Translate this page into:

Development and characterization study of bagasse with stubble reinforced polyester hybrid composite

⁎Corresponding author. humali.manit@yahoo.com (Huma Ali)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

In the present day, recycling and reducing environmental pollution are the primary objectives of sustainable development. A lot of experts are considering the possibility of creating a new composite technology with waste materials. This work aims to investigate the effects of waste material on mechanical and hydrophobic properties, with a particular focus on bagasse fiber with stubble. The tensile, flexural, impact, and hardness properties of bagasse with stubble polyester composite were investigated to see if it may be used as a novel material in various engineering applications for a longer life. To improve the impact resistance of the composite, bagasse fibers is mixed in different ratios with polyester and stubble as infill. Additionally, a very tiny amount of TiO2 was added to every sample. Tensile, flexural, and impact mechanical properties were assessed using the Universal Testing Machine, the Rockwell Hardness Testing Machine, and the Izod Impact Test. Samples were hand-set out using varying weight ratios of binder, filler, and fiber. The study's findings demonstrated that the sample with a higher percentage of bagasse fiber demonstrated better mechanical and hydrophobic qualities as compared to the neat and other samples. It is an economical, long-lasting, and environmentally responsible option for a variety of applications.

Keywords

Baggase

Composite

Stubble

Mechanical properties and hydrophobicity

1 Introduction

The natural world is made up of composite elements. A piece of wood is composed of lignin, a composite material that holds long cellulose fibers together. Composite materials are made by combining two or more materials that don't dissolve or mix together yet have certain unique qualities. The composite's distinct qualities are the result of the interactions between the many components. For thousands of years, people have used composite parts in a range of applications. Conventional metal alloys, ceramics, and polymeric materials cannot meet the demands of contemporary technologies, which demand resources with specific combinations of qualities. This is especially true for the materials needed for applications in transportation, underwater research, and aircraft. For example, structural materials with low density, strength, stiffness, resistance to impact and abrasion, and corrosion resistance are in greater demand from aviation engineers. There is a lot of risk associated with this combination of features (Zahi, 2013). Since strong materials are usually rather thick, increasing strength or stiffness generally results in a reduction of impact strength. The ranges and combinations of material attributes have expanded and continue to expand with the development of composite materials (Abraham et al., 2013). The automotive, marine, aerospace, and defence industries all make extensive use of composite materials. Natural fibers have been researched as composite reinforcements because they are more versatile than conventional materials and have better mechanical properties. A few examples of thermoset composites consisting of a matrix and a reinforcement matrix are vinyl ester, epoxy, and polyester (Ahmad et al., 2015). A composite is typically used to describe any multiphase material that demonstrates a significant proportion of each component phases' characteristics, leading to a higher realisation of the properties. The combined action concept states that by carefully combining two or more elements, one can create combinations with improved properties. Trade-offs in the characteristics of a mix are typical.

Bio composites derived from renewable resources have gained importance globally due to their biodegradable nature. Bio-composites are the materials most suited for use in a range of disciplines because of their benefits for environmental sustainability. In bio-composites, natural fiber serves as reinforcement and bio-polymer serves as the binder. Three types of natural fibers are distinguished: fruit, seed, and leaf fibers. Natural bio-fiber generated bio-composites (BBC) are biocompatible, biodegradable, lightweight, energy-efficient, and environmentally benign in comparison to other binder fabric composites. Research in polymer science and technology is currently concentrated on composites made from renewable resources (Madhu et al., 2022). The large-scale requirement for biodegradable composites makes BBC a challenging issue for researchers everywhere. The primary sources of natural fibers are hemp, flax, sisal, jute, coir, banana, bamboo, sun hemp, and pineapple. However, other fibers, like rice, wheat straw, soybeans, sugarcane, and other agricultural waste products, may work well as bio-fiber. Bio-composite has multiple applications in the sectors of biomedicine, agriculture, packaging, and other relevant engineering fields (Arun and Rajadurai, 2016). Recently, there has been a notable increase in demand for natural fibers and the composites derived from them as novel advanced engineering materials (Ramesh et al., 2018). The main reasons why natural fibers are utilised are their high specific strength-to-weight ratio, as well as the fact that they are inexpensive, lightweight, simple to manufacture, recyclable, and renewable (Elsheikh et al., 2022). Additionally, they consume less energy from fossil sources. The creation of these materials is the consequence of a paradigm shift favouring natural fibers over synthetic fibers, as the market for eco-friendly materials is growing (Arun and Viswanathan 2019). Natural fiber composites are highly sought after in several industries, including automotive, sporting goods, food or medication storage, and lightweight applications, because of their versatility (Vincent et al., 2020).

Sugarcane is grown as a crop all over the world, and the residue that remains after the juice is removed is called bagasse (Chockalingam et al., 2022). India is reported to produce more than 200 million tonnes of sugarcane bagasse annually. Sugarcane is a renewable and natural agricultural resource (Kabeyi 2022). Sugarcane bagasse is composed of roughly 50 % cellulose, 25 % hemicellulose, and 25 % lignin. Sugarcane bagasse functions well as a composite reinforcement because of its high cellulose content and crystalline structure. About 50 % of bagasse's chemical makeup is made up of beta-cellulose, 30 % is pentosanes, and 2 % is ash. The age, source, soil type, and extraction method of the fiber all affect its composition. The ash level of other natural fiber sources, like wheat and rice straw, is frequently higher than that of sugarcane bagasse. Consequently, these materials are used less often as raw materials in the production of composites. Pitch and rind are the ingredients of bagasse.

Stubble fiber material is a natural fiber derived from agricultural waste, specifically the remaining stalks of cereal crops including maize, wheat, and rice. Stubble fibers, also known as Parali fiber, are an inexpensive and sustainable reinforcement material for composite structures. It describes the brief stalks of crops left in the field after harvesting, including maize, wheat, and rice. The many Indian states all have a common trend of growing facial hair. Stubble fibers are a good choice for filler since they offer a number of advantageous qualities. They can increase the overall strength and stiffness of composite materials because of their high tensile strength, superior stiffness, and low density. In addition to being renewable and biodegradable, stubble fibers are an environmentally responsible and sustainable substitute for synthetic fibers (Mukesh et al., 2023). It describes the brief stalks of crops that are left in the field after harvesting, such as maize, wheat, and rice.

The affordability of stubble fiber material is one of its main benefits. Because the fibers are derived from agricultural waste, they are easily accessible and reasonably priced, making them a desirable choice for applications where cost is a key consideration. Additionally, stubble fibers are lightweight, which helps lessen the finished product's weight and enhance its functionality. Because of its affordable price and acceptable qualities, stubble fiber material is a potential material for composites overall. As studies on environmentally acceptable and sustainable substitutes for synthetic fibers continue, stubble fiber may gain popularity as a solution for a variety of applications across several industries (Sain, 2020).

The current study aims to determine the advantages of employing sugarcane bagasse as a reinforcing material. Determining how stubble and sugarcane bagasse particles impact the mechanical and hydrophobic properties of the high-performance polyester composite is the main objective of the current investigation.

2 Material and methodology

2.1 Material

Bagasse and stubble were collected from near village area of Bhopal, Madhya Pradesh, India. Both were washed, dried, and sieve of size 4.0 mm, Fig. 1.

(a) Crushed bagasse. (b) Stubble.

2.2 Development of composites

The polyester and its hardener, methyl ethyl ketone peroxide, had a weight to volume ratio of 10:1 (as stated in the catalogue). Following this, separate composite samples (Samples 1–4) have been produced by raising the proportion of bagasse in each sample in the subsequent ratios: polyester, neat (Sample 1), polyester + stubble + bagasse in the ratio of 60:25:15 (Sample 2), polyester + stubble + bagasse in the ratio of 60:20:20 by percentage weight (Sample 3), polyester + stubble + baggase in the ratio of 60:15:25 by percentage weight (Sample 4). 2 % of TiO2 of polyester was also added in each sample to enhance the mechanical properties. To ensure a consistent mixture, the components were carefully stirred together using the hand lay method. The mixture was then gradually poured into a square mould that was 170 mm in length, 170 mm in width, and 4 mm in thickness. The casting was left in situ for 24 h, and then composite samples were removed from their mould. Specimens of the required size were cut in order to assess their physical, mechanical, and to perform additional characterization (Fig. 2).

Sample 1: polyester, Sample 2: polyester + stubble + baggase in the ratio of 60:15:25, Sample 3: polyester + stubble + bagasse in the ratio of 60:20:20, Sample 4. polyester + stubble + bagasse in the ratio of 60:25:15 by percentage weight.

2.3 Mechanical properties of composites

2.3.1 Tensile properties

Using testing apparatus from Instron model 3382, the tensile strength of composite samples was ascertained in compliance with ASTM D 638. Composite samples measuring 150x12.99x4 mm were examined. To ensure that the outcomes could be repeated in compliance with ASTM D638-10, five specimens of each composite sample were assessed. Measurements were made of elongation at break and tensile strength.

2.3.2 Flexural strength

According to ASTM D 790, composite test samples underwent a three-point bending test. The flexural characteristics of composite materials were investigated using the Instron Machine Model 3382. At room temperature, rectangular samples with dimensions of 80 × 10 × 4 mm3 were investigated at a cross head speed of 3 mm/min. The support span for the flexural test was 64 mm. That means that an average of five ASTM D790-10 specimens was given to each type of sample.

2.3.3 Compressive strength

The rectangular composite samples had dimensions of 50 mm in length, 50 mm in width, and 4 mm in thickness. The ASTM D 3410 compression test was carried out in a UTM machine to ascertain the significant value of the compression strength of the composite materials.

2.3.4 Impact strength

Rectangular samples with dimensions of 67 × 10 × 3.5 mm was tested for Izod impact using an Izod impact tester on a Tinius Olsen impact 104 machine. Five samples were used to test each component, and the average result was then shown. The samples were all evaluated utilising ASTM D 256-10.

2.3.5 Hardness Rockwell Tester

According to ASTM D 785, the hardness test was conducted. The visco-elastic properties of the substance can be determined with the help of this test. The basis of this test method is the ability of a certain sort of indenter to penetrate a material when applied under specific conditions. Fig. 3 represent the instrument of Hardness Tester.

Representation of Hardness Tester.

2.3.6 Water uptake

Each of the abovementioned composite samples was cut into tiny 10 × 2 × 0.2 cm pieces for the water absorption test. The composite samples were submerged in 500 cc of room temperature distilled water for varying durations (10 min, 30 min, 2 h, 12 h, and 24 h). The samples were taken out of the flask using tissue paper. We calculated the water absorption capacity of the composite materials using the initial and end weights. The water absorption was calculated using the formula below:

2.4 Scanning electron microscopy

An SEM, or scanning electron microscope, can be used to view the morphology of the polymer composites. Secondary electrons are produced by the composite as a result of interactions between the electron beam and the surface area during the “scanning” process. The incident electrons' backscattering is an additional possibility. The intensity of the secondary or backscattered electrons is determined and compared with the intensity of the scanned electron beam. A contrasting image of the surface of the composite is shown on the screen. Following the tensile test, the composite's fracture surface was examined using a SEM (model: Phenom Pro). The samples were connected to a carbon tap and then given a 20-second gold coating. A 5 KV voltage was used in all of the images.

3 Results

3.1 Mechanical properties of different composite samples

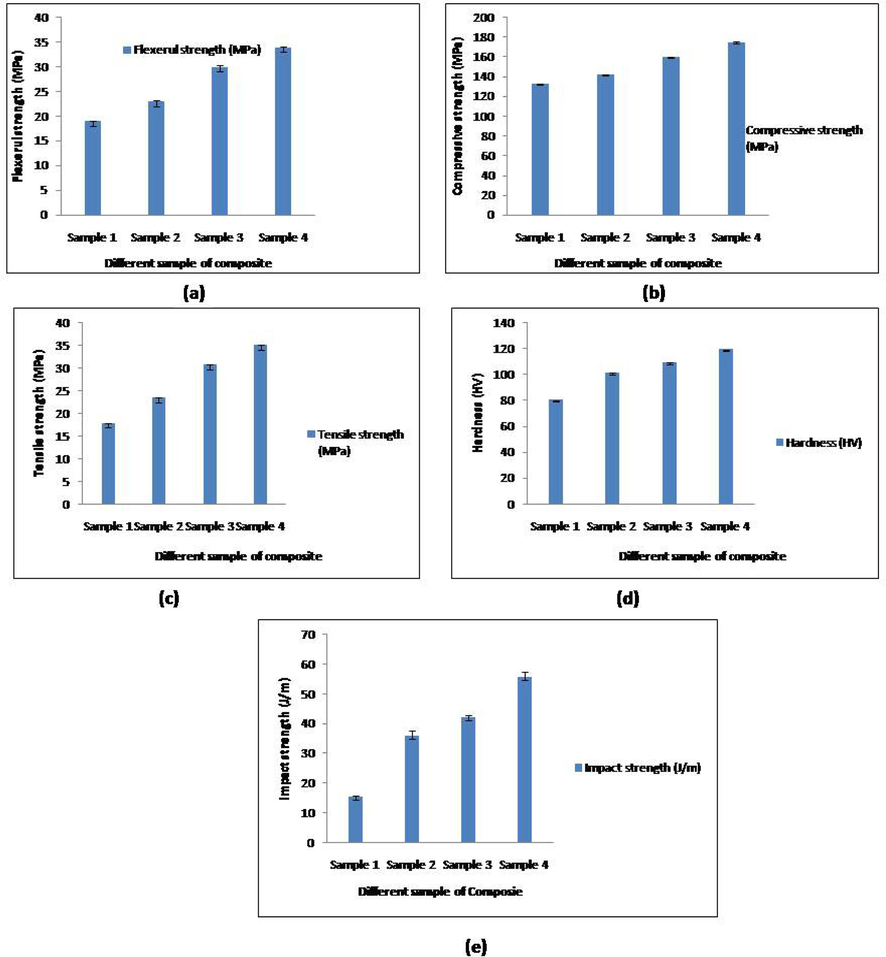

Fig. 4 depict the impacts of bagasse with stubble in various composite loading samples on various mechanical parameters, including compressive strength, tensile strength, flexural strength, impact, and hardness. For several mechanical testing, the average values of the preliminary results are taken. According to the experimental findings, by increasing the percentage of bagasse in stubble composites improves their tensile and flexural capabilities when compared to the neat sample. It was found that, all the mechanical characteristics were raised by the addition of bagasse in each sample, Fig. 4. All values include a variance on the third digit following the decimal to indicate uncertainty.

Consequence of bagasse with stubble loading on (a) Flexural strength (b) Compressive strength (c) Tensile strength (d) Hardness and (e) Impact strength of different samples of composite.

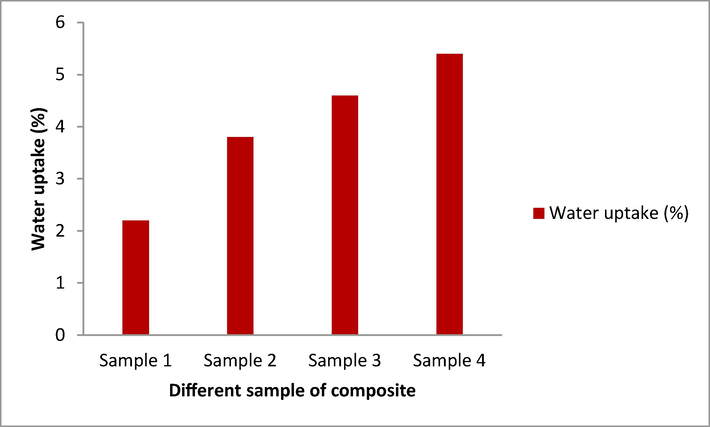

3.2 Water uptake

Fig. 5 shows how well various composite samples reinforced with bagasse and stubble absorb water. Bagasse enhances and can continue to increase over time the water absorption in composites. Composites' ability to absorb water is influenced by the fiber surface and matrix-fiber bonding.

Percentage of water uptake of different samples (Sample 1–4) of bagasse with rice husk composite.

3.3 Examination of several composite materials using scanning electron microscopy

Fiber-matrix adhesion, fiber dispersion in polymer matrix, surface roughness, adhesive failure, fractured surfaces, networks, and phase boundaries in blends are just a few of the studies and applications involving polymers and composites where SEM has been applied. Utilizing the scanning electron microscope (SEM) to understand more about the composition of composites is common practice. How to use SEMs to look at cracks in polymeric composites is still up for debate. Many authors favors conductive sputter coating over low-voltage or variable-pressure methods because it protects the original surfaces. SEM is used to evaluate the morphology of the various composite samples. Fig. 6 uses SEM micrographs of neat and polyester with bagasse and stubble in various ratios (a–d) to show the morphology of the materials. Fig. 6(a) depicts the sample without fiber, while Fig. 6(b) through (d) depict the sample with bagasse fiber and stubble. Samples of bio fiber composites showed a matrix and fiber that adhered strongly to one another. Fig. 6(a) shows how Sample A, a clean composite made of polyester, showed the existence of air bubbles without fiber surfaces. To enhance the interaction between the matrix and the fiber, the bio fiber surface is more porous and has obvious pores. Baggase increases the number of holes on the surface of the composites, improving their mechanical characteristics and enhancing fiber locking with the matrix.

SEM morphology of (a) Sample 1: Neat, (b–d) Sample 2–4.Polyester + bagasse fiber + stubble in different proportion.

4 Discussion

The rind is the hard-exterior layer made of low-molecular-weight fibers that includes lignin, hemicellulose, and cellulose. About 40–50 % of biomass is composed of cellulose, a linear polymer made up of D-glucose units joined by −1,4-glycosidic linkages and polymerized to a degree of 500–1500. The degree of polymerization results in hydrogen bonds both within and between molecules. Because of its secondary contacts and bond orientation, cellulose has a high tensile strength and is insoluble in most solvents, as predicted (Manzoor et al., 2012). Cellulose is naturally insoluble in most solvents and has a high tensile strength due to its secondary contacts and bond orientation. Since cellulose is hydrophilic, it might prevent products from breaking down and enzymes from diffusing into their surroundings (Wohlert et al., 2022). This is due to the fact that it causes a denser water layer to form. According to studies, bagasse has a crystallinity index of roughly 35 % and a density of 1.28 g/cc (Ibrahim et al., 2022). According to Kordkheili et al. (2012), the tensile modulus is 2.7 GPa and the reported tensile strength ranges from 20 to 50 MPa. Sugarcane bagasse is hydrophilic, like all other naturally occurring cellulosic fibers. This is a drawback because it absorbs moisture from the environment, which leads to swelling and a loss of mechanical characteristics. This natural fiber scarcity could be significantly reduced by altering them using various chemical processes (Karp et al., 2013).

Particle reinforcement may be equally as significant as fiber reinforcement in achieving the desired characteristics for polymer composites. The particles may enhance the unique wear, thermal, mechanical, and damping qualities of the composite. Composites are commonly formed using a variety of ceramics, nanoparticles, and metallic particles; however, novel bio-based particle types are becoming more and more popular for use in multi-dimensional composites (Agrawal et al., 2018). Composites may also use bio-based fillers made from animal, human, or marine waste (Alshahrani and Arun, 2022). These agricultural wastes can be transformed into beneficial bioceramics that aid in solid waste management, reduce pollution, and improve process efficiency (Neopolean and Karuppasamy, 2022). Epoxy composites made from biosilica particles produced from red matta rice husk ash was studied by Poomathi et al. It was discovered that the mechanical and fatigue behaviour of the composite was enhanced by the addition of biosilica particles (Poomathi and Roji, 2022). For several reasons, it can be challenging to create Bagasse-Stubble Composites suitable for use as structural materials. The good degree of stiffness found in composite materials can be increased even further by including fibers. However, this polymer matures relatively quickly, resulting in an increase in stiffness after a sudden reduction in deformability (Cui et al., 2020).

The samples' increased and improved stress transmission efficiency was made possible by a continuous interfacial region that emerged from improved compatibility (Kumar et al., 2022). A similar tendency is also observed for the bagasse fiber-reinforced composites (Balaji et al., 2017). In our case, impact resistance increased with the addition of bagasse fibers and with an increase in fiber content. The effect must be the sum of several local deformation events that take place during the deformation of the specimen (Vincent et al., 2022). It has been shown in the past that shear yielding which is caused by fibre fractures or debonding requires more energy than debonding alone. Local deformation processes often dictate the macroscopic properties of composites. Previous studies have shown a strong relationship between the strength of the composite and one of the local processes (Renner et al., 2010). It is noteworthy that composites made of natural fibres perform well in tensile applications. Similar findings were obtained by Mostafa et al. (2016) in a previous investigation. Bagasse composites absorb less energy than other biofibers because of the alkali treatment. The composite surface becomes rougher and absorbs water more quickly once bagasse is added. According to Kurniawan et al. (2013), water absorptivity rises with higher percentages of reinforcement in composites and falls with lower percentages of reinforcement.

Surface morphology cannot yet be quantified or broadly described. A variety of methods, including as atomic force microscopy, optical profilers, laser profilometry, and mechanical profilers, have historically been used to evaluate surface roughness. Quantitative surface morphology has recently been evaluated using image processing software and scanning electron microscope images (Shi et al., 2018). Surface characterization and quantification were carried out for surface assessment in the current work (Ibrahim et al., 2020). Researchers are increasingly paying more attention to these fiber hybrid reinforced composites because to their easy availability, low cost, light weight, and environmentally favourable design. The world of natural fiber-based hybrid composites is still relatively new to us.

Generally speaking, waste by-products like bagasse and stubble can be used responsibly to halt climate change, which is a serious threat to our ecosystem. Moreover, the garbage will serve a useful purpose. Due to its superior mechanical qualities, the resultant composite was utilised in the construction of automotive parts.

5 Conclusion

Green composites are becoming more and more popular as potential substitutes for synthetic fiber-reinforced polymer composites because of their accessibility, non-toxicity, and non-corrosive qualities. To achieve the required qualities, research on these fibers and their combined forms is currently being conducted globally. Based on their many uses and unique properties, fibers and composites are categorised. The development of environmentally friendly bio-composite materials offers a compelling chance to employ a range of fibers, including bagasse and stubble. It weighs less than earlier models and has better mechanical qualities. It could be utilised for massive head development in a nautical setting as well as liner materials for ships. In construction, automobile exterior sheets are used. The analysis concluded that less water immersion and improved mechanical characteristics were the results of the investigation. Reaming improved the mechanical characteristics of each prepared sample. Any produced composite material can be used to make vehicles.

CRediT authorship contribution statement

Huma Ali: Writing – review & editing, Writing – original draft, Validation, Methodology, Investigation. Savita Dixit: Writing – review & editing, Supervision, Investigation. Saud Alarifi: Writing – review & editing, Validation, Software, Formal analysis.

Acknowledgment

This research was supported by Researchers Supporting Project number (RSP2024R27), King Saud University, Riyadh, Saudi Arabia.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Environmental friendly method for the extraction of coir fibre and isolation of nanofibre. Carbohydr. Polymer.. 2013;15(92):1477-1483.

- [Google Scholar]

- Micro-fibrillar fiber of bicomponent polymer blends: Traditional paradigm with modern approach. Adv. Mater. Proc.. 2018;3(7):433-442.

- [Google Scholar]

- A review: natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol. Mater. Eng.. 2015;300(1):10-24.

- [Google Scholar]

- Mechanical, fatigue and DMA behaviour of high content cellulosic corn husk fiber and orange-peel biochar epoxy biocomposite: a greener material for cleaner production. J. Clean. Prod. 2022

- [Google Scholar]

- Thermo-mechanical characterization of siliconized E-glass fber/hematite particles reinforced epoxy resin hybrid composite. Appl. Surf. Sci.. 2016;384:99-106.

- [Google Scholar]

- Mechanical behavior of short bagasse fiber reinforced cardanol-formaldehyde composites. Fibers Polym.. 2017;18:1193-1199.

- [Google Scholar]

- Optimization of abrasive wear characteristics of polyethylene/acrylate copolymer nanocomposites. Adv. Mater. Sci. Eng. 2022

- [Google Scholar]

- Physical ageing of poly (lactic acid): factors and consequences for practice. Polymer. 2020;186:1-12.

- [Google Scholar]

- Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Cleaner Eng Technol.. 2022;8(100450):1-16.

- [Google Scholar]

- Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J. Mater. Res. Technol.. 2020;9(1):200-211.

- [Google Scholar]

- Pretreatment Strategies for delignification of Sugarcane bagasse: a review. Braz. Arch. Biol. Technol.. 2013;56(4):679-689.

- [Google Scholar]

- Some of the physical and mechanical properties of cement composites manufactured from carbon nanotubes and bagasse fiber. Mater. Des.. 2012;33:395-398.

- [Google Scholar]

- A review on applications of natural Fiber-Reinforced composites (NFRCs) Mater Today Proc.. 2022;50:1632-1636.

- [Google Scholar]

- Effects of repetitive processing, wood content, and coupling agent on the mechanical, thermal, and water absorption properties of wood/polypropylene green composites. J. Adhes. Sci. Technol.. 2013;27:1301-1312.

- [Google Scholar]

- Introduction to bio-based fibers and their composites. Adv. Bio-Based Fiber. 2022:1-20.

- [Google Scholar]

- Dilute sulphuric acid: a cheap acid for optimization for bagasse treatment. Science International (Lahore); 2012. p. :41-45.

- Effect of equi-biaxially fabric prestressing on the tensile performance of woven E-glass/polyester reinforced composites. J. Reinf. Plast. Compos.. 2016;35(14):1093-1103.

- [Google Scholar]

- Rice stubble: cotton fly waste composites for acoustic applications. J. Text. Inst.. 2023;1–15

- [Google Scholar]

- Characterization of silane treated opuntia short fbre and bagasse biosilica toughened epoxy resin composite. SILICON. 2022;40:9331-9340.

- [Google Scholar]

- Experimental investigations on Palmyra sprout fiber and biosilica-toughened epoxy bio composite. Biomass Conv. Bioref.. 2022;14(6):1-16.

- [Google Scholar]

- Drilling of pultruded and liquid composite moulded glass/epoxy thick composites: experimental and statisticalinvestigation. Measurement. 2018;114:109-121.

- [Google Scholar]

- Micromechanical deformation processes in PP/wood composites: Particle characteristics, adhesion, mechanisms. Compos. Part A-Appl.. 2010;41(11):1653-1661.

- [Google Scholar]

- Production of bioplastics and sustainable packaging materials from rice straw to eradicate stubble burning: a mini review. Environ. Conserv. J.. 2020;21(3):1-5.

- [Google Scholar]

- Measuring topographies form conventional SEM acquisitions. Ultramicroscopy. 2018;191:18-33.

- [Google Scholar]

- (2020) Strength characterization of caryota urens fbre and aluminium 2024–T3 foil multistacking sequenced SiC-toughened epoxy structural composite. Biomass Convers. Biorefn.. 2022;12(1):1-11.

- [Google Scholar]

- Cellulose and the role of hydrogen bonds: not in charge of everything. Cellul.. 2022;29:1-23.

- [Google Scholar]

- Enhanced properties of fly ash-reinforced unsaturated polyester composites. Int. J. Mater. Eng. Innov.. 2013;4:241-257.

- [Google Scholar]

Appendix A

Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.jksus.2024.103231.

Appendix A

Supplementary data

The following are the Supplementary data to this article: