Translate this page into:

Surface modification of date palm leaves by cold plasma treatment

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

The surface properties of bio-fibres change by surface plasma treatment without changing their internal properties. In this study, radio-frequency plasma was used to treat the surface of date palm leaves. Plasma treatment was conducted for different times (1, 5, and 8 min) and at different powers (80, 100, and 120 W), keeping the gas pressure fixed at 0.95 torr. Water-drop contact angles, scanning electron-microscope images, surface free-energy measurements, and X-ray diffraction spectra were recorded for the surfaces of the leaves after plasma treatment. Contact-angle values were found to decrease and the surface energy in decrease. The observed changes in surface properties are attributable to a combination of the increase in polar chemical functional groups.

Electron micrographs show improvement in the sample surface morphology after plasma treatment. The study showed that the surface modification of fibres by plasma could improve interfacial adhesion between the DPF and an epoxy matrix.

Keywords

RF-plasma treatment

Date palm leaves (DPL)

Contact angle measurements

Surface free-energy measurements

- DPL

-

date palm leaves

- SEM

-

Scanning electron microscope

- RF

-

radiofrequency

- DPF

-

date palm fibres

- XRD

-

X-ray diffraction

Abbreviations

1 Introduction

The date palm tree is a traditionally popular fruit tree in Saudi Arabia. It is also found in most of the Middle East and Northern Africa. Vast amount of residues from date palm trees are accumulate. It is estimated that each date palm tree produces more than 20 kg of residues and fibres annually (Aleid et al., 2015). These agricultural wastes can be used as reinforcing fibres for polymeric material (AL-Oqla et al., 2014).

Several studies have investigated the effect of different physical, chemical, or mechanical treatment on date palm fibres (Alawar et al., 2009; Jonoobi et al., 2011). Plasma treatment is an effective and environmentally friendly choice for surface modification of natural leaves. Moreover, it is a dry method that does not require water and generates lesser pollution (Zille et al., 2015). Plasma modification a can render a rough surface cleaning, ablation, or the etching effect of plasma on the surface. By controlling plasma variables, such as the nature of the gas, the discharge power, and the exposure time (Kalia et al., 2013; Dawood, 2020).

Plasma consists of a mixture of free radicals, electrons, and heavy particles. There are two types of plasma interactions with the surface: first the chain scission on the surface which results in surface etching, cleaning. Second is where activation is achieved by using ono polymerizing gases like helium, oxygen, air and nitrogen (Bozaci et al., 2013).

A non-thermal plasma under atmospheric pressure modifies both the morphology and composition of a polymer surface. After a very short treatment time, the surface is etched, the surface roughness is increased (Zhi et al., 2004), and the contact angle of liquid droplets is decreased (Kan and Yuen, 2010; Zhang et al., 2010). The effects of atmospheric plasma on the permeability properties of single jersey bamboo fabric have also been investigated. It was found that the plasma treatments increased water-vapor permeability but decreased air permeability (De Oliveira et al., 2017). Scanning electron-micrography (SEM) showed that the plasma modified the fibre surface (Guignard et al., 2015; Prakash et al., 2013).

In another work studied the effects plasma-induced on the surface properties of lignocellulosic natural coir fibres. Surface changes after plasma treatment confirmed by SEM analysis. Etching was observed in a fibre wall, which led to higher water absorption (Praveen et al., 2016).

Studies have attempted to explore the impacts of plasma treatment on the surface properties of coconut fibers to improve their wettability and hydrophilicity. The studies showed an increase in absorption capacity and wettability. Images SEM showed changes in the samples surface morphology after plasma treatment (De Oliveira et al., 2017).

It was observed that the plasma treatment of date palm fibers (DPF) cleaned the surface by removing the waxy layer impurities, and in turn increased surface roughness, which enhanced friction and improved interfacial adhesion between DPF (Gholami et al., 2018).

The aim of this study is to investigate the effect of air radiofrequency (RF) plasma treatment on the physical properties of (DPFs) at two different plasma parameters: treatment exposure times and RF powers. The contact angle of pure water drops, and the surface free energies of the fibres were measured. SEM and X-ray diffraction (XRD) were used to investigate the surface of the leaves after treatment with RF plasma.

I observed an enhanced surface of DPS post the plasma treatment.

2 Materials and methods

Samples of date palm leaves (DPLs) were collected from Al Medina Al Munawara in Saudi Arabia. Before testing, the samples were cleaned to remove dirt and dust. Filtered water was used to avoid damaging the outer surface. The samples were then cut into rectangles of approximately 1 × 2 cm2 and were left to dry at 25 °C for 72 h. Fig. 1 shows the samples after cleaning and drying.

Date palm fibre samples after cutting and drying.

3 Experimental setup

The DPLs were divided into two groups. The first group was treated with air RF plasma for different exposure times (1, 5, and 8 min), while the plasma power was kept constant at 100 W. The second group was treated at different discharge powers (80, 100, and 120 W), while the exposure time was fixed at 5 min. A control sample was left untreated.

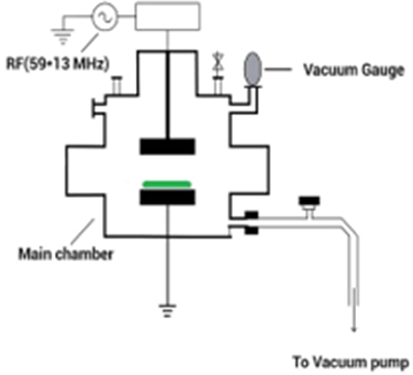

The plasma-producing chamber was cylindrical, of stainless steel, with 25 cm diameter and 36 cm height. It contained of two parallel stainless steel electrode plate with diameter 5 cm and a distance of 2.5 cm between them. The two electrodes were put inside dielectric ceramics and were connected with a RF power supply (13.56 MHz and 0–200 W).

A rotary pumping system brought the chamber to a base pressure of 10−4 Torr. The gas pressure was fixed at 0.95 torr and maintained at this value during all measurements. Fig. 2 shows the experimental setup used to generate the RF plasma.

Experimental setup used in this study, with date palm fibre sample (green) between electrodes in a plasma chamber.

3.1 Water drop test and contact angle measurements

The contact angles were measured using the drop test method. A 30 µl pure water drop was put by a micropipette onto each sample. The drops were deposited from a fixed height of 2 cm above the sample. The sample was placed on top of a plastic film to prevent the water from being absorbed by other substrates. The drops on the surface of the samples were photographed every 2 min. The images of the drops were captured by a digital camera. The contact angle θ formed between the drop and the surface was measured for each droplet image using the ImageJ software.

3.2 Surface free energy measurements

To calculate the apparent surface free energy , the relation between the equilibrium contact angles and the liquid surface tension can be used (Terpiłowski, 2017): where γι is liquid surface tension (water in this work), and θeq is equilibrium contact angle.

3.3 Scanning electron microscope

The surface morphology of the DPL samples was examined using an SEM (model JSEM 7400F, Joel, Japan). The accelerating voltage was 15 kV for all measurements.

3.4 X-ray diffraction measurements

The (XRD) data were recorded using a Lab X XRD-6100 (Shimadzu, Japan; 2 kW, NF, Cu tube).

4 Results and discussion

The effects of the two different RF plasma parameters, namely, plasma treatment times and RF power, on the morphology, XRD pattern and wettability properties of the DPL surface were investigated.

4.1 Contact angle measurements

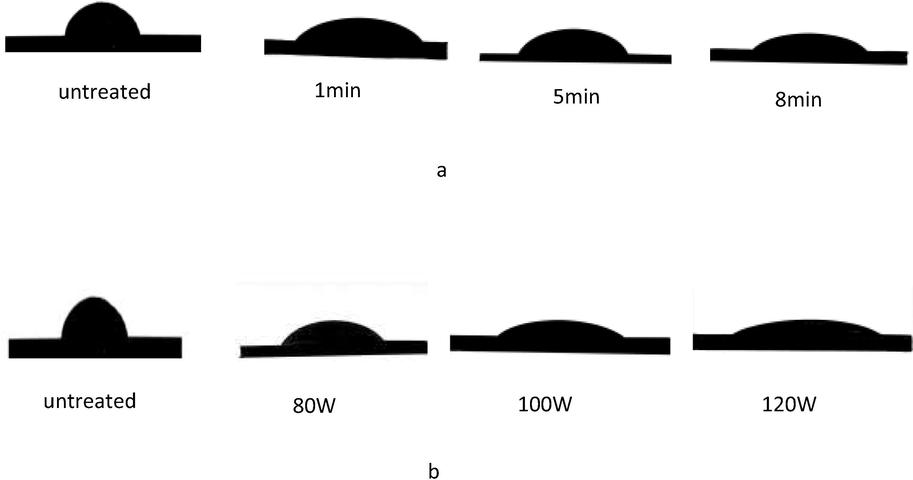

Fig. 3a shows images of a pure water drop on the surface of a DPL at an RF plasma power of 100 W with treatment times of 1,5 and 8 min. Fig. 3b shows images of a pure water drop that was treated for 5 min with RF plasma powers 80, 100, and 120 W.

Images of water drop on samples. (a) Images of a pure water drop on the surface of a date palm leaf at a plasma power of 100 W after various treatment times. (b) Images of a pure water drop on a date palm leaf treated for 5 min at various plasma powers.

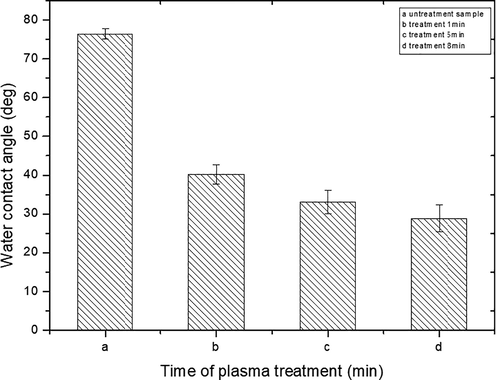

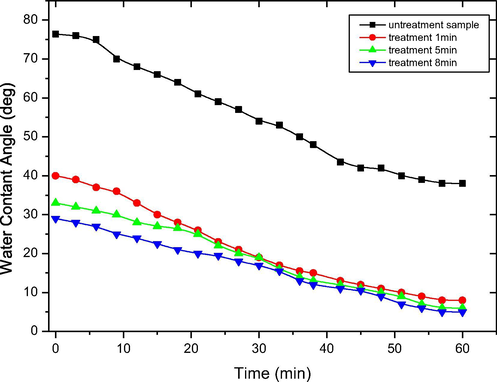

Fig. 4 shows the results of contact-angle measurement for the treated samples at a plasma power of 100 W and treatment time intervals of 1, 5, and 8 min. There was a marked decrease in the contact angle, from 76.4° for the untreated sample, to 40.2° for the treated sample at 1 min treatment, to 33° for the treated sample at 5 min, and to 28° for the treated sample at 8 min. The decrease in contact angles is indicative of the addition of hydrophilic groups to the sample surface (Conceição et al., 2019). In addition, after plasma treatment the contact-angle values decreased, an effect expected to be particularly large for polar liquids such as water. The contact angles of polar liquids decrease on surfaces treated by air plasma. These liquids have polarised covalent bonds, and it's have ability to form hydrogen bonds (Terpiłowski, 2017).

Surface contact angle of pure water drop on a date palm leaf at different plasma treatment times.

Fig. 5 shows the change in the contact angle value of the treated and untreated samples over one hour. Although the treated samples differ slightly among. Themselves, the effect is minor compared to the difference between the treated samples and the untreated sample.

Surface contact angle as a function of post-treatment time for pure water drops on date palm leaves treated for various time periods.

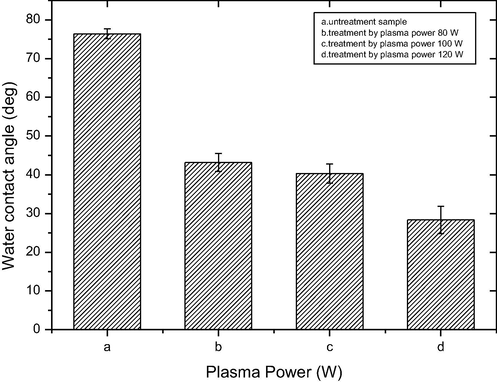

Fig. 6 shows the treated DPL samples, where the exposure time was 5 min and the plasma powers were 80, 100, and 120 W. The contact angle decreased when the plasma power increased; this implies that the wettability increased. The reason in Wettability changes is new surface polar groups formation.

Surface contact angle of pure water drop on date palm leaf at different plasma powers.

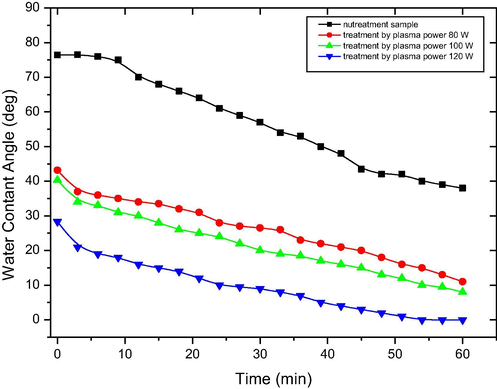

The contact angle for pure water decreased with time. This is due to the polarity of the water, the increased spreading of the drop on the DPL surface, and absorption into the DPL cellular structure. At a higher plasma power (120 W), the contact angle decreased to nearly zero (Fig. 7), which indicates that the surface wettability was at maximum.

Surface contact angle as a function of post-treatment time for pure water drops on date palm leaves treated at different plasma powers.

4.2 Surface free energy measurements

Table1a shows values of the surface energy for various plasma-treatment times at an RF power of 100 W, while Table 1b shows values of the surface energy for various plasma powers at a treatment time of 5 min.

Treatment at 8 min

Treatment at 5 min

Treatment at 1 min

Untreated sample

Sample

0.13

4.59

60.94

55.32

Surface energy (mJ/m2)

Treatment at 120 W

Treatment at 100 W

Treatment at 80 W

Untreated sample

Sample

4.85

35.47

7.13

55.32

Surface energy (mJ/m2)

Evidently, there were major changes in the surface free energy of the sample surface after RF plasma treatment. These changes are due, at least in part, to the electron-donor parameter of the apparent surface free energy, which increases as a result of adding polar groups at the time of surface plasma activation. Changes in surface properties are due to a combination of the increase of polar chemical functional groups.

4.3 SEM measurements

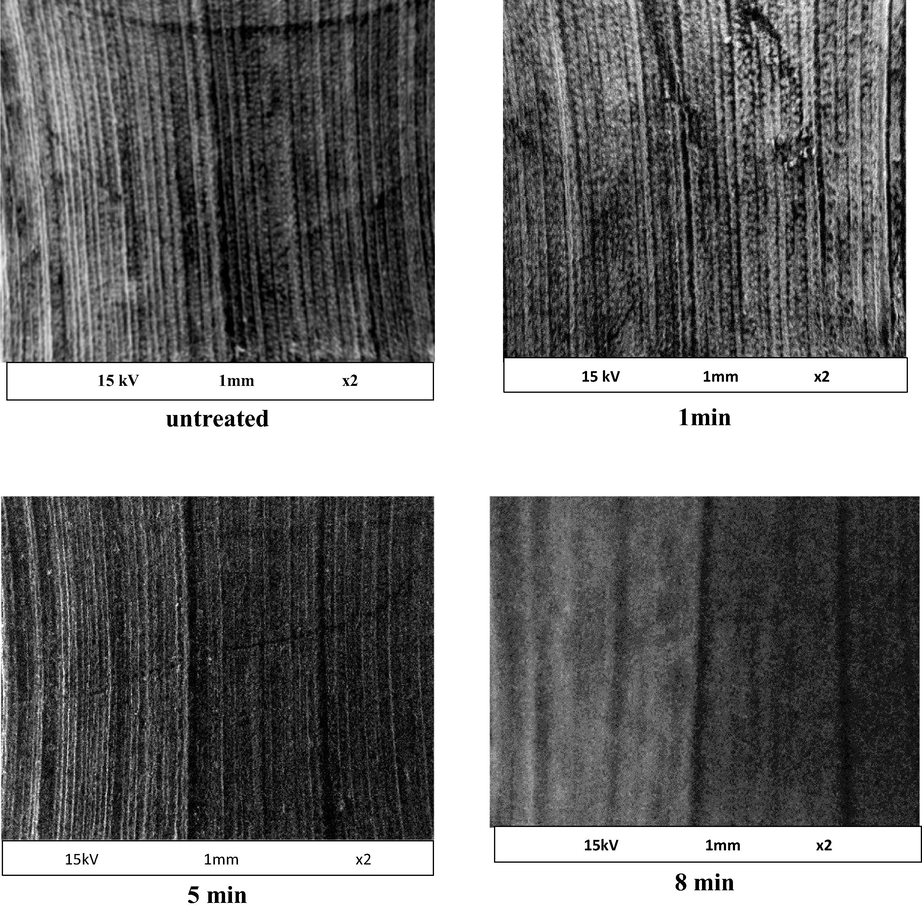

The SEM is used to examine the morphology surface of the DPL samples at an acceleration voltage of 15 kV. The micrographs of the untreated DPL sample and the samples after RF plasma treatment for different exposure times (1, 5, and 8 min, where the plasma power was kept constant at 100 W) are shown in Fig. 8.

Scanning electron micrographs of date palm leaves: (a) untreated sample; (b, c, and d) samples treated for various times at 100 W plasma power.

By increasing the plasma treatment times and/or the plasma power (to 100 W), the surface roughness of the fibres was altered, and the sample surface became homogeneous and smooth. The Etching effect is due to bombardment by plasma on the fibre surface, led to higher water absorption.

It was observed that the plasma treatment of DPFs cleans the surface by removing the waxy layer and impurities. This increases the surface softness, which improved interfacial adhesion between DPFs (Gholami et al., 2018).

4.4 XRD measurements

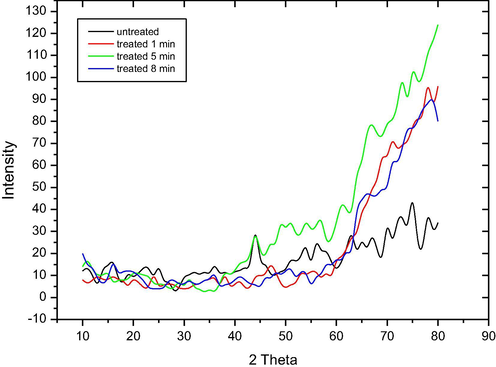

Fig. 9 shows XRD spectra of the untreated and treated samples at different exposure times and fixed plasma power of 100 W. The intensities of most peaks increased after plasma treatment. The figure shows that the integral intensity in the treated samples increases continuously increased 5 min, indicating an increase in ordering due to chain scission; it then decreases with further increase of the plasma-treatment exposure time. The XRD spectrum showed of fibre low crystallinity due to the high amorphous compounds and high lignin content in the fibres (Thygesen et al., 2005).

X-ray diffraction spectra of the untreated and treated samples at different exposure times and fixed plasma power of 100 W.

5 Conclusions

The RF plasma treatment is effective method that clean fibres and modulate their surfaces by changing their surface energies and addition different functional groups. This study used RF plasma to treat the surface of DPL using two different plasma parameters treatment exposure times and RF power.

Changes in the surface properties of DPLs were observed during treatments with RF plasma. The contact-angle values of a drop of pure water on the DPL surface decreased with increasing exposure time and plasma power. This highlights the increased wettability of the leaf surface. Wettability increase are consequent to the formation polar groups on the treatment surfaces.

SEM imaging confirmed the surface changes of the samples after plasma treatment. Enhancement of the surface roughness of the DPF was also found after plasma treatment in this study.

It was observed that plasma treatment cleans the surface of the DPF by removing the waxy layer and impurities and by increasing the surface roughness, which results in enhanced friction and mechanical interlocking between the fibre and epoxy resin. Based on these results, the surface modification of fibres by plasma could improve interfacial adhesion between the DPF and an epoxy matrix.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Processing and properties of date palm fibers and its composites. In: Biomass and bioenergy. Springer; 2014. p. :1-25.

- [Google Scholar]

- Characterization of treated date palm tree fiber as composite reinforcement. Compos. B Eng.. 2009;40(7):601-606.

- [Google Scholar]

- Date palm status and perspective in Saudi Arabia. In: Date Palm Genetic Resources and Utilization. Springer; 2015. p. :49-95.

- [Google Scholar]

- Effects of the atmospheric plasma treatments on surface and mechanical properties of flax fiber and adhesion between fiber-matrix for composite materials. Compos. B Eng.. 2013;45(1):565-572.

- [Google Scholar]

- Investigation of the wettability using contact angle measurements of green polyethylene flat films and expanded vermiculite clay treated by plasma. Mater. Res.. 2019;22(suppl 1)

- [CrossRef] [Google Scholar]

- Effect of RF plasma on moringa seeds germination and growth. J. Taibah Univ. Sci.. 2020;14(1):279-284.

- [Google Scholar]

- Effect of oxygen plasma treatment on tensile strength of date palm fibers and their interfacial adhesion with epoxy matrix. Sci. Eng. Comp. Mater.. 2018;25(5):993-1001.

- [Google Scholar]

- Functionalization of a bamboo knitted fabric using air plasma treatment for the improvement of microcapsules embedding. J. Textile Instit.. 2015;106(2):119-132.

- [Google Scholar]

- Characteristics of cellulose nanofibers isolated from rubberwood and empty fruit bunches of oil palm using chemo-mechanical process. Cellulose. 2011;18(4):1085-1095.

- [Google Scholar]

- Surface modification of plant fibers using environment friendly methods for their application in polymer composites, textile industry and antimicrobial activities: a review. J. Environ. Chem. Eng.. 2013;1(3):97-112.

- [Google Scholar]

- Effect of nature of gas on some surface physico-chemical properties of plasma-treated wool fiber. J. Adhes. Sci. Technol.. 2010;24(1):99-111.

- [Google Scholar]

- Effects of plasma treatment on the sorption properties of coconut fibers. Procedia Eng.. 2017;200:357-364.

- [Google Scholar]

- Effect of plasma treatment on air and water-vapor permeability of bamboo knitted fabric. Int. J. Thermophys.. 2013;34(11):2173-2182.

- [Google Scholar]

- Investigations of plasma induced effects on the surface properties of lignocellulosic natural coir fibres. Appl. Surf. Sci.. 2016;368:146-156.

- [Google Scholar]

- Terpiłowski, Konrad. 2017. Apparent surface free energy of polymer/paper composite material treated by air plasma. Int. J. Polymer Sci. 2017.

- On the determination of crystallinity and cellulose content in plant fibres. Cellulose. 2005;12(6):563-576.

- [Google Scholar]

- Surface treatment of polyethylene terephthalate films using DBD excited by repetitive unipolar nanosecond pulses in air at atmospheric pressure. IEEE Trans. Plasma Sci.. 2010;38(6):1517-1526.

- [Google Scholar]

- Surface treatment of polyethylene terephthalate film using atmospheric pressure glow discharge in air. Plasma Sci. Technol.. 2004;6(6):2576-2580.

- [Google Scholar]