Translate this page into:

A sustainable approach to green algal bioplastics production from brown seaweeds of Sabah, Malaysia

⁎Corresponding author. rahmath@ums.edu.my (Rahmath Abdulla)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

A significant concern in generating ecologically friendly plastics has paved a way for use of algae-based green bioplastics as a substitute for conventional plastics. This study signifies the production and characterization of biodegradable algae-based bioplastics using alginate extracted from brown seaweeds of Sargassum sp. found abundantly in coastal waters of Sabah, Malaysia. During the extraction of alginate from Sargassum sp., process variables such as the alkali (Na2CO3) concentration, temperature (°C), and time (hours) were optimized by employing ethanol method of extraction. The maximum yield of alginate (20.85 %) was obtained with the following conditions of 3 % of Na2CO3, at 95 °C and 3 h. Then, the extracted alginate was used to synthesize seven bioplastics with different formulations, one in the absence of invert sugar (green plasticizer) as control while the others were blended with 5 %, 10 % and 15 % of invert sugar (IS) respectively. The synthesized bioplastics were further characterized via mechanical test through tensile-strength (TS) and elongation at break (E) while its degradability was evaluated using soil burial test. The results reveal that bioplastics incorporated with IS enhanced the features of the bioplastics as they were more flexible, unlike the control bioplastics which were brittle. Among the formulations used, the bioplastics that comprised of alginate (Alg) 6 % with 5 % IS exhibited the highest TS and were able to degrade completely within 4 days. Thus, this study brings in an insight into the importance of Sargassum sp. as a potential feedstock for the development of green algae-based bioplastics to counter the plastic pollution problems as it can surpass the sustainability matter and environmental challenges caused by disposal of conventional plastics.

Keywords

Bioplastics

Sargassum

Alginate

Tensile strength

Bioplasticizer

Biodegradability

1 Introduction

Plastics are carbon-based polymers discovered almost 100 years ago. About 99 % of feedstocks for plastic production are from non-renewable resources (Nielsen et al., 2020). Nowadays, concerns about the sustainability of these petroleum-derived plastics have arisen because of their poor degradability, which makes them the most dangerous pollutants for the environment (Cucina et al., 2021; Bellasi et al., 2020). Moreover, chemicals from the plastics create additional recycling problems as they are known to be toxic (Zanchetta et al., 2021). Fossil fuel-based synthetic plastics are also resistant to the microbial attack. Thus, it takes a longer time for them to decompose in nature which eventually causes serious environmental pollution to the earth. Hence, a sustainable alternative for the conventional plastic is by producing bioplastics which can reduce the pollution to a greater extent (Ghernaout and Elboughdiri, 2021).

The term bioplastic is defined as either the bio-based origin of plastic or to the biodegradable character of a plastic which have evolved as a promising candidate that hold potential as substitute for petroleum-based plastics due to their biodegradability (Verma and Fortunati, 2019). Bioplastics biodegradability depends on the rate and route of the degradation (Narancic et al., 2020). Among them, polysaccharide is the one that has been often extensively investigated in terms of its characteristics.

Phycocolloids are polysaccharides of high molecular weight that are made up of simple sugars which are able to form viscous dispersion and/or gels when dispersed in water (Abdul Khalil et al., 2017; Venkatesan et al., 2017). There are three major phycocolloids from seaweeds namely agars, carrageenans, and alginates (Abdul Kadar et al., 2021). Seaweeds are highly valued due to their phycocolloid contents (Sudhakar et al., 2016). Algal biomass can be utilized to produce composites that are biodegradable and have strong mechanical properties (Katiyar et al., 2017; Zhu et al., 2017). Thus, in this research, the bioplastics production from the natural polysaccharides of Sargassum sp. of brown seaweeds of Sabah is studied. These species are often found attached or free floating on the rocky coasts of Sabah waters. It was selected due to its readily availability as a feedstock and one of its active compounds being alginate which is vital for synthesis of bioplastics (Rashedy et al., 2021). Moreover, so far there has been no reported research on bioplastics from Sargassum sp. of brown seaweeds of Sabah, Malaysia. The most similar study was Lim et al. (2018) which used brown algae Sargassum siliquosum J. Agardh fom Port Dickson, Malaysia as a raw material for the bioplastic film. Meanwhile, Hii et al. (2016) studied the potential of red seaweeds, Gracilaria salicornia for bioplastic film synthesis. A very limited amount of research exists on algae bioplastics as most are focused on using the algae for biofuels production (Zanchetta et al., 2021).

Seaweed is a promising and valuable feedstock for bioplastic production. However, as Chong et al. (2021) mentioned, an efficient, reliable and feasible process is essential to produce bioplastics in a low-cost manner in order to substitute synthetic plastics in the future. Technologies supporting development of bioplastics are still lacking and a challenge that are yet realized (Pessôa et al. 2021). Therefore, this research is hoped to provide new insights for further development of bioplastic production. This study aims to optimize the extraction process of alginate from brown seaweeds of Sargassum sp. by exploring the effect of three key variables such as alkali concentration (Na2CO3), temperature and time. Later the alginate was incorporated with green plasticizer, IS at different formulations to synthesize the bioplastics using film-casting technique. The synthesized green bioplastics were further characterized via mechanical and soil burial test to evaluate the potential of bioplastics made from brown seaweeds of Sabah, Malaysia.

2 Materials and methods

3 Results and discussion

3.1 Extraction of alginate

The dried Sargassum sp. was grounded to provide a larger surface area for those reagents involved in the pretreatment as well as in acid and alkali treatment to infiltrate the Sargassum sp. quickly (Chee et al., 2011). The powdered Sargassum sp. was pretreated with 0.2 % of formaldehyde to alleviate the tissue, promote discolouration by binding and eliminating the coloured pigments (Mazumder et al., 2016). The sodium alginate obtained in this study was light brown in colour due to the pretreatment with formaldehyde. Lim et al. (2018) reported that, the colour of the sodium alginate appeared darker for those extracted without using formaldehyde.

The pretreated Sargassum sp. was further treated with HCl to allow alginate to be more readily soluble in an alkaline solution and to enable the removal of external salts, leftover formaldehyde, unwanted compounds as well as to prepare acidic environment for the conversion of alginate salts (Łabowska et al., 2019). Upon being treated with Na2CO3 under heat, the alginic acid was converted into sodium alginate. The mixture was then centrifuged to retrieve sodium alginate followed by precipitation of the supernatant with three volumes of 90 % of ethanol since sodium alginate was unable to be dissolved in the mixture of alcohol and water (Aguanza et al., 2018).

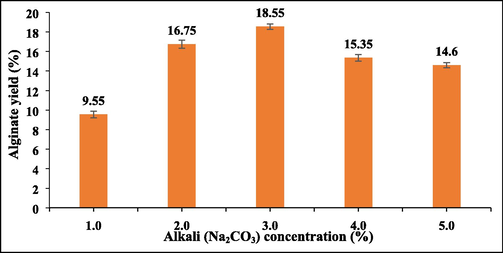

3.2 Effect of alkali (Na2CO3) concentration on alginate yield

Extraction at alkaline pH produces alginate with high concentration efficiency, while acidic extraction produces insoluble alginic acids from alginate salts which disrupt the extraction of alginate (Kartik et al., 2021). In the extraction of alginate from Sargassum sp, Na2CO3 was used as it converts the alginic acid into soluble sodium alginate which seems like a viscous gel (Łabowska et al., 2019). The concentrations of alkali were varied between 1.0 % and 5.0 % while other process variables remain constant at 95 °C and for a period of 3 h. Based on Fig. 1, the yield of crude alginate increased gradually from 9.55 % to 18.55 % as the Na2CO3 concentration increased from 1 % to 3 %. However, the yield started to decrease after that level. The yield of crude alginate was maximum at 3 % of Na2CO3 and the lowest was found at 1 %. This is due to the depolymerization of alginate conformation. The yield of sodium alginate extracted decreased upon a rise in alkali concentration because the mean molecular weight started to deteriorate due to a change in pH of the media which eventually affected the viscosity of the solution. However, study conducted by Yudiati et al. (2018) extracted the highest yield of Sargassum polycystum sodium alginate at 7 % and 9 % Na2CO3 concentration. This result is obtained because the process used 96 % ethanol for precipitation, which influenced the yield because of its ability to bind water from alginate solution separating the sodium alginate.

Effect of Na2CO3 concentrations on alginate yield (%).

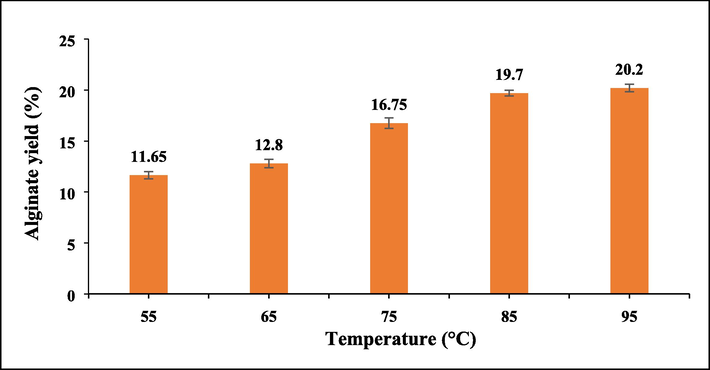

3.3 Effect of temperature (°C) on alginate yield

To extract alginate, Sargassum sp. with Na2CO3 was heated to elevated temperature. Effect of various extraction temperature on alginate yield was done at different temperature ranges from 55 °C to 95 °C. The other process variables were kept constant at 3 % Na2CO3 concentration and 3 h time. From Fig. 2, the alginate yield obtained between temperature 55 °C to 65 °C was smaller which was about 11.65 % to 12.80 %. However, the alginate yield started to increase from 16.75 % to 19.70 % at temperature of 75 °C to 85 °C. The highest alginate yield was extracted with 20.20 % at 95 °C. High temperature is said to be in favor of increasing the extraction yield of alginate (Fertah et al., 2017). In the work performed by Sugiono and Ferdiansyah (2019), highest alginate yield of 40.6 % produced at 90 °C, 2 h and 5 % Na2CO3 concentration. Mazumder et al. (2016) also reported that maximum yield of alginate extraction was obtained when the temperature ranges from 90 °C to 100 °C throughout the alginate extraction from Sargassum muticum. Although the temperature of extraction directly proportional to the yield of alginate extraction, yet at extremely high temperatures, degradation of alginate conformation results in a decrease of yield of alginate extracted (Kasim et al., 2013).

Effect of temperature (°C) on alginate yield (%).

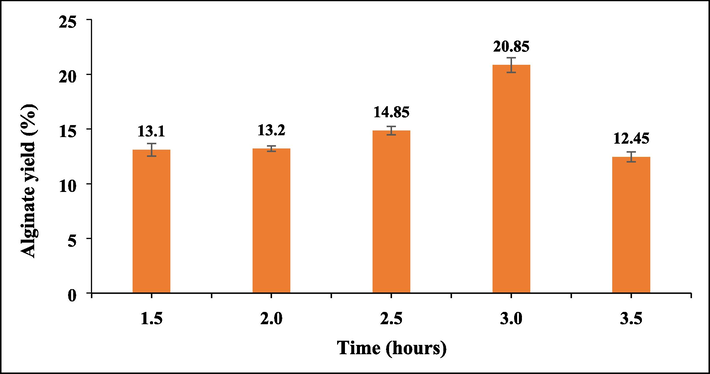

3.4 Effect of extraction time (hours) on alginate yield

The yield of alginate is also influenced by the extraction time. The extraction time range was varied from 1.5 h to 3.5 h keeping the other parameters fixed at 3 % Na2CO3 and a temperature of 95 °C. The alginate yield was 13.10 % during the first 1.5 h and continued to increase gradually until it reached 20.85 % at 3 h which shows a direct correlation between extraction time and yield of crude alginate obtained. The maximum amount of alginate yield was achieved at 3.0 h of extraction time as shown in Fig. 3. The result obtained was similar to study by Mazumder et al. (2016) in which the maximum yield of alginate for Sargassum sp. was achieved in 3 h time. Hambali et al. (2018) exhibited positive effect to the alginate yield at 2.5 h extraction times of alginate by 1 % to 3 % Na2CO3 concentration. Alginate extraction was facilitated due to the more seaweed cell walls broken at longer extraction time during the study which was done from 90 min–150 min (Silva et al., 2015).

Effect of extraction time (hours) on alginate yield (%).

However, longer extraction time will decrease the viscosity of alginate because of the depolymerization of the polymer chain of alginate (Łabowska et al., 2019; Sugiono and Ferdiansyah, 2019). In this study, there was a sudden decrease in the yield of crude alginate after 3 h because longer exposure of solvent to the Sargassum sp. promotes the liquid penetration into the Sargassum sp. and dissolves the alginate and eventually freeing it into the extraction medium. Fertah et al. (2017) states that at higher extraction process time, the yield obtained will be higher until it reaches their optimal point as the yield will decrease after that.

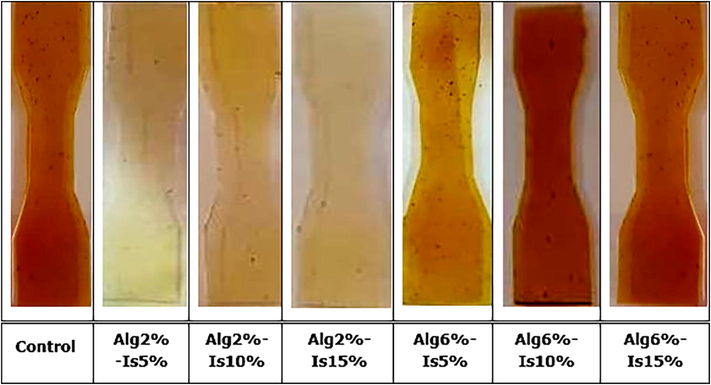

3.5 Bioplastics preparation and properties

The formulations of bioplastics are described with the following abbreviations: Alginate (Alg) and Invert Sugar (IS) and presented in Fig. 4. The formulation of bioplastics with a low concentration of Alg 2 % appeared light brown as compared to the formulation of bioplastics with a high concentration of Alg 6 %. The control film without the addition of IS (plasticizer) was stiff and slightly brittle while the other bioplastics samples incorporated with IS were flexible. However, bioplastics with higher concentration of IS were sticky (Pereira et al., 2011). Due to its hygroscopic properties, IS was used as a green plasticizer substituting glycerol in this study.

Formulations of bioplastics at different concentrations of Alg and IS.

3.6 Characterization of bioplastics

3.6.1 Mechanical test

One of the most important variables for plastic films are mechanical properties (Harunsyah et al., 2017). Tensile strength or TS is defined as the maximum load that a film can withstand without being fractured when tested (Fabra et al., 2018).

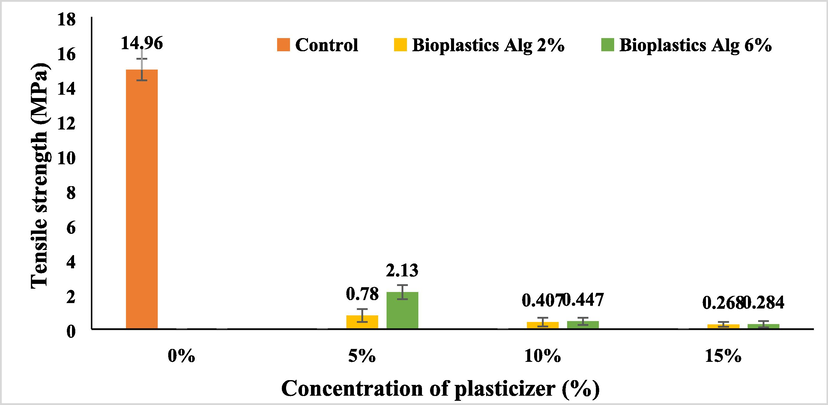

Based on Fig. 5, the existence of IS at a lower concentration of 5 % indicated higher TS value of 2.13 MPa for bioplastics with 6 % of Alg as compared to TS value of 0.78 MPa for bioplastics with 2 % of Alg. This is because bioplastic with Alg 6 % has more intermolecular hydrogen bonds as compared to bioplastic with Alg 2 %. When IS was incorporated into the bioplastics, overpower of strong hydrogen bonds were generated by Alg-Alg intermolecular interaction over Alg-IS interaction in bioplastic with Alg 6 % compared to bioplastic with Alg 2 %. However, the addition of IS concentration from 10 % to 15 % resulted in a significant reduction in the TS of bioplastics, regardless of the Alg concentration. The TS of bioplastics with Alg 2 % particularly declined from 0.780 MPa to 0.268 MPa and that of bioplastics with Alg 6 % dropped from 2.130 MPa to 0.284 MPa as plasticizer concentration increased to 15 % because IS destroyed the strong hydrogen bonds generated by Alg-Alg intermolecular interaction and encourages the development of hydrogen bonds between IS and Alg molecule. Hence, the TS reduced due to the ensuing weakening of the hydrogen bonds between Alg chains (Sanyang et al., 2015).

Tensile strength (MPa) of Bioplastic.

As for the control film without the incorporation of IS exhibited the highest TS value of 14.96 MPa. The control film was hard and stiff due to stronger hydrogen bonds generated by Alg-Alg intermolecular interaction. Previous studies also reported similar situation where a higher concentration of IS causes the matrix of the bioplastics to be less compact, ease the motion of alginate chains under stress, which eventually decrease the resistance of the bioplastics (Syaubari et al., 2018). Study by Krishnamurthy and Amritkumar (2019) reported that PV (polylactic acid and crude palm oil) film have the best TS of 5.24 MPa and least E of 3.49 % as compared to its other film because the palm oil that acted as a filler providing strength and toughness to the film, but the E was lower due to low ductility of PLA.

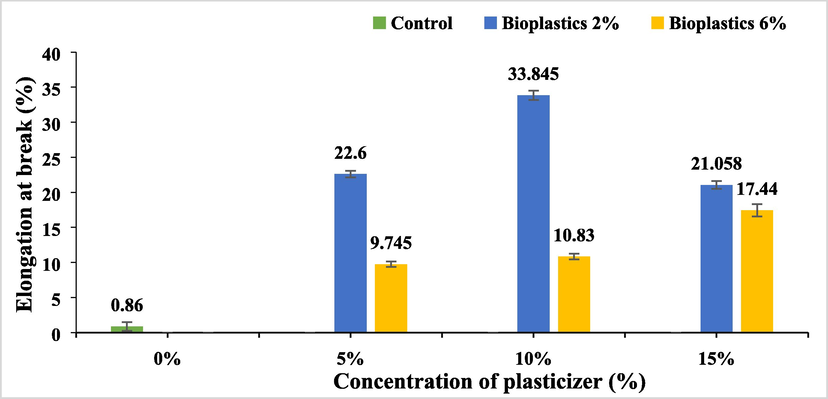

Elongation at break or E is defined as the extendibility of film length from initial length to the point of the break. The effect of IS concentrations on the elongation of bioplastics with different Alg concentration exhibits an opposite action as compared with their correspondent TS. The rise in IS concentration from 10 % to 15 % results in the increase of film elongation for bioplastics with Alg 6 % from 10.83 % to 17.44 % because the IS reduced the rigidity of the intermolecular bond between Alg chains and encourages the flexibility of films by permitting more chain movement. The result obtained was presented in Fig. 6 notably bioplastics with Alg 6 % proved that film elongation increased when the concentration of IS is high. However, film elongation for bioplastics with Alg 2 % decrease drastically from 33.85 % to 21.06 % when 15 % of IS was used. This phenomenon occurred due to anti-plasticization behavior or phase separation of highly plasticized alginate bioplastics. Similar condition was reported by Sanyang et al. (2015) in his study. However, the anti-plasticization effect was not observed in bioplastic with Alg 6 %. On the other hand, the control film exhibits the lowest film elongation due to the absence of IS. In short, the TS of bioplastics decreased when incorporated with a greater concentration of IS. This similar pattern was noticed in the work of various authors in evaluating the mechanical properties of bioplastics (Syaubari et al., 2018). In another study conducted by Lim et al. (2018) bioplastic film produced from Sargassum siliquosum have a E of 3.58 % and TS of 33.90 MPa.

Elongation at break (%) of Bioplastic.

3.6.2 Biodegradability by soil burial test

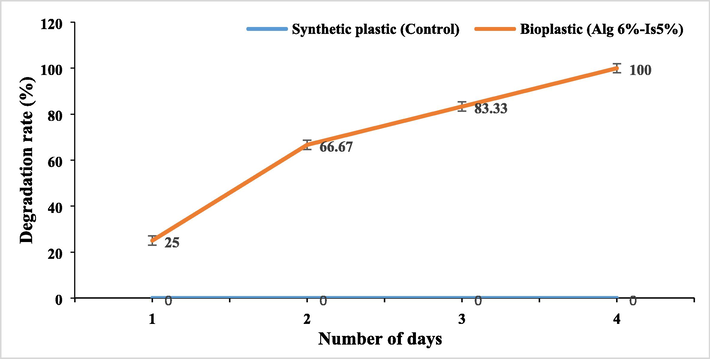

Biodegradability is defined as the ability of the polymer to be broken down by biological process which involves the reduction of molecular weight of macromolecules (Hii et al., 2016). Soil burial test was performed to identify the biodegradability of the synthetic plastic (control) and the bioplastics with the best formulation which was the Alg 6 %-IS 5 % as it possesses the satisfactory mechanical properties. The evolution of the degradation in the soil of the forementioned bioplastics during the experimental period was shown in Fig. 7. It can be deduced that synthetic plastic was resistant to degradation unlike bioplastics with Alg 6 %-IS 5 % that showed a rapid degradation within 4 days. This is because, degradation of synthetic plastics involves a complicated occurrence. Biodegradability is the ability of polymers to undergo structural alteration that resulted from the action of naturally occuring microorganisms such as fungi and bacteria (Shravya et al., 2021). However, synthetic plastics are extremely resistant to the microbial degradation. Therefore, it takes a longer time for them to decompose in soil which leads to a serious negative impacts on ecosystems (Bellasi et al., 2020). Petroleum-based plastic has lower degradation rate as compared to seaweed-based plastic.

Bioplastics degradation rate (%).

It was observed that the degradation rate of bioplastic increased continuously with the increase in the number of days. However, results acquired from Wahyuningtyas and Suryanto (2017) which developed bioplastic made from Cassava flour with glycerol had a complete degradation around day 9 to 12 because of the moisture uptake. If the soil is dry, degradability rate is reduced because of less microbial activity that occur in the soil (Shravya et al., 2021). In general, the microorganisms present in the soil will degrade and transform the carbon in the alginate polymer chains into CO2 and H2O as the microorganisms consume the blends starting with alginate particles which leads to loss of the structural feature (Lim et al., 2018).

4 Conclusion

Sargassum sp. was used to extract Alg through a series of processes. To identify the influence of the different variables on the yield of extraction, each of the parameters was varied while keeping others constant. As a result, the maximum yield of Alg was obtained when the alkali concentration, temperature and time of extraction were 3 %, 95 °C, 3 h respectively. Different formulations of Alg with IS as green plasticizer blend films were constructed via the solvent-casting method. Bioplastics with Alg 6 % regardless of the concentration of IS, appeared as dark brown compared to the bioplastic with Alg 2 %. The control film without the addition of IS was stiff and slightly brittle compared to bioplastics samples with IS which were reported flexible. However, bioplastics with a higher concentration of IS were sticky. The existence of IS at a lower concentration of 5 % indicated a higher TS value of 2.13 MPa for bioplastics with Alg 6 % as compared to TS value of 0.78 MPa for bioplastics with Alg 2 %. However, the addition of IS concentration from 10 % to 15 % resulted in a significant reduction in the TS. Hence, bioplastics with Alg 6 %-IS 5 % was used to perform soil burial test. The bioplastics started to degrade by 25 % on Day 1 and achieved 100 % degradation on Day 4 unlike synthetic plastic (control) that was resistant to degradation. This study provides a clearer overview regarding the production of green bioplastics from brown seaweeds of Sabah to the researchers and academicians. However, deeper studies are necessary to enhance the performance and efficiency of seaweed in producing biodegradable bioplastics at low cost. Therefore, this research is hoped to pave way for development of good quality green bioplastics from alginate, natural polysaccharide from brown seaweeds of Sabah, Malaysia.

CRediT authorship contribution statement

Karthiani Kanagesan: Conceptualization, Methodology, Validation, Formal analysis, Writing – original draft. Rahmath Abdulla: Conceptualization, Supervision, Writing – review & editing. Eryati Derman: Data curation, Writing – review & editing. Mohd Khalizan Sabullah: Investigation, Writing – review & editing. Natanamurugaraj Govindan: Visualization, Writing – review & editing. Jualang Azlan Gansau: Conceptualization, Resources, Writing – review & editing.

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors. The authors gratefully acknowledge Universiti Malaysia Sabah (UMS) and Universiti Malaysia Pahang (UMP).

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- A review on potential of algae in producing biodegradable plastic. Int. J. Eng. Adv. Res.. 2021;3:13-26.

- [Google Scholar]

- Biodegradable polymer films from seaweed polysaccharides: A review on cellulose as a reinforcement material. Express Polym. Lett.. 2017;11:244-265.

- [Google Scholar]

- Improving the extraction process of sodium alginate from Samu (Sargassum piluliferum) using the Plackett Burman design. Sci. Humanit. J.. 2018;12:54-65.

- [Google Scholar]

- Bellasi, A., Binda, G., Pozzi, A., Galafassi, S., Volta, P., Bettinetti, R., 2020. Microplastic contamination in freshwater environments: A review, focusing on interactions with sediments and benthic organisms. Environ. MDPI 7.

- Study on the determination of the optimum parameters for the inversion reaction. Ann. Food Sci. Technol.. 2015;399:399-402.

- [Google Scholar]

- Extraction and characterisation of alginate from brown seaweeds (Fucales, Phaeophyceae) collected from Port Dickson, Peninsular Malaysia. J. Appl. Phycol.. 2011;23:191-196.

- [Google Scholar]

- Advances in production of bioplastics by microalgae using food waste hydrolysate and wastewater: A review. Bioresour. Technol.. 2021;342:125947.

- [Google Scholar]

- Physicochemical properties of alginate-based films: Effect of ionic crosslinking and mannuronic and guluronic acid ratio. Food Hydrocoll.. 2018;81:442-448.

- [Google Scholar]

- The role of waste management in reducing bioplastics’ leakage into the environment: A review. Bioresour. Technol.. 2021;337:125459.

- [Google Scholar]

- Structural and physicochemical characterization of thermoplastic corn starch films containing microalgae. Carbohydr. Polym.. 2018;186:184-191.

- [Google Scholar]

- Extraction and characterization of sodium alginate from Moroccan Laminaria digitata brown seaweed. Arab. J. Chem.. 2017;10:S3707-S3714.

- [Google Scholar]

- Plastic waste pollution worsen by the COVID-19 pandemic: substitutional technologies transforming plastic waste to value added products. Open Access Libr. J.. 2021;08:e7622.

- [Google Scholar]

- Hambali, E., Wibawa Sakti, S.C., Fahmi, M.Z., Wahyudianto, F.E., Nuryono, Yessi, P., Yani, M., Sinurat, E., Pratama, B.S., 2018. Effect of extraction time and Na2CO3 concentration on the characteristics of alginate extracted from sargassum sp. IOP Conf. Ser. Earth Environ. Sci. 209, 012033.

- Mechanical properties of bioplastics cassava starch film with Zinc Oxide nanofiller as reinforcement. IOP Conf. Ser. Mater. Sci. Eng.. 2017;210:012015.

- [Google Scholar]

- Agar from malaysian red seaweed as potential material for synthesis of bioplastic film. J. Eng. Sci. Technol.. 2016;11:1-15.

- [Google Scholar]

- A critical review on production of biopolymers from algae biomass and their applications. Bioresour. Technol.. 2021;329:124868.

- [Google Scholar]

- Effects Of sodium carbonate concentration and temperature on the yield and quality characteristics of alginate extracted from Sargassum Sp. Res. J. Pharm. Biol. Chem. Sci.. 2013;8:660-668.

- [Google Scholar]

- Microalgae: An emerging source of energy based bio-products and a solution for environmental issues. Renew. Sustain. Energy Rev.. 2017;72:1083-1093.

- [Google Scholar]

- Synthesis and characterization of eco-friendly bioplastic from low–cost plant resources. SN Appl. Sci.. 2019;1:1-13.

- [Google Scholar]

- Methods of extraction, physicochemical properties of alginates and their applications in biomedical field - A review. Open Chem.. 2019;17:738-762.

- [Google Scholar]

- Sargassum siliquosum J. Agardh extract as potential material for synthesis of bioplastic film. J. Appl. Phycol.. 2018;30:3285-3297.

- [Google Scholar]

- Extraction of alginate from Sargassum muticum: process optimization and study of its functional activities. J. Appl. Phycol.. 2016;28:3625-3634.

- [Google Scholar]

- Narancic, T., Cerrone, F., Beagan, N., O’Connor, K.E., 2020. Recent advances in bioplastics: Application and biodegradation. Polymers (Basel) 12.

- Politics and the plastic crisis: A review throughout the plastic life cycle. Wiley Interdiscip. Rev. Energy Environ.. 2020;9:1-18.

- [Google Scholar]

- Preparation and characterization of films based on alginate and aloe vera. Int. J. Polym. Anal. Charact.. 2011;16:449-464.

- [Google Scholar]

- Technological prospection of microalgae-based biorefinery approach for effluent treatment. Algal Res.. 2021;60:102504.

- [Google Scholar]

- Evaluation and characterization of alginate extracted from brown seaweed collected in the red sea. Appl. Sci.. 2021;11:6290.

- [Google Scholar]

- Effect of plasticizer type and concentration on tensile, thermal and barrier properties of biodegradable films based on sugar palm (Arenga pinnata) starch. Polymers (Basel). 2015;7:1106-1124.

- [Google Scholar]

- Seaweed a sustainable source for bioplastic: a review. Int. Res. J. Mod. Eng. Technol. Sci.. 2021;3:2582-5208.

- [Google Scholar]

- Microwave-assisted alginate extraction from Portuguese Saccorhiza polyschides – influence of acid pretreatment. Int. J. Biotechnol. Bioeng.. 2015;9:30-33.

- [Google Scholar]

- Characterization, pretreatment and saccharification of spent seaweed biomass for bioethanol production using baker’s yeast. Biomass Bioenergy. 2016;90:148-154.

- [Google Scholar]

- Biorefinery sequential extraction of alginate by conventional and hydrothermal fucoidan from the brown alga, Sargassum cristaefolium. Biosci. Biotechnol. Res. Commun.. 2019;12:894-903.

- [Google Scholar]

- Synthesis of biodegradable plastic from tapioca with N-Isopropylacrylamid and chitosan using glycerol as plasticizer. IOP Conf. Ser. Mater. Sci. Eng. 2018:345.

- [Google Scholar]

- Introduction to seaweed polysaccharides. Seaweed Polysaccharides Isol. Biol. Biomed. Appl. 2017:1-9.

- [Google Scholar]

- Analysis of biodegradation of bioplastics made of Cassava starch. J. Mech. Eng. Sci. Technol.. 2017;1:24-31.

- [Google Scholar]

- Optimization of alginate alkaline extraction technology from Sargassum polycystum and its antioxidant properties. IOP Conf. Ser. Earth Environ. Sci.. 2018;139:012052.

- [Google Scholar]

- Algal cellulose, production and potential use in plastics: Challenges and opportunities. Algal Res.. 2021;56:102288.

- [Google Scholar]

- Reactive compatibilization of biodegradable poly(butylene succinate)/Spirulina microalgae composites. Macromol. Res.. 2017;25:165-171.

- [Google Scholar]