Translate this page into:

Bio-nanocomposite films loaded with lemon leaf extract for bio packaging application

⁎Corresponding authors. mslakshmi@clri.res.in (M. Suguna Lakshmi), sumathijones@gmail.com (C. Sumathi Jones), psk_66in@yahoo.com (Sasikumar Pattabi)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Objective

The present article details the preparation and characterization of bio-nanocomposite films loaded with nanoclays and chitosan which are the catalysts for retaining the fresh quality of flowers, fruits, and vegetables and extending their shelf life under packed with this film. The development of new packaging films is currently an emerging field for the consumers and edible goods trading industries. Hence, novel bio packaging films with a unique combination is essential to ensure optimum characteristics for the bio packaging films, thereby obviating synthetic plastics.

Methods

Synthesis and characterization of the formulated blends of carboxymethylcellulose incorporated with chitosan, nanoclays, epoxy, and polyethylene glycol with the addition of lemon leaf extract (LLE) and analysis of their antibacterial activity.

Result

The results indicate that when the jasmine flower buds were packed with the synthesized film, retain their buddy state for a minimum of 5 days at room temperature, freshness, and fragrance.

Conclusion

Hence, the nano-bio packaging film will ensure the transportation of daily harvested flowers, fruits, and vegetables from farms to firms, stores, and homes.

Keywords

Bio packaging

Nanocomposite films

Chitosan

Carboxymethylcellulose

1 Introduction

The nanocomposite is a novel generation of composite materials containing one of the constituent phases that have one dimension less than 100 nm (Samir et al., 2005 Pawar and Purwar, 2013). The well-dispersed nanoparticles enhance tensile properties and ductility as the small size is devoid of inducing high-stress concentrations in the matrix (Hatakeyama et al., 2004; Ren et al., 2003, Reza Arjmandi et al., 2015). Although these biodegradable polymers have mostly been used in the food industry and have not found broad applications in the packaging industries to replace conventional plastic materials, they can be an attention-grabbing way to overcome the curb of petrochemical resources in the future. Biodegradable plastics can form the foundation for environmentally better, eco-friendly alternatives (Fritz et al., 2001; Stevens et al., 2002; Meritaine da Rocha et al., 2018). Hence, there is pertinent research to develop eco-friendly substitutes with low density, cost-effectiveness, minimum technology involved in processing, and superior design in the packaging (Barton et al., 2014; DiogoVideira-Quintela et al., 2022).Table 1.. C: Carboxymethylcellulose, C: Chitosan, M: MMT, P: Polyethylene glycol (PEG), E: Epoxy, LLE: Lemon Leaf Extract.

Sl No

Code

w/w/w/w/w/w (Weight Ratios)

I

CCM

1:1:0.01:0:0:0

II

CCMP

1:1:0.002:0.05:0:0

III

CCMPE

1:1:0.002:0.05:0.01:0

IA

CCM-LLE

1:1:0.01:0.015

IIA

CCMP-LLE

1:1:0.002:0.05:0.015

IIIA

CCMPE-LLE

1:1:0.002:0.05:0.015

According to the Biodegradable Products Institute (BPI), biodegradable plastic is degraded by natural microorganisms in two steps fragmentation process. The packaging is certified as compostable and biodegradable (European standard EN-13432). Biopolymers are biodegradable polymers of monomeric units that are covalently bound to form larger structures and fragmented by the action of microorganisms, into carbon dioxide and water. Some of the biopolymers like starch cellulose and proteins are extracted or removed from biomass (Nawrath et al., 1995; Bratovcic et al., 2015).

CMC, an organic biopolymer obtained from various sources (trees, synthesized by algae, fungi, bacteria, and some animals) has a syndiotactic configuration of β (1, 4)-d-glucose unit. The properties of CMC include renewable nature, low density, and a relatively reactive surface which is mainly due to the hydroxyl groups. It is cost-effective and utilized in lotions, vitamin oils, and cosmetic products like binders and stabilizers and is extensively used in food packaging (Vartiainen et al., 2014; Kadajji et al., 2011; Jia Deng et al., 2022).

Chitosan is the primary biopolymer structurally similar to cellulose, synthesized from the deacetylation of chitin is a linear copolymer composed of d-glucosamine and N-Acetyl-d-glucosamine obtained by the partial deacetylation of chitin mostly found in the crustaceans, cell walls of fungi, and other biomaterials (Mohamed et al., 2011; Vazquez et al., 2015). The amino group enables chitosan to be a cationic polyelectrolyte (pKa ≈ 6.5), rare in nature with biodegradable, biocompatible, non-toxic with anticancer and antimicrobial properties (Gupta et al., 2004; Tripathi et al.,2008, María Flórez et al., 2021).

Montmorillonite, a sandwich-type structure consisting of tetrahedral silica sheets bilayer with a central octahedral alumina sheet carrying a high negative charge which can bond to the polymeric cations and enhances the mechanical properties and as well the antibacterial activities (Videira-Quintela et al., 2021). Epoxy compounds have superior mechanical behavior, good adhesion, anti-corrosion, excellent electrical properties, and inexpensiveness. Epoxies are used for various applications like coatings, adhesives, electronic packaging, and structural applications (Thori et al., 2015). The properties like different crosslink densities, molecular weight, and mechanical properties of an epoxy system depend upon the curing agent and conditions of the system (Chung et al., 2010; Eiras et al., 2009). Though bisphenol, an epoxy is toxic, is still considered a de facto standard in food packaging applications modified with eco-friendly chemicals and remains stable when it is in contact with aqueous, acidic, and alcoholic foodstuffs (Zineb Kadri et al., 2021).

The selection of LLE for making biopackaging film is due to its Citrus lemon volatile oil possessing phytochemical and antibacterial activity against Gram-positive from Staphylococcus aureus NRRL B-313, Bacillus cereus NRC and Gram-negative from Pseudomonas aeruginosa NRC B-32 and Escherichia coli NRC B-3703 (Mohsen Asker et al., 2020).

The biodegradable film is the biopolymer film consisting of one or two organic materials made of organic materials of polysaccharides, proteins, and lipids. If the films contain two natural materials that can be readily biodegraded, it called biocomposites degradable films (Rudrapatnam et al., 2001). The mechanical characteristics of protein-based films could improve by blending these biopolymers with synthetic polymers. A composite material is made up of the union of two or more components separated by a boundary that varies in form and chemical composition with superior quality to individual components and formed by aligning extremely active and inflexible constituents such as fibers and particulates in a binder called the matrix (Nourbakhsh et al., 2009). The materials have extraordinary mechanical properties (Croisier et al., 2013; Belmonte et al., 2015, Zhao et al., 2015).

The present study is on the preparation and characterization of bio-nanocomposite films using the unique blends of natural polymers of carboxymethylcellulose, and chitosan, film forming and crosslinking polymers of polyethylene glycol and epoxy, nanoparticles of montmorillonite of different ratios with the incorporation of LLE that offers extended shelf life by holding the freshness and fragrance of the packed product of highly perishables from the garden harvest. The physical properties of the films are determined by tensile testing. The thermal property uses thermogravimetric analysis and differential scanning calorimetry to observe the molecular degradation using heat exposure. The antioxidant activity of the film by using an ABTS assay. The antimicrobial activity is carried out against gram-positive (Bacillus subtilis) and gram-negative (E.coli) bacteria. The storage stability of the films is assessed through fragrance and freshness.

2 Materials and methods

2.1 Materials

The lemon leaves were collected from CSIR-CLRI garden, Chennai. Carboxymethylcellulose (CMC, C28H30Na8027; mp 270 °C; d 1.59; Molecular weight-90,000; D.S 0.70), Chitosan a Poly(d-glucosamine) Deacetylated chitin, (C12H24NO9), Montmorillonite (MMT, ((Na,Ca)0.33(AlMg)2(Si 4O10 )(OH)2 NH 2O) are purchased from Sigma-Aldrich. Epoxy (Diglycidylether of Bisphenol A resin (DGEBA, LY556, EEW 180–185, Density 1.23, Refractive Index 1.57 and viscosity 10,000 cP) is supplied by Ciba Specialty Chemicals Pvt. ltd., India. Triethylenetetramine (TETA, Aradur HY951) supplied by Huntsman International Pvt. ltd., India.

2.2 Preparation of plant extract

Leaves of lemon are thoroughly washed with distilled water, air-dried in a sterile condition for 48–72 hrs, and finely ground into powder. About 25 g of fine powder mixed with 100 ml methanol solution was placed in the shaking incubator overnight, collected, and filtered. The filtrates kept remained for air drying. The obtained residue is used for further studies.

2.3 Preparation of the CCM, CCMP, and CCMPE films

The chitosan (CN) solution is prepared at different concentrations using a 1 % acetic acid solution and stirred for about 4 h to attain a homogeneous mixture and the CMC solution with distilled water. Both the CMC and CN solutions are combined and stirred to obtain a homogenized blend. To the CMC/CN blend, a calculated ratio of MMT dispersions is incorporated to represent the compositions of CMC/CN/MMT abbreviated as CCM. To the CCM blend a calculated quantity of PEG, and PEG (P) with Epoxy (E) are added independently to obtain the blends of CCMP and CCMPE respectively. The homogenous mixture of CCM, CCMP, and CCMPE is cast in a petri dish and dried at 50 °C for 48 hrs and the films formed are removed from the Petri dish and stored in an air-tight container to use for further studies.

2.4 Preparation of CCM-LLE, CCMP-LLE, and CCMPE-LLE films

The lemon leaf extract (LLE) is added to the different composition blends of CCM, CCMP, and CCMPE at various ratios and coded based on their composition (Table 2). Each composition of blends is taken separately in an RB flask and stirred at room temperature for homogenization, cast on a petri dish, and dried at room temperature. The films are further cured at 50 °C for 48 hrs to ensure the completion of the crosslinking between the polymers. The formed films denoted as CCM-LLE, CCMP-LLE, and CCMPE-LLE are used in further studies.

2.5 Antioxidant assay (ABTS)

The stock solutions of 7.4 mM ABTS and 2.6 mM potassium persulfate solution and the working solution are prepared by taking equal quantities of stock solution and placing them in the dark for 12 h. Fresh ABTS solution is prepared for each assay. The sample was mixed in a 1:1 ratio with ABTS solution for 2 h in a dark condition and absorbance is measured using a spectrophotometer at 734 nm.

2.6 Antimicrobial activity by agar well diffusion method

The plant extract of 1.5 mg was dissolved in 1 ml of the respective solvent prepared and inoculated with the bacteria uniformly using a sterile cotton swab on a sterile Petri dish. 70 µL of plant extract were added to each well (7 mm diameter holes cut in the agar gel) in an individual plate and the control well was loaded with the respective solvent in each plate. The systems were incubated for 24 h at 36 °C ± 1 °C, after incubation, confluent bacterial growth was observed and inhibition was measured in cm.

2.7 Phytochemical screening

The extract of lemon leaves showed the presence of Terpenoids, Phenols, Steroids and Sterols, Phlobatannins, Saponins, and Cardiac Glycosides.

2.8 Thermal degradation (TGA/DSC)

Thermogravimetric analyses of CCM, CCMP, and CCMPE, and with LLE content, CCM-LLE, CCMP-LLE, and CCMPE-LLE are obtained and conditioned at 25 °C and 53 % of relative humidity and analyzed at STA 449F3 in a Thermogravimetric analyzer. About 10–20 mg was placed in a platinum crucible and heated from 20 to 1000 °C at a rate of 20 °C. The test was carried out in triplicate for each film.

2.9 Tensile testing and storage stability

The tensile strength (TS) of the film samples was determined according to ASTM standard method D 882–93 with a Universal Tensile testing machine (Instron). The experiment is carried out at 25 °C). The film samples are cut into rectangular specimens of size 2 mm × 10 mm. The gauge length is set at 10 mm between the two grips with the testing speed at 50 mm/min and observed during pulse intervals. The values of tensile strength are expressed as Mpa. Storage study is carried out with the films which are sealed, and flowers had been placed for the research purpose.

2.10 Degree of film degradation

About fifteen different test tubes containing 10 ml of nutrient broth plugged with cotton are taken and autoclaved. Then, 1 ml of microbial culture containing Bacillus subtilis and biofilm degradation studies are evaluated for 5 days.

2.11 Statistical analysis

All the experiments are in triplicates and quantitative data is obtained as mean, Standard deviation(S.D), Statistical analysis using one-way ANOVA, and a significant difference is considered P < 0.05.

3 Results and discussion

The composition of blends for the preparation of CCM-LLE, CCMP-LLE, and CCMPE-LLE films was standardized. The prepared films were subjected to physicochemical characterization.

3.1 Antibacterial activity

Table 2 illustrates the significant antibacterial activity of aqueous extract of lemon leaves against Bacillus sp. (2.2 cm) and E. coli SPS. (1.9 cm) for the sample (i) and (iv) and the least antibacterial activity for the sample (iii) and (iv) for the gram-negative bacteria. C: Carboxymethylcellulose, C: Chitosan, M: MMT, P: Polyethylene glycol (PEG), E: Epoxy, LLE: Lemon Leaf Extract.

Sample name

Organism/ Zone of inhibition

E.coil

Bacillus.sp

CCM

1.9 cm

2.2 cm

CCMP

1.8 cm

–

CCMPE

–

0.6 cm

CCM-LLE

–

2.2 cm

CCMP-LLE

1.6 cm

2.3 cm

CCMPE-LLE

0.1 cm

0.1 cm

3.2 Antioxidant assay

The antioxidant activity is nearly 80–85 %. The antioxidant activity of CCM-LLE, CCMP-LLE, and CCMPE-LLE is determined by measuring the decolorization of the ABTS. The radial cation reduction is expressed as the percentage of scavenging using the phenolic and flavonoid compounds of the extracts. A wavelength of 734 nm is used to measure the decolorization of radical cation without any intermediary radical. The ROS (Reactive oxygen species) released during the detoxification in the cells are antagonized by antioxidant compounds. This aids the cells from cell lysis or cell death. The antioxidant activities have been reported by many phytochemicals or secondary metabolites. The antioxidant activity of LLE is illustrated in Table 3. The 200 µg/mL of water extract shows the better antioxidant activity of aqueous extracts.

Samples

% of antioxidant activity

25 (µg/mL)

50 (µg/mL)

100 (µg/mL)

200 (µg/mL)

Aqueous extract

45.3

50.7

52.6

61.4

3.3 Phytochemical test

A brown ring is formed in the Liebermann test which indicates the presence of steroids. The appearance of violet color in Raymond’s test indicates the absence of Glycosides. In the case of the Froth test, there is a foam formation that confirms the presence of saponins and the appearance of dark green color in the Ferric Chloride test gives us the presence of tannins. The presence of secondary metabolites such as steroids, saponins, and tannins could be used to check the preservative property of the packaging films. (Fig. 1).

Schematic representation of the bio nanocomposite films prepared adding the lemon leaf extracts.

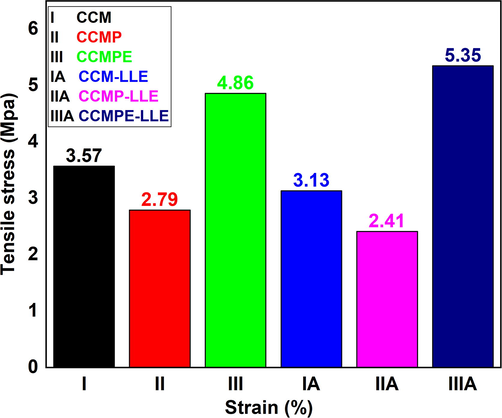

3.4 Tensile strength

The tensile strength properties are evaluated for the films loaded with LLE (CCM-LLE, CCMP-LLE, and CCMPE-LLE) and without LLE (CCM, CCMP, and CCMPE) (Fig. 2). The LLE-loaded films have exhibited a marginal decrease when compared to the without LLE load films due to the reduction in the crosslink density arising because of the presence of low molecular weight compounds that remain not linked with main chain segments. A decreased value observed in the CCMP sample is due to the PEG molecule which is a long and linear aliphatic chain that has acted as flexibility. The CCMPE films have exhibited the highest strength properties attributed to the three-dimensional curing structure exerted by the epoxy resin within the blends of the formulation.

Tensile strength properties of bio nanocomposite films.

3.5 Storage stability

The storage stability of the films is evaluated by packing jasmine flowers in each film for five days. After a specific period, it is observed that the flowers are found fresh and also maintained their natural fragrance without any decomposition odor.

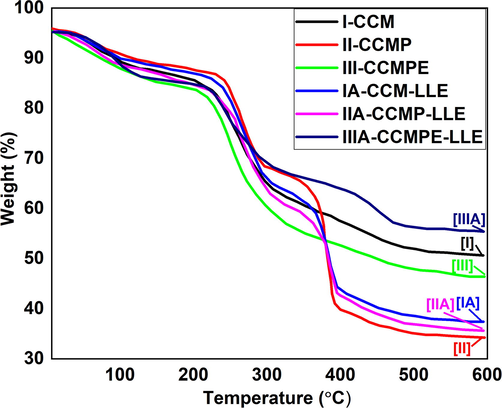

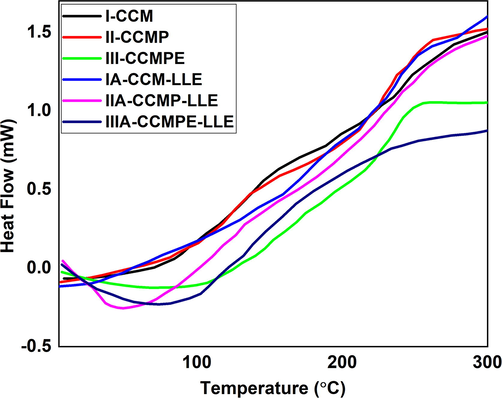

3.6 Thermal gravimetric analysis (TGA) / DSC curves of biofilms

TGA helps us to find out if the temperature starts degrading. The films are stable up to 250 °C. Beyond that temperature only thermal degradation takes place and shows the high thermal stability of the films. All the films are stable up to 80 °C. Therefore, the films can be used not only in cool temperatures, and room temperatures but also at higher temperatures. The graph interprets that there are three stages of degradation in the first curve around 60–100 °C and at 200 °C due to structural degradation of water molecules of the films, then due to degradation of major segment in polymers at 200 °C − 400 °C and the final curve occurs due to the carbonization of polymeric material at 400 °C − 700 °C. A 50 % degradation occurs at 300 °C and 400 °C respectively and the results are given in Fig. 3. The DSC analyses show a maximum glass transition temperature (Tg) at 107 °C for CCMPE-LLE, ie., Epoxy and PEG-loaded film. The CCMP-LLE, i.e., PEG-loaded film has shown a loss of moisture at 50 °C due to the hygroscopic nature of the PEG molecules. All the nano clay and Chitosan-loaded films have exhibited Tg values between 86 and 107 °C confirming the thermal stability of the prepared films as seen in Fig. 4.

Thermogravimetric analysis (TGA) of bio nanocomposite films.

Differential scanning calorimetric (DSC) analysis of bio nanocomposite films.

3.7 Degree of film degradation

The OD value lies between 0.05 and −0.05 for all the samples. In the present study, Chitosan, CMC-based films with added MMT and Epoxy are prepared by using different concentrations. With the modification of the clay dispersion technique, the films are obtained with better water barrier properties, demonstrating the importance of developing methods for the addition of plant extract to the polymer matrix. Similar results have been reported in earlier studies (Karpiński, 2015; Sudheer et al., 2014). The LLEs are tested against Gram-positive organisms and Gram-negative organisms. Of the two organisms, the extract has a very strong antibacterial activity against Gram-positive Bacillus. sp organisms and E.coli among Gram-negative organisms. Also, the technique is preceded by the thermal gravimetric analysis, then the biodegradability and storage stability assayed by the jasmine flowers was stable for 5 days. These results suggest a high potential for these films to be used as active packaging materials, and further studies must be developed to access bioactivity and behavior a long shelf-life (Srinivas et al., 2010; Cheng et al., 2014).

The reports of the present study corroborate with earlier investigations and indicate the high potential for the use of the nanocomposites in bio packaging applications (Gajanand et al., 2014; Samiey et al., 2014).

4 Conclusions

Bio nanocomposites are one of those man-made substances which have found extensive usage and utility in present-day activities from water bottles to airplanes. For the last 60 years, nanocomposites have grown progressively to form one of the more attractive domains in food science. The present study reveals the possibility of utilizing bio nanocomposites in food packaging owing to their antioxidant, and antimicrobial properties. Furthermore, due to thermostability and extended shelf life, the LLE-impregnated bio nanocomposite will pave way for biodegradable eco-friendly food packaging components in the food processing industry. However, its extensive use in other industries is being explored through further studies.

Acknowledgment

The authors M.Suguna Lakshmi and A.Tamilselvi acknowledges the facility provided by CLRI-CATERS and the funds from CSIR-CLRI (MLP13/1716 & MLP 18). The authors would also like to thank Sree Balaji Dental College and Hospital for their support.

Authors contribution

Authors have contributed equally.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Enhanced ductility and tensile properties of hybrid montmorillonite/cellulose nanowhiskers reinforced polylactic acid nanocomposites. J. Mater. Sci.. 2015;50(8):3118-3130.

- [Google Scholar]

- Phytochemical constituents and antibacterial activity of citrus lemon leaves. Center. 2020;44:194.

- [Google Scholar]

- Biopolymer chitosan and its derivatives as promising antimicrobial agents against plant pathogens and their applications in crop protection. Int. J. Carbohydrate Chem. 2011:1-29.

- [Google Scholar]

- Joanna Barton, Arkadiusz Niemczyk, Krystyna Czaja, Lukasz Korach, Beata Sacher-Majewska,2014, Polymer composites, bio composites and Nanocomposites. Production, Composition, Properties and application fields-Division of chemical technology and polymer chemistry.68,4:280-287.

- Review Effect of the Network Structure and Programming Temperature on the Shape-Memory Response of Thiol-Epoxy “Click” Systems. Polymers. 2015;7:2146-2164.

- [Google Scholar]

- Application of polymer nanocomposite materials in food packaging Croat. J. Food Sci. Technol.. 2015;7(2):86-94.

- [Google Scholar]

- Bioinspired layered materials with superior mechanical performance. Acc. Chem. Res.. 2014;47

- [Google Scholar]

- Chitosan-based biomaterials for tissue engineering. Eur. Polym. J.. 2013;49:780-792.

- [Google Scholar]

- Overview of renewable polysaccharide-based composites for biodegradable food packaging applications. Green chem.. 2022;24(2):480-492.

- [Google Scholar]

- Mechanical properties of polypropylene/calcium carbonate nanocomposites. Mat. Res.. 2009;12(4):517-522.

- [Google Scholar]

- María Flórez, Esther Guerra-Rodríguez, Patricia Cazón, , 2022, Chitosan for food packaging: Recent advances in active and intelligent films, Food hydrocolloids, 124, Part B, 107328.

- Environmental impacts of bio-based/ biodegradable packaging. Starch/ Starke. 2001;53:105-109.

- [Google Scholar]

- Gajanand, E., Soni, L.K., Dixit, V.K. 2014, Biodegradable polymers: A Smart Strategy for today’s crucial needs Critical Review in Pharmaceutical Sciences, 3 (1):1-70.

- Thermal Properties of Green Polymers and Biocomposites. Kluwer Academic Publishers; 2004.

- Water Soluble Polymers for Pharmaceutical Applications. Polymers. 2011;3:1972-2009.

- [Google Scholar]

- Study of the behavior of an epoxy coating food contact. Mor. J. Chem.. 2021;9N°4:681-698.

- [Google Scholar]

- Clay Minerals – Mineralogy and phenomenon of clay swelling in oil and gas industry. Adv. Mater. Sci.. 2015;15(43):37-55.

- [Google Scholar]

- Pradip Kumar Gupta, Joydeep Dutta, Tripathy, V.S. 2004, Chitin and Chitosan: Chemistry, properties, and applications. JSIR. 63 (01), 20-31.

- Preparation and properties of biodegradable starch–clay nanocomposites. Carbohydr. Polym.. 2010;79:391-396.

- [Google Scholar]

- Food Packaging and Preservation. Elsevier; 2018. p. :307-342.

- Mini review: Plant polymers for biodegradable plastics: cellulose, starch, and polyhydroxyalkanoates. Mol. Breed. 1995;1(2):105-122.

- [Google Scholar]

- Influence of Nanoclay and Coupling Agent on the Physical and Mechanical Properties of Polypropylene/Bagasse Nanocomposite. J. of the app. Polymer Science. 2009;112(3):1386-1390.

- [Google Scholar]

- Biodegradable Polymers in Food Packaging. American Journal of Engineering Research (AJER). 2013;02(5):151-164.

- [Google Scholar]

- Organic-inorganic hybrid polymers as adsorbents for removal of heavy metal ions from solutions. Materials. 2014;7:673-726.

- [Google Scholar]

- Review of Recent Research into Cellulosic Whiskers, Their Properties and Their Application in Nanocomposite Field. Biomacromolecules. 2005;6:612-626.

- [Google Scholar]

- Srinivas, P.R., Philbert, M., TQ, , Q., Kokini, J.L., Santos E, Chen, H., Peterson, C.M., Friedl, K.E., Ngutter, C.M., Hubbard, V., Reed, P.S.., Miller N, Betz JM, Milner JDJ, Rossi. A. 2010, Nanotechnology Research: Applications in Nutritional Sciences, J Nutr.;140 (1): 119–124.

- Green Plastics, An Introduction to the New Science of Biodegradable Plastics. New Jersey, USA: Princeton University Press; 2002. 238 pp., Cloth

- Effect of Filler Content on the Performance of Epoxy/PTW Composites. Adv. Mater. Sci.. 2014;2014:1-11.

- [Google Scholar]

- An approach of composite materials in industrial machinery: advantages, disadvantages, and applications. Inter. J of Res. Eng. Tech.. 2013;02:350-355.

- [Google Scholar]

- Chitosan-based antimicrobial films for food packaging applications. e-Polymers. 2008;093:1-7.

- [Google Scholar]

- Biopolymer Films and Coatings in Packaging Applications, A Review of Recent Developments. Mater. Sci. Appl.. 2014;5:708-718.

- [Google Scholar]

- Chitosan and its potential use as a scaffold for tissue engineering in regenerative medicine biomed. Res. Int. 2015:1-16.

- [Google Scholar]

- Recent advances in polymer-metallic composites for food packaging applications. Trends Food Sci. Technol.. 2021;109:230-244.

- [Google Scholar]

- Composites of Polymer Hydrogels and Nanoparticulate Systems for Biomedical and Pharmaceutical Applications. Nanomaterials. 2015;5:2054-2130.

- [Google Scholar]