Translate this page into:

Potential application of bamboo powder in PBS bamboo plastic composites

⁎Corresponding author. yhq0373342@163.com (Hongqi Yang)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Biodegradable composites were prepared by adding ZnO, Si3N4, and bamboo charcoal (BC) based on biodegradable plastic Poly (butylene succinate) (PBS). The results show that different filling rates have an effect on the mechanical properties of the composites. When the bamboo powder filling amount reaches 40%, the mechanical properties of the composite material are the best. Overall, The mechanical and chemical structure as well as the thermal data showed that the best condition for the production of decayed wood plastic composite was 150 °C for 10 min, while TiO2, Si3N4, and BC accounting for 3%, 3%, and 5% of PBS weight, respectively, and the proportions of bamboo powder and PBS of 40% and 60%. The most important thing is that TD-GC–MS found that the composite has less organic volatiles, indicating that it is a green and healthy composite.

Keywords

Bamboo plastic composites

Si3N4

Chemical structure

Thermal properties

Biodegradable

1. Introduction

Bamboo Plastic Composites (BPC) are a new type of composite made by mixing and forming bamboo sawdust, bamboo or bamboo residue, and other fibers as the main raw material at high temperature, mixed with molten thermoplastic resin (mainly PE, PP, and PVC) (Jeanette and Laurent 2005; Stark, 2006). As a new type of polymer material, plastic products are widely used, due to their small weight, ease of processing, beauty, and practicality. Plastic products add convenience to people's lifes; however, the production of its waste has caused severe environmental pollution (Shen et al., 2017). Poly (butylene succinate), is a fully biodegradable polymer material with good biocompatibility and bioadsorption (Mi et al., 2015; Koronis et al., 2013). At present, a large number of studies focus on the modification of traditional plastics, and relatively few studies focus on the modification of PBS. China is the center of bamboo cultivation and China’s bamboo area accounts for 47% of the national bamboo forest area. 85% of the world's bamboo is mainly distributed in Hunan, Jiangxi, Fujian, and other places, providing the fastest growing and best material, with the most uses and the largest economic value.

It remains a major problem to combine the two different polar materials in the field of BPC. Among these, bamboo fibers are the reinforcing material, and resin is the matrix material. The interface compatibility between the bamboo fiber and the thermoplastic resin is an important issue in the development of BPC. At present, researchers have tried to explore the interface combination of PVC wood-plastic composites with several new modifiers. Jiang and Kamdem (2004) treated the bamboo fiber with ethanolamine solution to prepare the PVC/wood fiber composite material. The research results showed that the adhesion between the two phases is strong. Natural chitosan is the second largest biomass resource in the world and has a very similar chemical structure to lignocellulose. It is the only natural alkaline polysaccharide found in humans so far. It is also a strong Lewis basic electrolyte with good physical and mechanical properties, biocompatibility, and biodegradability (Rinaudo, 2006; Xu et al., 2014).

In this study, the fiber “cellulose” and the animal fiber “chitosan” are distributed in the PBS, either crossed with each other or randomly, and in addition to the conventional polymer chain entanglement and physical interface combination. The development of high performance bamboo plastic composites can provide the foundation for the further expansion of a more widespread and more advanced application of the material, based on the improvement of the acid-base interaction between PBS and cellulose. It is of great theoretical significance and academic value to study the optimization of chitosan/cellulose/PBS composite process and the mechanism of network-like hinge bonding. Therefore, due to the technical defects existing in the bamboo plastic composite material, this study chooses the most representative chitosan as the compatilizer, and investigates the effect of ZnO, TiO2, and Si3N4 on the BPC by using bamboo powder and PBS as raw materials, while exploring the mechanism of chitosan action on the bamboo plastic interface. This will provide basic theory and technical support for the solution of quality defects of bamboo plastic composite materials and will aid the development of high performance interface compatible bamboo plastic composite products (Yang et al., 2017). Therefore, this has important theoretical research value and practical significance.

2. Material and methods

2.1. Experimental materials

The bamboo powder was air dried and crushed into 40–80 mesh. Chemicals include: ZnO, TiO2, Si3N4, and PBS.

2.2. Experimental methods

Mold Pressing: 150 °C, 10 min, and 8–10 MPa. The PBS samples were prepared for the following tests (Table 1).

Samples

Bamboo powder (%)

PBS (%)

ZnO (%PBS)

TiO2 (%PBS)

Si3N4 (%PBS)

BC (%PBS)

Y1

40

60

5

Y2

40

60

1

5

Y3

40

60

3

5

Y4

40

60

5

5

Y5

40

60

1

5

Y6

40

60

3

5

Y7

40

60

5

5

Y8

40

60

1

5

Y9

40

60

3

5

Y10

40

60

5

5

Y11

40

60

3

3

5

Y12

40

60

3

3

5

Y13

40

60

3

3

5

Y14

40

60

3

3

3

5

Performance analysis: Mechanical Properties Analysis (GB/T17657-2013 and GB/T1040.5-2008), X-ray diffractometry (XRD, General Analysis, Beijing General Instrument Co., Ltd., Beijing, China), Fourier transforminfrared spectroscopy (FT-IR, IR100), thermogravimetric analysis (TGA, 209-F1 TG, Netzsch, Germany), and thermal desorption-gas chromatography-mass spectrometry (TDS-GC–MS, DANI Co., Ltd., Italy) (Jiang et al., 2017; Peng et al., 2014).

3. Results and discussion

3.1. Analysis of mechanical properties

The measured results are listed in Table 2. The result show that mechanical properties of the samples changed significantly after mixing with different proportions of bamboo powder, PBS, ZnO, TiO2, Si3N4, and BC. Compared to the samples, Y1, Y2, Y3, and Y4, with the addition of ZnO, the failing load, MOR, MOE, and tensile strength of the composites increased and then decreased. When the ZnO accounting for 1% of the PBS weight, the physical and mechanical properties of BPC achieved the best condition. The chemical bonds between ZnO and PBS improve the interface bonding between ZnO and PBS and facilitate the transmission of stress; however, due to the increasing amount of ZnO, the aggregation phenomenon increases, and the dispersion becomes worse, therefore reducing the tensile strength and bending strength of the composite material. The composite materials have a good mechanical property when adding TiO2 (5%) or Si3N4 (3%). The best hot pressing process is 150 °C for 10 min, TiO2 and Si3N4 accounting for 3% and 3% of PBS, and the proportion of bamboo powder and PBS is 40% and 60%, respectively. This is mainly because TiO2 has an enhancement effect in BPC, while TiO2 can be evenly distributed in BPC. When the composite is subjected to external forces, TiO2 can effectively prevent material breakage. However, a better chemical connection exists between Si3N4 and PBS, thus improving the compatibility of composite materials, so that the physical properties of composite materials increase.

Samples

Failing load (N)

MOR (MPa)

MOE (MPa)

Tensile strength (MPa)

Y1

129

30.68

2397

10.659

Y2

139

33.06

2519

10.693

Y3

115

27.35

2222

8.615

Y4

125.5

29.85

2650

10.22

Y5

128.5

30.56

2366

11.115

Y6

133.5

34.06

2862

13.844

Y7

149.5

38.14

3163

11.651

Y8

139.5

35.59

2813

11.886

Y9

158

40.31

2906

12.923

Y10

148.5

37.88

3188

12.081

Y11

122

31.12

2517

8.028

Y12

160.5

40.94

3192

13.746

Y13

147.5

37.63

3294

9.961

Y14

143

36.48

3343

13.455

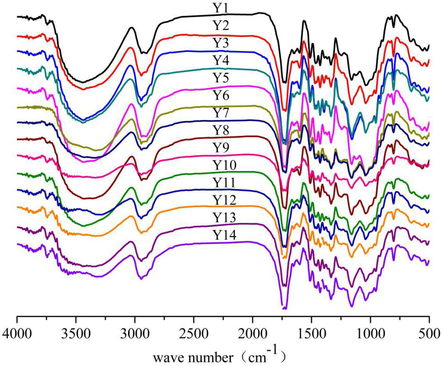

3.2. Analysis of FT-IR

The spectra of the 14 samples listed above are shown in Fig. 1. For PBS composites, the absorption peaks observed at 2951 cm−1 and 2907 cm−1 were ascribed to the C–H asymmetric stretching vibration in the CH3 group (Ranzieri et al., 2007). At 3043 cm−1, the absorption peak was the C–H stretching vibration of alkene. Meanwhile, the absorption peak at 2851 cm−1, 1384 cm−1 and were attributed to the C–H symmetric stretching vibration of CH3 group (Jiang et al., 2018a,b). At 1455 cm−1, the absorption peak represented the C–H asymmetric bending vibration in the CH3 group. At 724 cm−1, the absorption peak was the in-plane rocking vibration of CH2 group. Region at 3100–3000 cm−1, 1600–1450 cm−1, 860–680 cm−1 were the C–H stretching vibration (Zhang et al., 2015). The broad and medium intensity peak at 961 cm−1 is attributed to the –C–OH bonding of carboxylic groups in PBS. Stretching vibration of ester carbonyl (>C⚌O) groups was observed at 1723 cm−1. The band at 1042 cm−1 corresponds to the –O–C–C– stretching vibration of PBS (Priftis et al., 2009). In PBS, methyl and methylene C–H stretching bands occur at 2956 and 2835 cm−1, respectively (Zhang et al., 2015). At 1660–1628 cm−1, strong hydrogen bonds are formed between composites (Jiang et al., 2018a,b). When ZnO, TiO2, and Si3N4 were added to BPC, the absorption peaks in the remaining ranges were not significantly different from those without ZnO, TiO2, and Si3N4, except for 3039–2868 cm−1 and 1858–1673 cm−1.

FT-IR spectra of PBS Bamboo Plastic composites.

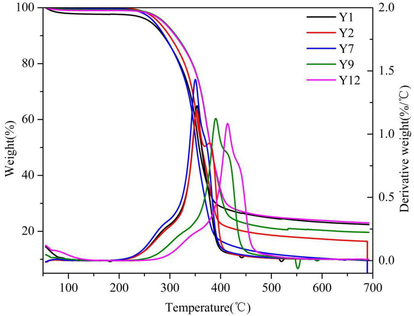

3.3. Analysis of TGA and DTG

The thermal stability of BPC determined its flame retardant properties to a large extent (Liu et al., 2016). Fig. 2 presents the thermogravimetric (TG) and derivative thermogravimetric (DTG) curves (100–700 °C). From the Fig. 2, the samples Y1, Y2, Y7, Y9, and Y12, each group TGA curve were almost the same for all samples, with minor difference. The curves have a long and gentle period, and the maximum heat loss temperature were 353 °C, 352 °C, 350 °C, 390 °C, and 413 °C, respectively. At 700 °C, the mass loss was 78.4%, 83.6%, 90.5%, 80.5%, and 77.8% for the Y1, Y2, Y7, Y9, and Y12 samples, respectively. At 100 °C, the mass loss was 2.1%, 0.1%, 0.5%, 1%, and 1% for the Y1, Y2, Y7, Y9, and Y12 samples, respectively, the mass loss is small, which indicates that the initial decomposition temperature of the material and good heat resistance. This is mainly because hydrogen bonds have a strong affinity, which reduces movement of the polymer chains near the interface (Wen et al., 2014).

TGA and DTG thermal curves of PBS bamboo plastic composites.

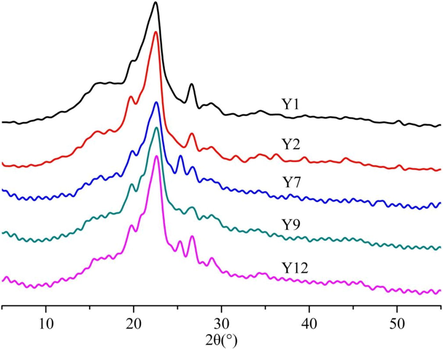

3.4. Analysis of XRD

The X-ray diffraction pattern of the PBS bamboo plastic composites is shown in Fig. 3. The diffraction pattern of each sample shows three strong diffraction peaks at 2θ = 19.5°, 21.9°, and 22.6°, respectively. The XRD curve is basically consistent, indicating that the crystal structure of PBS did not change with the increase of the ZnO, TiO2, and Si3N4 and BC. After adding ZnO, TiO2, and Si3N4, the crystallinity of the composites was significantly reduced. It may be that the ZnO, TiO2, Si3N4, PBS, and bamboo powder formed a strong interfacial bonding force. The motion and rearrangement of PBS polymer chains have been hindered, which has greatly changed the crystallinity and crystal structure of PBS. The changes of crystallization properties showed that the compound use of TiO2 and Si3N4 improved the compatibility between PBS and bamboo powder. In addition, the important crystal diffraction peaks have the same shape and position, indicating no chemical change between PBS and TiO2 and Si3N4.

XRD test result spectrum of PBS bamboo plastic composites.

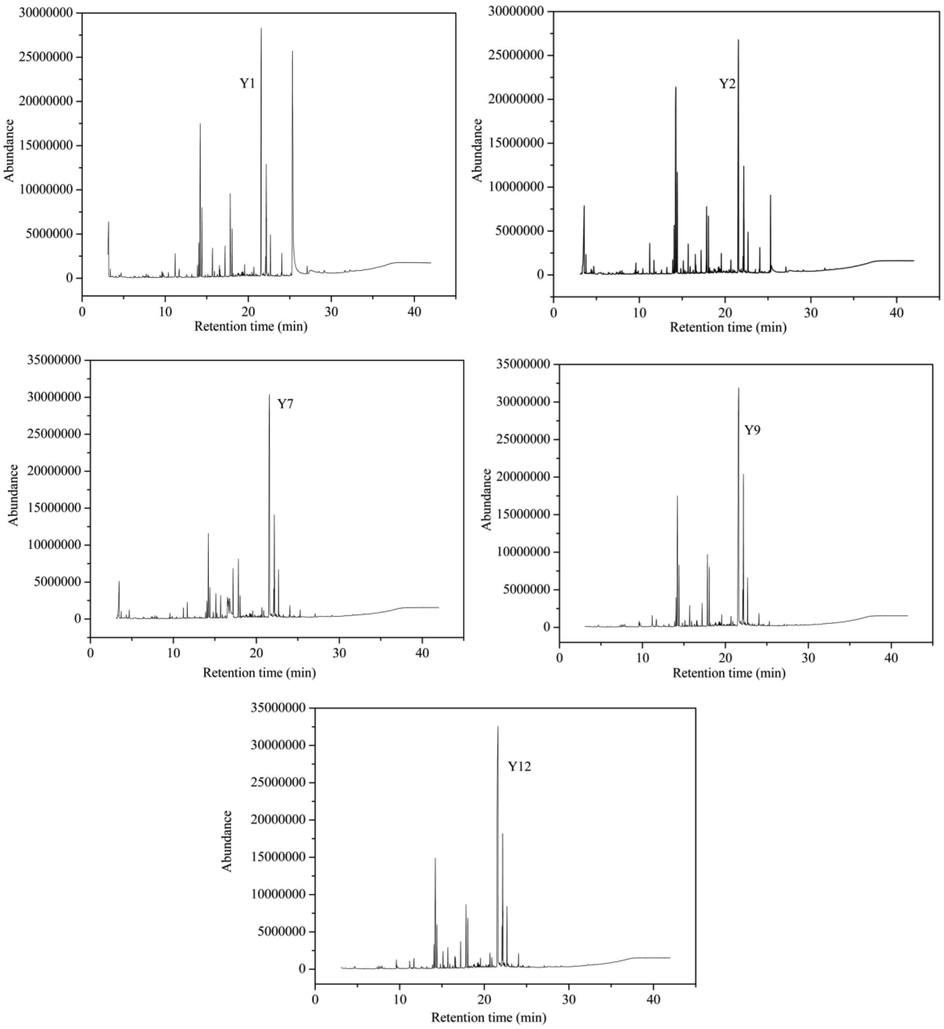

3.5. Analysis of TDS-GC–MS

The total ion chromatograms of Y1, Y2, Y7, Y9, and Y12 PBS Bamboo Plastic composites are shown in Fig. 4. The results of TDS-GC–MS analysis, 31 chemical constituents were identified in 49 peaks of Y1 volatiles; 3 chemical constituents were identified in 79 peaks of Y2 volatiles; 32 chemical constituents were identified in 55 peaks of Y7 volatiles; 27 chemical constituents were identified in 34 peaks of Y9 volatiles; 26 chemical constituents were identified in 36 peaks of Y12 volatiles. TDS-GC–MS analysis showed a specific trend in the retention time of the different components of the PBS composite, suggesting that the 120 °C volatiles of the PBS composite included acetic acid, phenol and its derivatives, and benzene and its derivatives, which inhibit fungal growth. This suggests that PBS composites at 150 °C, 12 min, showed the least toxic components. In all, there are many hydrocarbons and lipid compounds in the organic volatiles of PBS Bamboo Plastic composites with less toxic components, which was a relatively new type of green and healthy composite material.

Total ion chromatogram of Y1, Y2, Y7, Y9, and Y12 PBS bamboo plastic composites.

After mixing bamboo powder, PBS, ZnO, TiO2, Si3N4, and bamboo charcoal (BC), the mechanical properties of the samples changed significantly. Consequently, the composite materials have a good mechanical property when adding Si3N4 and bamboo charcoal (BC). When TiO2, Si3N4, and BC are used together, the composite properties exert a strong effect on the composite properties. FT-IR and XRD analysis showed that PBS and bamboo powder can form strong hydrogen bonds, C–O, C⚌O, and O–C–O when adding ZnO, TiO2, Si3N4, and BC. TGA and DTG analysis showed significantly enhanced composite thermal stability after adding Si3N4. The TDS-GC–MS show that there are many hydrocarbons and lipid compounds in the organic volatiles of PBS Bamboo Plastic composites with less toxic components, which was a relatively new type of green and healthy composite material.

Acknowledgments

This research was supported by the Planned Science and Technology Project of Hunan Province, China (No. 2016SK2089; No. 2016RS2011), Major scientific and technological achievements transformation projects of strategic emerging industries in Hunan Province (2016GK4045), Academician reserve personnel training plan of lift engineering technical personnel of Hunan Science and Technology Association (2017TJ-Y10).

Declaration of Competing Interest

All the authors hereby agreed and confirm that there is no conflict of interest for this research work and publication of this paper.

References

- Durability of wood flour-plastic composites exposed to accelerated freeze-thaw cycling part I. Rigid PVC matrix. Vinyl Addit. Technol.. 2005;11:1-8.

- [Google Scholar]

- Development of poly (vinyl chloride)/wood composites. A literature review. J. Vinyl Addit. Technol.. 2004;10:59-69.

- [Google Scholar]

- Molecules and functions of rosewood: dalbergia stevenson. Arab. J. Chem.. 2018;11:782-792.

- [Google Scholar]

- Treating n-butane by activated carbon and metal oxides. Toxicol. Environ. Chem. 2017:1-12.

- [Google Scholar]

- Preparation and properties of novel flame-retardant pbs wood-plastic composites. Arab. J. Chem.. 2018;11:844-857.

- [Google Scholar]

- Green composites: A review of adequate materials for automotive applications. Compos. B Eng.. 2013;44:120-127.

- [Google Scholar]

- Fabrication of green lignin-based flame retardants for enhancing the thermal and fire retardancy properties of polypropylene/wood composites. ACS Sustain. Chem. Eng.. 2016;4

- [Google Scholar]

- Ship identification algorithm based on 3d point cloud for automated ship loaders. J. Coastal Res. 2015:28-34.

- [Google Scholar]

- Immune effects of extractives on bamboo biomass self-plasticization. Pakistan J. Pharm. Sci.. 2014;27:991-999.

- [Google Scholar]

- Surface-initiated titanium-mediated coordination polymerization from catalyst-functionalized single and multiwalled Carbon Nanotubes. Macromolecules. 2009;42:3340.

- [Google Scholar]

- Charge-sensitive vibrations in\r, p\r, -Chloranil:? The strange case of the cc antisymmetric stretching. J. Phys. Chem. B. 2007;111:12844-12848.

- [Google Scholar]

- Chitin and chitosan-properties and applications. Prog. Polym. Sci.. 2006;31:603-632.

- [Google Scholar]

- A deep q-learning network for ship stowage planning problem. Polish Maritime Res.. 2017;24:102-109.

- [Google Scholar]

- Effect of weathering cycle and manufacturing method on performance of wood flour and high density polyethylene composites. Appl. Polymer Sci.. 2006;100:3131-3140.

- [Google Scholar]

- Understanding the chemical and structural transformations of lignin macromolecule during torrefaction. Appl. Energy. 2014;121:1-9.

- [Google Scholar]

- Effects of chitosan as biopolymer coupling agent on the thermal and rheological properties of polyvinyl chloride/wood flour composites. Compos. B Eng.. 2014;58:392-399.

- [Google Scholar]

- Synthesis and comparison of photocatalytic properties for bi2wo6 nanofibers and hierarchical microspheres. J. Alloy. Compd.. 2017;695:915-921.

- [Google Scholar]

- Synthesis of zinc phosphonated poly (ethylene imine) and its fire retardant effect in low density polyethylene. Ind. Eng. Chem. Res.. 2015;54:3247-3256.

- [Google Scholar]