Translate this page into:

Rheological behavior and storage studies of sprouted onion pastes from four onion varieties

⁎Corresponding author at: Deptt. of Food Technology and Nutrition, Lovely Professional University, Punjab, India. ishratmajid89@gmail.com (Ishrat Majid)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Objective

The study was carried out to investigate the rheological behavior and storage studies of sprouted onion pastes from four varieties (Punjab White, Punjab Naroya, PRO-6 and commercial).

Methods

The storage study of paste samples from raw and sprouted onions packaged in polyethylene terephthalate (PET) bottles was carried out at room temperature (25 ± 1 °C) after thermally processing them at 80 °C for 15 min. All the paste samples were periodically analyzed for the change in quality characteristics viz, colour, pH, titratable acidity, TSS(∘B), TS (%), Water activity, Moisture (%), Total phenol content (mg/g), Total flavonoid content (mg/g), Total antioxidant capacity (mg/g), DPPH (%) and microbial count. The rheological properties of raw and sprouted onion paste samples were studied using Modular Compact Rheometer MCR-102 equipped with parallel plates geometry.

Results and conclusions

Sprouted onion pastes were found to retain quality characteristics with lesser color changes, higher total phenolics, total flavonoids, antioxidant activity and microbial stability than raw pastes during storage. Storage period and its interactive effect with the variety and sprouting had significant (P < 0.05) effect on total antioxidant capacity, DPPH radical scavenging activity, L*, a* and b* values of onion pastes as revealed by multiple analysis of variance (MANOVA). The rheological studies of onion pastes depicted that the elastic modulus (G′) and viscous modulus (G″) decreased in all the sprouted paste samples which showed their decreased frequency dependency. In addition to the effect of sprouting the paste samples behaved either as a strong gel or weak gel depending on the concentration of the paste. This study showed that variety, sprouting and storage period resulted in onion pastes with different physicochemical composition, antioxidant potential and rheological characteristics. The intensity of change in quality parameters identified the opportunities of using sprouting process to enhance the storage stability and impart desirable rheological properties to onion pastes for various food applications.

Keywords

Sprouted onion paste

Storage

Rheology

Color change

Variety

1 Introduction

Onion (Allium cepa L.) crop holds a unique position in the economic growth of India as it is the second largest onion producing country in the world. Indian onions are well known for their pungency and serve as highest foreign exchange earner among the fruits and vegetables (Majid et al., 2018). There is a huge demand of Indian onions in daily cuisine across the world and the country has exported 12,01,245.29 MT of fresh onion to the world for the worth of Rs. 2747.41 crores during the year 2015–16 (APEDA, 2017). Onion as an extra ordinarily nutritious vegetable has gained enormous significance due to its well-established health benefits like, reducing coronary diseases and imparting anti-fungal and anti-bacterial properties (Majid and Nanda, 2017a). The characteristic aroma and flavor of onion make it an important savory constituent during food processing. The characteristic culinary flavor of onions arises from volatile organic sulphur-containing compounds which are produced by the action of alliinase enzyme on non-volatile precursors, during disruption of tissue of the onion cells, as a result of chopping, cutting, maceration, and mastication. The unstable heat labile primary reaction products like thiosulfinates and sulfenic acids are generated which dissociate on heating to form other stable sulfur compounds that provide a characteristic fresh onion flavor (Koutidou et al., 2017). In order to take advantage of the potential health benefits with retention of color and fresh flavor of onion, there is a need to develop onion products that not only have desired functionality but also are stable over a longer storage time (Majid et al., 2019a, 2019b). Among several commercially available onion products paste is considered one such product that offers convenience in usage while maintaining the original colour and flavour in a semi-solid form. Various factors affect the delicate flavor and color during processing and storage which include variety, process conditions viz, pH, %acidity, packaging material, time, temperature, non-enzymatic and enzymatic browning (Ahmed and Shivhare, 2001). In order to define various quality parameters of food pastes, knowledge of the rheological properties is important for controlling the flow behavior of the end product (Razavi and Karazhiyan, 2012; Ahmed, 2004). The study of rheological behaviour is regarded as an important tool which gives an insight into the structural organization of foods and is influenced by various factors like total soluble solids/concentration, temperature and particle size (Ahmed et al., 2004). Modern concept of healthy nutrition has led to the increased consumption of sprouted vegetable products (Oh et al., 2017) and in our previous study sprouted onions were also found to have higher protein content, ascorbic acid content, antioxidant activity, anthocyanin content and flavonoids than raw ones (Majid et al., 2016). Due to recognized benefits of sprouting in onion convenience products like powder and paste with enhanced nutritional and functional potential were developed from sprouted onions (Majid and Nanda, 2017a, 2017b, 2016). Since several above mentioned studies have been reported on the characterization of sprouted onion products but no study has been conducted on the rheological properties and storage studies of sprouted onion products. Therefore, this study was engrossed to study the rheological behaviour and change in physicochemical composition during storage of onion paste developed from four Indian sprouted onion varieties.

2 Materials and methods

2.1 Preparation of paste

Onion bulbs of raw and sprouted onion varieties (Punjab Naroya, Punjab white, PRO-6 and commercial) were peeled, cut and immediately processed into a puree using a laboratory size grinder (Morphy Richards, Swinton, UK). The purees after passing through a 14-mesh sieve in order to get the product of uniform consistency were held at room temperature (25 ± 1 °C) for 1 h in a covered container to allow the enzymatic action to occur for the development of colour and flavour. The raw and sprouted onion pastes were prepared by adding 10% common salt (sodium chloride) to the respective purees to increase their total soluble solids (TSS). The prepared pastes were subjected to the adjustment of pH by the addition of desired quantity of 0.3% citric acid solution (Majid and Nanda, 2016).

2.2 Storage studies

The storage study of paste samples from raw and sprouted onions packaged in polyethylene terephthalate (PET) bottles was carried out at room temperature (25 ± 1 °C) after thermally processing them at 80 °C for 15 min. All the paste samples were periodically analyzed for the change in quality characteristics viz, colour, pH, titratable acidity, TSS(∘B), TS (%),water activity, moisture (%), total phenol content (mg/g), total flavonoid content (mg /g), total antioxidant capacity (mg/g), DPPH (%) and microbial count.

2.3 Physico-chemical properties

Total soluble solids (°Brix) at 25 °C was determined using a hand held digital Refractometer (Erma Hand Refractometer, Erma Inc. Tokyo, Japan) and total solids using a vacuum oven at 70 °C until constant weight was obtained. pH as an index of microbial activations was measured using a digital pH-meter (Eutech instruments pvt ltd, Singapore) at 25 °C. The % titratable acidity was determined by titrating the diluted paste against 0.1 N NaOH solution using phenolphthalein indicator and expressed in terms of citric acid. Water activity (aw) of the paste samples was determined using water activity meter (Aqualab CX2T, Decagon Devices, USA) (Majid and Nanda, 2016).

2.4 Colour measurement

The colour of raw and sprouted paste samples was determined using a colorimeter (Model CR-10, Konica Minolta Sensing, Inc. Japan) equipped with D 65 illuminant. Three colour values, namely lightness (L*), redness/greenness (a*) and blueness/yellowness (b*) values were noted.

2.5 Phytochemical analysis

2.5.1 Sample extraction

Paste sample (0.5 g) was weighed and centrifuged for 15 min at 5000 rpm at 4 °C. The supernatant was separated and stored at 25 °C for further studies.

2.5.2 Determination of total flavonoid content and total phenolics

The total flavonoids and phenolics were expressed as mg of quercetin equivalents per g and mg of gallic acid equivalents per g of fresh weight of sample respectively. The methods are described in detail elsewhere (Majid and Nanda, 2016).

2.5.3 Total antioxidant capacity

The total antioxidant capacity based on the reduction of Mo (VI) to Mo (V) by the extract and subsequent formation of a green phosphate/Mo (V) complex at acidic pH was expressed as GAE (Gallic acid equivalent) following the method of Ruanma, Shank and Chairote (2010).

2.5.4 DPPH radical scavenging activity

The percentage of DPPH scavenging activity was determined as follows, DPPH Radical Scavenging Activity (%) = [(Ao − A1)/A0] where Ao is the absorbance of control and A1 is the absorbance of the sample (Majid et al., 2016a).

2.6 Microbiological analyses

The microbiological analyses of raw and sprouted onion paste samples in terms of standard plate count (SPC), coliforms, lactobacillus spp. yeast and mold count was carried out following the procedure of the International Commission on Microbiological Specifications (ICMSF, 1992) at zero time, and then at an interval of one month. Plate count agar (PCA) for determination of standard plate count and acidified potato dextrose agar (PDA) for determination of yeasts and molds count were used. Coliforms were determined using violet red bile agar. Numbers of micro-organisms were expressed as CFU g-1 of the sample and evaluated in duplicates.

2.7 Dynamic rheological properties

The rheological properties of raw and sprouted onion paste samples were studied according to the method described by Bayod et al. (2008) with modifications using Modular Compact Rheometer (Physica MCR-102, Anton Paar, Gaz, Austria) MCR-102 equipped with parallel plates geometry. The diameter of plates was 30 mm and a gap of 1 mm between the plates was set to measure the samples at 25.0 ± 0.5 °C with two repetitions Five grams of each paste samples were reconstituted to a concentration of 20, 30, 40 and 50 by adding desired quantity of water in a 100 ml test tube and vortexing it on the highest speed for 2 min. Samples were allowed to equilibrate for approximately 1 h at room temperature before rheological measurements were taken by monitoring the storage (G′) modulus and loss modulus (G″) of the prepared onion pastes. Strain sweep (0.01–100%) was first operated at 1, 10 and 100 Hz to determine the linear viscoelastic range of the paste samples and were subjected to frequency sweep ranging from 0.1 to 100 Hz at 0.5% constant strain. Storage modulus (G′) and loss modulus (G″) were continuously recorded as a function of frequency. The frequency dependence of onion pastes was modeled with the power law parameters, k′, n′, k″ and k″, as calculated by equation below, Eqs. (1) and (2):

3 Statistical analysis

The significant main effects as well as interactive effect of variety, sprouting, and storage duration on analyzed parameters at P < 0.05 were determined by subjecting the triplicates of all determinations to multiple analysis of variance (MANOVA) by using Statistica.v.12. (StatSoft India Pvt. Ltd. New Delhi, India).

4 Results and discussion

4.1 Moisture content and water activity

In both raw and sprouted (Table 1) paste samples there was gradual decrease in moisture content and water activity during storage. The decrease in water activity was found to be dependent on the extent of moisture loss. The multiple analysis of variance (MANOVA) results depicted a significant (P < 0.05) effect of variety and sprouting with non significant effect of storage period on moisture content and water activity of onion paste samples. However, the interactive effect of storage period and variety was found to have significant (P < 0.05) on both moisture and water activity. The decrease in water activity with decreasing moisture content during storage was also reported in tomato rasam paste (Maity and Raju, 2015). The decrease in moisture content during storage is attributed to the desiccation of paste like materials with time (Das and Radhakrishna, 2001). Results are expressed as mean values ± standard deviations.

Punjab White

Punjab Naroya

PRO-6

Commercial

Parameter

Storage period (days)

Raw

Sprouted

Raw

Sprouted

Raw

Sprouted

Raw

Sprouted

pH

0

4.03 ± 0.02

3.89 ± 0.11

4.01 ± 0.11

3.81 ± 0.10

4.05 ± 0.04

4.01 ± 0.01

4.06 ± 0.04

4.09 ± 0.02

30

4.08 ± 0.05

4.01 ± 0.08

4.02 ± 0.16

3.96 ± 0.11

4.06 ± 0.19

4.02 ± 0.65

4.08 ± 0.15

4.11 ± 0.07

60

4.10 ± 0.16

4.08 ± 0.14

4.05 ± 0.05

4.06 ± 0.21

4.07 ± 0.18

4.06 ± 0.38

4.09 ± 0.36

4.14 ± 0.16

90

4.11 ± 0.03

4.09 ± 0.10

4.06 ± 0.12

4.10 ± 0.02

4.09 ± 0.22

4.08 ± 0.26

4.12 ± 0.19

4.15 ± 0.45

120

4.14 ± 0.09

4.12 ± 0.29

4.08 ± 0.20

4.14 ± 0.07

4.12 ± 0.24

4.11 ± 0.15

4.15 ± 0.08

4.18 ± 0.26

Acidity (%)

0

0.34 ± 0.02

0.40 ± 0.18

0.35 ± 0.05

0.47 ± 0.04

0.32 ± 0.04

0.37 ± 0.03

0.31 ± 0.02

0.25 ± 0.06

30

0.33 ± 0.03

0.37 ± 0.02

0.33 ± 0.19

0.46 ± 0.08

0.30 ± 0.06

0.35 ± 0.18

0.28 ± 0.06

0.23 ± 0.18

60

0.31 ± 0.01

0.35 ± 0.15

0.31 ± 0.11

0.45 ± 0.28

0.29 ± 0.11

0.34 ± 0.26

0.26 ± 0.11

0.21 ± 0.10

90

0.28 ± 0.03

0.34 ± 0.23

0.30 ± 0.05

0.41 ± 0.22

0.28 ± 0.04

0.32 ± 0.09

0.25 ± 0.17

0.20 ± 0.02

120

0.27 ± 0.06

0.30 ± 0.01

0.29 ± 0.04

0.40 ± 0.05

0.26 ± 0.17

0.30 ± 0.13

0.23 ± 0.20

0.19 ± 0.06

TSS (°B)

0

21.03 ± 0.50

16.01 ± 1.50

24.04 ± 0.50

23.01 ± 1.50

21.50 ± 1.50

16.50 ± 1.30

23.00 ± 1.32

18.02 ± 2.50

30

21.56 ± 0.91

16.42 ± 0.86

24.63 ± 1.16

23.59 ± 0.98

21.84 ± 0.75

17.04 ± 1.18

23.48 ± 1.53

18.59 ± 1.84

60

22.32 ± 0.34

16.65 ± 0.75

24.91 ± 1.26

24.11 ± 1.16

22.35 ± 1.36

17.38 ± 1.64

23.88 ± 1.25

18.95 ± 0.86

90

22.85 ± 0.67

17.23 ± 0.49

25.21 ± 1.48

24.61 ± 1.52

22.75 ± 1.28

17.52 ± 1.45

24.57 ± 1.22

19.21 ± 1.47

120

23.07 ± 1.13

17.68 ± 1.35

25.72 ± 1.86

25.09 ± 1.79

23.42 ± 1.32

17.96 ± 1.11

24.71 ± 1.53

19.75 ± 1.62

TS (%)

0

22.46 ± 0.84

20.00 ± 0.87

26.02 ± 0.50

25.20 ± 1.81

22.7 ± 1.76

20.73 ± 0.89

25.0 ± 1.32

21.02 ± 1.0

30

22.62 ± 1.27

20.55 ± 1.29

26.47 ± 0.72

25.35 ± 1.38

23.28 ± 0.62

21.13 ± 1.12

25.26 ± 1.10

21.55 ± 1.19

60

23.15 ± 1.14

20.85 ± 1.37

26.90 ± 1.46

25.74 ± 1.42

23.93 ± 1.54

21.65 ± 1.59

25.73 ± 0.65

21.82 ± 1.58

90

23.68 ± 0.66

21.12 ± 0.99

27.11 ± 1.22

25.86 ± 1.69

24.57 ± 1.28

21.86 ± 1.70

26.06 ± 0.44

22.36 ± 1.36

120

23.92 ± 1.25

21.54 ± 1.21

27.29 ± 0.57

26.55 ± 0.83

24.92 ± 1.66

22.15 ± 1.72

26.36 ± 1.26

22.64 ± 1.53

Water activity

0

0.77 ± 0.02

0.88 ± 0.09

0.72 ± 0.03

0.82 ± 0.09

0.75 ± 0.04

0.87 ± 0.11

0.74 ± 0.17

0.84 ± 0.05

30

0.77 ± 0.04

0.87 ± 0.07

0.71 ± 0.06

0.81 ± 0.04

0.74 ± 0.16

0.86 ± 0.07

0.73 ± 0.03

0.83 ± 0.18

60

0.76 ± 0.08

0.86 ± 0.11

0.71 ± 0.05

0.80 ± 0.12

0.73 ± 0.11

0.84 ± 0.15

0.72 ± 0.04

0.82 ± 0.08

90

0.75 ± 0.01

0.85 ± 0.15

0.70 ± 0.01

0.79 ± 0.03

0.73 ± 0.06

0.85 ± 0.10

0.71 ± 0.16

0.81 ± 0.12

120

0.74 ± 0.02

0.84 ± 0.03

0.68 ± 0.02

0.77 ± 0.08

0.72 ± 0.09

0.83 ± 0.02

0.70 ± 0.06

0.81 ± 0.17

Moisture (%)

0

69.72 ± 0.37

70.58 ± 0.87

67.91 ± 0.87

68.71 ± 0.59

69.34 ± 1.31

70.23 ± 1.72

68.20 ± 0.93

69.83 ± 0.97

30

68.42 ± 2.15

69.27 ± 1.67

66.54 ± 0.75

67.63 ± 0.43

68.72 ± 1.16

69.53 ± 0.89

67.36 ± 1.66

68.46 ± 1.16

60

67.39 ± 1.18

68.54 ± 1.38

65.28 ± 1.52

66.38 ± 1.13

67.54 ± 0.95

68.46 ± 1.63

66.45 ± 2.17

67.58 ± 0.54

90

66.19 ± 1.65

67.45 ± 1.54

64.18 ± 1.78

65.16 ± 1.42

66.81 ± 1.27

67.58 ± 1.48

65.28 ± 2.05

66.11 ± 1.28

120

65.63 ± 1.36

65.96 ± 1.61

63.74 ± 1.22

64.48 ± 1.80

65.28 ± 1.36

66.72 ± 1.70

64.79 ± 1.44

65.56 ± 1.46

4.2 pH value and % acidity

The pH of raw and sprouted onion pastes showed slow and gradual increase with storage with subsequent decrease in % acidity (Table 1). The MANOVA (Table 5) results revealed significant (P < 0.05) effect of variety and storage period with non significant effect of sprouting on both pH and acidity. The interactive effect of variety and sprouting as well as storage period and sprouting were found to be significant (P < 0.05) on pH and acidity of onion pastes. At the end of the storage period of four months the % acidity of sprouted paste samples was found to be more which implied greater stability of sprouted onion pastes than their corresponding raw paste samples. The change in pH value during storage might be due to the dissociation of organic compounds as reported in ginger paste (Rubila and Ranganathan, 2016) and the increase in acidity due to conversion of sugars into acids present in the paste samples (Gamli and Ibrahim, 2007).

4.3 TSS (°B) and TS (%)

In both raw and sprouted onion pastes a slight increase in TSS (°B) and TS (%) was observed during storage (Table 1). Similar trend of increase in TSS (°B) and TS (%) during storage was reported in ginger paste (Devi et al., 2016). Both TSS (°B) and TS (%) value of sprouted paste samples were lower than the raw onion pastes which indicated that there was decrease in TSS (°B) and TS (%) due to rapid utilization of soluble sugars during sprouting (Majid and Nanda, 2016). The MANOVA results demonstrated the significant (P < 0.05) effect of variety and sprouting with non significant effect of storage period on TSS (°B) and TS (%).

4.4 Color changes

The change in color values (L*, a* and b*) during storage was observed in raw and sprouted (Table 2) onion paste samples from all the four onion varieties. All the paste samples showed decrease in L* value (lightness) and a* value (green/red) with an increase in b* value (yellow). Similar trend of change in color values during storage was observed by Ahmed and Shivhare (2001) in onion paste. The change in color values can be attributed to the increase in non-enzymatic browning with storage period and the decreased lightness and increased yellowness in sprouted onion pastes might be attributed to increased anthocyanin content with sprouting in onion varieties (Majid et al., 2016a). MANOVA results (Table 5) depicted significant (P < 0.05) effect of variety, sprouting, storage time as well as their interactions on L*, a*, b* values of onion pastes. Results are expressed as mean values ± standard deviations.

Punjab White

Punjab Naroya

PRO-6

Commercial

Parameter

Storage period (days)

Raw

Sprouted

Raw

Sprouted

Raw

Sprouted

Raw

Sprouted

color

L*-value

0

56.70 ± 0.44

51.90 ± 0.20

54.00 ± 0.36

48.83 ± 0.31

40.43 ± 0.42

38.60 ± 0.36

45.47 ± 0.35

44.80 ± 0.22

30

54.32 ± 0.04

49.67 ± 0.14

53.46 ± 0.59

47.59 ± 0.62

39.43 ± 0.35

37.83 ± 0.42

44.37 ± 0.11

43.36 ± 0.43

60

53.26 ± 0.27

47.83 ± 0.25

52.71 ± 0.45

46.35 ± 0.49

37.56 ± 0.19

36.25 ± 0.14

42.84 ± 0.80

42.56 ± 0.18

90

51.14 ± 0.17

46.54 ± 0.38

50.96 ± 0.73

45.26 ± 0.15

36.35 ± 0.21

35.51 ± 0.75

41.69 ± 0.52

41.05 ± 0.05

120

50.65 ± 0.24

45.28 ± 0.16

49.58 ± 0.22

44.19 ± 0.54

35.61 ± 0.60

33.66 ± 0.55

40.54 ± 2.03

40.73 ± 1.15

a-value

0

−2.50 ± 0.40

−0.63 ± 0.31

2.10 ± 0.20

2.83 ± 0.31

9.70 ± 0.36

14.03 ± 0.15

9.03 ± 0.15

13.40 ± 0.37

30

−3.08 ± 0.36

−0.85 ± 0.11

1.84 ± 0.35

1.96 ± 0.45

8.41 ± 0.83

12.93 ± 0.26

8.64 ± 0.33

12.43 ± 0.58

60

−4.25 ± 0.13

−0.96 ± 0.92

1.62 ± 0.63

1.73 ± 0.65

7.35 ± 0.45

11.26 ± 0.22

7.32 ± 0.48

11.62 ± 0.71

90

−4.96 ± 0.57

−1.53 ± 1.10

1.50 ± 1.37

1.59 ± 0.23

6.25 ± 0.62

10.46 ± 0.31

6.15 ± 1.05

10.25 ± 0.28

120

−5.36 ± 0.54

−1.87 ± 0.77

1.38 ± 0.74

1.45 ± 0.11

5.27 ± 0.86

9.65 ± 0.37

5.59 ± 0.07

9.64 ± 0.24

b-value

0

8.40 ± 0.26

8.80 ± 0.36

5.03 ± 0.15

8. 05 ± 0.61

0.13 ± 0.06

3.70 ± 0.30

4.07 ± 0.21

4.50 ± 0.30

30

8.89 ± 0.16

8.92 ± 0.54

5.76 ± 0.37

8.75 ± 0.27

0.53 ± 0.04

3.84 ± 0.06

4.16 ± 0.46

4.65 ± 0.58

60

9.23 ± 0.03

9.12 ± 0.67

5.95 ± 0.96

9.21 ± 0.66

0.62 ± 0.07

3.96 ± 0.13

4.27 ± 0.73

4.81 ± 0.92

90

9.64 ± 1.18

9.52 ± 0.22

6.38 ± 1.46

9.64 ± 0.59

0.74 ± 0.01

4.14 ± 0.17

4.30 ± 0.05

4.90 ± 0.73

120

9.83 ± 1.36

9.68 ± 1.12

6.61 ± 1.45

9.85 ± 1.16

0.85 ± 0.12

4.25 ± 0.23

4.36 ± 1.26

5.12 ± 0.55

TPC (mg/g)

0

3.45 ± 0.09

4.79 ± 0.22

4.60 ± 0.23

5.00 ± 0.06

4.78 ± 0.14

5.23 ± 0.11

4.18 ± 0.13

4.43 ± 0.25

30

3.31 ± 0.04

4.64 ± 0.04

4.56 ± 0.26

4.86 ± 0.17

4.60 ± 0.04

5.14 ± 0.24

4.00 ± 0.28

4.32 ± 0.05

60

3.25 ± 0.13

4.55 ± 0.08

4.17 ± 0.20

4.62 ± 0.03

4.29 ± 0.07

4.94 ± 0.26

3.88 ± 0.35

4.19 ± 0.26

90

2.94 ± 0.16

4.18 ± 0.19

3.97 ± 0.05

4.50 ± 0.09

4.11 ± 0.18

4.86 ± 0.15

3.69 ± 0.15

3.78 ± 0.13

120

2.75 ± 0.10

4.05 ± 0.14

3.72 ± 0.01

4.26 ± 0.12

3.85 ± 0.30

4.73 ± 0.16

3.51 ± 0.22

3.65 ± 0.45

TFC (mg /g)

0

2.27 ± 0.04

2.64 ± 0.21

2.75 ± 0.05

2.96 ± 0.12

3.46 ± 0.17

3.72 ± 0.40

2.35 ± 0.12

2.48 ± 0.17

30

2.15 ± 0.09

2.51 ± 0.16

2.68 ± 0.26

2.81 ± 0.16

3.37 ± 0.36

3.63 ± 0.38

2.26 ± 0.06

2.31 ± 0.23

60

2.08 ± 0.11

2.48 ± 0.27

2.54 ± 0.34

2.75 ± 0.27

3.26 ± 0.45

3.58 ± 0.46

2.17 ± 0.57

2.27 ± 0.37

90

1.94 ± 0.21

2.36 ± 0.32

2.40 ± 0.04

2.63 ± 0.33

3.18 ± 0.40

3.46 ± 0.33

2.04 ± 0.41

2.16 ± 0.30

120

1.85 ± 0.28

2.25 ± 0.20

2.36 ± 0.17

2.55 ± 0.39

2.95 ± 0.25

3.39 ± 0.80

1.92 ± 0.29

1.97 ± 0.35

Total antioxidant capacity (mg/g)

0

5.14 ± 0.05

5.85 ± 0.05

6.38 ± 0.41

6.76 ± 0.79

7.14 ± 0.03

7.69 ± 0.55

5.87 ± 0.10

5.93 ± 0.23

30

5.00 ± 0.67

5.74 ± 0.06

6.25 ± 0.34

6.68 ± 0.96

7.00 ± 0.59

7.57 ± 0.34

5.70 ± 0.27

5.86 ± 0.46

60

4.90 ± 0.83

5.61 ± 0.51

6.13 ± 0.65

6.54 ± 0.48

6.84 ± 0.45

7.43 ± 0.36

5.62 ± 0.33

5.74 ± 0.28

90

4.76 ± 0.51

5.50 ± 0.73

5.89 ± 0.62

6.42 ± 0.17

6.75 ± 0.51

7.33 ± 0.84

5.54 ± 0.21

5.59 ± 0.75

120

4.65 ± 0.66

5.45 ± 0.26

5.72 ± 0.93

6.32 ± 0.55

6.62 ± 0.36

7.26 ± 0.76

5.41 ± 0.57

5.52 ± 0.80

DPPH (%)

0

21.18 ± 0.18

26.71 ± 1.53

41.67 ± 0.71

51.84 ± 1.92

48.35 ± 0.13

64.52 ± 1.30

22.98 ± 1.48

27.56 ± 1.43

30

21.07 ± 1.30

26.36 ± 0.56

41.25 ± 1.64

51.76 ± 2.54

48.10 ± 1.19

64.38 ± 0.89

22.85 ± 2.43

27.43 ± 1.87

60

20.67 ± 0.54

25.89 ± 1.17

40.78 ± 1.39

51.54 ± 2.11

47.93 ± 2.05

64.10 ± 1.53

22.62 ± 1.67

27.36 ± 2.14

90

20.27 ± 1.22

25.24 ± 1.63

40.54 ± 1.88

51.11 ± 1.86

47.15 ± 2.00

63.79 ± 2.61

22.47 ± 1.93

27.17 ± 2.36

120

19.86 ± 1.68

24.91 ± 1.74

40.22 ± 2.06

51.03 ± 2.75

46.83 ± 2.45

63.53 ± 2.26

22.20 ± 0.64

27.04 ± 2.52

4.5 Total phenolics and total flavonoid content

The total phenolics and total flavonoid content in both raw and sprouted onion pastes showed a gradual decrease with increase in storage period (Table 2). A significant (P < 0.05) effect of variety, and sprouting with non significant (P < 0.05) effect of storage period was observed on total phenolic and total flavonoid content of onion pastes. The differences between raw and sprouted onion pastes ranged from 2.75 to 4.73 mg/g for total phenolics and 1.85–3.39 mg/g for total flavonoids at the end of storage period with highest content of phenolics and flavonoids in sprouted paste sample from PRO-6 onion variety. The sprouted paste samples were thus found to have higher content of both total phenolics and flavonoids than raw onion pastes at the end of storage period of four months. The same trend of difference and decrease in total phenolics and total flavonoids was observed between fresh and packaged juice concentrate by Jiang et al. (2016). The decreased level of total phenolics and total flavonoids might be due ingress of ambient air during storage that enhanced the enzyme activity (Mediani et al., 2014).

4.6 Total antioxidant capacity and DPPH radical scavenging activity

The antioxidant capacity of and DPPH radical scavenging activity raw and sprouted onion pastes decreased with storage (Table 2). The sprouted onion pastes retained better antioxidant potential than raw onion pastes and possessed higher anti oxidant activity at the end of storage period. The significant (P < 0.05) effect of variety, sprouting and storage period was found on total antioxidant capacity and DPPH radical scavenging activity of paste samples. The decrease of antioxidant capacity with storage corresponds with the study reported by Nekvapil et al. (2012) who evaluated the decrease of antioxidant potential during storage. The decrease in antioxidant potential during storage was earlier reported in a study by Cordero et al.(2009) in which they credited the loss of antioxidant activity to the oxygen permeability of PET packaging.

4.7 Microbiological analyses

The microbiological quality of raw and sprouted onion pastes is presented in Table 3. The TPC (CFU/g) during a period of four month storage increased from <100 in all paste samples to a highest of 600 in case of commercial raw onion paste. Coliforms/g in paste samples increased from nil to 10 in case of raw Punjab White paste, <10 in sprouted Punjab White paste, 100 in raw Punjab Naroya paste and <100 in raw and sprouted paste samples from PRO-6 and commercial onion variety. Lactobacillus/g and yeast and mold/g during storage in onion pastes increased from nil to <100. The microbial count in onion pastes was found to be similar to reported in other food pastes like coriander paste (Ahmed et al., 2004). The sprouted onion pastes were found to be microbiologically stable as TPC (CFU/g), coliforms/g, lactobacillus/g and yeast and mold/g count was found to be less than raw onion pastes throughout the storage period. It can thus be inferred that sprouted onion pastes were microbiologically safe during storage and the stability can be ascribed to the process of sprouting.

Punjab White

Punjab Naroya

PRO-6

Commercial

Parameter

Storage period (days)

Raw

Sprouted

Raw

Sprouted

Raw

Sprouted

Raw

Sprouted

TPC (CFU/g)

0

<100

<100

<100

<100

<100

<100

<100

<100

30

100

<100

<100

<100

<100

<100

100

<100

60

150

100

100

<100

100

<100

300

100

90

300

200

250

100

250

100

500

300

120

600

400

300

200

450

150

600

450

Coliforms/g

0

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

30

<10

Nil

Nil

Nil

<10

Nil

<10

Nil

60

<10

Nil

10

<10

<10

<10

<10

<10

90

<10

<10

<100

10

10

<10

10

<10

120

10

<10

100

<100

<100

<100

<100

<100

Lactobacillus/g

0

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

30

<10

<10

<10

Nil

Nil

Nil

<10

Nil

60

<10

<10

10

<10

10

<10

<10

10

90

10

<10

<50

<10

10

<50

10

<50

120

100

<100

<100

<100

<100

<100

<100

<100

Yeast and Mold/g

0

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

30

Nil

Nil

<10

Nil

<10

Nil

<10

10

60

Nil

Nil

10

<10

10

<10

10

<10

90

<100

<10

<50

10

<100

10

<100

10

120

100

<100

<100

<100

<100

<50

<100

<100

4.8 Rheological measurements

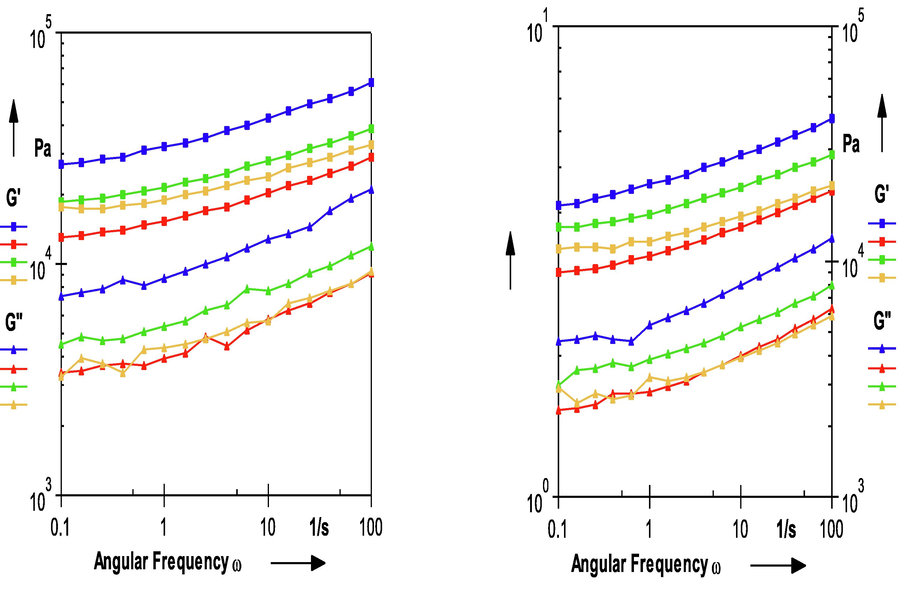

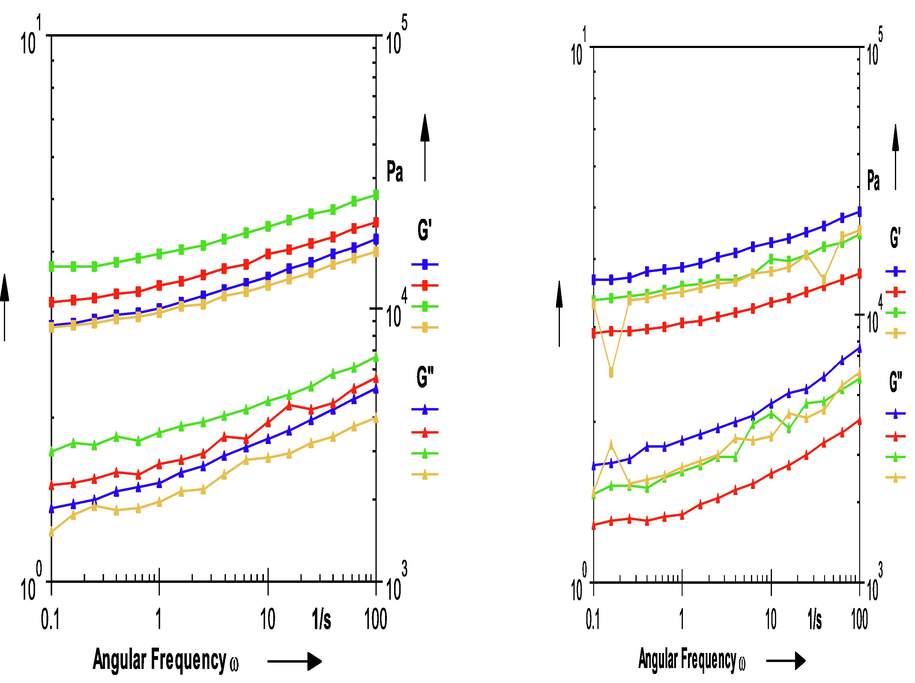

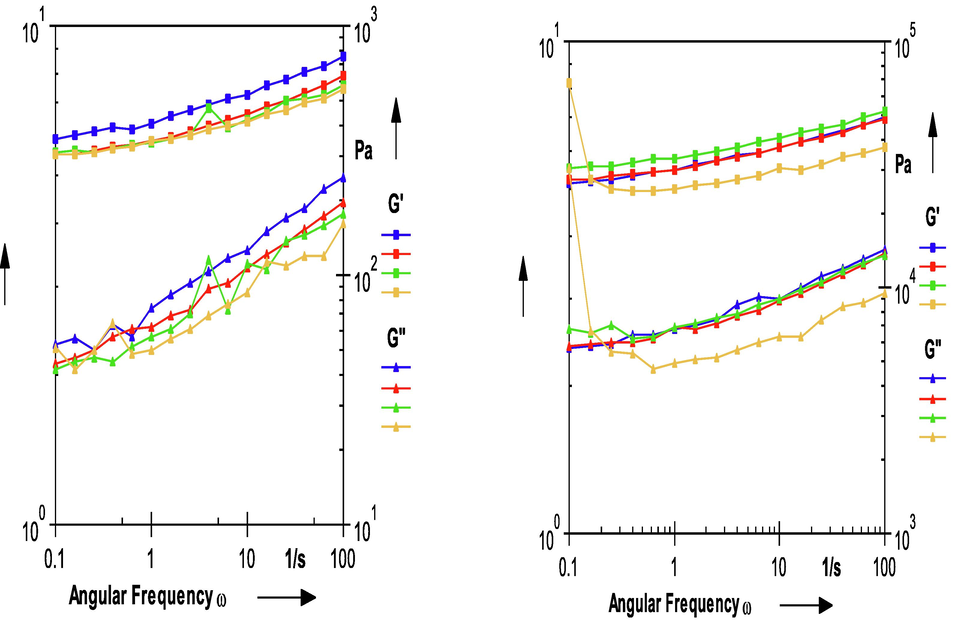

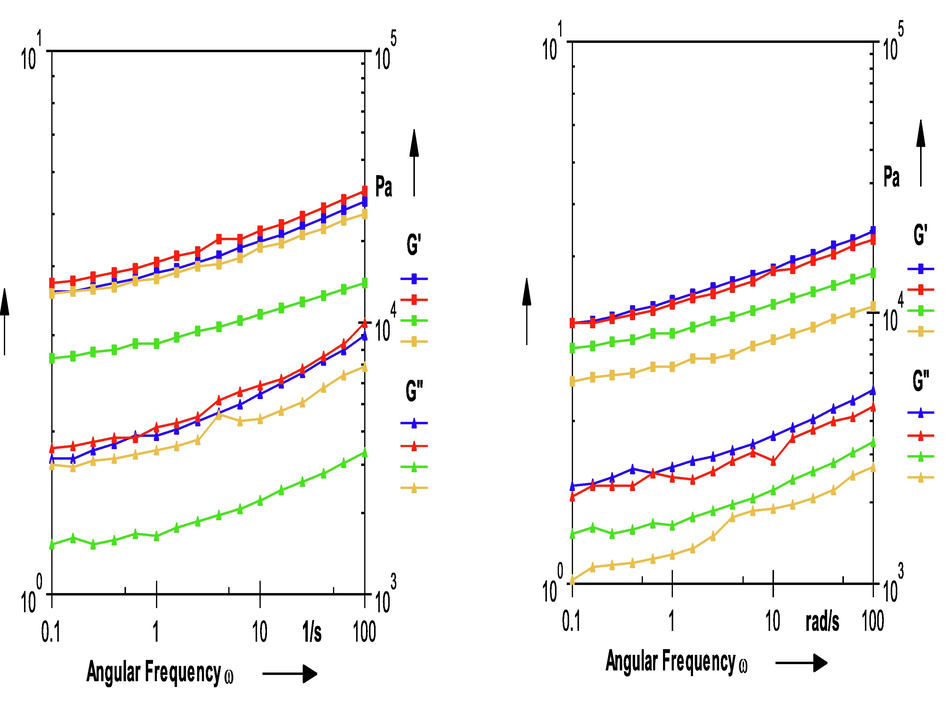

4.8.1 Effect of sprouting on the rheology of onion pastes

The rheological behaviour of raw and sprouted paste samples as a function of angular frequency in terms of storage (G′) and loss moduli (G″) are presented in Figs. 1 (a, b), 2 (a, b), 3 (a, b) and 4 (a, b) Both storage (G′) and loss moduli (G″) as a function of the frequency ω increased with increasing frequencies, in raw as well as sprouted onion paste samples. Similar trend in rheological behaviour has been observed in tomato paste (Bayod et al., 2008) and sprouted onion powders (Majid et al., 2018). The dependency of the moduli to the frequency seems to be explained by a power-law relationship (Eqs. (1) and (2)). However, in the studied samples, at ω < 0.6 Hz, the loss modulus G″ was almost independent of ω and minimum at low frequencies, in both raw and sprouted paste samples which is typical of highly structured materials. The power-law relationship is hence only valid at higher frequencies, ω > 0.6 Hz, and the parameters obtained from Eqs. (1) and (2) are summarized in Table 4. A multiple analysis of variance (MANOVA) of the effects of variety, sprouting and storage period on pH, *Mean significant at P < 0.05.

a. Commercial raw onion paste (CMR) G′-CMR20 (

), G′-CMR30 (

), G′-CMR30 (

), G′-CMR40 (

), G′-CMR40 (

), G′-CMR50 (

), G′-CMR50 (

), G″-CMR20 (

), G″-CMR20 (

), G″-CMR30 (

), G″-CMR30 (

), G″-CMR40 (

), G″-CMR40 (

), and G″-CMR50 (

), and G″-CMR50 (

). b. Commercial sprouted onion paste (CMS) G′-CMS 20 (

). b. Commercial sprouted onion paste (CMS) G′-CMS 20 (

), G′-CMS 30 (

), G′-CMS 30 (

), G′-CMS 40 (

), G′-CMS 40 (

), G′-CMS 50 (

), G′-CMS 50 (

), G″-CMS 20 (

), G″-CMS 20 (

), G″-CMS 30 (

), G″-CMS 30 (

), G″-CMS 40 (

), G″-CMS 40 (

), and G″-CMS 50 (

), and G″-CMS 50 (

).

).

a. Punjab White raw onion paste (PWR) G′-PWR 20 (

), G′-PWR 30 (

), G′-PWR 30 (

), G′-PWR 40 (

), G′-PWR 40 (

), G′-PWR 50 (

), G′-PWR 50 (

), G″-PWR 20 (

), G″-PWR 20 (

), G″-PWR 30 (

), G″-PWR 30 (

), G″-PWR 40 (

), G″-PWR 40 (

), and G″-PWR 50 (

), and G″-PWR 50 (

). b. Punjab White sprouted onion paste (PWS) G′-PWS 20 (

). b. Punjab White sprouted onion paste (PWS) G′-PWS 20 (

), G′-PWS 30 (

), G′-PWS 30 (

), G′-PWS 40 (

), G′-PWS 40 (

), G′-PWS 50 (

), G′-PWS 50 (

), G″-PWS 20 (

), G″-PWS 20 (

), G″-PWS 30 (

), G″-PWS 30 (

), G″-PWS 40 (

), G″-PWS 40 (

), and G″-PWS 50 (

), and G″-PWS 50 (

).

).

a. Punjab Naroya raw onion paste (PNR) G′-PNR 20 (

), G′-PNR 30 (

), G′-PNR 30 (

), G′-PNR 40 (

), G′-PNR 40 (

), G′-PNR 50 (

), G′-PNR 50 (

), G″-PNR 20 (

), G″-PNR 20 (

), G″-PNR 30 (

), G″-PNR 30 (

), G″-PNR 40 (

), G″-PNR 40 (

), and G″-PNR 50 (

), and G″-PNR 50 (

). b. Punjab Naroya sprouted onion paste (PNS) G′-PNS 20 (

). b. Punjab Naroya sprouted onion paste (PNS) G′-PNS 20 (

), G′-PNS 30 (

), G′-PNS 30 (

), G′-PNS 40 (

), G′-PNS 40 (

), G′-PNS 50 (

), G′-PNS 50 (

), G″-PNS 20 (

), G″-PNS 20 (

), G″-PNS 30 (

), G″-PNS 30 (

), G″-PNS 40 (

), G″-PNS 40 (

), and G″-PNS 50 (

), and G″-PNS 50 (

).

).

a. PRO-6 raw onion paste (PRO-6 R) G′-PRO-6 R 20 (

), G′-PRO-6 R 30 (

), G′-PRO-6 R 30 (

), G′-PRO-6 R 40 (

), G′-PRO-6 R 40 (

), G′-PRO-6 R 50 (

), G′-PRO-6 R 50 (

), G″-PRO-6 R 20 (

), G″-PRO-6 R 20 (

), G″-PRO-6 R 30 (

), G″-PRO-6 R 30 (

), G″-PRO-6 R 40 (

), G″-PRO-6 R 40 (

), and G″-PRO-6 R 50 (

), and G″-PRO-6 R 50 (

). b. PRO-6 sprouted onion paste (PRO-6S) G′-PRO-6S 20 (

). b. PRO-6 sprouted onion paste (PRO-6S) G′-PRO-6S 20 (

), G′-PRO-6S 30 (

), G′-PRO-6S 30 (

), G′-PRO-6S 40 (

), G′-PRO-6S 40 (

), G′-PRO-6S 50 (

), G′-PRO-6S 50 (

), G″-PRO-6S 20 (

), G″-PRO-6S 20 (

), G″-PRO-6S 30 (

), G″-PRO-6S 30 (

), G″-PRO-6S 40 (

), G″-PRO-6S 40 (

), and G″-PRO-6S 50 (

), and G″-PRO-6S 50 (

).

).

Punjab White

Punjab Naroya

PRO-6

Commercial

Raw

Sprouted

Raw

Sprouted

Raw

Sprouted

Raw

Sprouted

Storage Modulus (G′)

R2

0.98

0.99

0.97

0.98

0.98

0.99

0.97

0.98

k′

32569.21

7395.28

12363.35

15692.75

14368.42

19541.38

15834.02

18562.36

n′

0.06

0.07

0.09

0.10

0.09

0.09

0.06

0.07

Loss Modulus (G″)

R2

0.85

0.96

0.95

0.97

0.97

0.98

0.94

0.96

K″

2614.52

1502.31

2144.64

2481.93

3782.36

5125.35

1645.18

1845.60

n″

0.15

0.19

0.14

0.16

0.14

0.17

0.13

0.15

Effect

SS

Degree of Freedom

MS

F

p

Intercept

1991.127*

1*

1991.127*

588510.4*

0.000000*

Type of variety

0.116*

3*

0.039*

11.4*

0.000003*

Sprouting

0.009

1

0.009

2.6

0.109924

Storage period

0.298*

4*

0.074*

22.0*

0.000000*

Type of variety × Sprouting

0.028*

3*

0.009*

2.8*

0.046763*

Variety × Storage period

0.047

12

0.004

1.2

0.324757

Sprouting × Storage period

0.047*

4*

0.012*

3.5*

0.011735*

Type of variety × Sprouting × Storage period

0.047

12

0.004

1.1

0.334658

Error

0.271

80

0.003

All of the onion paste samples were well fitted into power law model, Eqs. (1 & 2), with the R2 ranging from 0.85 to 0.99, n′ and n″ value <1 (ranging from 0.06 to 0.19) and thus showing shear thinning behavior. The power law parameters relating the storage modulus (G′) and loss modulus (G″) to frequency for each paste sample presented in Table 4 showed decreased frequency dependency of sprouted paste samples as values of n′ and n˝ increased. The power law coefficients, k′, n′, k″ and n″ as represented by the magnitude of G′ and G″ respectively at a given frequency showed that storage modulus considerably exceeded loss modulus which indicates their visco elastic behavior. In the present study, G′ and G″ values for the raw onion paste samples were greater than those for the sprouted, and the G′ values were much higher than G″ values at all ω values with a small frequency dependency. The decrease in G′ and G″ values in sprouted paste samples all over the frequency range investigated was found which is in accordance with the results reported by Singh et al., (2001). This showed that the relative contribution of elastic (G′) nature of onion pastes decreased in sprouted samples which may be due to increase in proteolytic activity during sprouting.

4.8.2 Effect of concentration on the rheology of onion pastes

In both types of pastes (raw and sprouted) storage modulus (G′) increased slightly with increasing frequencies whereas loss modulus (G″) remained constant or decreased slightly at low frequencies (ω), and then increased with increase in frequency ω. This implied that both storage modulus (G′) and loss modulus (G″) as a function of the frequency ω depicted the same behaviour in raw and sprouted onion pastes. However, a pronounced effect of concentration of a particular type of paste was observed on storage modulus (G′) and loss modulus (G″) in the entire frequency range analyzed. Pastes samples up to the concentration of 40% showed an increase in both loss and storage modulus with increase in frequency however at higher concentration (50%) both loss and storage modulus initially decreased up to 0.6 frequency and then increased with increase in frequency in both raw and sprouted paste samples. The behaviour of pastes as gels which occurs when storage modulus (G′) is higher than the loss modulus (G″) at given frequency was also found to be influenced by the concentration of paste sample. This type of behaviour was noticed in commercial raw onion paste at 20% and 40% concentration, raw Punjab Naroya paste at all concentrations (20, 30, 40 and 50%), sprouted commercial onion paste at 20% and sprouted Punjab Naroya paste at 20, 30 and 40% concentration. The another group of pastes where loss modulus considerably exceeded storage modulus at given frequency and particular concentration among raw onion pastes were commercial onion paste at 30 and 50% concentration, PRO-6 and Punjab White paste at all concentrations (20,30,40 and 50%) while, in case of sprouted paste samples it was commercial paste sample at 30, 40 and 50%, Punjab Naroya at 50%, Punjab White and PRO-6 at all concentrations (20,30,40 and 50%). The above observations revealed that onion pastes do not show the same trends with respect to their source (variety) nor with respect to the treatment (raw or sprouted) i.e. paste from a particular variety behaved either as a strong gel or weak gels depending upon the concentration and type of paste (raw or sprouted). The above-mentioned findings implied that irrespective of the source and treatment, different components in the paste samples behaved differently at variable dilutions giving rise to different networks. Thus, the behaviour of paste samples at higher concentrations correspond to that of ‘‘physical gels’’ or ‘‘weak gels’’, while at lower concentrations they correspond to entanglement networks.

5 Conclusions

Sprouted onion pastes exhibited the better retention of color, total phenols, total flavonoids and antioxidant activity throughout the storage period as compared to raw onion pastes. Irrespective of the variety and sprouting the magnitude of change in quality parameters were influenced by the storage period. Sprouting process also influenced the rheological properties with less frequency dependency of flow behaviour in onion pastes. The paste from sprouted onions with enhanced functional potential throughout the storage period unveils their potential for long term use as phyto additive for culinary purposes. It can thus be concluded that process of sprouting can be used to improve the storage stability of onion pastes at ambient conditions.

Acknowledgements

The authors are highly grateful to Department of Vegetable Science, Punjab Agricultural University, Ludhiana for providing onion variety and UGC, New Delhi for providing financial assistance. The authors extend their appreciation to the Researchers supporting project number (RSP-2020/173) King Saud University, Riyadh, Saudi Arabia.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Rheological behavior and color changes of ginger paste during storage. Int. J. Food Sci. Technol.. 2004;39:325-330.

- [Google Scholar]

- Colour kinetics and rheology of coriander leaf puree and storage characteristics of the paste. Food Chem.. 2004;84:605-611.

- [Google Scholar]

- Thermal kinetics of color degradation and storage characteristics of onion paste. LWT-Food Sci. Technol.. 2001;34:380-383.

- [Google Scholar]

- APEDA. (2017). Cited from http://apeda.gov.in/apedawebsite/SubHead_Products/Onions.htm). Accessed on 16-08-17.

- Rheological and structural characterization of tomato paste and its influence on the quality of ketchup. LWT - Food Sci. Technol.. 2008;41:1289-1300.

- [Google Scholar]

- Identification, quantitation, and method validation for flavan-3-ols in fermented ready-to-drink teas from the Italian market using HPLC-UV/DAD and LC-MS/MS. J. Sep. Sci.. 2009;32:3643-3651.

- [Google Scholar]

- Preservation of mutton as ready-to-eat curry by hurdle technology. J. Food Sci. Technol.. 2001;38:287-289.

- [Google Scholar]

- Physicochemical and microbiological characteristics of ginger paste (cv. Suprabha) during storage in different packaging and temperature conditions. Cogent Food Agric.. 2016;2:1223261.

- [Google Scholar]

- The effect of different packaging and storage conditions on the quality of pistachio nut paste. J. Food Eng.. 2007;78:443-448.

- [Google Scholar]

- Microorganisms in foods-I: their significance and methods of enumeration (2nd ed.). Canada: International Commission on Microbiological Specifications for Foods. University of Toronto Press; 1992.

- Changes in Total Phenolic and Flavonoid Content and Antioxidative Activities during Production of Juice Concentrate from Asian Pears (Pyrus pyrifolia Nakai) Food Sci. Biotechnol.. 2016;25:47-51.

- [Google Scholar]

- Koutidou, M., Grauwet T., Loey, A.V., Acharya, P. (2017). Impact of processing on odour-active compounds of a mixed tomato-onion puree. Food Chem., 228, 14–25.

- Development of shelf stable tomato rasam paste using hurdle technology. Int. Food Res. J.. 2015;22:171-177.

- [Google Scholar]

- Rheological, thermal, micro structural and functional properties of freeze dried onion powders as affected by sprouting. Food Bio Sci.. 2018;22:105-112.

- [Google Scholar]

- Instrumental texture and flavonoid profile of paste developed from sprouted onion varieties of Indian origin. Int. J. Food Prop. 2016

- [CrossRef] [Google Scholar]

- Majid, I., Nanda, V., 2017a. Total phenolic content, anti oxidant activity and anthocyanin profile of sprouted onion powder. Acta Alimentaria, Int. J. Food Sci., Article in press.

- Effect of sprouting on the physical properties, morphology, and flowability of onion powder. J. Food Meas. Charact. 2017

- [CrossRef] [Google Scholar]

- Effect of sprouting on physicochemical, antioxidant and flavonoid profile of onion cultivars. Int. J. Food Sci. Technol.. 2016;51:317-324.

- [Google Scholar]

- Moisture sorption isotherms and quality characteristics of onion powder during storage as affected by sprouting. J. Food Meas. Charact.. 2019;13:775-784.

- [Google Scholar]

- Impact of sprouting on the degradation kinetics of color and vitamin C of onion powder packaged in different packaging materials. J. Food Process. Preserv. 2019

- [CrossRef] [Google Scholar]

- Effects of Different Drying Methods and Storage Time on Free Radical Scavenging Activity and Total Phenolic Content of Cosmos caudatus. Antioxidants. 2014;3:358-370.

- [Google Scholar]

- Decrease in the antioxidant capacity in beverages containing tea extracts during storage. Sci. World J. 2012

- [CrossRef] [Google Scholar]

- Inhibition of Salmonella typhimurium on radish sprouts using nitrogen-cold plasma. Int. J. Food Microbiol.. 2017;1605:30105-30108.

- [Google Scholar]

- Rheological and textural characteristics of date paste. Int. J. Food Prop.. 2012;15:281-291.

- [Google Scholar]

- Phenolic content and antioxidant properties of green chilli paste and its ingredients. Maejo Int. J. Sci. Technol.. 2010;4:193-200.

- [Google Scholar]

- Accelerated shelf life study of zingiber officinale paste. Int. J. Pharma Bio Sci.. 2016;7:251-254.

- [Google Scholar]

- Effect of sprouting conditions on functional and dynamic rheological properties of wheat. J. Food Eng.. 2001;47:23-29.

- [Google Scholar]