Translate this page into:

Development of a culvert inventory and inspection framework for asset management of road structures

*Corresponding author. Tel.: +1 817 272 0507; mobile: +1 816 294 6767; fax: +1 817 272 2630 Najafi@uta.edu (Mohammad Najafi) http://www.cuire.org (Mohammad Najafi)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

The deteriorating highway culvert infrastructure has become a major challenge for the 21st century. While more importance usually is given to highway embankments, pavements, and bridges, the maintenance of culverts has commonly been neglected. For the purpose of this study, culvert is defined as storm sewers and drainage structures crossing roads, railroads and highways consisting of concrete, corrugated metal, and plastic materials and spanning less than or equal to three meters (10 feet). As many culverts reach the end of their design life, the departments of transportation (DOTs) overseeing maintenance of road structures are in need of a model to track the existing culverts and forecast their remaining service life. Therefore, the main goal of this research was to assess the status of culvert asset management in the U.S.A. and to develop a framework by providing protocols and condition rating systems for culvert inventory and inspection. Performance scores for the culverts are calculated using an Analytical Hierarchy Process (AHP) to determine the magnitude of the deterioration and assist in short- and long-term planning. Analytical Hierarchy Process (AHP) is a structured technique addressing complex decisions. With prescribing the problem and an appropriate decision, the AHP helps the decision makers to find the one that best suits their needs. The developed model contributes to an effective culvert asset management strategy.

Keywords

Culvert inventory and inspection framework

Drainage structures and storm sewers

Asset management

Road structures

- ACA

-

advanced condition assessment

- ADT

-

average daily traffic

- AHP

-

analytical hierarchy process

- ANN

-

artificial neutral network

- AOR

-

adjusted overall rating

- BCA

-

basic condition assessment

- CAF

-

condition assessment framework

- CCTV

-

closed circuit television

- CIDCF

-

culvert inventory data collection format

- CMP

-

corrugated metal pipe

- DOT

-

Department of Transportation

- FAHP

-

fuzzy analytic hierarchy process

- GASB 34

-

Government Accounting Standard Board – rule 34

- GIS

-

geographic information systems

- MRUTC

-

Midwest Regional University Transportation Research Center

- MDOT

-

Michigan Department of Transportation

- ODOT

-

Ohio Department of Transportation

- OSHA

-

Occupational Safety and Health Administration

Abbreviations

1 Introduction

Managing underground infrastructure is a challenging task, requiring estimation of service life of assets, risk analysis of failures and their impacts on the quality of life. Factors such as poor asset management and maintenance practices and inadequate inspection programs may result in sudden failure of the deteriorated underground infrastructures. The deteriorating culverts and drainage structures demand the local and state agencies to implement proper inventory and inspection programs. However, predicting the remaining life and monitoring the condition of underground pipelines and culverts remain a difficult task (Najafi, 2005).

Culvert inspection and management have been important topics among the present day transportation researchers. The Ohio Research Institute for Transportation and the Environment, at the University of Ohio, made an important contribution to these topics with the report entitled “Risk Assessment and Update of Inspection Procedures for Culverts” (Mitchell et al, 2005). They introduced a culvert inspection system from data collected at sixty culvert sites. They reported that loss of culvert integrity could result in temporary roadway closure with considerable remediation costs, and total collapse of culverts could result in a major safety risk for motorists. The statistical analysis of the culverts indicated that culvert age, material type, and flow characteristics such as abrasiveness, pH, and velocity were significant variables for the overall performance of the culverts.

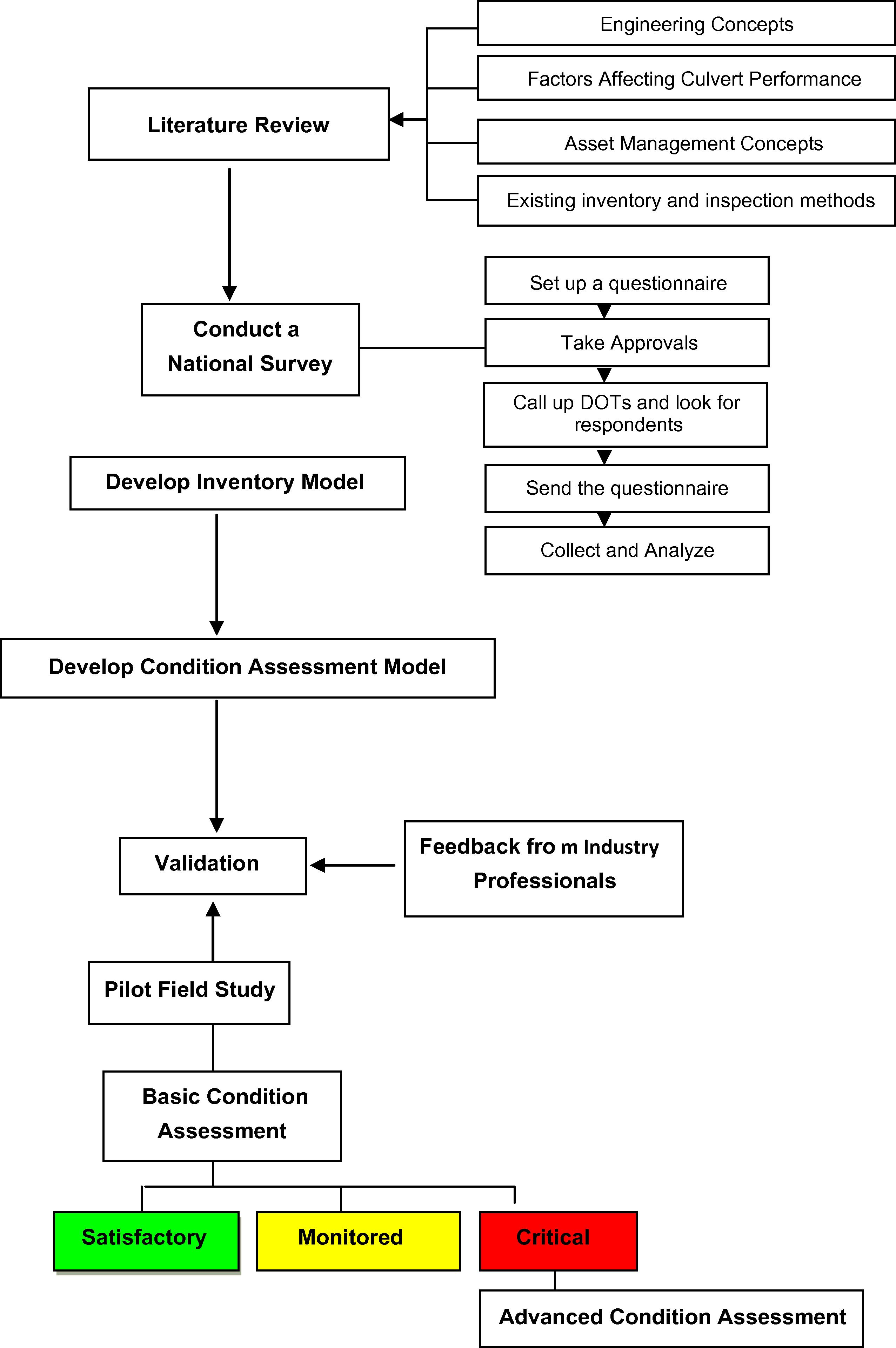

Analytical Hierarchy Process (AHP) has been used as a tool for infrastructure management because of its ability to reflect the way people think and make decisions by simplifying a complex decision into a series of one-on-one comparisons (Smith and Tighe, 2006). Applications of AHP can be found in many fields such as portfolio selection, transportation planning, manufacturing system design, and artificial intelligence (Shtub et al., 2005). Al-Barqawi and Zayed (2008) use AHP as well as Artificial Neutral Network (ANN) in designing a robust model to assess the condition and to predict the performance of water infrastructure. AHP and fuzzy comprehensive evaluation method have been used in the risk evaluations as well. For instance, Shu et al. (2009) use AHP for design and implementation of water environment safety. Lee and Wang (2008) use AHP for data mining, and Wang and Wang (2006) use AHP for construction risk evaluation. Moreover, based on AHP, several other evaluation methods have been developed, such as the hierarchical reasoning mode in condition assessment of buried pipes (Bai et al., 2008), the integrated model to evaluate losses in water distribution systems (Asadiyani Yekta et al., 2008), and the risk assessment model of special equipment based on Fuzzy Analytic Hierarchy Process (FAHP) and Artificial Neutral Network (ANN) (Li et al., 2008). Fig. 1 illustrates the research plan used for this study.

Flow chart for culvert inventory and inspection model.

2 Culvert Inventory Data Collection Format (CIDCF)

The Culvert Inventory Data Collection Format (CIDCF) (Najafi et al, 2008) is a process for identifying and numbering culverts in a systematic and organized way. It provides a starting point to understand the current overall condition of culverts, which has been overlooked for years. This model is composed of a set of useful questions in the form of a protocol to identify culverts. The identification data include logical details of the culvert, its components, and the surrounding area. Once culverts are identified and entered in the inventory database, they can be linked to various information and decision support systems for financial, economical, and managerial purposes. The culvert inventory database can also be presented as a layer in the state DOT GIS record.

The CIDCF model consists of fifty five questions grouped into six modules – general, structural, hydraulic, safety, repair, and other information as necessary (see Table 1). All the questions should be coded as given in the inventory manual.

Modules

Sections

Questions

1. General information

1. Date of inventory

2. Name of the person

3. State code

4. Country code

5: Place code

6. Inventory code

7. Functional classification:

8. Mile marker

9. Year built

10. Latitude

11. Longitude

12. Maintenance responsibility

13. Average daily traffic (ADT)

14. Approach roadway width

15. Culvert marker

2. Structural information

Barrel

16. Shape

17. Material

18. Number of cells

19. Length

Geometric Dimensions

20. Diameter

21. Span

22. Rise

23. Rt =

24. Rc =

25. Rs =

26. Rb =

27. R =

Metal Pipes

28. Pitch

29. Depth

30. Gauge: (thickness)

31. Maximum height of cover from crown to road surface

3. Additional information

Type of End Treatment

32. Type

33. Material

34. Thickness

Other

35. Slope of embankment

36. Skew angle

37. Roadway material

38. No. of lanes

4. Hydraulic information

39. Streambed material

40. Drainage area

41. Design peak flow:

42. Manning’s coefficient ‘n’

43. Design discharge ‘Q’

44. Design headwater depth

45. Slope of the culvert

46. Bank protection

47. Type of fish passage

48. pH of water

5. Safety item

49. Type

50. Material

51. Span

6. Renewal information

52. Type of renewal

53. Date of renewal

54. Type of renewal

55. Date rehabilitated

The general identification of the culvert location is the first module in the inventory model and aims to identify the culvert from regional information to specific culvert structure.

The second module of the CIDCF model refers to structural information. In this module, it is very important to understand the structural or design concepts of the culvert. It can be used to measure the structural deteriorations during inspection. The third module of the CIDCF model refers to additional information which identifies the components of the culvert and other related features. This module is used to measure distress or deficiencies in various culvert components. The fourth module of the CIDCF model refers to identification related to hydraulics of the culvert. Hydraulic features are major factors affecting the design performance of the culverts. Identification of these features in the inventory model during culvert inspections helps to determine the rate of deterioration of the culvert due to hydraulic factors. The fifth module of the CIDCF model refers to identification of the safety features of the culvert such as culvert grates and guardrails. The identification and assessment of these features are a part of highway safety for travelers. Also, defects in these components may indicate problems in the culvert underneath them. The sixth and final module of the CIDCF model refers to identification of previous repair or renewal of the culvert. This information gives an understanding of the problems or defects existing in the culverts and the methods or techniques used to repair or rehabilitate them.

3 Condition Assessment Framework (CAF)

The Condition Assessment Framework (CAF) (Najafi et al., 2008) is a set of protocols that identifies culverts which are underperforming, determines the reasons for their deficiencies, predicts when failures are likely to occur, and develops short and long term plans for their preservation. This model is based on the inventory data collection format, literature review, field studies, and discussions with the DOTs. The condition assessment framework is divided into two categories as Basic Condition Assessment and Advanced Condition Assessment. After a thorough development and study of the final ratings of these two categories, the likeliness of failure is predicted.

3.1 Basic Condition Assessment (BCA)

The Basic Condition Assessment (BCA) (Najafi et al., 2008) category consists of a general inspection of the culvert, its components, and the surrounding area. It is the first and the quickest way of collecting relevant and good information for culverts during inspection. The assessment begins by recording the general identification of the inspection site and culvert structure. Then the various components of the culvert are inspected for defects against a condition rating system. The culvert and its components are assigned a condition rating value ranging from 1 to 5; one being failure/critical and 5 being excellent. The selection of a 5-point scale approach against other approaches is to make the process straight forward and easy to understand for entry-level inspectors. Using an Analytical Hierarchical Process, relative weights for culvert components are assigned and a culvert performance score is finally calculated. Based on the performance score, the culvert is categorized into three different zones: Red Zone which indicates verge of failure, Yellow Zone indicating intermediate stage and Green Zone indicating a safe condition. The culverts having performance score above 3.5 out of 5 fall in the Green Zone; these culverts are in good condition and can be inspected between 5 and 7 years. The culverts having performance score between 2.5 and 3.5 fall in the Yellow Zone and in a satisfactory condition, needing inspection in the next 3–5 years. The culverts having performance score less than 2.5 fall in the Red Zone, and are investigated further for “Advanced Condition Assessment.” Based on the zoning, short and long term planning for culvert preservation and maintenance should be implemented.

Module one of the BCA refers to general information of the culvert. The items in this module are the same as the ones considered in module one of the CIDCF model. They are as follows: state code, county code, place code, culvert identification number, year built, and date of inspection, inspector’s name, and maintenance responsibility.

Module two of the BCA refers to site information. Recording the time, season, and temperature during the inspection is important because these factors have some influence on the effectiveness of the inspection. The items included in this module are: inspection season, climate, time of inspection, type of stream, type of inspection, water level, pH of water, soil resistivity, vegetation, and natural hazards.

Module three of the BCA refers to the identification of the culvert. Basic structural understanding is necessary before inspection of any culvert. Comparison of the inspected geometric dimensions with the design dimensions would indicate various structural defects. The items included in this module are: shape, material, number of cells, type of end treatment, and geometric dimensions.

Module four of the BCA refers to the condition assessment of the culvert. This module lists the various components of the culvert to be inspected against a condition rating system as illustrated in Table 2, which defines the magnitude of the defects. The inspector should carefully inspect the culvert and assign a rating for each culvert component. This system is based on the Government Accounting Standard Board – Rule 34 (GASB, 1999). The GASB – 34 systems requires that a measurement or rating scale be used for condition assessment of any asset and a minimum acceptable condition be established as a benchmark. The condition rating system in module four for various components of the culvert is as follows:

Rating

Condition

5

Looks new or in excellent condition, No Corrosion or Abrasion the finished surface is intact. No debris.

4

Age deterioration is minor, minor corrosion and abrasion, no deformations, Minor waterway blockage due to debris.

3

Age deterioration is moderate, Moderate corrosion and abrasion, Moderate obstruction caused due to debris

2

Age deterioration is significant or failure of the invert is imminent, heavy corrosion or abrasion, Maximum waterway is blocked due to debris

1

Ends totally/partially broken

3.1.1 Condition of the inverts

Condition of the inverts creates a major impact on the performance of the culvert. Common problems with the inverts are abrasion, corrosion, and debris. Age deterioration was seen in most of the culverts during initial field studies. Table 2 gives the rating system for the condition of the inverts.

3.1.2 Condition of end protection (Headwall, Wingwall)

End protections such as headwall and wingwall in culverts are usually fabricated in concrete. They should be inspected for common concrete problems such as cracks, spalling, scaling, leakage, efflorescence, and reinforcing steel corrosion. Table 3 gives the rating system for condition of end protection.

Rating

Condition

5

Looks new or in excellent condition

4

Good condition, light scaling, hairline cracking, no leakage

3

Horizontal and diagonal cracking with or without efflorescence, minor rusting, leakage and erosion, minor scaling, differential or rotational settlement

2

Cracking with white efflorescence, major cracks, failure is imminent

1

Total/partial collapse of end protection

3.1.3 Condition of the roadway

The condition of the roadway above the culvert may indicate structural or hydraulic problems in the culvert. Settlement of the roadway is a common problem and is caused in part to poorly compacted embankment material; and/or joint failure; or if the culvert is hydraulically not sound then the water may overtop the roadway. Cracks and pavement patches may indicate structural problems associated with the culvert. The condition rating system for the condition of roadway is shown in Table 4.

Rating

Roadway

Embankment

Footing

5

Looks new and in excellent condition

Soil in very good condition, no erosion found in and around the structure

Footing intact and in good condition

4

Minor settlement of the roadway not more than, no cracks

Minor erosion away from the structure, no problem to the culvert

Minor erosion or cracking or settlement in the footing

3

Minor settlement of the roadway and minor cracks

Moderate erosion near the structure, no cracks on the headwall

Moderate cracking or differential settlement of the footing

2

Heavy settlement of the roadway or major cracks

Slope stability problem near the culvert, extensive hairline cracks found near the headwall

Severe differential settlement has caused distortions in the culvert

1

Roadway collapse is imminent

Embankment has collapsed or failure is imminent

Culvert has collapsed or failure is imminent

3.1.4 Condition of the embankment

Deterioration of embankments is commonly caused by defective culverts. Erosion is a common problem, which is caused by undercutting and rotation of culvert footings or culvert wall failure, or severe differential settlements. Erosion sometimes causes the backfill to flow, which may develop sinkholes. Embankment defects sometimes lead to cracking in headwalls or wingwalls as well. The condition rating system for embankment is shown in Table 4.

3.1.5 Condition of the footings

Footings should be inspected for settlement along the length of the footing; they are mostly affected by erosion. CMPs can tolerate some differential settlement but will be damaged due to excessive settlement. The stretching or compression of CMPs results in cracking or crushing across the footing. Deterioration in concrete footings may lead to distortions as well. The condition rating system for culvert footings is shown in Table 4.

3.1.6 Overall condition of culvert

The overall condition of the culvert is determined by taking into account all the hydraulic, structural, environmental, and social factors. The analysis is done without differentiating the culvert in type and size. Table 5 shows a condition rating system for the overall condition of the culvert.

Rating

Condition

5

Newly installed or lined culvert

4

Looks new with possible discoloration of the surface

3

Medium rust or scale, pinholes throughout the pipe material

2

Heavy rust or scale, major cracks with spalling, exposed surface of the reinforcing steel

1

Culvert is structurally or hydraulically incapable to function

Module five of the BCA category is the calculation of the performance score for the culvert. The steps followed when calculating the performance score for all the components selected in the condition rating system are as follows:

Step 1: Each culvert component selected previously is pair-wise compared with the remaining components by importance on the overall performance of the culvert. Table 6 presents a pair-wise comparison.

Step 2: A matrix of comparison is developed after all pair-wise comparisons are made. The values entered in the matrix of comparison are based on inspector’s knowledge in culvert inspection and maintenance. An example of development of the matrix is given in Table 7.

Step 3: The values below the diagonal of the matrix are the reciprocals of the corresponding elements which are above the diagonal. The next step is to normalize each column of the matrix by summing all the elements in a column and dividing each element in that column by this sum. For the first column, each element will be divided by (1 + 0.333 + 0.333 + 0.333 + 0.2 + 0.2) = 2.4. Thus, the new values in the first column are (1/2.4) = 0.4167, (0.333/2.4) = 0.1388, (0.333/2.4) = 0.1388, (0.333/2.4) = 0.1388, (0.2/2.4) = 0.0833, (0.2/2.4) = 0.0833. Table 8 presents the normalized matrix.

Step 4: The final step consists on averaging each set of rows for the normalized matrix. So, for the first row, the new value is (0.4167 + 0.5454 + 0.4000 + 0.3428 + 0.2941 + 0.3333)/6 = 0.3887. Similar calculations are done to obtain relative weights for the remaining rows. The relative weights of the components according to their level of importance in performance calculation are shown in Table 9.

| Importance level | Description |

|---|---|

| 1 | Equal importance |

| 2 | Moderate importance |

| 3,4,5 | Intermediate importance |

| 6 | Strong importance |

| 7 | Extreme importance |

| Culvert | Invert | End Treat | Footing | Roadway | Embankment | |

|---|---|---|---|---|---|---|

| Culvert | 1.000 | 3.000 | 3.000 | 3.000 | 5.000 | 5.000 |

| Inverts | 0.333 | 1.000 | 2.000 | 2.000 | 4.000 | 4.000 |

| End treat | 0.333 | 0.500 | 1.000 | 2.000 | 2.000 | 2.000 |

| Footing | 0.333 | 0.500 | 0.500 | 1.000 | 4.000 | 2.000 |

| Roadway | 0.200 | 0.250 | 0.500 | 0.250 | 1.000 | 1.000 |

| Embankment | 0.200 | 0.250 | 0.500 | 0.500 | 1.000 | 1.000 |

| Total | 2.400 | 5.500 | 7.500 | 8.750 | 17.000 | 15.000 |

| Culvert | Invert | End Treat | Footing | Roadway | Embankment | |

|---|---|---|---|---|---|---|

| Culverts | 0.417 | 0.545 | 0.400 | 0.343 | 0.294 | 0.333 |

| Inverts | 0.139 | 0.182 | 0.267 | 0.229 | 0.235 | 0.267 |

| End Treat | 0.139 | 0.091 | 0.133 | 0.229 | 0.118 | 0.133 |

| Footing | 0.139 | 0.091 | 0.067 | 0.114 | 0.235 | 0.133 |

| Roadway | 0.083 | 0.045 | 0.067 | 0.029 | 0.059 | 0.067 |

| Embankment | 0.083 | 0.045 | 0.067 | 0.057 | 0.059 | 0.067 |

| Type | Relative weights |

|---|---|

| Overall culvert condition | 0.389 |

| Condition of inverts | 0.220 |

| Condition of end treat | 0.140 |

| Condition of footings | 0.130 |

| Condition of roadway | 0.058 |

| Condition of embankment | 0.063 |

Module six of the BCA refers to the zoning of the culverts based on their performance. The formula for calculating the performance score of the culvert is as follows:

The performance score for a culvert is a factor used as a benchmark to develop short and long term planning. Based on the performance score, culverts are zoned into three categories – Red, Yellow, and Green. Ideally, the maximum score a culvert can obtain is 5.0 and the minimum is 0. A performance score higher than 3.5 indicates a green zone or safe, between 2.5 and 3.5 indicates a yellow zone or intermediate and lower than 2.5 indicates a red zone – danger.

3.2 Advanced Condition Assessment (ACA)

The ACA is a detailed inspection of the culvert structure. Any culvert with a performance score below 2.5 will ultimately be inspected using the ACA. The objective of the ACA is to have a condition rating system for problems causing deterioration specific to concrete, metal, and plastic culverts. The assessment begins with the detailed inspection at the inlet, outlet, and inside the culvert pipe. The condition rating system is evaluated between 5 and 0; and is used as a benchmark for identification of problems. Using Analytical Hierarchy Processes (AHP), relative importance weights are calculated for all culvert problems following the steps indicated below.

-

Each culvert problem is pair-wise compared with the overall deterioration of the culvert using Table 6 for the ratings.

-

The matrix of comparison as shown in Table 7 is developed after all pair-wise comparisons are made.

-

Thus following the above Steps 5, 6 and 7 relative weights of the deteriorating factors are calculated as illustrated in Tables 10 and 11. The performance score is calculated using the formula:

| Condition rating factors | Relative weight |

|---|---|

| Cracking | 0.317 |

| Scouring | 0.170 |

| Settlement | 0.156 |

| Joint opening | 0.152 |

| Misalignment | 0.135 |

| Concrete surface | 0.069 |

| Condition rating factors | Relative weight |

|---|---|

| Misalignment | 0.235 |

| Settlement | 0.138 |

| Vegetation | 0.138 |

| Seam | 0.175 |

| Shape | 0.175 |

| Corrosion | 0.105 |

| Scouring | 0.069 |

4 Validating the CIDCF and CAF models

To validate the two models, a pilot field study was conducted in Mid- Michigan. The first step in the pilot study was to identify the culverts for condition assessment. A request was sent to the Michigan Department of Transportation (MDOT) to recommend a few culverts in bad condition. MDOT suggested inspecting culverts on M 13, Shiawassee County; about 500 culverts there were on the verge of deterioration. An old inventory list and as-built drawing of the highway M 13 were studied to find the location of the culverts. Permission from MDOT was obtained to inspect the public utility (culverts) on the highway M 13. Occupational Safety and Health Authority (OSHA) regulations for safety were studied which prohibited work within confined space and this includes the interior of the culvert. In this case Closed-Circuit Television (CCTV) was the best option for the interior inspection.

The inspection team looked for either the culvert marker or the roadway condition in locating the actual culvert. At the culvert site, the following step by step procedure was used in validating the model:

Step 1: The culvert was issued an 11 digit unique identification number based on the following details:

-

Route signing prefix

-

Level of service

-

Route number

-

Directional suffix

-

Structure number

For culvert 1; which was located on US 127 in Ingham County, Michigan, the identification number was as follows:

-

Route signing prefix – US numbered highway, so code 2 as the first digit

-

Level of service – Business, so code 5 as the second digit

-

Route number – 127, so code 00127 as the next 5 digits

-

Directional suffix – South, so code 3 as the eight digit

-

Structure number – A01 was coded as the structure number as it was the first culvert in the direction of inventory

So, the 11 digit unique identification number for culvert 1 is – 25001273A01. The identification number for other culverts is as shown in Table 12.

Culvert

Identification number

1

25001273A01

2

31000131B01

3

31000131B02

4

31000131B03

5

31000131B04

6

31000131B05

Step 2: The next step was to perform the Basic Condition Assessment (BCA) for the components using the condition rating system developed in Section 3.1 above.

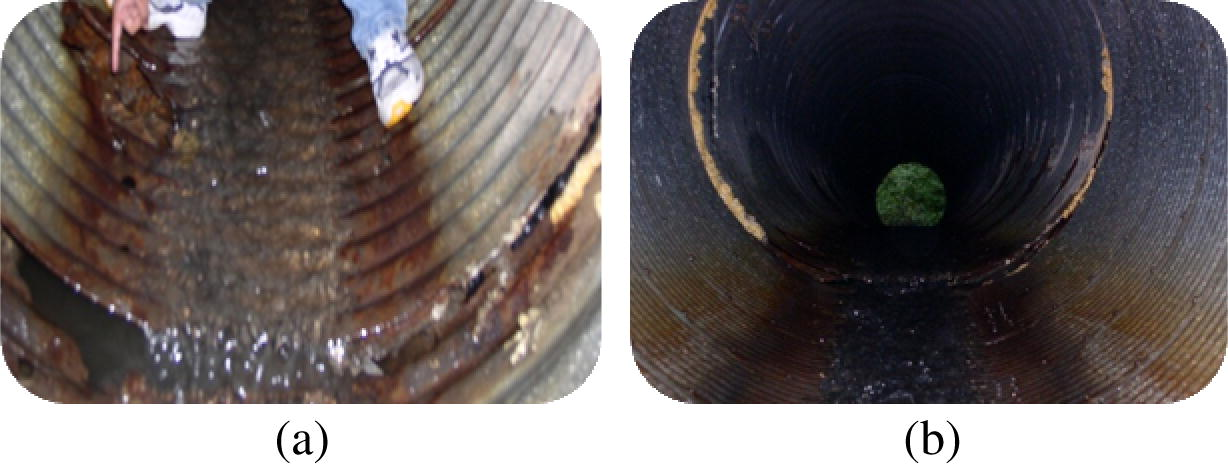

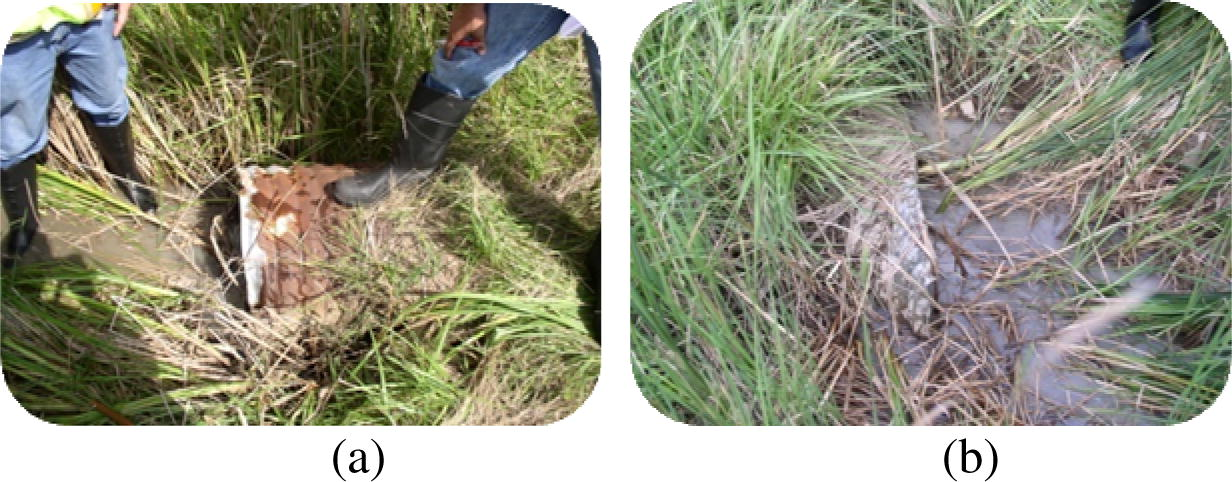

The culvert 25001273A01 (1200 mm/48 in. circular CMP) located in Ingham County was about 65 years old and was scheduled for replacement in 2006. The invert was damaged (formation of a big hole, about one in. in diameter) and corroded in few places as shown in Fig. 2(a). The headwall and wingwall at the culvert outlet had major spalling and cracks in few places. The embankment had moderate erosion around the structure. A layer of the concrete bed had eroded and perched due to high velocity of flowing water at the outlet. The water was flowing back at the inlet due to serious misalignment of the culvert from its design (Fig. 2(b)). The road above the culvert looked new and was in excellent condition. The condition rating for this culvert is as shown in Table 13.

(a) Big hole and corrosion in the invert of the culvert 25001273A01. (b) Misalignment of the culvert 25001273A01.

Culvert rating components

Condition rating

25001273A01

31000131B02

31000131B02

31000131B04

31000131B05

31000131B05

Condition of the invert

1

2

3

3

2

2

Condition of end treatment

3

1

1

1

5

5

Condition of overall culvert

2

3

1

1

1

1

Condition of roadway

5

5

3

3

1

1

Condition of embankment

3

3

2

2

3

3

Condition of footing

5

5

5

5

5

5

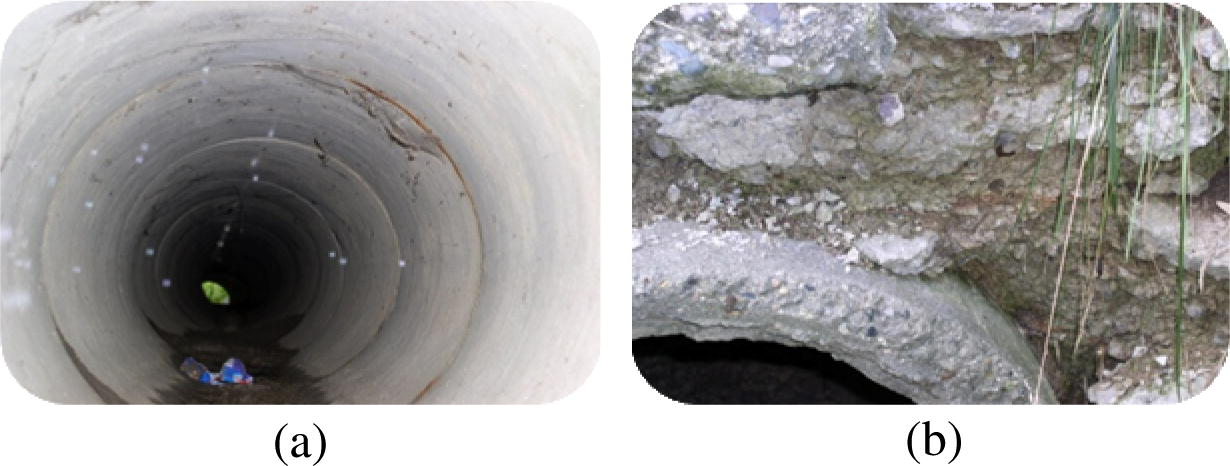

The culvert 31000131B01 (600 mm/24 in. Circular Concrete) located in Shiawassee County was about 65 years old and was on the verge of failure. Age deterioration was significant with heavy vegetation surrounding the culvert. The headwall was partially broken as shown in Fig. 3(b); minor cracks and major spalling were found inside the culvert structure. Moderate misalignment of the culvert was found as shown in Fig. 3(a). The erosion around the headwall was moderate. This may be one of the reasons for headwall failure. The roadway above the culvert structure was in excellent condition. The condition rating system for this culvert is as shown in Table 13.

(a) Misalignment of the culvert. (b) Failure of the headwall due to heavy spalling.

The culvert 31000131B02 (600 mm/24 in. Circular Concrete) located in Shiawassee County was also about 65 years old. The invert was eroded due to heavy transportation of soil sediment through the culvert. Flow was obstructed at the invert due to deposition of soil sediment. The joint opening in the middle of the culvert was significant which resulted in soil infiltration and misalignment of the culvert as shown in Fig. 4(a). The culvert headwall and the barrel were partially broken as shown in Fig. 4(b). This can be due to heavy superimposed load or due to significant soil erosion surrounding the headwall. The culvert was surrounded by heavy vegetation. The roadway had minor settlement and cracks as shown in Fig. 4(c) This may have been caused by the joint opening in the middle of the culvert, and ultimately may lead to shape deformation of culvert or loss of backfill material. Overall the culvert deterioration was very significant. The condition rating system for this culvert is as shown in Table 13.

(a) Significant misalignment of the culvert structure. (b) Vegetation and heavy spalling in the headwall. (c) Cracks on the roadway surface.

The culvert 31000131B03 (Slab – 2.4 m/8 ft opening, 2.1 m/7 ft rise; Concrete, rectangular in shape) located in Shiawassee County was also about 65 years old. Age deterioration was moderate with moderate settlement of vegetation and soil which is also referred to as scouring. Minor cracking was found at the construction joints between the top slab and walls. Minor infiltration on the side walls of the culvert is as shown in Fig. 5; minor cracks on the roadway due to infiltration. The headwall and wingwall have hairline cracks and the embankment is eroded. The footings are in good condition. The condition rating system for this culvert is as shown in Table 13.

Condition of culvert 31000131B04.

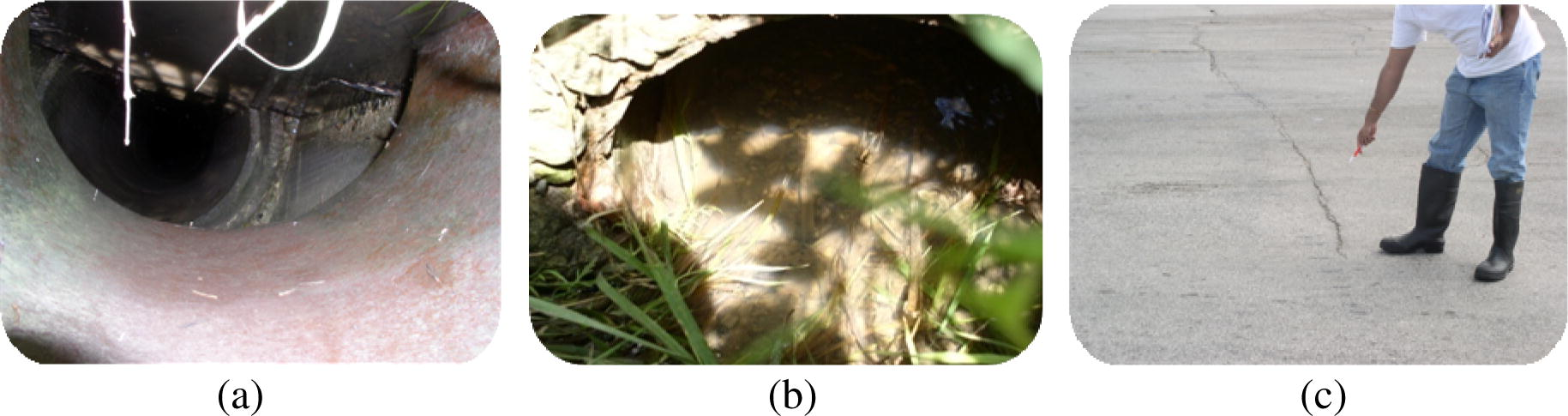

The culvert structure 31000131B04 (600 mm/24 in. CMP Circular) was totally failed. The pipe was completely closed on one side. Overall, the pipe was corroded inside and outside as shown in Fig. 6(a) and (b). The roadway has a pothole and moderate cracks due to culvert deterioration. The embankment was partially eroded. The culvert has no end treatment. The condition rating for this culvert is as shown in Table 13.

(a) Corrosion on the outside surface of the CMP. (b) Total failure of the culvert end.

The culvert 31000131B05 (Slab – 2.4 m/8 ft opening, 2.1 m/7 ft rise, Rectangular in shape) is located in Shiawassee County and was also about 65 years old. This concrete culvert was deteriorated, but functioning normal. There was moderate deposition of soil sediments over the invert, and headwalls and wingwalls were heavily damaged with spalling. This has led to heavy corrosion of the reinforcing bars as shown in Fig. 7. There was minor cracking between the footing and wingwall; the roadway above the culvert has potholes and major cracks. The embankment was heavily eroded. The condition of the footing looks good. Overall, the culvert is in poor condition. The condition rating for this culvert is as shown in Table 13.

Condition of culvert structure 31000131B05.

Step 3: The third step in this process is to calculate the performance score of the culverts and categorize them into three zones – Green, Yellow and Red. The performance score is calculated by multiplying the condition rating of each component with their respective relative weight and finally summing up all the vales. The performance score for culvert 25001273A01 is as shown below in Table 14.

Culvert 25001273A01

Condition rating

Relative weight

Performance score

Condition of the invert

1

0.21115

0.21115

Condition of end treatment

3

0.14175

0.42525

Condition of overall culvert

2

0.39280

0.78560

Condition of roadway

5

0.05901

0.29505

Condition of embankment

3

0.06378

0.19134

Condition of footing

5

0.13118

0.65590

Final performance score

2.56000

The final performance score for culvert 25001273A01 is 2.56. This culvert will be categorized under the yellow or intermediate zone for short and long term planning. Similar calculation is done for other culverts and categorized as shown in Table 15.

Culvert identification number

Performance score

Zone

31000131B01

2.884

Yellow

31000131B02

2.120

Red

31000131B03

3.800

Green

31000131B04

2.430

Red

31000131B05

2.470

Red

The final step in the validation process was to identify the culverts in danger zone and calculate the Advanced Condition Assessment (ACA) performance score. The culverts in red zone are inspected in detail for specific problems and are given a condition rating between 5 and 0, where ideally 5 is excellent or new condition and 0 is complete failure. The ACA performance score is calculated in the same way as BCA as shown in the previous step. The ACA consists of inspection of the culvert barrel; if the culvert is not functioning or totally damaged, then the ACA performance score will be near to zero. Since, the culvert 31000131B04 was totally collapsed, the ACA performance score is calculated as zero. The ACA performance score for culverts 31000131B02 and 31000131B05 are as shown in Tables 16 and 17. Table 18 provides the validation summary for CIDCF and CAF models.

Culvert 31000131B02

ACA condition rating

ACA relative weight

ACA performance score

Cracking

2

0.3170

0.6340

Scouring

5

0.1703

0.8515

Settlement

2

0.1563

0.3126

Joint problem

1

0.1521

0.1521

Misalignment

1

0.1348

0.1348

Concrete surface

4

0.0690

0.2760

Final performance score

2.361

Culvert 31000131B05

ACA condition rating

ACA relative weight

ACA performance score

Cracking

1

0.3170

0.3170

Scouring

4

0.1703

0.6812

Settlement

2

0.1563

0.3126

Joint problem

3

0.1521

0.4563

Misalignment

4

0.1348

0.5392

Concrete surface

3

0.0690

0.2070

Final performance score

2.5133

Culvert No.

Location

Shape

Material

Span

BCA score

Zone

ACA score

Year built

25001273A01

Ingham

Circular

CMPb

48 in. (1219 mm)

2.560

Yellow

–

–

31000131B01

Shiawassee

Circular

Concrete

24 in. (609 mm)

2.884

Yellow

–

1931

31000131B02

Shiawassee

Circular

Concrete

24 in. (609 mm)

2.120

Red

2.361

1931

31000131B03

Shiawassee

Slab

Concrete

96 in. (2438 mm)

3.800

Green

–

1931

31000131B04

Shiawassee

Circular

CMP

24 in. (609 mm)

2.430

Red

–

1931

31000131B05

Shiawassee

Slab

Concrete

96 in. (2438 mm)

2.470

Red

2.513

1931

5 Conclusions

The main goal of this research was to develop a model for culvert inventory and inspection as a part of the asset management strategy. The asset inventory and inspection model is the foundation in developing any management strategy for preserving our deteriorating culvert infrastructure. This research developed a model for culvert inventory and inspection and validated the model by conducting a pilot field study.

The culverts throughout the nation are facing significant performance challenges as many are nearing the end of their design life. These culverts are in need of special attention in terms of proactive or preventive asset management. Many DOTs throughout the nation do not have appropriate protocols to track and inspect these deteriorating culverts. The models developed in this research project for a condition rating system and performance calculator will assist the state and local agencies in making proper decisions and in implementing a good asset management program.

The field study conducted in Michigan, successfully identified six culverts using a unique identification number and assessed the condition of the culverts. Three out of six culverts inspected were in the danger zone. The common problems identified were misalignment, joint failure, cracking, spalling, corrosion, scouring, age, erosion of the embankments, potholes or cracks on roadway, heavy vegetation and settlement problems. The DOTs can use this model in categorizing the culverts in different zones and develop short and long term plans for each zone.

Acknowledgement

This research project was possible through a grant from the Midwest Regional University Transportation Research Center (MRUTC) at the University of Wisconsin—Madison, the Michigan Department of Transportation (MDOT), and the Ohio Department of Transportation (ODOT).

References

- Infrastructure management: integrated AHP/ANN model to evaluate municipal water mains’ performance. Journal of Infrastructure Systems. 2008;14(4):305-318.

- [Google Scholar]

- An integrated model to evaluate losses in water distribution systems. Water Resource Management. 2008;1:1-2.

- [CrossRef] [Google Scholar]

- Bai, H., Sadiq, R., Najaran, H., 2008. Condition Assessment of Buried Pipes Using Hierarchical Evidential Reasoning Model, Journal of Computing in Civil Engineering, Vol. 22, No. 2, March 1, 2008. ©ASCE, ISSN 0887-3801/2008/2-114-122.

- Government Accounting Standards Series (GASS), 1999. “Statement No. 34 of the Governmental Accounting Standards Board,” No. 171-A, June 1999.

- Lee, S., Wang, J., 2008. Integrated AHP using data mining for credit evaluation. IIE Annual Conference and Expo 2008, May 17, 2008–May 21, 2008, P822–827.

- Li, X. D., Qiu, C. L., Zhang, G. M., et al., 2008. The risk assessment model of special equipment based on F-AHP and ANN. Proceedings – 4th International Conference on Natural Computation (ICNC), ICNC 2008, P540–545.

- Mitchell, G. F., Masada, T., Sargand, S. M., Tarawneh, B., Stewart, K. E., Mapel, S., and Roberts, J., 2005. “Risk Assessment and Update of Inspection Procedures for Culverts,” Report No. FHWA/OH-2005/002.

- Trenchless technology – pipeline and utility design.Construction and Renewal. New York: McGraw-Hill; 2005.

- Najafi, M., Wallace, R., and Baxter, R., 2008. Hydraulic Analysis of a Corrugated Metal Pipe (CMP) CIPP-Lined Culvert, Proceedings of No-Dig 2008 Conference, Dallas, Texas, April 27–May 2, 2008.

- Najafi, M., Salem, S., Bhattachar, D., Salman, B., Patil, R. and Calderon, D., 2008. An Asset Management Approach for Drainage Infrastructures & Culverts, Midwest Regional University Transportation Center – Wisconsin Department of Transportation. June, 2008. Available at <http://www.cuire.org>.

- Project Management, Processes, Methodologies, and Economics (Second ed.). Upper Saddle River, NJ: Prentice Hall; 2005.

- Analytic hierarchy process as a tool for infrastructure management, transportation research record: pavement management. Monitoring, Evaluation and Data Storage; and Accelerated Testing (1974):3-9.

- [Google Scholar]

- Design and implementation of water environment safety risk assessment model based on AHP. Chinese Journal of Scientific Instrument. 2009;30:P1009-P1013.

- [Google Scholar]

- Fuzzy comprehensive evaluation for construction project risks based on uncertainty AHP. Journal of Shenzhen University Science and Engineering. 2006;23(1):48-53. (in Chinese)

- [Google Scholar]