaluation. The validation process resulted in the finalized list of 16 factors, where the experts deducted four factors and added two more relevant factors. The two added factors are “Adoption of green emerging technologies” and “Employing motion and occupancy sensors and timer-based power control system”, while the subtracted four factors are “Embracing biotechnological advancement”, “Procurement of energy-efficient materials, resources, and technologies”, “Developing an energy efficiency network (EEN)”, and “Installation of variable frequency drive (VFD)”. Selection of the research decision experts (DEs) was carried out using the purposive sampling method (Alam et al., 2024a; Bhattacharya et al., 2024; Shakur et al., 2024), a method that is useful for choosing decision experts in order for particular assessment towards achieving the research goal (Bari et al., 2024; Alam et al., 2024b). Fig. 1 shows the whole framework followed in this research study.

In the second stage, after finalizing the list of driving factors, a survey questionnaire was designed to examine these factors further. A linguistic scale corresponding to IVT2IFN was applied to collect the feedback of the experts regarding their interrelationships. This process begins with gathering the DEs' feedback via semi-structured interviews and an organized questionnaire. Next, the IVT2IF-DEMATEL approach is applied to ascertain the factors ranking, grouping, and causal relationships. Subsection 2.4 provides a full description of the IVT2IF-DEMATEL method's process. The final step involved the DEs validating the research results. The research findings and their many ramifications were finally discussed following the validation.

All the respondents were professional energy and textile experts with at least eight years of experience in the relevant field. A face-to-face physical interview was conducted to gather expert feedback from DEs. About 16 DEs from the textile-energy sector were approached, and 12 of them (75% response rate) consented to take part in the survey work, both in validating factors as well as analysis. The 12 participating decision experts' general profiles are shown in Table 3.

Decision Experts

Background

Rank

Institution Category

Experience (In Years)

1

Ph.D. in Textile Engineering

Associate Professor

University

13

2

M.Sc. in Industrial Engineering

Textile General Manager

Private Textile Company

11

3

B.Sc. in Electrical Engineering

Regulatory Commission Member

Government Power Division

11

4

M.Sc. in Mechanical Engineering

Maintenance Manager

Private Textile Company

10

5

B.Sc. in Electrical Engineering

Audit Manager

Government Power Division

12

6

Ph.D. in Textile Engineering

Assistant Professor

University

9

7

M.Sc. in Environmental Science & Engineering

Sustainability and Compliance Manager

Multinational Textile Company

13

8

B.Sc. in Electrical Engineering

Power Manager

Government Power Division

9

9

M.Sc. in Textile Engineering

Assistant Maintenance Manager

Private Textile Company

8

10

Ph.D. in Mechanical Engineering

Professor

University

18

11

M.Sc. in Industrial Engineering

Associate Professor

University

10

12

B.Sc. in Textile Engineering

Textile manufacturing Manager

Private Textile Company

8

3.2 IFS and IVT2IF theory

The fuzzy set (FS) has a range of membership grades that give a natural way to deal with ambiguous expressions and judgments of experts (Debnath et al., 2023; Al Zihad et al., 2023). Moreover, it offers rigorous mathematical expertise to address quantification issues with high flexibility to represent complex computing information (Gholamizadeh et al., 2022). Ordinary Type-1 fuzzy sets cannot directly deal with uncertainty effectively during the modeling of the framework since their membership functions are completely crisp in the interval [0,1]. Type-2 fuzzy sets, on the other front, have a more acute potential of capturing uncertainty since their grades of membership are fuzzy, along with the inclusion of a secondary membership degree (Debnath et al., 2023). Furthermore, Type-1 fuzzy sets have a two-dimensional membership function, whereas Type-2 sets include a new third dimension that provides additional degrees of freedom for experts to model uncertainty directly and more precisely (Debnath et al., 2023). Interval type-2 fuzzy sets provide an additional capability to simulate more complex decision-making processes by expanding the solution space, enabling better accuracy (Chen et al., 2022).

An extension of FS, called intuitionistic fuzzy set (IFS) theory, is characterized by three functions: a membership, a non-membership, and a hesitant function (Yu et al., 2022). In comparison to FS, it can model the imprecision in experts' subjective ambiguous assessments in a more comprehensive and flexible manner, with a degree of hesitation and disagreement. Furthermore, it includes three levels of information, making it superior in extracting opinions in the real world, where decision-makers frequently get unclear about their decisions (Ocampo & Yamagishi, 2020). Later, as an extension of IFS, the interval-valued intuitionistic fuzzy set (IVIFS) was developed, in which the membership, non-membership, and hesitation functions take the shape of an interval rather than a crisp value (Li et al., 2021). Using Type-2 fuzzy sets instead of ordinary ones, it would improve precision while dealing with uncertain information (Chen et al., 2023). The following describes the basic framework of the Interval-valued Type-2 Intuitionistic Fuzzy (IVT2IF) system ((Ocampo & Yamagishi, 2020; Chen et al., 2023; Debnath et al., 2023):

Definition 1 Let W be a standard fuzzy set, and M be a finite, non-empty set whereas corresponds to membership function such that .

Let, and a fuzzy set, where m ∊ W and the membership function of m ∊ W is denoted by .

Definition 2 The IFS in set M can be expressed as

Where W corresponds to the fixed set.

In Equation (1),

is used for representing

and

. Ideally, for m∈M to the fixed set W, the membership degree of knowledge deficiency is indicated as

while the non-membership degree of the perception is written as

. The degree of non-determinacy (or uncertainty) of the element

to the intuitionistic fuzzy set W is represented by the following equation:

Where .

Definition 3 (Jin & Zhang, 2023). An IVIFS in is indicated by , where , , are intervals, expressing the degree of membership, non-membership, and hesitation, respectively, of element in set . Consequently, , for .

Definition 4 (Xu & Gou, 2017). Let

is a compilation of IVT2IFNs and

, is the weight vector of

with

, then the interval-valued type 2 Intuitionistic fuzzy weighted geometric (IVT2IFWG) operator is a projecting

. Where,

Definition 5 (Öztayşi et al., 2021). Equation (4) defuzzifies the linguistic phrase by utilizing the fuzzy numbers α and β. As a result, the crisp value is attained from the linguistic phrase.

3.3 DEMATEL method

DEMATEL method is defined by its ability to study the comprehensive effect of factors and identify the critical factors and their relationship, which results in their classification into ‘cause’ and ‘effect’ groups while assessing their importance (Agarwal et al., 2023; Bandil et al., 2023). Furthermore, it is a system factor analysis technique that uses diagraphs and matrices to expose the system structure relation via logical causal relationships among various factors (Asadi et al., 2022). This method has the advantage of clearly identifying the correlativity and indirect relationship among components, as well as the degree of strength and weakness of the relationship (Debnath et al., 2023). In addition, it assists DEs in understanding how to improve programs by taking into account the cause-effect diagram of criteria and judging the value of each factor to the outcome (Kashyap et al., 2022). The following represents the basic steps of the DEMATEL method:

Step 1: Assume that the pairwise comparison contains F elements. For this reason, the Direct-Relation Matrix (DRM) is built. The pairwise comparison is developed by an expert group of N members based on the DEs' feedback. The DRM for the zth decision expert is persued by .

where, , corresponds to the impact of the factor on the factor .

The aggregate DRM,

where

and

is regarded as the

expert’s significance. Then,

can be defined as follows:

Step 2: Equations (6) and (7) are used to apply normalization of the aggregate DRM. First, the maximum value of the sum of the values of all datasets from a row is calculated using Equation (6).

Following that, normalization was done through Equation (7).

Step 3: Equation (8) is utilized to show the Total Relation Matrix (TRM), T.

T basically expresses the influential correlationship among all driving factors, which was determined using Equation (9).

Here, , corresponds to the element of matrix in the row and column, respectively, while corresponds to the identity matrix.

Step 4: The driving factors are grouped into cause-and-effect categories.

Equation (10) is utilized to calculate the sum of the columns, denoted as

.

Similarly,

represents the sum of the rows, which is calculated using Equation (11). The graph for cause-and-effect is produced by projecting the numerical value of (

+

,

−

).

Step 5: To compare the significance of each driving factor, the “Prominence Vector” is written as . Again, is the expression for the “Relation Vector”, which is divided into two groups: cause group when ; and effect group when ; .

3.4 Interval Valued Type 2 Intuitionistic Fuzzy DEMATEL (IVT2IF −DEMATEL) method.

To effectively deal with the inherent vagueness of judgments inside the DEMATEL approach and improve the method's performance in dealing with ambiguity, an interval-valued type 2 intuitionistic fuzzy (IVT2IF) set is employed to construct a hybrid framework. IVT2IF is a more comprehensive fuzzy set than conventional fuzzy sets (Debnath et al., 2023), containing additional design degrees of freedom with the interval-valued fuzzy sets, yielding more relevant results for decision-making and strategy formulation research (Ocampo & Yamagishi, 2020). As a result, IVT2IF-DEMATEL has been a popular hybrid framework for a variety of domain applications in recent times (Chen et al., 2023; Debnath et al., 2023).

Till date, there is no application of IVT2IF-DEMATEL in the field of textile manufacturing. As a result, a novel approach is employed by analyzing the driving factors boosting energy efficiency in textile manufacturing in emerging economies utilizing IVT2IF-DEMATEL. The following outlines the fundamental steps of IVT2IF- DEMATEL:

Step 1: Define the main driving factors behind the promotion of energy efficiency in textile production in emerging economies.

The driving factors encouraging energy efficiency are determined through semi-structured interviews, iterative processes, and reductive methods. Table 2 contains the preliminary factors as well as their associated codes.

Step 2: Use novel preference scales in order to gather linguistic data.

The DE's evaluations are acquired by ranking the driving factors using the linguistic scale and substituting them with the appropriate IVT2IF numbers (Chen et al., 2023; Debnath et al., 2023). Table 4 shows the linguistic scale and the IVT2IF values.

Linguistic

Abbreviation

IVT2IF

No influence

N

([0.060, 0.260],[0.700, 0.900])

Very low influence

VL

([0.220, 0.420],[0.540, 0.740])

Low influence

L

([0.060, 0.260],[0.700, 0.900])

High influence

H

([0.540, 0.740],[0.220, 0.200])

Very high influence

VH

([0.700, 0.900],[0.060, 0.260])

Step 3: Aggregate the IVT2IF values.

Equation (5) of Definition 4 is used to aggregate the IVT2IF values. As part of Appendix B, corresponding to supplemental material, Table B1 displays the aggregated data.

Step 4: Acquire initial DRM crisp value.

Using Equation (4), the defuzzified procedure converts the aggregated data into crisp values of the DRM. In Appendix B of the supplemental material, Table B2, displays the DRM crisp values.

Step 5: Develop the subsequent normalized DRM.

Equations (6) and (7) are used to normalize the initially established DRM. Since 9.554 is the highest value for all rows and columns combined, each component of the original DRM is divided by this number (Table B2). The result of normalized DRM is displayed in Table B3 of Appendix B (see supplemental material file).

Step 6: Develop the TRM.

Equation (9), which is used to create the TRM from the previous normalized DRM, is presented in Table B4 of Appendix B (see supplemental material file). To get the and values, the and values are computed using Equations (10) and (11). Tables 6 and 7 present the prominence order of driving factors and the cause group & effect group classified by .

Step 7: Form a causal relationship diagraph.

To prevent the identical negligent impact of analysts, DEs, and specialists, a threshold value (θ) is needed. TRM's mean and standard deviation are added together in order to generate the threshold value (θ). The contributing component i affects the factor j when . The causal relationship diagraph, produced with the ( + , − ) data set, contains directed arrows based on the influencing effect among factors. T has a mean of 0.246 and a standard deviation of 0.046, yielding θ = 0.292.

4 Results

By using the IVT2IF-DEMATEL technique, the prominence order of the driving factors encouraging energy-efficient textile manufacturing in emerging economies has been uncovered, as shown in the following Table 5. The ranking order of the driving factors is ascertained based on their level of influence (D+R) as F4 > F6 > F2 > F15 > F12 > F13 > F7 > F1 > F14 > F12 > F9 > F3 > F8 > F10 > F5 > F16.

Code

Driving Factors

D + R

Prominence Ranking

F4

Implementing effective in-house energy management measures

9.180

1

F6

Adopting advanced machinery & total productive maintenance

9.020

2

F2

Adopting renewable energy

8.738

3

F15

Adoption of green emerging technologies

8.456

4

F12

Strengthening government support

8.405

5

F13

Rising energy prices

8.270

6

F7

Establishing an energy audit system

8.262

7

F1

Incorporating circular economy in the production process

8.048

8

F14

Raising consumer awareness about energy efficiency

7.963

9

F12

Appropriate production planning

7.529

10

F9

Installing IoT devices to manage gas combustion and minimize excess steam generation

7.416

11

F3

Adopting alternative waterless dyeing technology

7.354

12

F8

Reduction and control of compressed air leaks

7.245

13

F10

Insulation of machinery, boilers & transmission system

7.217

14

F5

Employing nano-filtration ETP

6.654

15

F16

Employing motion and occupancy sensors and a timer-based power control system

6.352

16

The ranking of the causes and effects in order of importance is presented in Table 6. 8 driving factors are found as causal factors (when D-R >0) and 8 driving factors as effect factors (when D-R < 0). F2 > F12 > F13 > F15 > F7 > F6 > F4 > F11 are the driving factors in the cause group, while F3 > F14 > F16 > F5 > F1 > F10 > F9 > F8 are the driving factors in the effect group.

Code

Driving Factors

D-R

Ranking

Group

F2

Adopting renewable energy

1.094

1

Cause

F12

Strengthening government support

1.071

2

F13

Rising energy prices

0.655

3

F15

Adoption of green emerging technologies

0.403

4

F7

Establishing an energy audit system

0.305

5

F6

Adopting advanced machinery & total productive maintenance

0.182

6

F4

Implementing effective in-house energy management measures

0.149

7

F11

Appropriate production planning

0.057

8

F3

Adopting alternative waterless dyeing technology

−0.144

1

Effect

F14

Raising consumer awareness about energy efficiency

−0.169

2

F16

Employing motion and occupancy sensors and a timer-based power control system

−0.418

3

F5

Employing nano-filtration ETP

−0.495

4

F1

Incorporating circular economy in the production process

−0.537

5

F10

Insulation of machinery, boilers & transmission system

−0.636

6

F9

Installing IoT devices to manage gas combustion and minimize excess steam generation

−0.676

7

F8

Reduction and control of compressed air leaks

−0.841

8

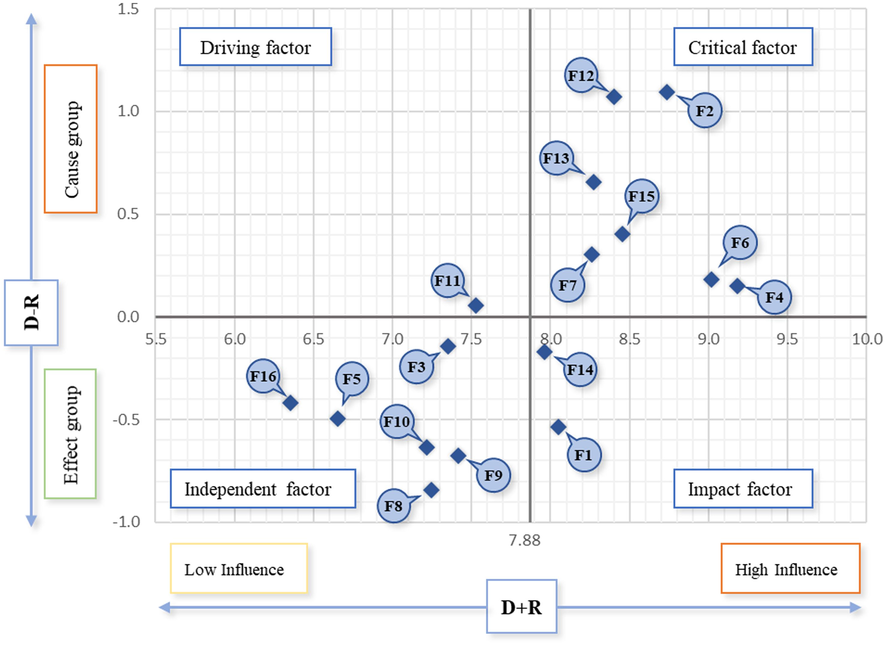

Tables 5 and 6 are used to generate a cause-and-effect diagram, as shown in Fig. 2. The diagram is illustrated in cartesian coordinates, with D+R alongside the X-axis and D-R alongside the Y-axis. The driving factors are divided into four clusters: driving factors (C1), independent factors (C2), critical factors (C3), and impact factors (C4). The cause group incorporates the driving factors (C1) and critical factors (C3), whilst independent factors (C2) and impact factors (C4) are in the effect group. The critical factors exhibit the highest influencing factor, retaining its location in the high influence and causal group region. Policymakers need to focus more on these driving factors to promote energy-efficient textile manufacturing in emerging economies. Contrariwise, impact factors (C4) appear to be the most influential driving factor cluster located in the effect group.

Illustration of the cause-and-effect group of the driving factors.

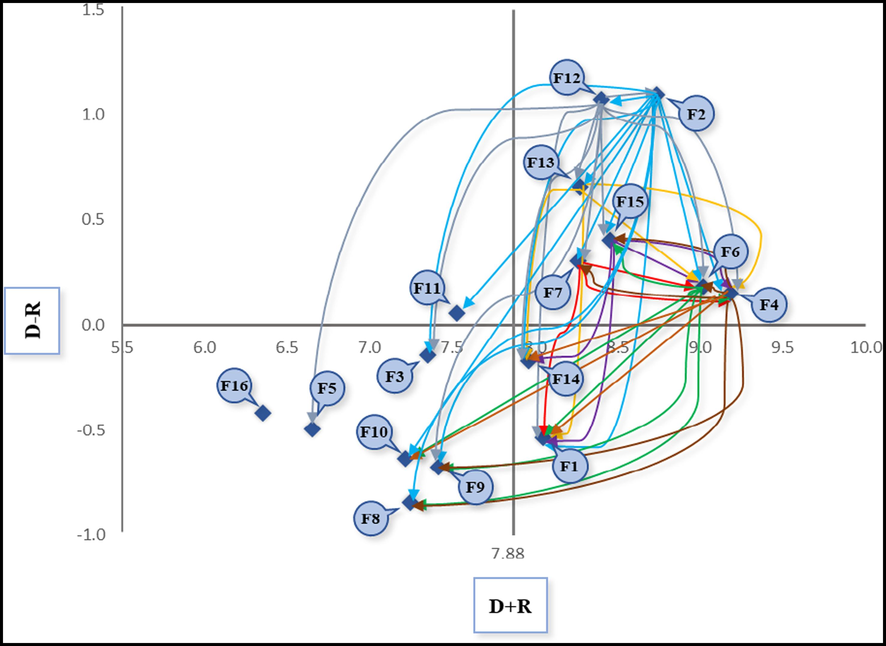

The causal relationship between the driving factors is illustrated in Fig. 3. A total of sixteen × sixteen (16×16) relationships are possible. Since it is difficult to illustrate every connection, the threshold value (θ), which is equal to the total relation matrix's (T) mean (μ) plus standard deviation value (τ), was set to produce the digraph. Consequently, the study's threshold value, θ = 0.246 + 0.046 = 0.292, is determined.

Co-relationship among the driving factors.

5 Discussion

From the prominence ranking shown in Table 6, “Implementing effective in-house energy management measures (F4)” appears to be the most significant driving factor in promoting energy-efficient textile manufacturing in emerging economies among all the driving factors. Energy management is vital since it continuously minimizes companies' energy use and associated energy expenditures (Lawrence et al., 2019). Putting a strong emphasis on in-house energy management measures is not only crucial for improving internal cost-effective operations but also for adopting energy-efficient practices, reducing environmental impact, conserving resources, encouraging technological innovation, and thus, improving the energy efficiency by 3–4% (Hasan et al., 2019). Furthermore, as emerging economies’ textile industries are anxious to prevent the energy sector unpredictabilities caused by obvious disruptions in energy due to the Russia-Ukraine war, it is evident that implementing energy management strategies is the most significant driving factor that emerging economies must prioritize to boost resiliency during the crisis time.

“Adopting advanced machinery & total productive maintenance (F6)” has been found to be the second most prominent driving factor in promoting energy efficiency in textile manufacturing. In textile firms, the usage of obsolete machines raises power consumption, while old-fashioned and outdated production techniques require additional processing; thus, embracing modern and efficient technology-driven machineries can significantly reduce machine power consumption, waste, and rework in the production process, as well as eliminate superfluous motion (Chen & Lin, 2020). Furthermore, total productive maintenance not only upholds an orderly operational environment but also nurtures a collective commitment towards equipment upkeep, early error identification, and preemptive malfunction mitigation, thereby fostering heightened inter-departmental synergy. Its cascading effect simplifies machinery efficiency, safety, and dependability while imbuing them with energy frugality (Achamu et al., 2018).

The third most influential driving factor is “Adopting renewable energy (F2)”, indicating that manufacturers must focus more on renewable energy usage rather than burning fossil fuels (Amin et al., 2022). Renewable energy adoption in the energy-intensive textile industry offers a substantial and beneficial contribution to sustainable development by abating the depletion of natural resources, replenishing expeditiously than the rate of usage, dwindling dependence on fossil fuels, and optimizing the use of agricultural waste and algae biofuel for power generation in the textile sector, thereby mitigating environmental harm and enhancing overall efficiency (Alam et al., 2024b). For example, textile manufacturers can use solar energy which can reduce reliance on natural gas and fuel in various aspects of textile manufacturing, including lighting, cooling, office equipment, and temperature control systems (Irfan et al., 2019).

“Adoption of green emerging technologies (F15)” is found as the fourth most significant driving factor in fostering energy efficiency. For instance, according to experts, by creating an environmentally conscious architectural design that maximizes natural daylight, promotes efficient air circulation, and integrates personalized lighting circuits and temperature controls, energy consumption can be minimized through diminished reliance on artificial lighting and mechanical ventilation which, in turn, increases energy efficiency (Alagbe et al., 2019). However, government support, including financial incentives, attractive loans, subsidies for audits, and tax exemptions, is crucial to motivating textile owners to adopt energy-efficient production methods (Hasan et al., 2018). This makes “Strengthening government support (F12)” the fifth most significant driving factor.

Recently, there has been a 250% spike in gas prices worldwide, which has impacted gas-importing countries, including Bangladesh (Milewska & Milewski, 2022). Hence, the government can do strategic planning by withdrawing energy subsidies that force textile manufacturers to seek cost-effective and energy-efficient alternatives, which entails implementing energy-efficient technologies, processes, and practices, ultimately promoting sustainable and resource-efficient production methods (Abbas et al., 2018). Therefore, “Rising energy prices (F13)” can be justified as the sixth significant driving factor. “Establishing an energy audit system (F7)” is the seventh most important driving factor to promote energy efficiency. It is because implementing continuous sub-metering for energy end-use enables precise allocation of power to equipment, product lines, and processes while also holding departments accountable for energy costs, thus enabling textile companies to assess energy performance, develop solutions, and project investment requirements for energy efficiency enhancements based on the obtained data (Johansson & Thollander, 2018). The eighth significant driving factor emerges to be “Incorporating circular economy in the production process (F1)”. The circular economy concept emphasizes the recycling (both open and closed) of textile waste and the reuse of water (Manickam & Duraisamy, 2019). Incorporating circular economy principles will improve energy efficiency in optimized operations, recover heat energy, minimize redundant stages, and reduce overprocessing (Christensen, 2021). “Raising consumer awareness (F14)” and “Appropriate production planning (F11)” are the ninth and tenth significant driving factors, respectively. Elevating consumer awareness about energy-efficient textile manufacturing can substantially influence demand for sustainable products and push businesses to adopt energy-efficient practices and properly coordinated production processes (Soepardi & Thollander, 2018). Through appropriate production planning, a 25% reduction in SEC value is attainable. Furthermore, manufacturing planning significantly affects the overall energy usage when the dyeing machines are operating at maximum load capacity, which can save a remarkable 23% on energy. (Özer & Güven, 2021).

In this study, the interrelations between driving factors depend on whether the driving factor is associated with the cause or effect group. In the case of the cause group, “Adopting renewable energy (F2)” and “Strengthening government support (F12)” constitute the most significant and critical driving factors, wielding the greatest influence over the other driving factors. Emerging economies' textile sectors are primarily reliant on fossil fuels (Debnath et al.,2024). Due to the disruption and crisis of fossil fuel supply, the adoption of renewable energy has become the top-most importance (Davis et al., 2020). Renewable energy cannot only power modern dyeing machines that require less water, but it also can act as an enticing marketing element, increasing customer awareness and ensuring consistent power for motion sensors (Kumar et al., 2021). In addition, the government needs to step up and express its intention to address the impending energy problem. As an illustration, government programs and regulations can serve to promote the application of IoT devices and smart technologies in energy management (Borowski, 2021). In addition, the government can direct consumers toward energy-conscious choices and provide incentives for businesses to adopt circular economy practices in the textile industry (Patwa et al., 2021). “Rising energy prices (F13)” is the third most important and critical factor in the cause group, as increased energy prices will result in the implementation of other subsequent driving factors to energy efficiency. Escalating energy prices drives textile manufacturers to adopt energy-saving measures such as automated systems, insulation, and compressed air leak reduction to reduce energy consumption and costs in operations. “Adoption of green emerging technologies (F15)” is the fourth most important and critical factor in the cause group, as green architectural design maximizes the use of renewable energy sources like sunlight and air, dwindling dependency on artificial lighting and ventilation that uses electricity produced from burning fossil fuels. Also, the green textile facility is more likely to follow circular economy ideas, such as recycling and material reuse, and it shows the company's dedication to sustainability that can be utilized to inform customers about the value of energy efficiency, raising their awareness (Christensen, 2021). “Establishing an energy audit system (F7)” is the fifth most impactful causal as well as critical factor as it results in accountability for energy cost across the departments, enabling the company to assess energy performance. Energy audits can find compressed air leakage, inefficient or excessive gas combustion and steam generation, and heat loss in machinery, boilers, and transmission systems (Kaya et al., 2021). “Adopting advanced machinery & total productive maintenance (F6)” is the sixth most impactful causal as well as critical factor. Advanced machinery, equipped with built-in sensors, automation capabilities, and IoT integration can enhance efficiency across various processes (Sathyan, 2020). Finally, “Implementing effective in-house energy management measures (F4)” and “Appropriate production planning (F11)” are the two causal factors that correspond to the causal ranking, respectively.

Based on the analysis provided in Fig. 2 and Table 6, the effect driving factors discovered in this study (F3 > F14 > F16 > F5 > F1 > F10 > F9 > F8) pose to have direct influence by the causal driving factors. “Adopting alternative waterless dyeing technology (F3)”, “Raising consumer awareness about energy efficiency (F14)”, and “Employing motion and occupancy sensors and a timer-based power control (F16)” have been less affected in the causal ranking order, but due to their proximity to the cause group, they remain quite significant. Still, they are also impacted by the causative group factors. As depicted in Fig. 3, “Adopting alternative waterless dyeing technology (F3)”, “Raising consumer awareness about energy efficiency (F14)”, and “Incorporating circular economy in the production process (F1)” are influenced by the “Adopting renewable energy (F2)” and “Strengthening government support (F12)” factors. The waterless dyeing method for polyester, utilizing CO2 or air, which is renewable instead of water, is a sustainable alternative to traditional dyeing procedures (Hossain et al., 2018). Modern dyeing machines that use less water can be powered by renewable energy, which can also be an enticing marketing element for increasing customer awareness (Kumar et al., 2021). Moreover, the government can encourage consumers toward more energy-efficient options and give incentives for enterprises to use circular economy techniques in the textile industry (Patwa et al., 2021). Factors like “Implementing effective in-house energy management measures (F4)” and “Adopting advanced machinery & total productive maintenance (F6)” impact factors such as “Reduction and control of compressed air leaks (F8)”, “Installing IoT devices to manage gas combustion and minimize excess steam generation (F9)” and “Insulation of machinery, boilers & transmission system (F10)”. Advanced machines with improved insulation, IoT integration facilities, and prompt air leak detection features can contribute to energy savings. Besides, a dedicated full-time energy manager should be integrated into the management structure, given the authority to implement energy efficiency measures like air leak checkups, necessary device installation, and machine insulation (Lawrence et al., 2019). “Rising energy prices (F13)” influence factors such as “Raising consumer awareness about energy efficiency (F14)” and “Incorporating circular economy in the production process (F1)”. For instance, consumers may become more conscious of energy-efficient products and practices as energy prices increase. It can also drive textile manufacturers to adopt a circular economy approach that can help reduce energy consumption through recycling and reusing (Christensen, 2021). Finally, “Employing nano-filtration ETP (F5)” is the effect group factor, which is also influenced by a cause group factor.

Fig. 3 also depicts that “Adopting renewable energy (F2)” holds the most significant causal relationship with other driving factors, while the causal driving factors “Strengthening government support (F12)” and “Rising energy prices (F13)” are also heavily linked to other driving factors, respectively. Thus, in order to support energy-efficient textile manufacturing, legislators, decision-makers, and regulatory committees should accentuate the three quintessential factors.

The outcomes of this study differ notably from prior comparable research studies conducted on various industries and nations. For instance, Chang et al. (2022) used big data analytics to create a framework for optimizing production facilities that were capable of saving more than 10% of energy consumption. Hasan et al. (2018) used a case study approach and identified important drivers and barriers to implementing energy efficiency practices. They highlighted cost savings from reduced energy use as the key reason behind energy efficiency among the surveyed steel plants. Several other important elements were also identified as significant contributions to the industry's pursuit of energy efficiency. These included long-term strategic considerations, fears about prospective energy cost rises, and the impact of foreign competitiveness, but they did not rank them by their importance or investigate their interrelationships. Costa et al. (2019) used ecological footprint methodology to analyze energy and resource consumption in dying, printing, and finishing processes in the textile industry and evaluated enhanced technology and cleaner production alternatives that will help to minimize water consumption and effluent volume. Hasan et al. (2019) performed a case study strategy to study the phenomenon of energy efficiency and found that the most important driver for energy efficiency among the textile mills surveyed was the “energy management scheme”, followed by “risk of future high energy prices” and “assistance from energy professionals” but falls short of uncovering the mutual relationships among the driving factors to promote energy efficiency. However, the causal interrelationships and hierarchy of importance of the resulting driving factors can be discovered by employing an Interval-valued Type 2 Intuitionistic Fuzzy (IVT2IF) technique and a decision-making trial and evaluation laboratory (DEMATEL) to assess the findings (overall prominence). Our study found that adopting renewable energy, strengthening government support, and implementing effective in-house energy management measures are the most significant driving factors in promoting energy-efficient textile manufacturing for sustainable energy consumption in the emerging economy context. It also shows which factors are more important than others. This knowledge can help managers and policymakers plan better and invest their resources wisely, making the textile sector more energy-efficient and productive. Nonetheless, no previous study has focused on the cause-and-effect relationship of driving factors promoting energy efficiency, specifically to support the textile industry of an emerging economy. As a result, the findings of this study stand out from those of other related studies.

6 Implications.

6.1 Theoretical Implications.

This study provides a holistic perspective of exhaustive scrutiny of the energy crisis, emerging economy, sustainable energy consumption, and multiple-criteria decision-making (MCDM) process. This research has multiple theoretical implications. First, it identifies the crucial driving factors for energy-efficient textile manufacturing while accounting for the energy crisis in burgeoning economies. This study can subsequently identify and appraise these driving factors in energy-efficient production across different manufacturing industries. Second, the integration of IVT2IFN with the DEMATEL approach is used to mitigate the vagueness and uncertainty in human judgment. The methodological framework establishes a nexus between the driving factors for energy-efficient textile manufacturing. This can direct policymakers and academics toward more in-depth research, allowing them to understand the pivotal factors driving sustainable energy utilization within various economic contexts. This research reconciles prevailing voids in the relevant literature and lays a groundwork for future practitioners to extend the research with alternative decision-making tools.

6.2 Practical Implications.

The study has various significant practical implications within the realm of manufacturing domains. Textile is a notably energy-intensive industry that also serves as the bedrock of Bangladesh’s economy. Hence, the findings of this study are positioned to promote the formation of a textile sector distinguished by prudent energy use and increased environmental consciousness. Through meticulous analysis, the research has identified and prioritized the driving factors required for conducting energy-conserving textile manufacturing. Since the possible direct influence of causal driving factors on effectual ones, decision-makers should pay close attention to the critical causal driving factors, encouraging the search for energy-efficient modalities. This study has pinpointed critical driving factors, implementation of in-house energy management measures, adoption of renewable energy, adoption of advanced machineries, seeking government support, high energy prices, energy audit system, and the adoption of green emerging technologies. These driving factors are mostly correlated with other driving factors. This study can also refine the conceptual paradigms on the roles and obligations of both stakeholders and consumers by assessing the negative operational and environmental impact of energy-intensive production.

A dedicated full-time energy manager, proactive strategy planning by officials, and prudent budget allocations are required for energy-efficient initiatives. Harnessing the potential of renewable energy reservoirs, the textile manufacturing sector can reduce reliance on natural and fossil fuels, resulting in better-utilized energy usage and negative environmental impact. Policymakers should also make decisions about financial incentivization and assimilation of advanced machineries that will consume less energy, nurturing an environment of economic efficiency and environmental responsibility. The study unfolds some managerial implications as well. The study’s findings can guide officials in formulating regulations that promote energy-efficient paradigms, culminating in a textile industry with reduced energy consumption and environmental footprint. This research can foster synergistic collaboration among textile manufacturers, researchers, and policymakers to collectively work toward an industry entrenched in energy-conscious practices.

6.3 Implication for Sustainability.

This study is also linked with multiple sustainable development goals (SDG), demonstrating how sustainable practices in the industry contribute to bigger global goals. “Adopting renewable energy (F2)” can serve to achieve SDG 7 (Affordable & Clean Energy) by lowering dependency on conventional fuels, which will help to assure affordable, reliable, and sustainable energy while also mitigating environmental impacts associated with energy production. Renewable energy sources are inexhaustible and abundant, assuring existing energy demands without compromising the needs of future generations, which is the motive of sustainable energy consumption.

Adopting energy-saving techniques within the textile industry will lead to better productivity, operational efficiency, and energy security and curtail energy costs, resulting in job creation and decent work opportunities. Energy parsimony achieved from energy-conserving technologies will contribute to a more sustainable and resilient energy ecosystem. Also, it will encourage economic growth by propelling technological advancement. Thus, it can be helpful to achieve SDG 8 (Decent Work & Economic Growth). “Adopting advanced machinery and total productive maintenance (F6)”, “Adoption of green emerging technologies (F15)” and “Implementing effective in-house energy management measures (F4)” depict progress in industry and infrastructure, facilitating sustainable industrialization, enhanced resource utilization, and technological upgradation, all of which will satisfy SDG 9 (Industry, Innovation, and Infrastructure). Furthermore, by promoting energy conservation and increased energy efficiency, these factors will address both the economic and environmental dimensions of sustainable energy consumption.

Implementing circular economy concepts in manufacturing processes ensures resource reduction, reuse, and recycling, supporting sustainable resource use. The closed-loop system of circular economy principles will meet sustainable energy utilization by minimizing wastes, prolonging the product life cycle, and encouraging efficient practices of energy. Properly coordinating production operations through appropriate production planning can result in significant energy savings. Furthermore, insulating machineries can significantly contribute to energy conservation. The integration of in-house energy management measures with energy audit systems aids in sustainable management and efficient use of resources. These factors are critical in supporting sustainable energy consumption and achieving SDG 12 (Responsible Consumption and Production). A green textile plant has a low ecological footprint, which results in reduced carbon emissions, minimized waste disposal, and improved natural resource usage, all of which contribute to more sustainable practices. When paired with the use of renewable energy, it can help to achieve SDG 13 (Climate Action) by deducting emissions and encouraging the development of renewable energy sources. Abatement of environmental impacts such as climate change, air pollution, water & soil pollution, and biodiversity loss will harmonize these factors with SDG 13 (Climate Action). The factors elucidated in this study are influential in hindering sustainable energy consumption, which decreases environmental impacts and resource consumption. These strategies are not only helpful in achieving global environmental well-being, but they will also improve energy security in the face of energy scarcity concerns while expediting sustainable development.

7 Conclusion

The textile industry, a traditional pillar industry in emerging economies like India and Bangladesh, requires substantial energy for manufacturing. Enhancing energy efficiency is crucial to account for the lack of energy sources in emerging economy countries. It helps to bridge the gap among energy demand and supply and serves as an enforceable strategy for boosting both economic and environmental sustainability. So, in response to the significant amount of energy necessity, scarce energy resources, increased expenditure of fossil fuel, inflationary pressures, and increased production cost, executing energy-efficient strategies is obvious in the textile sector to move towards a more sustainable business and reduce reliance on energy imports. Promoting energy efficiency in emerging economies requires finding the efficiency driving factors contributing to sustainability, considering the impact of COVID-19 and Russia-Ukraine conflict situations on the textile sector that no existing literature has admitted. This research addresses the gap in existing studies by utilizing the IVT2IF-DEMATEL framework to identify the driving factors and evaluate their interrelationships in order to derive long-term conclusions.

The study conducted an initial analysis to identify the factors driving energy efficiency in the textile manufacturing sector. This analysis was based on a complete examination of existing literature. The IVT2IF technique engaged twelve experts to ascertain and authenticate the driving factors of utmost significance. This process culminated in the identification of sixteen factors that were deemed suitable for subsequent examination. The study employed the DEMATEL to analyze the causal relationships among the factors. As a result, eight factors were identified as causes, and eight factors were identified as effects in relation to promoting energy efficiency in the textile industry of developing countries. “Implementing effective in-house energy management measures (F4)” stood out as the most influencing factor. “Adopting renewable energy (F2)”, “Strengthening government support (F12)”, and “Rising energy prices (F13)” turned out to be the most important causal factors. These factors can have a major impact on the other effect group factors listed, hence boosting energy efficiency in the textile industry. The top three influenced factors in the effect group were “Adopting alternative waterless dyeing technology (F3)”, “Raising consumer awareness about energy efficiency (F14)”, and “Employing motion and occupancy sensors and a timer-based power control (F16)”. If the causal elements within the system are adequately treated, the driving forces of the effect group may be automatically addressed as well. This study’s Implications for theoretical development, managerial procedures, and policy-making in the textile industry are highly significant, which have been discussed in detail in section 5. The study outcomes is expected to aid industrial managers and policymakers in promoting energy efficiency in the textile manufacturing sector and thus contribute to attaining various significant sustainable development goals, such as SDG 7, 8, 9, 12, and 13.

This study, like others, has limitations that necessitate additional research. Further work is required to enhance the study's cause-and-effect link by statistical analysis using a larger sample size because the cause-and-effect relationship lacks statistical validity. Other new hybrid approaches, such as Fermatean fuzzy theory, can be applied. Regression-based methods, such as spline regression modeling or fuzzy regression analysis, can also be utilized to predict, handle, and optimize the identified driving factor-implemented regulatory system in a more flexible and interactive manner. Using machine learning (ML) and artificial intelligence (AI) in research can also strengthen future studies and improve the accuracy of previous decisions.

Furthermore, the findings of this research, particularly the identified factors driving energy efficiency, can be applied beyond textiles. For example, industries such as manufacturing, automotive, or chemicals that are also energy intensive could benefit from understanding and implementing similar strategies to improve their energy efficiency as well as sustainability. Finally, the study identifies 16 driving factors, which may not be all-inclusive. In subsequent efforts, more pertinent factors could potentially be identified and evaluated utilizing the same or alternative frameworks.

Funding

The authors received no funds, grants, or other financial support for this research project.

CRediT authorship contribution statement

Saifur Rahman Tushar: Writing – original draft, Visualization, Validation, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Md. Shamsul Arefin Imtiazh: Writing – original draft, Visualization, Investigation, Formal analysis, Data curation. Rafsun Bin Noor: Writing – original draft, Formal analysis, Data curation. Md. Fahim Bin Alam: Writing – original draft, Visualization, Formal analysis, Data curation. A.B.M. Mainul Bari: Writing – review & editing, Visualization, Validation, Supervision, Project administration, Investigation. Abu Reza Md. Towfiqul Islam: Writing – review & editing, Validation. Mohammad Mahbub Kabir: Writing – review & editing, Visualization.

Acknowledgments

The authors would like to thank the experts who took their valuable time to provide feedback for this study.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Abbas, S. Z., Kousar, A., Razzaq, S., Saeed, A., Alam, M., & Mahmood, A. (2018). Energy management in South Asia. In Energy Strategy Reviews (Vol. 21, pp. 25–34). Elsevier Ltd.

- TPM and RCM Implementation in Textile Company for Improvement of Overall Equipment Effectiveness. International Journal of Advances in Scientific Research and Engineering. 2018;4(10):129-136.

- [Google Scholar]

- An empirical investigation and assessment of entrepreneurial learning factors: a DEMATEL approach. J. Res. Mark. Entrep.. 2023;25(1):127-149.

- [Google Scholar]

- The influence of energy consumption and democratic institutions on output and CO 2 emissions in Bangladesh: a time–frequency approach. Energy Syst.. 2020;11:195-212.

- [Google Scholar]

- Fuzzy logic, geostatistics, and multiple linear models to evaluate irrigation metrics and their influencing factors in a drought-prone agricultural region. Environ. Res.. 2023;234:116509

- [Google Scholar]

- O.A. Alagbe M.A. Caiafas B.O. Olayemi O.O. Joel November). Enhancing Energy Efficiency through Passive Design: a Case Study of Halls of Residence in Covenant University, Ogun State Vol. 640, No. 1 2019 IOP Publishing p. 012017).

- Analysis of the enablers to deal with the ripple effect in food grain supply chains under disruption: Implications for food security and sustainability. Int. J. Prod. Econ.. 2024;109179

- [Google Scholar]

- Assessing the factors influencing the adoption of geothermal energy to support the national grid in emerging economies: Implications for sustainability. Sustainable Operations and Computers 2024

- [CrossRef] [Google Scholar]

- Energy security and sustainable energy policy in Bangladesh: From the lens of 4As framework. Energy Policy. 2022;161:112719

- [Google Scholar]

- Drivers and barriers of electric vehicle usage in Malaysia: A DEMATEL approach. Resour. Conserv. Recycl.. 2022;177:105965

- [Google Scholar]

- Assessing the kid's behaviour with factors of social media advertising: DEMATEL application. Journal of Advances in Management Research. 2023

- [Google Scholar]

- Gender-based vulnerability and adaptive capacity in the disaster-prone coastal areas from an intersectionality perspective. Clim. Risk Manag.. 2024;43:100581

- [Google Scholar]

- A Fuzzy Synthetic Evaluation Approach to Assess the Risks Associated with Municipal Waste Management: Implications for Sustainability. Green Technologies and Sustainability. 2024;2(2):100087

- [Google Scholar]

- Digitization, digital twins, blockchain, and industry 4.0 as elements of management process in enterprises in the energy sector. Energies. 2021;14(7):1885.

- [Google Scholar]

- Big data analytics energy-saving strategies for air compressors in the semiconductor industry–an empirical study. Int. J. Prod. Res.. 2022;60(6):1782-1794.

- [Google Scholar]

- Assessment of eco-efficiency change considering energy and environment: A study of China’s non-ferrous metals industry. J. Clean. Prod.. 2020;277:123388

- [Google Scholar]

- Measuring technological innovation efficiency using interval type-2 fuzzy super-efficiency slack-based measure approach. Eng. Appl. Artif. Intel.. 2022;116:105405

- [Google Scholar]

- An integrated interval-valued intuitionistic fuzzy technique for resumption risk assessment amid COVID-19 prevention. Inf. Sci.. 2023;619:695-721.

- [Google Scholar]

- Towards a circular economy in cities: Exploring local modes of governance in the transition towards a circular economy in construction and textile recycling. J. Clean. Prod.. 2021;305:127058

- [Google Scholar]

- Ecological Footprint as a sustainability indicator to analyze energy consumption in a Portuguese textile facility. Int. J. Energy Environ. Eng.. 2019;10:523-528.

- [Google Scholar]

- Nanofiltration for textile dye–water treatment: experimental and parameter estimation studies using a spiral wound module and validation of the Spiegler–Kedem-based model. Sep. Sci. Technol.. 2017;52(7):1216-1224.

- [Google Scholar]

- Assessment of renewable energy transition pathways for a fossil fuel-dependent electricity-producing jurisdiction. Energy Sustain. Dev.. 2020;59:243-261.

- [Google Scholar]

- Analyzing the factors influencing the wind energy adoption in Bangladesh: A pathway to sustainability for emerging economies. Energ. Strat. Rev.. 2023;50:101265

- [Google Scholar]

- A grey approach to assess the challenges to adopting sustainable production practices in the apparel manufacturing industry: Implications for sustainability. Results in Engineering. 2024;21:102006

- [Google Scholar]

- Fuzzy sets theory and human reliability: Review, applications, and contributions. Linguistic Methods under Fuzzy Information in System Safety and Reliability Analysis 2022:91-137.

- [Google Scholar]

- Energy management practices in Bangladesh's iron and steel industries. Energ. Strat. Rev.. 2018;22:230-236.

- [Google Scholar]

- Drivers and barriers to industrial energy efficiency in textile industries of Bangladesh. Energies. 2019;12(9):1775.

- [Google Scholar]

- Evaluation of present and future wastewater impacts of textile dyeing industries in Bangladesh. Environmental Development. 2018;26:23-33.

- [Google Scholar]

- Solar energy development in Pakistan: Barriers and policy recommendations. Sustainability. 2019;11(4):1206.

- [Google Scholar]

- Do energy efficiency networks help reduce barriers to energy efficiency?-A case study of a regional Swedish policy program for industrial SMEs. Renew. Sustain. Energy Rev.. 2021;151:111579

- [Google Scholar]

- A review of barriers to and driving forces for improved energy efficiency in Swedish industry–Recommendations for successful in-house energy management. Renew. Sustain. Energy Rev.. 2018;82:618-628.

- [Google Scholar]