Translate this page into:

Prospects of nanostructured composite materials for energy harvesting and storage

⁎Corresponding author at: Department of Mechanical Engineering, Tshwane University of Technology, Pretoria, South Africa. ibrahimidowu47@gmail.com (Idowu D. Ibrahim)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

In the 21st century, energy demand and the attendant environmental degradation, are among the most challenging issues. The concern is due to the high dependence, globally on fossil fuels as a form of energy generation. Over 6.5 billion people worldwide require approximately 13 Terawatts of energy for their day-to-day needs. In order to achieve the required energy demand, there is a need to diversify into other forms of energy; in this case, renewable energy. In so doing, there is the need to study, extensively, alternative materials and sources needed for energy generation, storage, distribution and application. There has been a significant advancement in energy generation, conversion and storage, such as fuel cells and solar cells, photovoltaic cells, supercapacitors, batteries, etc. The emergence of nanostructured and composite materials has resulted in some significant contributions towards the improvement in the energy industry development. Renewable energy, such as wind and solar energies, depend considerably, on the environmental conditions, which are not always stable. Hence, in order to harness the energy from these sources and to adequately store such energy, there is a need for a high-performance energy conversion and storage system for the energy generation process. In this regard, carbon nanomaterials, metallic sulphides, titanium oxide and many other nanostructured materials have been studied, to a large extent, for energy conversions and storage devices. The importance of nanostructured and composite materials has shown, from researches, to resolve the issues surrounding energy from generation to storage.

Keywords

Nanostructured

Composites

Renewable energy

Energy application

1 Introduction

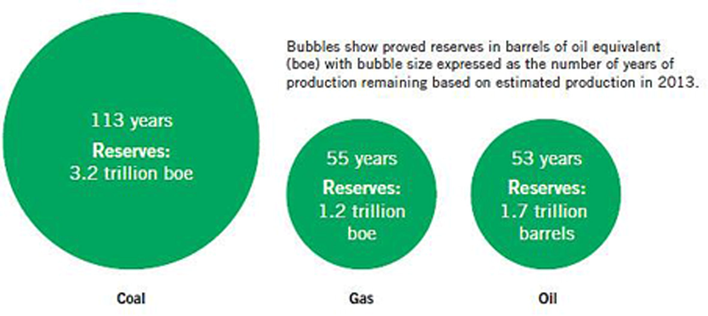

Recently, a large number of scientific research has been reported on the overwhelming challenges emanating as a result of the increase in energy demand. The increasing demand for energy is due to rapid population growth, industrialization and technological advancement. The hazardous effect of the conventional method of energy generation from fossil fuels (natural gas, oil and coal), is another key issue, globally. More than 80% of the global energy requirement comes from fossil fuels and the global energy demand projection (Global Carbon Capture and Storage Institute LTD, 2014a) for 2035, is assumed to be 40% higher than what it was in 2010. Several reports on the possible depletion of fossil fuels have been in the public domain, but according to a report by BP oil Statistical Review of World Energy in 2014, it will take over 113 years to finally exhaust the fossil fuel reserves (Fig. 1).

Available fossil fuels reserves for many decades. Source (Global Carbon Capture and Storage Institute Ltd, 2014b).

Environmental concern is one of the driving forces to be considered in the search for alternatives to fossil fuels as energy, even though it has the potential to still meet the demands. To this effect, renewable and sustainable energy has been largely explored as a solution to environmental sustainability. These alternative clean energies include: solar, wind, geothermal, hydro, wave/tidal and biogas. In order to harness these energies (i.e., generation and storage), there is a need for new and novel materials. The material can either be metal, ceramic or polymer matrix (or a hybrid of any of the three materials). In this report, emphasis will be placed more on polymer matrix composites. If the total solar radiation from the sun, over a period of only 1 h can be converted and stored, it has the potential to meet the global energy demand for a whole year (Ganesh, 2014; Lewis and Nocera, 2006).

In most part of Africa, solar radiation is effective for a period of between 6 and 8 h on a daily basis, making it a valuable resource for the African community. This solar radiation potential is equally possible in other parts of the world. Composite materials have proven to be very helpful for energy generation, conversion and storage. The conductive ability of certain polymeric materials is an advantage for their utilization in the energy sector. Furthermore, the properties can be improved by introducing nanoparticle into the polymer matrix, where the nanoparticle acts as the discontinuous phase and the polymer matrix is the continuous phase. Nanosized and nanostructured materials are largely in use to tackle the pressing energy challenges associated with the conversion of energy (Buller and Strunk, 2016). A substantial number of researches has been published in this area, highlighting the importance of nanostructured and composites materials (Liu et al., 2014; Lou and Chen, 2015; Ran et al., 2015).

Kumar et al. (2017), explained the importance of nanostructured materials as an effective alternative energy storage material, which can be a replacement for the conventionally used materials. Nanostructured materials can be in the form of metal-based nanomaterials, nanostructured inorganic materials, coordination polymers, carbon nanomaterials, etc. The authors further highlighted the area of applications (Li-ion batteries, supercapacitors and solar cell) and the advantages and challenges that are associated with incorporating nanostructured materials into polymer composites.

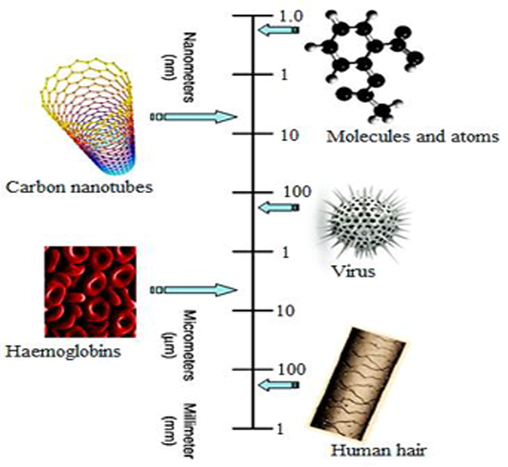

Meeting the energy demand globally will require continuous focus and development of new materials. New and improved materials contribute a great deal to the economy of any country because it leads to technological advancement and in return generate foreign exchange and leading to income generation for the country. Stronger materials have been developed by introducing nanomaterial into the matrix. Nanostructured material is when at least one dimension of the constituting components are in the nanosize of ≤100 nm. A better understanding of what a nanosize material looks like, in comparison to other material sizes, is shown in Fig. 2. Nanostructured materials have proven to have better physical, chemical and biological properties than the conventional materials with no nanoparticles inclusion (Kashiwazaki et al., 2009; Díaz et al., 2015; Lee et al., 2016; Castañeda et al., 2017). Therefore, this study focuses on the relevance of nanostructured and composite materials, used for energy applications in areas, such as supercapacitor, solar cells, fuel cells and batteries.

Comparison of nanosize material with other material sizes. Adopted from Simões and Takeda (2017).

2 Nanostructured materials and composites

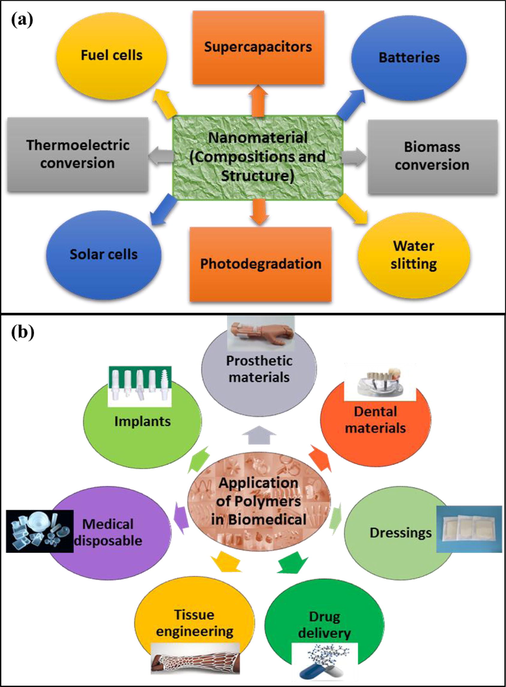

Advance material development has gone beyond the use of single material to a combination of various individual materials in order to form hybrid composites. The properties of the matrices can be improved significantly by introducing a reinforcing material in the form of a discontinuous phase; fiber has been widely utilized. More recently, nanosize material has gained considerable attention, since tremendous results have been reported with nanoparticle-based composites (Mallakpour and Ezhieh, 2017; Sharma et al., 2019; Sahoo et al., 2018; Ji et al., 2018). Nanoparticle-based composites have found useful applications in several fields of engineering and health, as illustrated in Fig. 3. Table 1 shows the various categories of nanoparticles and examples of each category.

Areas of application of nanostructured and composite materials in (a) energy (b) medical.

Organic macromolecular (polymeric particles)

Inorganic non-metallic nanoparticles

Carbon-based nanoparticles

Metal-based nanoparticle

Surface area (nm2)

Nanospere diameter (nm)

References

Dendrimers

Synthetic amorphous silica

Carbon black

Gold

314–31400

10–100

Nanocomposix-a

Titanium dioxide

Carbon nanotube

Silver

314–31400

10–100

Nanocomposix-b

Aluminium oxide

Graphene

Irona

–

5–30

Sigma-Aldrich

Platinumb

0.15–2,8c

2,5–9

Shao et al. (2013), Chiang et al. (2015)

Palladiumd

0.61–0.83c

4.5

Shao et al. (2013)

Cadmiume

–

7.2

Raj and Rajendran (2017)

Zirconium

5–10f

50–100

American-Elements, Opalinska et al. (2015)

Andrew et al. (2014) highlighted the recent work and challenges encountered in synthesizing and the characterization of magnetoelectric multi-ferroic materials (combination of ferromagnetic and ferroelectric). Single-phase materials of ferromagnetism and ferroelectricity existence is not a common phenomenon; this has further contributed to the development of composite materials made of multi-ferroic. Nanostructured and composite materials ensure the development of this rare material, however, the properties of magnetoelectric have not been fully expressed. This means that there is still the need for further research work in order to maximize the potentials of the material. The properties of this novel material can be enhanced if the structure-property relationship of the material at the nanoscale, is better understood. This aspect of nanoparticle-based composite materials is very crucial since the overall properties and areas of application are determined, based on the understanding of the material.

Another important area where nanostructured materials are widely used is in microwave receptors. In comparison, microwave heating has several advantages over conventional heating methods. These benefits according to Haque (1999), include:

-

Transfer of energy as opposed to heat transfer

-

Fast heating

-

Volumetric heating

-

Non-contact heating

-

Selective material heating

-

Quick start-up and stopping

-

A higher level of safety and automation

-

Heating from the inner portion of the material body

Materials with poor dielectric loss properties are usually discouraged because they respond poorly to the microwave electromagnetic radiation. In order to enable the usability of such materials, particles in the form of nanoscale receptors are incorporated into the materials, thereby increasing the dielectric loss properties and making it absorb the microwave energy and ultimately converting it to the desired heat.

Majdzadeh-Ardakani and Banaszak Holl (2017), studied the effect of surface modification and interfacial interaction between the base materials and the nanostructured receptors, knowing that the level compatibility between the nanostructured receptor and matrix will determine the performance of the system. From their study, the following observations are concluded:

-

Miscibility of the fillers with base polymers was achieved due to the adequate surface modification of the fillers. Furthermore, voids or defects were minimized in the composites, thereby leading to a significant increase in the dielectric loss because there was a decrease in the current leakages.

-

Percolative composites, consisting of conductive fillers and insulating polymers, have shown remarkable promises for the next generation of materials suitable for energy harvesting and storage. This is due to the very high dielectric constants, recorded near the percolation threshold.

-

Conductive polymers and carbon materials (including silicon carbide and graphene) are good microwave absorbers.

-

Composite materials consisting of a three-phase structure of conducting polymer, magnetic particles and graphene are promising candidates for obtaining improved dielectric properties and high dielectric loss.

In a similar study, Al-Gaashani et al. (2018), developed SiC-based composites, used to absorb microwave and to convert it to heat, for the purpose of rapidly synthesizing nanostructured materials. The dielectric loss properties of the composites increased by incorporating 10% of vanadium or aluminium oxide, represented by (90% SiC + 10% V2O3) and (90% SiC + 10% Aℓ2O3), respectively. The temperature of the microwave oven after 2 min was 1750 °C, operating at 2.45 GHz. The authors further explained that the temperature that was attained could be as a result of the formation of amorphous alumina-silica phase or silica-vanadate glass phase. The composites produced was then used as a heater for the synthesis of oxide nanostructures, at a fast rate.

Nanostructured-based composites have been reported to have enhanced ultra-violet (UV) shielding and increased electrical conductivity. This technology has been used to develop wearable devices, e.g. cotton fabric. Veluswamy et al. (2017), developed a cotton fabric that was coated with ZnO/Sb-/AG-/ZnO composites, which was simply carried out by modifying the composites with ZnO, by synthesizing via the solvothermal method. From their report, 83.96 and 471.9 μV/K, respectively, were recorded for the UV shielding and the thermopower. The study has proven that a cotton fabric (insulator) can conveniently be converted into a conductive fabric, simply by ingeniously incorporating nanostructured materials.

3 Areas of application of nanostructured materials (energy harvesting and storage)

Recent advancement and requirement in several fields have brought about a great improvement in human lives; i.e. health, agriculture, industries and finance. In many ways, these sectors have witnessed technological growth and this growth has something to do with materials. In recent years, new and novel materials have been discovered, thereby, creating further growth that is currently being experienced. Interesting research works have been reported, showcasing the rich contribution of material development to the global community. These areas include: environmental (Theerthagiri et al., 2017), agriculture (Antonacci et al., 2017), medical (Brazaca et al., 2017; Venditti, 2019), construction (Campillo et al., 2004), aerospace (Weston et al., 2010), automotive (Garces et al., 2000), energy (Barber et al., 2009), etc. Razavi (2018), reported on the use of bio-based materials, which are products of living organisms, for consumer goods, packaging, medicine, electronics, construction, transportation and other green technologically-inclined applications. The inclusion of bio-based nanostructured materials has further promoted the application of bio-based materials. Bio-nanomaterials are gradually revolutionizing the field of science and engineering, thereby making it possible to develop materials that are compatible with the human body and are environmentally-friendly. These materials, have almost zero impact on the environment, therefore, they are widely used materials in biomedical applications (Okamoto and John, 2013). The quest for new and novel materials that are compatible with the human body and with high strength and low-weight, has led to the emergence of the hybridization of bio-based materials with nanostructured materials. Thus, they have been successfully utilized for tissue repairs, wound closure and dressing, tissue regeneration, etc. Despite the successes recorded with such materials, there is still a lot of work to be done. Magesh et al. (2018), highlighted the limitations/drawbacks associated with nanostructured materials for medical applications and there are short-term performance and difficulties in large-scale manufacturing.

3.1 Supercapacitors

Gholivand et al. (2015) prepared nanocomposite of copper oxide and polyaniline (CuO/PANI) by using in-situ polymerization technique. The materials were characterized by cyclic voltammetry at various potential scan rates (ranging between 5 and 100 mV/s) and electrochemical impedance spectroscopy. The capacitance retention rate and the specific capacitance of 75% and 185 F/g, respectively were recorded as compared 30% and 76 F/g for the pure CuO nanoparticle. In a similar study, Ates et al. (2015) recorded the highest specific capacitance of 286.35 F/g at a scanning rate of 20 mV/s for the same material, as reported by Gholivand et al. (2015).

3.2 Photovoltaic cells

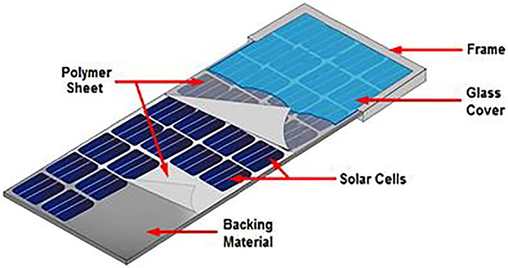

The photovoltaic (PV) technology is a process of converting solar radiation from sun to electrical energy. This occurs when electromagnetic radiation from the sun falls on a semiconductor, leading to electron excitation and thereby enhancing, very strongly, the conductivity. Two types of PV technology that are available in the market, include: (a) crystalline silicon-based PV cells and (b) thin film technologies that are made from different semiconducting materials (cadmium telluride, amorphous silicon and copper indium gallium dieseline) (Sagadevan, 2013). Fig. 4 shows a typical solar cell (photovoltaic cell). The glass cover increases the light transmittance and protects the layers in contact from being damaged, leading to improved cell efficiency; the backing material helps to minimise the effect of weather on the material and for mechanical strength for a long-lasting system operation; the polymer sheet prevents water and dust from entering the cell and acts as an anti-shock or vibration and the solar cells, which previously were made from relatively heavy and brittle semiconductors, e.g. silicon. Recently, PV cells have been developed from conductive polymers or polymer induced with nanoparticles to create the conductive properties.

Schematic diagram of a solar cell. Adopted from (Electrical Technology).

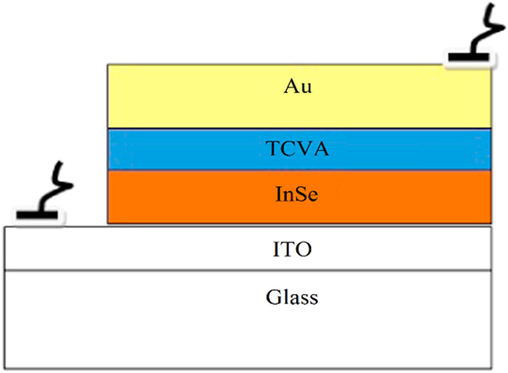

Al Garni and Darwish (2017), fabricated hybrid organic-inorganic solar cells that have a configuration of ITO/InSe/TCVA/Au, by using the method of thermal evaporation. Where TCVA is the p-type material of dye 4-tricyanovinyl-N,N-diethylaniline, an acceptor-donor, InSe is an n-type conductor of layered semiconductor, ITO is the cover for the substrates of glass and Au is the deposited gold electrodes. The assembly arrangement is shown in Fig. 5. From their study, the followings are observed: the execution of solar cells was enhanced due to the good interface between InSe and TCVA films, an increase in power efficiency conversion as the temperature of the photovoltaic cell increased, thereby, limiting the temperature range to between 303 and 373 K, TCVA/InSe cell showed a 157 at ±1 V rectification ratio and a nine-fold improvement in the conversion efficiency was observed. There is a need to further explore the use of nanostructured materials for PV cell, this is due to the undiscovered potentials that exist in the field of solar cells for energy generation and conversion (Tsakalakos, 2008).

Schematic layout of hybrid ITO/InSe/TCVA/Au solar cell. Adopted from Al Garni and Darwish (2017).

3.3 Electrocatalysis

Electrocatalysis mainly focuses on the electrochemical reactions between an electrolyte and an electrode at the interface (Groß, 2018), therefore, making electrocatalytic processes relevant technology in terms of sustainable future energy. The evolution of hydrogen via electrocatalytic water splitting is an important approach for the sustainability of hydrogen-based fuels; this is due to the possibility of hybridizing it with other renewable energy sources, such as wind, solar and biomass, just to mention a few, without compromising the high energy conversion efficiency of hydrogen (Ouchi and Henzie, 2017). Hydrogen has gained global interest due to its’ environmental-friendliness. In order to produce hydrogen fuel to a level of global resource, there is a need to introduce nanostructured-based materials. Of all the nanostructured materials, platinum (Pt) gives the most efficient result. The drawbacks of using Pt are scarcity and high cost, hence, these have led to the exploration of other metals, such as nickel (Ni), molybdenum (Mo) and Cobalt (Co), which happen to be of low-grade when compared with the Pt-based catalyst, as explained by Wang et al. (2018). The authors studied the use of alternative metals, e.g., ruthenium (Ru) to prepare hybrid of Ru and polyaniline (Ru-PAni) catalyst. Based on their result, it was reported that 2 wt% Ru loading, gave approximately 6.8 times better than the commercial 20 wt% Pt/C catalyst (where C is carbon).

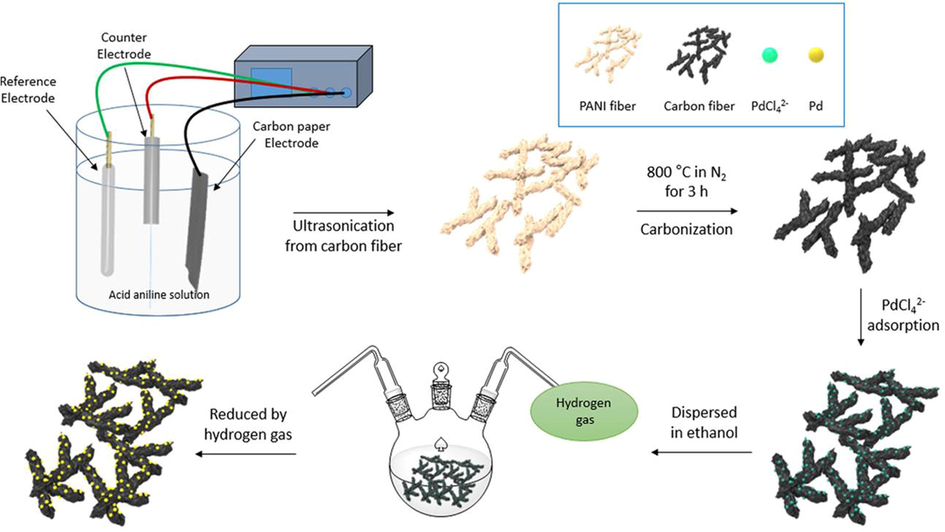

In a separate research conducted by Shim et al. (2018), the use of alternative metal, other than the high-cost platinum (Pt) for catalyst application was investigated. The noble metal considered was palladium (Pd), this is due to the low cost of the material and the growing interest for its’ various applications (gas sensors, energy storage and fuel cells) (Liang et al., 2013; Ye et al., 2016; Rajkumar et al., 2017). Fig. 6 shows the process of synthesizing Pd nanoparticle embedded N‐doped carbon fibers (Pd/N‐C), as prepared by Shim et al. by maintaining the Pd loading at 1.5 wt%. At the end of the experiment, hybrid Pd/N‐C-modified electrode displayed two dynamic ranges (of between 0.1–10 μm and 10–200 μm) and a detection limit of 29.44 ± 0.77 nm, making it a viable catalyst for electrochemical sensing.

Schematic diagram of synthesizing hybrid Pd/N‐C material. Adopted from Shim et al. (2018).

Another nanostructured-based material that has been used for catalyst applications in the past is metal/N-containing polymer composite (e.g. Fe-N-C catalyst). The use of carbon-based catalysts for oxygen reduction reaction (ORR) was also reported by Wang et al. (2015a,b). The proposed mechanism and approach used by the authors have opened up new possibilities for the development of sustainable carbon-based functional materials.

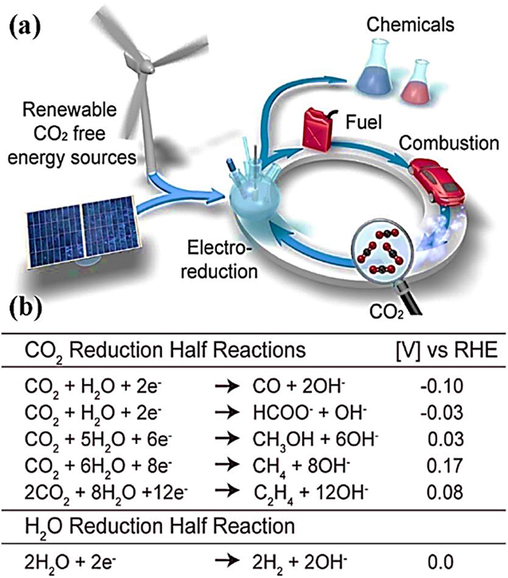

In other research work, nonprecious metal catalysts has been developed for electrochemical reduction of CO2 (Wang et al., 2015a,b; Alshammari et al., 2017). These kind of catalysts are categorise into five namely: organic frameworks, doped carbons, metal oxides and sulphides, partially oxidized metals and metals. Wang et al. (2016), explained how electrochemical reduction of CO2 is a valuable means of converting environmentally harmful CO2 into precious fuels. The authors further explained the importance of using this approach and it include: the rate of reaction is easily controllable, can be conducted below ambient conditions and total recycling of the supporting electrolytes is possible making the general chemical consumption to be minimized to water only. The energy input can be from renewable energy, therefore, water and CO2 are converted into industrial chemicals and fuels as shown in Fig. 7. There is the possibilities of the CO2 reduction reactions electron transfer to be 2, 6, 8 and 12 as represented in Fig. 7b. The product of these reactions are carbon monoxide (CO), methanol (CH3OH), formic acid (HCOOH), ethanol (CH3CH2OH), formaldehyde (HCHO), acetate (CH3COOH), methane (CH4), ethylene (CH2CH2), and many others. This process has the potentials of opening sustainable pathway for energy conversion and storage. Continued effort and extensive research in developing new and novel nonprecious nanostructured catalyst materials have shown great promises for future production of fuels and industrial chemicals through electrochemical CO2 reduction.

(a) Artificial way of recycling carbon powered by renewable electricity sources (solar and wind) and (b) Various representative of half reactions and reduction capability of CO2 reduction reactions, with that of the hydrogen evolution reaction. Adopted from Wang et al. (2016).

4 Conclusion

The energy sector has received a significant boost due to the development of new and novel materials from nanostructured and composites materials. Nanostructured materials have a way of meeting the requirements, which are unachievable by conventional materials that have been in use for several decades. This review presents an understanding of the importance of advanced materials in the present age and time. The development of novel materials is made possible by the current technological advancement in nanostructured and composite materials. The emergence of nanostructured and composite materials has resulted in great contributions towards attaining some strategic improvements in the energy industry and other fields, such as health, aerospace, automotive, construction, agriculture, environment, etc.

Several nanostructured materials, such as gold, silver, iron, platinum, palladium, nickel, ruthenium, tin, silicon, zirconium, etc. have been employed for various energy conversion and storage strategies. The essence of using these materials is due to the exceptional properties they can offer; properties, such as high thermal conductivity, high-strength-to-weight ratio, ability to work at extreme temperatures, good electrical conductivity, good insulation and low cost of certain nanoparticles. The use of nanostructured materials can improve the specific capacitance and capacitance retention rate of supercapacitors. Furthermore, the energy conversion efficiency of photovoltaic cells can be enhanced due to the presence of the nanostructured material.

The production of hydrogen fuel through a process known as electrocatalytic water splitting is a global focus. Nanostructured-based materials, e.g. platinum happens to be the most efficient catalyst, however, it has some drawbacks (i.e., high cost and scarcity). This review has highlighted on two materials (Ru and Pd) that can be used as a substitute for Pt. Continuous researches in this field will lead to the emergence of new, cost-effective and durable materials that have useful applications for energy generation/harvesting, conversion and storage.

Acknowledgments

The financial support from the Council for Scientific and Industrial Research (CSIR) and Department of Science and Technology (DST), South Africa under the umbrella of CSIR-BIS program is greatly appreciated.

References

- Photovoltaic performance of TCVA-InSe hybrid solar cells based on nanostructure films. Solar Energy Mater. Solar Cells. 2017;160:335-339.

- [Google Scholar]

- Development of microwave susceptors based on SiC composites and their application for a one-step synthesis of ZnO nanostructures. Ceram. Int.. 2018;44(7):7674-7682.

- [Google Scholar]

- Catalytic activity of bimetallic AuPd alloys supported MgO and MnO2 nanostructures and their role in selective aerobic oxidation of alcohols. J. King Saud Univ. Sci.. 2017;29(4):561-566.

- [Google Scholar]

- American-Elements. <https://www.americanelements.com/zirconium-nanoparticles-7440-67-7>. (accessed online 12.07.18).

- Prospects for nanostructured multiferroic composite materials. Scr. Mater.. 2014;74:38-43.

- [Google Scholar]

- Nanostructured (bio) sensors for smart agriculture. TrAC Trends Anal. Chem.. 2017;98:95-103.

- [Google Scholar]

- Supercapacitor behaviors of polyaniline/CuO, polypyrrole/CuO and PEDOT/CuO nanocomposites. Polym. Bull.. 2015;72:2573-2589.

- [Google Scholar]

- Polymer composite and nanocomposite dielectric materials for pulse power energy storage. Material. 2009;2:1697-1733.

- [Google Scholar]

- Nanostructured materials and nanoparticles for point of care (POC) medical biosensors. In: Medical Biosensors for Point of Care (POC) Applications. Elsevier; 2017. p. :229-254.

- [Google Scholar]

- High-performance nanostructured materials for construction. Spec. Publ. R. Soc. Chem.. 2004;292:215-226.

- [Google Scholar]

- Graphite felt as a versatile electrode material: properties, reaction environment, performance and applications. Electrochim. Acta. 2017;258:1115-1139.

- [Google Scholar]

- Characterization of platinum nanoparticles deposited on functionalized graphene sheets. Materials. 2015;8(9):6484-6497.

- [Google Scholar]

- Enhanced energy density of carbon-based supercapacitors using Cerium (III) sulphate as inorganic redox electrolyte. Electrochim. Acta. 2015;168:277-284.

- [Google Scholar]

- Electrical Technology. <https://www.electricaltechnology.org/2015/06/how-to-make-a-solar-cell-photovoltaic-cell.html>. (accessed online 16.03.18).

- Conversion of carbon dioxide into methanol–a potential liquid fuel: fundamental challenges and opportunities (a review) Renewable Sustainable Energy Rev.. 2014;31:221-257.

- [Google Scholar]

- Polymeric nanocomposites for automotive applications. Adv. Mater.. 2000;12:1835-1839.

- [Google Scholar]

- Nanostructured CuO/PANI composite as supercapacitor electrode material. Mater. Sci. Semicond. Proc.. 2015;30:157-161.

- [Google Scholar]

- Global Carbon Capture and Storage Institute LTD, 2014. Fossil Fuels Will Continue to Dominate Energy Consumption Patterns.

- Global Carbon Capture and Storage Institute LTD, 2014. Fossil Fuel Supply Remains Abundant.

- Computational modeling of electrocatalytic reactions. In: Wandelt K., ed. Encyclopedia of Interfacial Chemistry. Oxford: Elsevier; 2018.

- [Google Scholar]

- Microwave energy for mineral treatment processes—a brief review. Int. J. Miner. Process.. 1999;57:1-24.

- [Google Scholar]

- Fabrication of polypyrrole/chitosan nanocomposite aerogel monolith for removal of Cr (VI) J. Polym. Environ.. 2018;26:1979-1985.

- [Google Scholar]

- Fabrication of porous chitosan/hydroxyapatite nanocomposites: their mechanical and biological properties. Bio-Med. Mater. Eng.. 2009;19:133-140.

- [Google Scholar]

- Nanostructured materials: a progressive assessment and future direction for energy device applications. Coord. Chem. Rev.. 2017;353:113-141.

- [Google Scholar]

- High performance hybrid energy storage with potassium ferricyanide redox electrolyte. ACS Appl. Mater. interfaces. 2016;8:23676-23687.

- [Google Scholar]

- Powering the planet: chemical challenges in solar energy utilization. Proc. Natl. Acad. Sci. U.S.A.. 2006;103:15729-15735.

- [Google Scholar]

- Mesoporous metal–nitrogen-doped carbon electrocatalysts for highly efficient oxygen reduction reaction. J. Am. Chem. Soc.. 2013;135:16002-16005.

- [Google Scholar]

- SO2-tolerant Pt-MoO3/C catalyst for oxygen reduction reaction. J. Energy Chem.. 2014;23:358-362.

- [Google Scholar]

- Aligned carbon nanostructures based 3D electrodes for energy storage. J. Energy Chem.. 2015;24:559-586.

- [Google Scholar]

- 19 – use of nanostructured materials in implants. In: Narayan Roger, ed. Nanobiomaterials. Woodhead Publishing; 2018.

- [Google Scholar]

- Nanostructured materials for microwave receptors. Prog. Mater. Sci.. 2017;87:221-245.

- [Google Scholar]

- Citric acid and vitamin C as coupling agents for the surface coating of ZrO2 nanoparticles and their behavior on the optical, mechanical, and thermal properties of poly (vinyl alcohol) nanocomposite films. J. Polym. Environ. 2017:1-12.

- [Google Scholar]

- Nanocomposix-a. <https://nanocomposix.com/pages/gold-nanoparticles-physical-properties>. (accessed online 11.07.18).

- Nanocomposix-b. <https://nanocomposix.com/pages/silver-nanoparticles-physical-properties>. (accessed online 11.07.18).

- Synthetic biopolymer nanocomposites for tissue engineering scaffolds. Prog. Polym. Sci.. 2013;38:1487-1503.

- [Google Scholar]

- Size-dependent density of zirconia nanoparticles. Beilstein J. Nanotechnol.. 2015;6:27-35.

- [Google Scholar]

- Ouchi, K., Henzie, J. Hydrogen generation sailing ship: Conceptual design and feasibility study. OCEANS 2017-Aberdeen, 2017. IEEE, 1–5.

- Synthesis, structural, optical and dielectric properties of cadmium sulfide nanoparticles as photocathode for a solar cell. In: Recent Trends in Materials Science and Applications. Cham: Springer; 2017. p. :159-170.

- [Google Scholar]

- Facile and novel synthesis of palladium nanoparticles supported on a carbon aerogel for ultrasensitive electrochemical sensing of biomolecules. Nanoscale. 2017;9:6486-6496.

- [Google Scholar]

- Preparation of nano-PANI@ MnO2 by surface initiated polymerization method using as a nano-tubular electrode material: the amount effect of aniline on the microstructure and electrochemical performance. J. Energy Chem.. 2015;24:388-393.

- [Google Scholar]

- 2 – Bio-based nanostructured materials. In: Narayan R., ed. Nanobiomaterials. Woodhead Publishing; 2018.

- [Google Scholar]

- Recent trends on nanostructures based solar energy applications: a review. Rev. Adv. Mater. Sci.. 2013;34:44-61.

- [Google Scholar]

- degradation study of biobased polyester-polyurethane and its nanocomposite under natural soil burial, UV radiation and hydrolytic-salt water circumstances. J. Polym. Environ.. 2018;26:1528-1539.

- [Google Scholar]

- Electrochemical surface area measurements of platinum-and palladium-based nanoparticles. Electrochem. Commun.. 2013;31:46-48.

- [Google Scholar]

- Novel development of nanoparticles to bimetallic nanoparticles and their composites: a review. J. King Saud Univ. Sci.. 2019;31:257-269.

- [Google Scholar]

- Facile synthesis of palladium-nanoparticle-embedded n-doped carbon fibers for electrochemical sensing. ChemPlusChem. 2018;83:401-406.

- [Google Scholar]

- Sigma-Aldrich. <https://www.sigmaaldrich.com/technical-documents/articles/technology-spotlights/iron-oxide-nanoparticles-characteristics-and-applications.html>. (accessed online 12.07.18).

- Basic concepts and principles. In: Ferreira M., Leite F.D.L., Oliveira O.N., eds. Nanostructures. Elsevier; 2017. p. :1-32.

- [Google Scholar]

- Recent advances in MoS2 nanostructured materials for energy and environmental applications–a review. J. Solid State Chem.. 2017;252:43-71.

- [Google Scholar]

- Incorporation of ZnO and their composite nanostructured material into a cotton fabric platform for wearable device applications. Carbohy. Polym.. 2017;157:1801-1808.

- [Google Scholar]

- Morphologies and functionalities of polymeric nanocarriers as chemical tools for drug delivery: a review. J. King Saud Univ. Sci.. 2019;31:398-411.

- [Google Scholar]

- C and N hybrid coordination derived Co–C–N complex as a highly efficient electrocatalyst for hydrogen evolution reaction. J. Am. Chem. Soc.. 2015;137:15070-15073.

- [Google Scholar]

- Nanostructured nonprecious metal catalysts for electrochemical reduction of carbon dioxide. Nano Today. 2016;11(3):373-391.

- [Google Scholar]

- Gelatin-derived sustainable carbon-based functional materials for energy conversion and storage with controllability of structure and component. Sci. Adv.. 2015;1(1):e1400035

- [Google Scholar]

- Spatially confined assembly of monodisperse ruthenium nanoclusters in a hierarchically ordered carbon electrode for efficient hydrogen evolution. Angew. Chem. Int. Ed.. 2018;57:5848-5852.

- [Google Scholar]

- Nanostructured Co–W coatings produced by electrodeposition to replace hard Cr on aerospace components. Trans. IMF. 2010;88:47-56.

- [Google Scholar]

- Facile synthesis of palladium nanodendrites supported on graphene nanoplatelets: an efficient catalyst for low overpotentials in lithium–oxygen batteries. J. Mater. Chem. A. 2016;4:578-586.

- [Google Scholar]