Translate this page into:

Impact of olive oil and potassium carbonate pretreatment on physico-chemical properties of sun-dried Sundar Khani raisins (Vitis vinifera L.)

⁎Corresponding authors. naila.ali@imbb.uol.edu.pk (Naila Ali), zaib.nisa@imbb.uol.edu.pk (Zaib-un Nisa)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Sundar Khani is native grape variety of Pakistan which has long berry length and significantly rich in taste and sweetness. There is limited literature on pretreatment and drying data for this valuable variety of Grapes. Current study was conducted to investigate the physio-chemical indices of potassium carbonate (K2CO3) and olive oil combined treatments followed by natural sun drying method. The effects of 2 % K2CO3 pretreatments alone and in combination with various amounts of pure olive oil (1 %, 2 %, and 3 %) were studied. The results showed that, physical attributes like raisin length, width, volume, weight and total replication weight increased under distilled water treatment, while, combination of 2 % K2CO3 + 3 % Olive oil significantly reduced the drying time, 2 % K2CO3 + 1 % Olive oil gave higher final yield, rehydration ratio was highest under dH2O treatment and greater decay loss was observed at 2 %K2CO3 + 2 % olive oil. Further, 2 % K2CO3 displayed higher ratios of total soluble solids, sugars and peroxidase enzyme activity as well as titratable acidity, anthocyanins, total phenols, flavonoids were maximum at 2 % K2CO3 + 2 % Olive oil pretreatment. In addition, 2 % K2CO3 + 3 % Olive oil increased the Catalase enzyme activity as well as achieved higher scores in the evaluation of sensory attributes particularly morphological form, color and overall acceptance. This study aimed to investigate the physicochemical indices of Sundar Khani grapes under different pretreatment and sun-drying conditions using K2CO3 and olive oil and it could be suggested that raisin production of Sundar Khani by using above mentioned treatments along with sun drying could have future scope both in export and industrial markets due to its incredible reduction in drying and processing time.

Keywords

Grapes

Physical

Biochemical

Drying

Sensory

Cultivar

1 Introduction

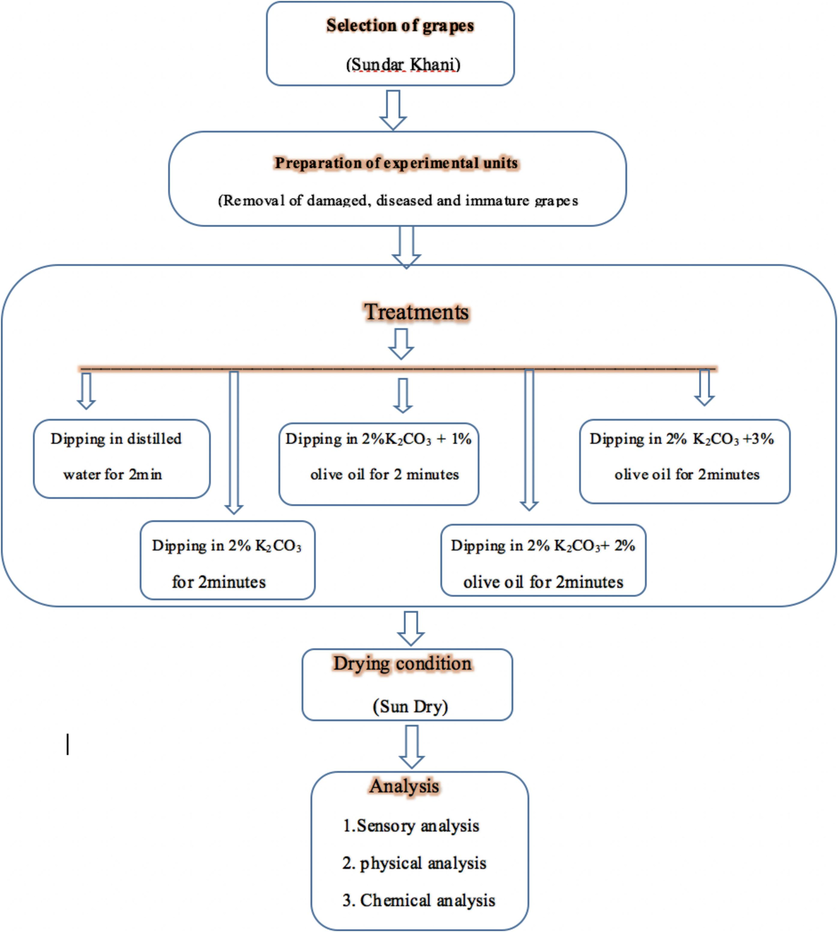

The production of fruit-derived snacks are of great interest globally due to increasing number of users which seeks for latest food products with enhanced nutritious value and functional properties of compounds in current global market (Tylewicz et al., 2020; Zyzelewicz et al., 2021). In this regard, Grapes dried Raisins have remarkably higher concentrations of phenolic compounds such as flavonoids and phenolic acids exhibiting strong antioxidant properties, micronutrients such as carbohydrates including glucose and fructose and minerals such as potassium, magnesium and iron (Thiruchelvi et al., 2020). Grapes contain large amount of phenolic compounds exhibiting antimicrobial properties (Ali et al., 2019) and grape derived-Raisins are rich in nutrition, and they can be blended into other foods to boost their flavor and nutritional value (Wang et al., 2021). Generally, raisin production process comprised of three stages, named as pretreatment, drying and post drying. The drying process is of significant importance to enhance or reduce the raisin quality due to their direct effects on drying duration, sugar concentration and antioxidant enzyme activities (Sabra et al., 2020). The grape drying process can be achieved by different traditional approaches such as shade drying or sun drying as well as through modern approaches such as hot air drying, shielding film drying, vacuum drying and microwave drying, product quality is different with different drying methods, although moderm methods provide more precise control over conditions that help in retaining more nutrients as compared to the traditional methods (Chang et al., 2016; Thiruchelvi et al., 2020; Olmo-Cunillera et al., 2020). Drying is a method for reducing moisture levels. This is good for grape preservation because it minimizes the possibility of microbial development, reduces enzymatic breakdown and also removes the moisture-mediated adverse responses. Therefore, drying Grapes reduces the chance of spoiling the fruit and increase the consumption life (Bhandari, 2015; Xiao, 2015). Sun drying along with chemical dipping has been practiced in Turkey while mechanical drying commonly practice in US (Doymaz, 2006; Wang et al., 2021).Fig. 1.Table 1..

The schematic presentation of raisin treatment and production process.

Treatments

Applications

Distilled water

Potassium carbonate

Olive oil

T0D1

Distilled water

0 % K2CO3

0 % olive oil

T1D1

Distilled water

2 % K2CO3

0 % olive oil

T2D1

Distilled water

2 % K2CO3

1 % olive oil

T3D1

Distilled water

2 % K2CO3

2 % olive oil

T4D1

Distilled water

2 % K2CO3

3 % olive oil

Direct drying of fresh Grapes is not commonly used due to the presence of a waxy skin layer that makes it difficult to remove water (Adiletta et al., 2016). Pretreatments remove this waxy layer ensuring maximum water removal thus, enhancing the efficacy of the drying process. This not only reduces energy consumption but also increases the quality preservation of the final product, such as antioxidant retention during drying (Farias et al., 2020). According to certain research, the drying process increases the sugar concentration in Grapes (Franco et al., 2004). As a result, there is a considerable improvement in the fiber content, nutrient composition, antioxidant activity, and total phenolic compounds in Raisins compared with fresh fruit (Sério et al., 2014). Pretreatments for fruit drying process include hot water dipping or by using chemicals like sulphur, potassium metabisulfide (KMS), potassium hydroxide (KOH), sodium hydroxide (NaOH), potassium carbonate (K2CO3), and ethyl or methyl oleate emulsions to speed up drying and enhance product colour (Shi et al., 2008). In recent study, K2CO3 was used along with olive oil and ethyl oleate in hot water under three different drying ways solar tunnel dryer, cabinet tray dryer and natural sun drying. Grape berries pretreatment with ethyl oleate and K2CO3 took less time to dry as compared to sun drying with no pretreatment (Shafiq et al., 2022)).

In Pakistan, the northern districts of Punjab, Baluchistan, and KPK have greater grape diversity and have been farmed on an area of 15,000 ha with a production of 643 thousand tons (GOP, 2013). However, all of these areas required characterisation for optimal manufacturing (Sajid and Ahmed, 2008). The Potohar area of Punjab province is becoming well-known for commercial production of Grapes' early maturity genotypes due to the region's favorable temperature conditions. The contribution of Pakistan in global grape production is less than 1 % showing a significant room for growth of this valuable crop if modern agricultural, post-harvest handling and advanced drying methods are used (Akram et al., 2019; Olmo-Cunillera et al., 2020). There are number of reports available in literature regarding pretreatments and drying methods from Indian, Chinese and Turkiye Grapes cultivars. However, there is limited literature on Grapes cultivars from Pakistan in terms of standardizing pretreatment and drying conditions. this study aimed to investigate the physicochemical characteristics and sensory attributes of sun-dried Sundar Khani Grapes pretreated with olive oil and K2CO3 solutions. A novel aspect of this study is a comprehensive analysis of combined effect of potassium carbonate and olive oil solutions on this unique underexplored Sundar Khani variety of grapes, offering potential for enhanced market appeal and export opportunities.

2 Methodology

2.1 Experiment Location

The present study was led at the General Botany Laboratory of the Institute of Molecular Biology and Biotechnology, University of Lahore in summer 2022. Grape cultivar Sundar Khani was used in this study.

2.2 Pre-drying treatment of Grapes

The Grapes (Sundar Khani) were purchased from local market and screened appropriately on the basis of uniform size and color, healthy skin, absence of any physical damage and firmness in the laboratory prior the experiment in August 2022.To ensure the quality of the berries, any cracked, ill, malformed, or discolored ones were carefully sorted out and discarded. Additionally, to remove any dust or irrelevant berry that may have been stuck to the berries, they were thoroughly rinsed with water. The five treatments included dipping Grapes in distilled water, 2 % K2CO3 solution, and combinations of 2 % K2CO3 with 1 %, 2 %, and 3 % pure olive oil. Each treatment repeated in three replications on 1.5 kg sample size per replication. Washed and air-dried fresh Grapes were dipped in the solutions for 2 min. Open-air sun drying experiments were carried out during August and September 2022 with temperature ranges from 24.9 to 35.5 °C, average humidity was from 40-56 %, average dew points 15.8–21.5, total sun hours 372–413 h and this meterological data optimize the drying conditions to achieve best balance between efficacy, cost and product quality. The experimentation was performed in a Completely Randomized Design (CRD) on top roof to maximize exposure to direct solar radiation.

2.3 Determination of raisin physical attributes

Various physical parameters such as raisin length, raisin width, raisin volume, raisin weight, drying time, final yield, rehydration ratio (RR), decay loss %, were recorded. The length and width of raisin was recorded with the help of Vernier caliper. The volume of Raisins was recorded by using water displacement method (Costa et al., 2016) and results calculated by using formula.

Volume = initial value – final value.

Following forumula was used to calculate RR given by Lokhande et al. (2017) The decay loss was calculated as followed by Hakimi et al. (2021). The weight of spoiled Raisins due to fungus attack or other environment conditions, was noted to calculated the decay loss after raisin production by using following formula.

2.4 Measurement of biochemical attributes

Total soluble solids (Brix %) were determined by using Abbe refractometer (Abbe bench refractometer, 2WAJ). pH was recorded by using pH meter (Digital pH meter − “pH-2005″ − JP Selecta). Titratable acidity was studied by using the visual titration technique given by Ranganna (1986). The acidity was calculated by using the following formula Raisins were analyzed for sugars, reducing and non-reducing sugars using the Lane and Eyon method (Ranganna, 1977). The total phenolic content in the samples was determined using the calibration curve of Gallic Acid as described by Savitri et al. (2019). For Flavonoid estimation, the calibration curve of Quercetin was employed. Anthocyanin content was assessed following the method outlined by Srivastava et al. (2012). Catalase activity was examined using the method proposed by Chance and Maehly (1955), while Peroxidase activity was determined using the method proposed by Kuroda et al. (1990).

2.5 Sensory examination

A sensory evaluation test of Raisins was performed at the Department of Botany, The University of Lahore, Punjab by using a 5-point Hedonic scale. The panel consisted of 12 semi-trained participants, both male and female, aged between 22 to 40 years. The sensory qualities assessed included appearance, color, texture, taste, flavor, and general acceptability of the Raisins. A questionnaire and the five-point hedonic scale test were utilized for the evaluation process.

2.6 Statistical exploration

The data was evaluated through a computer-based software (statistix 8.1) using one-way ANOVA (Analysis of Variance) which is commonly used in comparing means of more than two treatments and probability were checked by Tukey’s HSD(Honest Significant Difference) test to make pairwise comparison betweent he means.

3 Results

3.1 Physical parameters

This experiment was planned to evaluate the individual and combine effects of pretreatments with K2CO3 and olive oil on the physical attributes of dried Grapes berries (Sundar Khani). Different parameters such as length, width, volume, weight of single berry, total weight of whole sample, drying time, final yield, rehydration ratio, final yield and decay loass of dried Raisins were determined (Table. 2a, b). The result showed that, T0D1 (dH2O) displayed higher values of raisin length, width, volume, weight of one raisin and total weight of whole sample of Raisins as compared to other treatments. Whereas, among other treatments, maximum raisin length was exhibited when treated with 2 % K2CO3, width, weight of single raisin and total weight of sample was maximum when treated with 2 % K2CO3 solution and 1 % olive oil, while the maximum volume of the Raisins was observed after the pretreatment of 2 % K2CO3 solution in combination with 3 % olive oil (Table 2a). Reduction in drying time was observed in raisings when treated with 2 % K2CO3 and 3 % olive oil by 62 % on the combine effects of pretreatments with K2CO3 and olive oil on the physio-chemical attributes of dried Grapes berries (Sundar Khani). Similarly, an increase 25 % in final yield was observed when Grapes were pretreated with 2 % K2CO3 and 1 % olive oil as compared to the Raisins produced without pretreatment. With regard to rehydration ration Raisins produced after treating with 2 % K2CO3 in combination with 2 % olive oil exhibited 8 % improvement in percent rehydration ratio, whereas, 100 % less decay loss has been observed in the Raisins produced when pretreated with 2 % K2CO3 and dried under sun (Table 2b). Each value is a mean of triplicates; values sharing different alphabetic letters indicate significant differences (P ≤ 0.05) among treatments; *, ** and *** indicate significance at P ≤ 0.05, P ≤ 0.01 and P ≤ 0.001, respectively; ns indicates non-significant differences. (T0D1; dH2O, T1D1; dH2O + 2 %K2CO3, T2D1; dH2O + 2 %K2CO3 + 1 % Olive Oil, T3D1; dH2O + 2 %K2CO3 + 2 % Olive Oil, T4D1; dH2O + 2 %K2CO3 + 3 % Olive Oil). Each value is a mean of triplicates; values sharing different alphabetic letters indicate significant differences (P ≤ 0.05) among treatments; *, ** and *** indicate significance at P ≤ 0.05, P ≤ 0.01 and P ≤ 0.001, respectively; ns indicates non-significant differences. (T0D1; dH2O, T1D1; dH2O + 2 %K2CO3, T2D1; dH2O + 2 %K2CO3 + 1 % Olive Oil, T3D1; dH2O + 2 %K2CO3 + 2 % Olive Oil, T4D1; dH2O + 2 %K2CO3 + 3 % Olive Oil).

Treatments

Length

(cm)Width

(cm)Volume

(cm3)Weight

(g)Total weight

(g)

T0D1

1.80a

0.87a

0.53a

0.60a

132.66a

T1D1

1.69b

0.71c

0.44b

0.53b

125.66b

T2D1

1.68b

0.83ab

0.46b

0.56ab

129.33ab

T3D1

1.62bc

0.79b

0.45b

0.46c

124.33c

T4D1

1.55c

0.80b

0.48ab

0.44c

126.00b

ANOVA (F Value)

Treatments

***

***

***

***

***

Treatments

Drying time (hrs)

Final yield (%)

Rehydration ratio (%)

Decay loss (%)

T0D1

569.00a

24.93c

0.80a

2.683a

T1D1

539.33ab

25.16bc

0.79b

0.000

T2D1

219.00c

26.53a

0.73c

0.149c

T3D1

336.00b

25.90ab

0.73c

1.669b

T4D1

213.33bc

25.20bc

0.78bc

1.913ab

ANOVA (F Value)

Treatments

***

***

ns

***

3.2 Biochemical parameters

An interactive effect of pretreatment of 2 % K2CO3 with different concentrations of olive oil has been studied (Table 3). It was observed that gradual decrease in total soluble solids (TSS) and pH has been observed and maximum 3 % and 9 % reduction has been exhibited, respectively, after 2 % K2CO3 and 2 % olive oil pretreatment as compared to control sample. A gradual reduction in pH of the raisin pulp has also been observed and 9 % decrease in pH has been observed in pretreated Raisins with 2 % K2CO3 and 1 % olive oil. Highest titratable acidity (36 %) has been noted in the Raisins produced after 2 % K2CO3 and 2 % olive oil pretreatment, however increase in all pretreated samples of Raisins has been observed as compared to non-treated control samples. Total soluble sugars, reducing and non-reducing sugars has also been determined in this study. An increasing trend was observed during the experiment regarding these attributes in the retreated samples as compared to non-treated samples of Raisins, an increase of 2 %, 9 % and 56 % improvement in total soluble sugars, reducing and non-reducing sugars has been observed, respectively, in Raisins produced after the pretreatment of 2 % K2CO3 as compared to non-treated raisin samples. Each value is a mean of triplicates; values sharing different alphabetic letters indicate significant differences (P ≤ 0.05) among treatments; *, ** and *** indicate significance at P ≤ 0.05, P ≤ 0.01 and P ≤ 0.001, respectively; ns indicates non-significant differences. (T0D1; dH2O, T1D1; dH2O + 2 %K2CO3, T2D1; dH2O + 2 %K2CO3 + 1 % Olive Oil, T3D1; dH2O + 2 %K2CO3 + 2 % Olive Oil, T4D1; dH2O + 2 %K2CO3 + 3 % Olive Oil).

Treatments

Total soluble solids (%)

pH

Titratable acidity (%)

Total soluble sugars (%)

Reducing sugars (%)

Non reducing sugars (%)

T0D1

82.70a

4.63a

0.56c

73.75b

64.39ab

2.95bc

T1D1

81.56b

4.42ab

0.66bc

74.71a

70.83a

6.82a

T2D1

81.21b

4.30bc

0.83ab

69.73c

65.61b

4.75ab

T3D1

80.25c

4.20c

0.86a

68.81d

67.72ab

3.74c

T4D1

80.89b

4.34b

0.73b

67.60e

64.39c

4.42b

ANOVA (F Value)

Treatments

ns

ns

**

***

ns

***

3.3 Sensory analysis

Sensory analysis was also performed on the Raisins produced after Grapes pretreatment with 2 % K2CO3 in combination with different concentrations of olive oil and drying under direct sunlight (Table 4). It was observed that the studied sensory attributes (morphological appearance, color, texture, aroma, taste, flavor and overall acceptance exhibited changes in the pretreated Raisins as compared to the controlled samples. Morphological appearance secured 19 % more favour on hedonic scale when treated with 2 % K2CO3 alone and in combination with 3 % olive oil as compared controlled sample of Raisins. Color of the Raisins pretreated with 2 % K2CO3 and 3 % olive oil got 15 % more score as compared to non-pretreated Raisins. Wherase, texture and aroma scored 10 % and 11 % more on hedonic scale as compared to the Raisins which were not pretreated. Although taste and flavor secured more point in the non-treated Raisins, however, overall acceptance was maximum (11 %) for the Raisins produced after treating with 2 % K2CO3 and 3 % olive oil as compared to the control samples. Each value is a mean of triplicates; values sharing different alphabetic letters indicate significant differences (P ≤ 0.05) among treatments; *, ** and *** indicate significance at P ≤ 0.05, P ≤ 0.01 and P ≤ 0.001, respectively; ns indicates non-significant differences. (T0D1; dH2O, T1D1; dH2O + 2 %K2CO3, T2D1; dH2O + 2 %K2CO3 + 1 % Olive Oil, T3D1; dH2O + 2 %K2CO3 + 2 % Olive Oil, T4D1; dH2O + 2 %K2CO3 + 3 % Olive Oil).

Treatments

Morphological appearance

Color

Texture

Aroma

Taste

Flavour

Overall acceptance

T0D1

3.36b

3.67b

3.58b

3.33b

4.08a

4.00a

4.00a

T1D1

4.17a

4.00ab

3.75ab

3.17c

3.67ab

3.75a

4.33a

T2D1

4.00ab

4.25a

4.00a

3.75a

4.00a

3.83a

4.17a

T3D1

3.67b

3.75b

3.75ab

3.67ab

3.92ab

3.83a

4.00a

T4D1

4.17a

4.33a

3.83a

3.42b

3.75b

3.83a

4.50a

ANOVA (F Value)

Treatments

***

ns

ns

ns

***

ns

ns

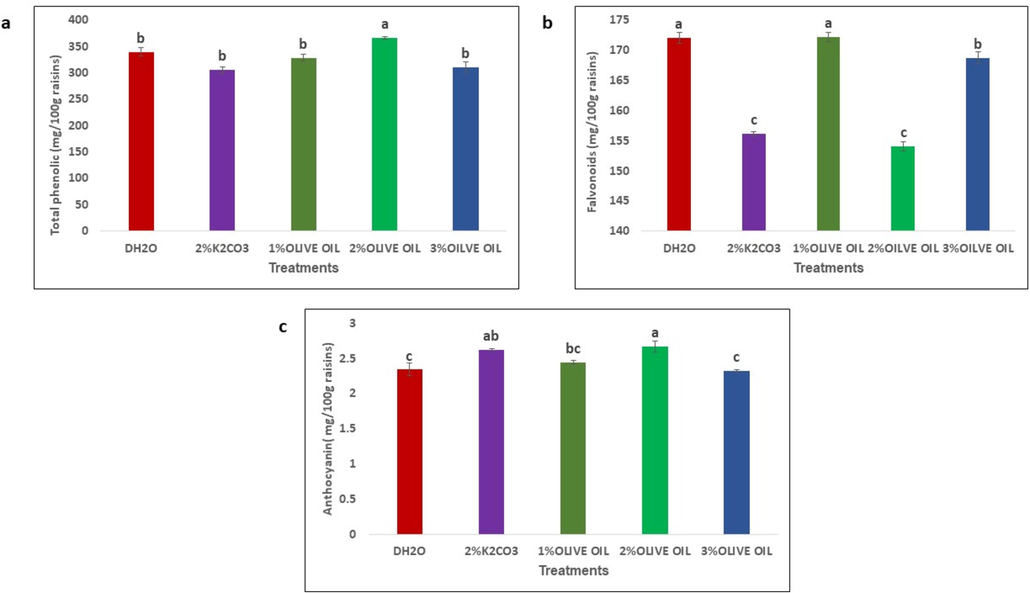

3.4 Secondary metabolites

Secondary metabolites including phenolics, flavonoids and anthocyanins were measured in the current study (Fig. 2). It was observed that total phenolic content was 7 % more in the Raisins pretreated with 2 % K2CO3 in combination with 2 % olive oil as compared to the control samples of Raisins. As far as flavonoid were studied a maximum difference of 10 % less content was observed in the Raisins pretreated with 2 % K2CO3 with 2 % olive oil as compared to the Raisins produced after washing with distilled water without treating with any solution. With regard to anthocyanin, an improvement of 13 % was observed in the Raisins pretreated with 2 % K2CO3 along with 2 % olive oil in comparison to the non-treated Raisins samples (Fig. 2).

The effect of different pretreatment solutions on secondary metabolites of raisins produced from Sundarkhani grapes. Mean values are the average of five replicates. The upper case alphabetic letters indicate significant differences (P ≤ 0.05) among treatments using Tukey's HSD test.

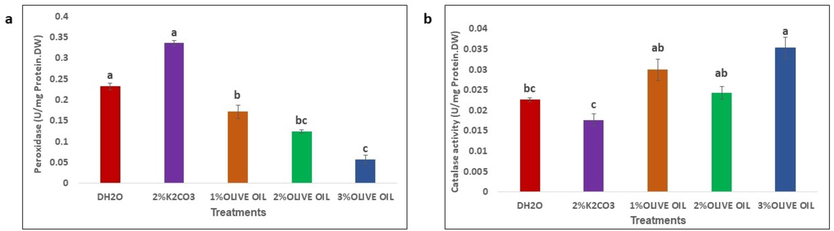

3.5 Antioxidant activity

In the current study, antioxidant activity including catalase and peroxidase activities have also been studied (Fig. 3). The results showed an increase of 24 % catalase activity in the Raisins pretreated with 2 % K2CO3 in combination with 3 % olive oil as compared to non-treated Raisins. While peroxidase activity was maximum (30 %) in the Raisins produced after treating Grapes with 2 % K2CO3 as compared to the controlled samples of Raisins.

The effect of different pretreatment solutions on antioxidant activities of raisins produced from Sundarkhani grapes. Mean values are the average of five replicates. The upper case alphabetic letters indicate significant differences (P ≤ 0.05) among treatments using Tukey's HSD test.

4 Discussions

Raisins are a high-value food made from dried grape fruit. Natural drying of Grapes is challenging due to the presence of a hydrophobic waxy cuticle on the berry surface that limits water loss thus protecting the fruit during ripening although making the natural drying slower. Pretreatment is an essential step in the raisin production process in which the waxy coating is removed or altered increasing the water evaporation during drying of Grapes. Physical, chemical and blanching are prominent procedures for disrupting the wax layer on the grape surface to accelerate drying. Pawar et al. (2023) reported the effect of water pretreatment on grape size, weight and moisture content. They said that soaking grapes in water before drying helps in skin softening resulting in an increase in effectiveness of moisture removal leading to reduction in overall grape dimensions but improving the uniformity and quality of final dried product thus improving their market appeal.

The present study is conducted to observe the morphological and physiological variations among the Raisins produced from the pretreated Grapes with different solutions (2 % K2CO3 alone or in combination with 1 %, 2 % or 3 % olive oil) drying under direct sunlight (Tables 2a,b). Solar drying has been investigated by several researchers (Srivastava et al., 2021), and it has proven to be beneficial for producing high-quality Raisins in less time. However, solar dryers require additional heating for continuous operation, homogeneous air dispersion for improved quality, and shorter drying times. Industrial-scale hybrid drying systems using modern techniques like as microwave, infrared, radio frequency, and so on must be developed to be relevant for raisin production under unfavorable weather circumstances (Pawar et al., 2023).

Maintaining the standards Maximum length, width, volume and weight of Raisins was recorded in the Grapes pretreated with dH2O which is in line with the findings of Pawar et al. (2023) who investigated a similar outcome when worked on Thompson seedless Raisins pretreated with 2.5 % K2CO3 + 1.6 % ethyl oleate. Length of the Raisins differ because of the difference in varieties of Grapes used in the study. Sundar Khani Grapes are thicker and larger in size compared to Thompson seedless Grapes due to genetic differences between the two cultivars. Genetic factors influence grape size and width, resulting in variations among different grape varieties. Environmental factors can also play a role in grape size. Moreover, Lokhande et al. (2017) reported that the fresh weight of Grapes is reduced after drying under different conditions due to high temperature for raisin production. Increased temperature tends to reduce the moisture content of fresh Grapes, resulting in decreased weight of fresh Grapes after drying resulting in an as an increase in moisture diffusion transfer coefficients, thus reducing the drying time for raisin production. Pretreatment through chemical solublization, using solvents and surfactants to disrupt the lipid structure on grape skin by dissolving the waxy components provide a high barrier to moisture transfer, according to Patidar et al. (2021). Yield of the Raisins after drying can be affected by the environmental factors like insects and pollution cause berry degradation and results in reduced the yield of Raisins (Okasha et al., 2023). The coating also exhibited antifungal and antibiotic properties and hence prohibited the disease occurrence thus causing reduction in decay loss. In this study, Rehydration ratio of Raisins has shown more tendency when treated with pretreatment solutions which is in accordance to the reports of Lokhande et al. (2017) showing the effect of different microwave powers on the rehydration ratio of dried Thompson grape Raisins. The high value of rehydration ratio indicated better moisture retention, leading to a juicer texture preferred by consumers and the dried product had a good quality because the pores allow water to return into cells (Ahmad and Zaidi, 2022). This improved texture and freshness increase the marketability and consumer satisfaction.

The Raisins were evaluated for sensory and biochemical quality attributes and the results exhibited that overall coating of solutions in the form of pretreatment had prolonged storage life as compared to non-pretreated Grapes as pretreatment maintained various attributes like appearance, TSS, titratable acidity, pH, antioxidant activity, anthocyanins, flavanoids and total phenolic content. Generally, all coatings prohibited the decay incidence (Qamar et al., 2018). The climate has a significant impact of the grape quality, including anthocyanin accumulation. The process of drying the Grapes with pre-treatment of extra virgin olive oil brought about changes in the qualitative and quantitative profile of phenolic compounds of BRS Morena. Grapes as the Raisins produced without any pre-treatment, due to the long drying time, presented lower retention of flavonoids and anthocyanins (Olivati et al., 2019)).

Pretreatment in the current study exhibited an improvement in the antioxidant activities (catalase and peroxidase) of the Raisins which is in agreement to the findings of the Keskin et al. (2022) who reported higher levels of CAT and POD when Grapes were pretreated with oak ash and K2CO3. Pretreatments under solar light promotes the activity of catalase, mitochondrial oxidase, and other enzymes. Thus, it is specifically associated with iron-containing enzymes such as peroxidases (PODs), catalases (CATs), and aconitases. Such a union adversely or favorably alters enzyme activity, dramatically affecting tissue and plant resistance to oxidative stress (El-Mesery et al., 2022).

5 Conclusions

The findings of this study highlight the importance of pretreatment and drying methods in reducing drying time while achieving desirable physio-biochemical and organoleptic qualities. The combination of 2 % K2CO3 with 3 % olive oil was optimal for reducing drying time and enhancing sensory attributes, while 2 % K2CO3 with 2 % olive oil yielded the highest levels of beneficial compounds. Using the specified pretreatments, particularly a 2 % K2CO3 with 2 % olive oil solution, and drying under direct sunlight shows promise from both industrial and health perspectives. Although this work provides preliminary results of optimizing rehydration ratio which can significantly enhance the raisin quality aligning with consumer preferences for juicy texture, further investigation is needed to understand the mechanism of action of pretreatment solutions on the waxy layer of grape skin. The combination of pretreatments and drying methods is crucial for producing high-quality Raisins. Future research should focus on explaining pretreatment methods and exploring innovations to improve the rehydration efficiency and overall product quality.

CRediT authorship contribution statement

Mariam Shabir: Methodology, Investigation, Conceptualization. Bilal Bari: Investigation, Conceptualization. Naila Ali: Writing – review & editing, Methodology, Conceptualization. Zaib-un Nisa: Writing – review & editing, Writing – original draft, Methodology, Conceptualization. Rattandeep Singh: Formal analysis, Data curation, Conceptualization. Mohammad Abul Farah: Formal analysis, Data curation, Conceptualization.

Acknowledgement

The authors would like to extend their sincere appreciation to the Researchers Supporting Project number (RSPD2024R694), King Saud University, Riyadh, Saudi Arabia.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Drying characteristics and quality of grape under physical pretreatment. J. Food Eng.. 2016;172:9-18.

- [CrossRef] [Google Scholar]

- Postharvest quality evaluation of pineapple during drying. ACS Food Sci. Technol.. 2022;2:592-603.

- [Google Scholar]

- Ampelographic and genetic characterization of grapes genotypes collected from Potohar region of Pakistan. Pak. J. Agri. Sci. 2019;56:595-605.

- [Google Scholar]

- Antibacterial activity of leaf extract of seven grape cultivars against six strains of Bacteria. Advancements in Life Sciences.. 2019;06(04):159-164.

- [Google Scholar]

- Chance, B., Maehly, A., 1955. Assay of catalases and peroxidases. pp:136.

- Review of Dried Fruits: Phytochemicals, Antioxidant Efficacies, and Health Benefits. J. Funct. Foods. 2016;21:113-132.

- [Google Scholar]

- Measurement of volume of macaw palm fruit using traditional and the digital Moiré techniques. Revista Brasileira De Engenharia Agrícola e Ambiental. 2016;20:152-157.

- [Google Scholar]

- Drying kinetics of black grapes treated with different solutions. J. Food Eng.. 2006;76:212-217.

- [CrossRef] [Google Scholar]

- Recent developments in solar drying technology of food and agricultural products: A review. Renew. Sustain. Energ. Rev. 2022;157:112070

- [Google Scholar]

- Microwave hydrodiffusion and gravity as pretreatment for grape dehydration with simultaneous obtaining of high phenolic grape extract. Food Chem. 2020

- [CrossRef] [Google Scholar]

- Off-vine grape drying effect on volatile compounds and aromatic series in must from Pedro Ximénez grape variety. J. Agric. Food Chem. 2004;52:3905-3910.

- [Google Scholar]

- GOP, 2013. Agriculture Statistics of Pakistan. , Ministry of Food Agriculture Livestock. Islamabad, Pakistan.

- Impact of Evaporative cooling technology & Post-harvest treatments on shelf life and quality of tomato of two different harvesting stages (Solanum lycopersicum var. Pearson) J. Ecoscience Plant Revolut. 2021;2:8-16.

- [CrossRef] [Google Scholar]

- Drying Grapes after the Application of Different Dipping Solutions: Effects on Hormones, Minerals, Vitamins, and Antioxidant Enzymes in Gök Üzüm (Vitis vinifera L.) Raisins. Plants. 2022;11:529.

- [Google Scholar]

- Changes in chloroplast peroxidase activities in relation to chlorophyll loss in barley leaf segment. Physiol. Plant.. 1990;80:555-560.

- [Google Scholar]

- Effect of microwave drying on textural and sensorial properties of grape Raisins. Int. J. Chemtech Res.. 2017;10:938-947.

- [Google Scholar]

- Assessment of Raisins Byproducts for Environmentally Sustainable Use and Value Addition. AgriEngineering. 2023;5:1469-1480.

- [Google Scholar]

- Effect of the pre-treatment and the drying process on the phenolic composition of Raisins produced with a seedless Brazilian grape cultivar. Food Res Int. 2019;116:190-199.

- [Google Scholar]

- Traditional and recent development of pretreatment and drying process of Grapes during raisin production: A review novel pretreatment and drying methods of Grapes. Food Frontiers. 2021;2:46-61.

- [Google Scholar]

- Pawar, D.A., Giri, S.K., Sharma, A.K., 2023. Novel alternative pretreatment approaches for production of quality Raisins from Grapes: Opportunities and future prospects Food Process Eng 2023;46:e14305, 2–26.

- Effect of Aloe vera Gel, Chitosan and Sodium Alginate Based Edible Coatings on Postharvest Quality of Refrigerated Strawberry Fruits of cv. Chandler, J. of Hort. Sci and Tech.. 2018;1(1):8-16.

- [Google Scholar]

- Manual of analysis of fruit and vegetable products. Tata McGraw-Hill; 1977.

- Handbook of analysis and quality control for fruit and vegetable products. Tata McGraw-Hill Education; 1986.

- Grape Bioactive Molecules, and the Potential Health Benefits in Reducing the Risk of Heart Diseases. Food Chem. X. 2020;12:100149

- [Google Scholar]

- Evaluation of various levels of mineral nutrients and plant growth regulators for In vitro culture of grape. Pak. J. Bot. 2008;40:329-336.

- [Google Scholar]

- Effect of extraction solvent on total phenol, total flavonoid content and antioxidant activities of extract plants Punica granatum, Vitis vinifera L, Ficus carica L. and Olea europea. In: AIP Conference Proceedings. AIP Publishing. 2019.

- [Google Scholar]

- Analysis of commercial grape Raisins: Phenolic content, antioxidant capacity and radical scavenger activity. Ciênc. Tec. Vitivin. 2014;29:1-8.

- [Google Scholar]

- Effects of Pretreatments and Drying Methods on Drying Kinetics and Physical properties of Raisins. Biological Forum. 2022;14:155-160.

- [Google Scholar]

- Effect of berry size and sodium hydroxide pretreatment on the drying characteristics of blueberries under infrared radiation heating. J. Food Sci.. 2008;73:E259-E265.

- [Google Scholar]

- A comprehensive overview on solar grapes drying: Modeling, energy, environmental and economic analysis. Sustainable. Energy 2021

- [Google Scholar]

- Correlation of antioxidant activity and phytochemical profile in native plants. Nutrition & Food Science. 2012;42:71-79.

- [Google Scholar]

- Thiruchelvi, R., Jayashree, P., Nayik, G, A., Gull, A., Ahad, T., Thakur, M., Shah, T. R., Paray, M. A. & Haq, R. (2020). Raisin. In: Nayik, G.A., Gull, A. (eds) Antioxidants in Vegetables and Nuts - Properties and Health Benefits. Springer, Singapore. https://doi.org/10.1007/978-981-15-7470-2_27.

- Effect of drying method and cultivar on sensory attributes, textural profiles, and volatile characteristics of grape Raisins. Drying Technol.. 2021;39:495-506.

- [CrossRef] [Google Scholar]

- Guest Editorial: Some mitigation strategies for climate change. Drying Technol.. 2015;33:1679-1680.

- [Google Scholar]