Translate this page into:

A comprehensive overview on the preservation techniques and packaging of processed meat products: Emphasis on natural derivatives

⁎Corresponding author. hsshin@sejong.ac.kr (Hakdong Shin)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Consumer's perspective on the quality is a variable that makes preservation and processing of various meat products a difficult task. To overcome the issue of spoilage and shelf life extension, with the expanded interest in maintaining a good quality of raw meat items, innovations took a lead in preservation techniques. Many innovations, such as applying high hydrostatic pressure, super chilling process, natural bio preservatives, and dynamic packaging had been proposed and researched. While a portion of these advancements is effective at inactivating the small-scale biotic factors especially identified with food-borne ailments, they are not successful against spores. To expand their adequacy against vegetative cells, a blend of a few preservation methods under the supposed thought had been explored. Besides preservation, modern packaging techniques are adopted to increase their shelf life. Packaging mainly aids in preventing color changes and preserves the nutritive value of processed meat. This review throws light on preservation techniques, modern and traditional packaging trends that takes place in the meat industry. Technology driven innovations like nanomaterial based preservation and packing techniques and marine derivatives as potential alternatives in preservation are discussed. The effect of COVID 19 on processing industries is also discussed in this review.

Keywords

Microorganisms

Spoilage

Shelf life

Meat processing

Balanced diet

Marine preservatives

1 Introduction

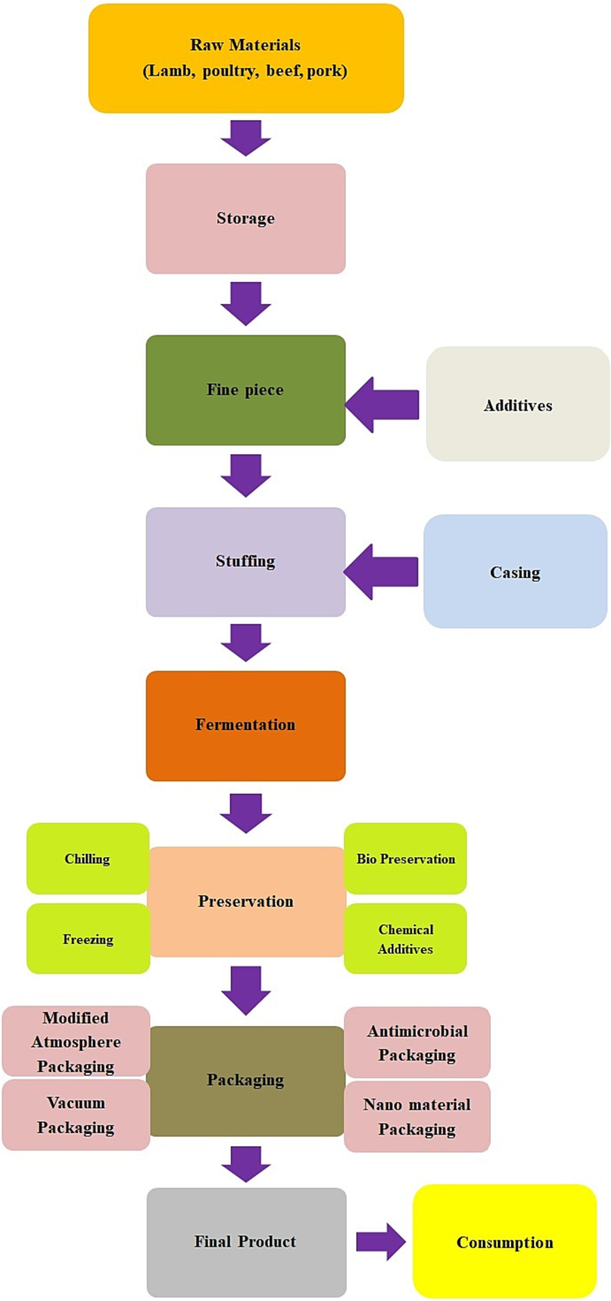

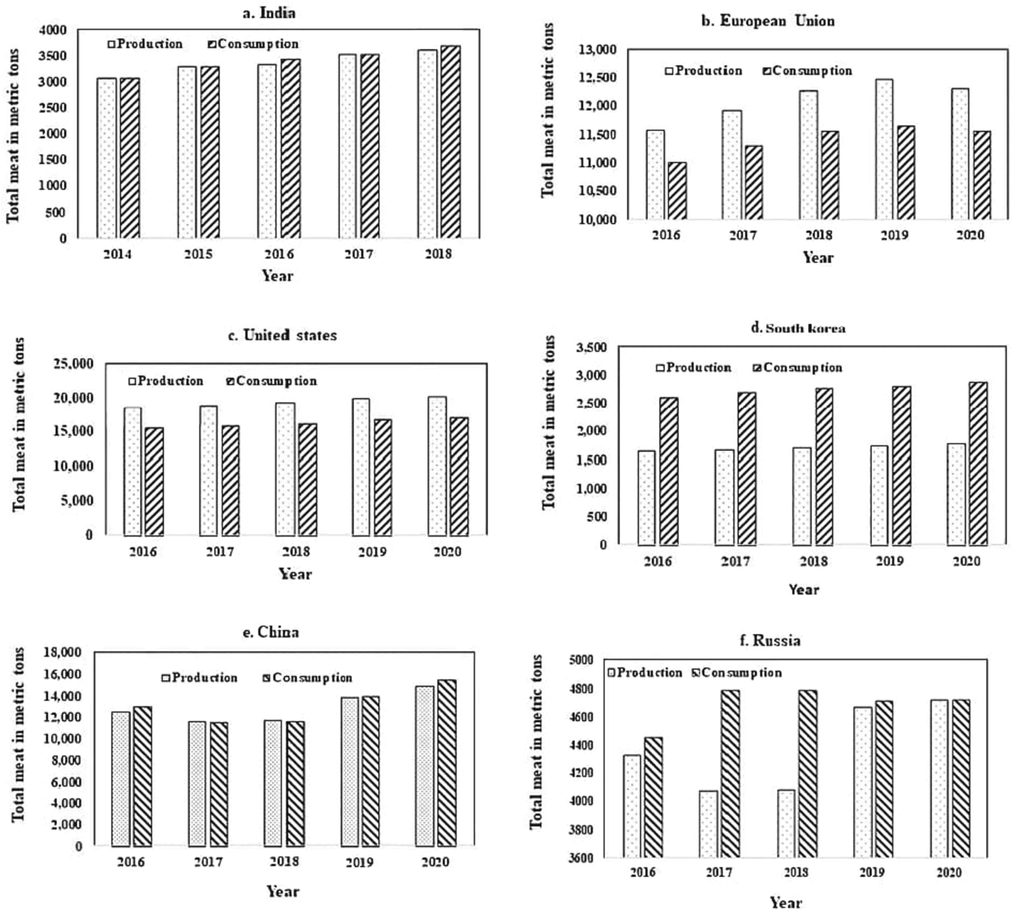

Meat is vulnerable to the growth of pathogenic organisms that attributes to their spoilage and their extended storage may result in health complications when it is consumed under unfavorable conditions (Woraprayote et al., 2016). Hence processing meat plays a predominant role which may aid in keeping the meat under favorable conditions till human consumption. Processed meat includes the point from which fresh meat is subjected to various methods until the endpoint where it is purchased by the consumers for consumption. (Fig. 1) shows a detailed flowchart of the steps involved in meat processing. The increased demand for meat products with quality, eco-friendly, effective cost and preservation packaging of the meat products without damaging the sensory and quality attributes attracts the customers that finally form the vision and mission in meat industries. Global consumption of meat accounts for 280 million tons per year and is expected to be doubled by 2050. Production and consumption of meat are at an equal rate in India. In European Union the production exceeds far greater than the consumption rate. The production is much lesser compared to consumption in South Korea. In Russia the production rate is much lower compared to consumption rate. Meat production and consumption is significantly high in the US, (about 20,000 metric tons) followed by China (of about nearly 15,000 metric tons of meat) (Fig. 2). The problems yet to be resolved by meat industries include,

-

Reducing the contamination causing bacteria that leads to health complications by consumption of the affected products.

-

The pollution is to be controlled until it reaches the final part of consumption

-

Alleviate the disease-causing microbial growth on the products.

- A flowchart explaining the steps involved in meat processing.

- The extent of poultry meat production and consumption in various countries.

This review on the other hand is focusing on areas of preservation and packaging including both conventional methods and newer innovative approaches along with the emerging trends in the meat industry to resolve the aforesaid issues.

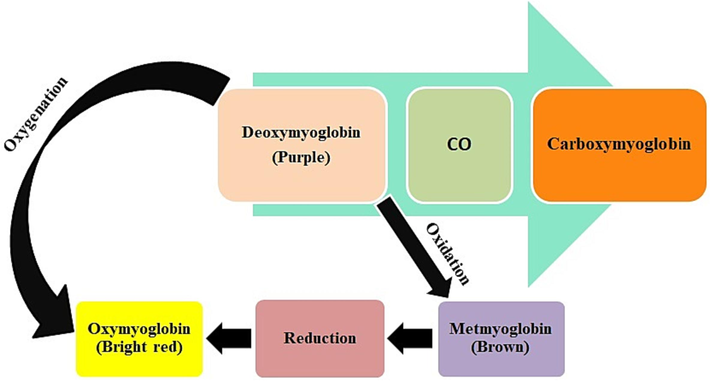

2 Meat oxidation –a reason behind the colour change

Oxidation of lipids and protein may also hold a larger role in the worsening of the quality of meat. Oxidative changes guide color, flavor, odour, and the formation of secondary metabolites that are harmful to human beings (Falowo et al., 2014). Deposited triglycerides or tissue phospholipids are the sites where oxidation occurs. Hemoglobin and myoglobin contain ferric iron within the heme molecule which accounts for the strong oxidative properties (Boutron-Ruault et al., 2017). When the meat is exposed to the atmosphere, the protein myoglobin is converted into oxymyoglobin which gives a red colour, and extended contact results in metmyoglobin turning the meat to brownish-red color. Even though color change does not necessarily indicate that the meat is spoiled whereas color plays a vital role in the consumer's perspective. The change in colour of meat is modified by the quantity and chemical state of myoglobin, Metmyoglobin Reducing Activity (MRA), vitamin E feeding, curing, wrapping film, etc. (Fig. 3) shows a detailed flowchart of the process in the colour variation of meat products. The use of antioxidants in the meat industry to avoid protein oxidation and lipid peroxidation is critical. Furthermore, active packaging is being researched as a viable solution to improve the shelf life of beef products (Ribeiro et al., 2019). Furthermore, there is widespread concern about our health, and consumers reject chemical chemicals. Antioxidant components are also important for developing healthy products because of their health advantages, although further research is needed. Polyphenols are abundant in the leaves of various plant species, and their use in the production of meat products has been studied.

The process involved in the reason for colour change of meat products.

3 Preservation techniques – An outline

The ancient methods of preservation, curing, and salting of meat products are generally practiced for their extended shelf life (Lonergan, et al., 2019). The preservation of meat was mostly done by the use of salt and the process is known as curing. Salt inhibits the growth of microorganisms through the removal of water from organisms. The extracellular spaces are enlarged when the concentration of salt increases due to the development of large ice crystals resulting in decreased water holding capacity. But the grouping of salt can influence the nature of meat (Jiang et al., 2018). Dehydration, curing, smoking, and low-temperature processing include some of the other conventional methods. Similarly, bacteriocins (proteins or peptidic toxins that are produced by one bacteria that affects the mechanism of closely related bacterial strains) which obtained from lactic acid bacteria, in combination with various other preservation techniques may reduce the spoilage by creating a series of hurdles (Woraprayote et al., 2016). Table 1 shows the method of preservation in various countries.

Country

Methods of Preservation

Advantage

India

Smoking, salting, Sun drying

Smoked fish are rich in nutrients

Chilling

Absorbs marinades and seasonings better and has a crispier skin after cooking

China

Basic salt marinating and wind drying

Extends shelf life

Australia

Canning

Longer shelf life

UK

Preserving beef in brine

Infuses the meat with savoury, flavour, and texture

New Zealand

Chilling

Maintains natural quality of meat

Argentina

Canning

Healthy, lasts longer

Russia

Smoking, Curing, and Drying

Increases Quality of Meat Products

South Korea

Drying, Smoking, pickling, curing

Reduce the amount of moisture to prevent the growth of microbes

3.1 Chilling

The process of chilling for meat has both advantages and disadvantages for shelf life, hygiene, safety, color, tenderness, and so on. Chilling in air diminishes the cadaver surface temperature and upgrades remain to dry; and hinder the development of microscopic organisms in meat. At chilled temperature when the time of storage is extended, it will result in an increase of tenderness in meat but may cause undesirable flavor development and microbial growth (Coll Cardenas & Olivera, 2016). There are many types of chilling such as conventional chilling, ultra-rapid chilling, super chilling, spray chilling, and so on.

Calcium is released from the sarcoplasmic reticulum and mitochondria of meat after post mortem leads to activation of calcium-dependent protease, called calpains. Proceeded chilled capacity results in calpains disintegrating myofibril proteins, a process known as proteolysis. The meat becomes tendered and shears force (SF) decreases as proteolysis occurs. Also, expanded chilled stockpiling temperature decreases with the stability of color. And additionally expanded anaerobic chilled stockpiling term brings instant discoloration to the presentation of oxygen, which has been found to happen corresponding to lipid oxidation (Kerry & Tyuftin, 2017).

3.2 Super chilling

During super chilling or Very Fast Chilling (VFC), the low temperature obtained may also result in a substantial release of calcium from the sarcoplasmic reticulum of myofibrils (Kerry & Tyuftin, 2017). Super chilling is where the temperature of the item is diminished beneath the point of solidification of a specific item. Once the primary surface freezing is completed, the dissemination of ice equilibrates, and it is maintained at a uniform temperature where it is obtained for distribution and storage.

3.2.1 Benefits of VFC

The period of the utility of new meat increments by 1.4–4.0 occasions during VFC demolishes a large portion of the microorganisms when compared to other chilling techniques. When super chilling is performed the ice formed on the surface of meat absorbs the heat until it reaches equilibrium. Thus an inside ice supply is reached forestalling the requirement for outer ice around the item during transportation (Duun & Rustad, 2007). Super chilling hindered the biochemical aspect of the debasement of salmon filets. The timeframe of realistic usability of superchilled chicken and salmon is half longer contrasted with chilled items, while superchilled cod 46 % in the longer period of utility contrasted with the chilled items (Claussen, 2011).

3.3 Freezing

Freezing reduces the enzymatic activity in meat. Transfer of heat coefficient, cooling temperature, thermodynamic aspects of meat or quantity is some of the dependent attributes to determine the rate of freezing of pork in a particular system (Landerslev et al., 2018). Consumers would have criteria for selection of meat during purchase by visual appearance while eating; satisfaction is fulfilled by a combination of tenderness, flavor, and juiciness. By freezing, most of these qualities are negatively modified and they associate solidified meat to lower quality items. It is believed that diminishing the quality of meat occurs in freezing and fresh meat has been preferred by consumers. A few examinations revealed that buyers couldn't see contrasts between fresh and frozen meat in texture and flavor (Antonio & Belles, 2019). During frozen storage, the advancement of oxidative procedures is profoundly identified with the physical condition of water, which eventually relies upon temperature. At temperatures above 40˚C, the dissolving of water begins in the thinning of meat, which would open the entryway for atomic portability and consequently in synthetic responses.

3.4 Ionising radiation

The application of ionizing radiation to meat is a technology that improves the life span of meat products by eliminating microbes. It is perceived that the inactivation of microbes is initiated through ionizing radiation and the reason behind this is the deactivation of DNA (Farkas, 2006). When the irradiation dose is increased, the inactivation of bacteria (Bacillus mycoides, Bacillus weihenstephanensis and Psychrobacillus psychrodurans isolated from Irish brown crab) forming spore also increases by its concentration. (Abanto et al., 2018).

In the UK, 'The food (control of irradiation) Regulations (1991)' permits certain forms of food might be illuminated up to a specific measurement and under 'The Food labeling (Amendment) (irradiated food) Regulations (1991) all foods that are irradiated are required to have a mark showing that they have got such treatment. When the meat is packed after the irradiation process, there is a larger quantity of total fluid separation by Transglutaminase (TG), myofibrillar protein solubility is increased and simultaneously protein reaction is decreased. Gamma-ray has a low variance of separation of total fluid after adding TG and the highest protein solubility among all ionizing radiation (Kim,et al., 2020).

3.5 Use of chemical preservatives for preservation

Humans used various products in addition to foodstuffs for consumption over a long period (Kerry and Tyuftin, 2017). To stop lipid rancidity, off-flavors, oxidation, and balance color antioxidants are used which may be natural or synthetic. Eliminating electrons from the food system is known as oxidation of meat, which in turn produces free radicals. The production of hydrogen peroxide starts when meat lipids oxidize which consequently produces volatile compounds, for example, aldehydes, ketones, acids, and alcohols which give undesirable flavors in meat (Pateiro et al., 2018). Myoglobin to metmyoglobin oxidation of meat pigment produces an undesirable brown color formation and also makes a decline in meat quality and consumer acceptance. Artificial antioxidants such as Butylated hydroxyl anisole (BHA) and butylated hydroxyl toluene (BHT), which are also utilized in meat to stop lipid oxidation as inhibitory substances or free radical scavengers (Nair et al., 2020). Binder additives are added to keep a uniform scattering of fat all through the item and to prevent loss of water during various phases of processing, heating, storage, and cooling. The binder additives used in meat and meat items are phosphates, thickener, starches, sodium alginate, carrageenan, and so on. It is worth highlighting the phosphate functions in meat products, which is to increase the stabilization of emulsion and to increase the water retention capacity (Gómez et al., 2020).

3.6 Application of bio preservatives

Bio preservatives, also known as natural preservatives or bio preservatives, are substances derived from natural sources like plants, microbes, or their metabolic products, which are used to extend the shelf life of food products, including meat. They serve as an alternative to traditional chemical preservatives, such as sodium nitrate, sodium nitrite, and various synthetic antioxidants (Davidson & Branen, 2005) (Hammes & Hertel, 2009). Essential oil, phytochemical extracts, chitosan, lactic acid, nisin, lysozymes, and so on are some natural compounds that can be used for meat preservation technology (Zhou et al., 2010; Lim et al., 2013). Spices and herbs turned out to be generally preferred for food utilization for all the reasons and their utilization as additives for a considerable length of time prompted the advancement of ethnic dishes, which are still in the presence of today’s world.

Chitosan is a sugar that is obtained from the hard outer skeleton of shrimp, crab, and lobster. Chitosan can be utilized as a preservative of food in materials used for packaging because chitosan has the capability of forming a film with antimicrobial properties. The growth of bacteria, yeast, and fungi is inhibited by chitosan in the storage of meat products due to its broad range of antimicrobial activity (Dutta et al., 2009). Montano-Sanchez et al., (2020), reported the effect of increased physicochemical and microbiological qualities of born-in pork samples during storage by using chitosan in combination with green tea water extract. The addition of 0.1 % and 0.5 % green tea water extract in a 1 % chitosan coating is successful in retarding the MDA formation and growth of microbes.

Lactococcus lactis bacteria produce an antibacterial peptide which is known as Nisin that is used for the preservation of food. Weight loss is one of the factors that affect meat during refrigeration. This was used to overcome by Gelatin-based film embedded with nisin and catechin. The results showed no increase in loss of weight or concentration of oxygen in the inner layers of meat products after 7 days of storage (Kaewprachu et al., 2018). Glutathione, a decreasing tripeptide Glu-Cys-Gly containing receptive cysteine which is available in new meat gets connected with the nisin which is utilized as an additive at various destinations through Michael expansion. So it needs further care in using nisin as a preservative (Abdullah et al., 2010). Less amount of nisin is required in liquid foods because of its unbound and persistent motion in a fluid system in contrast to semisolid or solid foods where the movement of nisin and reaction with microorganisms are consistently limited. And also in liquid food, the molecular motion of dissolvable parts is exponentially more prominent than in strong nourishments thus the concentration of nisin required in fluid food is less when contrasted with strong food sources. Glycation of nisin will reduce the preservative efficacy in the storage and processing of foods (Abdullah,et al., 2010). Lucerna hay can also be used to improve productivity, meet nutritional value, and preserve aspects (redness of meat) in a period of inadequate pastureland availability (Ponnampalam et al., 2020).

Phenolic compounds present in the essential oil are responsible for antibacterial activity in the preservation of meat. Some essential oil that is used as a preservative is obtained from oregano, rosemary, thyme, and cinnamon essential oils. Their implementations are improving in industries of pharmaceutical, food, and cosmetics (Mahmoudzadeh,et al., 2017). Plasma TO/SF (silk fibroin) nanofiber layer was made and waiting for the futuristic works. The bactericidal movement of TO (thyme basic oil) on Salmonella typhimurium development after 0.5 h and 1 h of TO treatment, the complete populace of Salmonella typhimurium in the MIC (minimal inhibitory fixation) bunch was decreased about 99.23 % and 99.89 % separately, while the absolute populace of Salmonella typhimurium was fundamentally diminished about 99.99 % and 99.999 % in the MBC(minimal bactericidal concentration) family. These outcomes showed that TO be a powerful antibacterial operator against Salmonella typhimurium and are ready to eliminate the microscopic organisms within a small period (Lin, Liao, & Cui, 2019). Mohamed & Mansour, 2012, evaluated the result of adding rosemary and marjoram essential oils within frozen beef patties and storing successfully for 3 months placed at −18˚C. Doses of 200 mg/kg of essential oil of these aromatic compounds were added and appeared to be powerful against the oxidation of lipid. Besides, the after-effects of the sensory properties additionally mirrored a constructive outcome of essential oil fusion and the item has a greater favor between food specialists. Ferulago angulata (chavil) essential oil (FAE) can delay or prevent oxidation of lipid content in meat without affecting the chemical composition and physical quality of meat. This shows that FAE essential oil can improve beneficial fatty acids in meat and also the quality of meat (Parvar et al., 2018). Bacteriocins are used as a preservative in sausages.

Emerging companies are harnessing the power of natural ingredients to create edible coatings that establish a protective barrier, all while remaining imperceptible to our senses. This innovation benefits all players within the food supply chain by minimizing waste and increasing profitability.

One noteworthy example is Sufresca, an Israeli startup specializing in bio-based edible coatings designed for agricultural products. These coatings serve to prolong the shelf life of fresh produce and mitigate losses due to changing environmental conditions, all the while preserving their freshness. Additionally, Sufresca's protective coating operates selectively, specifically targeting openings or damaged areas on the surfaces of items like arils and berries. This targeted approach effectively prevents anaerobic fermentation and the development of undesirable flavors over time. As a result, farmers and retailers can maximize the value of their agricultural yields.

Chinova Bioworks, a startup based in Canada, specializes in creating natural preservatives derived from extracts of mushrooms. Their flagship product, known as Chiber, is crafted from fibers sourced from the stalks of white button mushrooms. These fibers play a crucial role in extending the freshness of various products while also preventing the growth of bacteria. Consequently, they enhance the overall quality and stability of the product throughout its shelf life. Chiber is employed in the manufacturing of a wide range of items, including fruits, beverages, sauces, and plant-based dairy products.

3.7 Marine derivatives in preservation

Mangroves, seaweeds, salt marshes, etc. can also be used to preserve meat products. Detailed studies on these compound individual characteristics in the field of preservation may create a revolution in the meat and meat processing industries.

3.7.1 Mangroves

Mangrove leaf extracts have a strong antibacterial, antiviral and antioxidant activity. It also contains a variety of constituents such as saponins, tannins, phenol, glycosides, oils, etc. The antimicrobial effect of this leaf extraction treatment varies depending upon the kind of bacteria. In the process, gram-positive bacteria (Klebsiella pneumonia) were more resistant, because of the cell wall structure in bacteria (Behbahani,et al., 2018). Mangrove leaf extract in combination with the teak extract acts as an antioxidant that reduces the abnormal iron formed in beef and it is the major factor in the free radical formation that destroys the nutritional content in beef. This can neutralize the free iron that damages the cell (Berebein et al., 2020). The species such as Ceriops decandra (Griff) Ding Hou and Aegiceras corniculatum (L.) Blanco (Myrsinaceae), Excoecaria agallocha L. (Euphorbiaceae), Avicennia officinalis L. (Avicenniaceae) and Lumnitzera racemosaWilld possessed higher antibacterial potency against Staphylococcus aureus (Chandrasekaran et al., 2008). In the processing of fish nuggets, wheat flour can be replaced with mangrove fruit flour because of its larger content of protein (Amalia et al., 2016).

3.7.2 Sea weeds

Seaweeds are subjected to a wide range of ecological imbalances likequick change in temperatures, osmotic pressure, light, and drying. Strong oxidizing factors and free radicals can be formed due to these factors but seaweeds rarely suffer from some major photodynamic destruction. Apart from these, seaweeds were found to play an important part in enhancing food quality, since it contains an adequate amount of dietary iodine and fibers (Cofrades et al., 2008). The seaweeds help in the evaluation of harder and fibrous composition with greater properties of fat and water holding capacity by the impact on the properties of gel/emulsion meat systems, an outcome which is mainly pronounced with wakame. Seaweeds provide dietary fiber and also contain some compounds which are bioactive namely antioxidants, carotenoids, or polyphenols which help in increasing the product's potential health-beneficial properties. The change of color in meat products falls on the kind of seaweed utilized (Cofrades et al., 2008). Further seaweeds are used in meat to change salt usage which exhibits choice to more advantageous foodstuffs with functional characteristics even though some contrary outcomes have been shown in writings. In this view, a few difficulties ought to be conquered, for example, sufficient choice of the seaweed in the capacity of the ideal attributes in the final items including the measurements utilized. It is also essential to assess attentively the nutritional, sensorial, and physiochemical properties after the addition of seaweeds and also the life span of redeveloped items and microbiology stability (Gullon,et al., 2020). Carrageenans are the additives used in foods and drinks. These are obtained by extraction with aqueous alkali or water from red weeds, especially the members of Rhodophyceae. These are synthesized as structural polysaccharides. Carrageenan can retain water and form gels in meat products. So it is used in texture modifying, either for gelation and retention of the liquid present in the meat. They can also be used as a brine source in meat and it is introduced in 3 ways such as through massaging, injection, or blending along with meat batters (Trius et al., 2009).

3.7.3 Salt marshes

Gram-positive bacteria are reduced greatly by the antimicrobial activity of Salicornia brachiata. Glasswort (Salicornia fruticosa) had appreciable efficacy in lowering the yeast and mold counts, aerobic plate count, thiobarbituric acid, and pH of fresh minced beef stored at 4˚C (Elsebaie et al., 2013).

4 An insight into packaging techniques

Packaging also plays a chief role as they help in keeping the product intact and preventing exposure to the harmful environment (Rahman,et al., 2018). Packaging techniques include creating a vacuum (vacuum packaging) and modifying the atmosphere by changing the gas composition surrounding the product (modified atmosphere packaging) and various other methods are discussed in this topic (Kerry and Tyuftin, 2017). pH, protein oxidation, lipid oxidation, color, sensory evaluation, and microbiological analysis were conducted to determine whether the meat products are spoiled or not (Lorenzo & Gomez, 2012). Generally, packaging enhances the appearance, shelf life, and market value of a product. The shelf life of a product may be defined according to a consumer's preference generally it is the time in between packaging until the end consumption, during which the properties remain allowable (Lorenzo and Gomez, 2012). Even though organoleptically undesirable products may not especially be perilous as the consumers presume. A Biopolymer obtained from red algae known as carrageenan is used in making effective carrageenan film combined with olive leaf extract is experimented for determining its efficacy in the packaging of lamb meat (Martiny et al., 2020). Similarly, research shows that alginates which were initially used in preserving fruits and vegetables when utilized as a part of an intelligent packaging system may yield a promising multi-function packaging system (Kontominas, 2020). Thus overall packaging also plays a vital role in the meat processing industry. Biodegradable packaging also plays a major role in attracting consumers (Göksen et al., 2021). Petroleum-based packaging was also available but due to its effects on the environment, its application is reduced (Heydari-Majd et al., 2019). (Vilela et al., 2016) studied the antimicrobial effect of essential oils on minced meat stored in different temperature conditions.

4.1 Packaging- ancient practices

In the traditional handling of meat products, raw meat is not packed or wrapped in leaves, paper, etc. In earlier days it is generally a seasonal industry. There was no mechanical refrigeration to help in shielding the meat from ruining in any event when salt treatment was utilized; activities were restricted for the most part to the winter months. The tradition was used to pack meat through the winter, heap the barrels on the outside of the ground and afterward sell in the spring. Traditionally the meat is protected by drying and is occasionally packed in linen bags, pottery, or baskets to ease transport and storage and also to give some kind of defense against dust, insects, etc. Conventional packaging of food is a static framework, which gives insurance against outside situations, physical help, and improvements. Dissemination, transport and the capacity of items are the primary procedure that is ensured by this packaging (LIoyd et al., 2018). The packaging materials that are utilized in former times act in securing and transportability, yet additionally bestows taste and wellbeing to food items. Bundling is a way to expand the worth and capacity of the item. Normal materials are utilized in conventional bundling which can be rotted effectively and have an amicable character with nature. A few leaves, for example, banana and Thaumatococcus danielli are utilized as a material for bundling in times past. Banana leaves are utilized to wrap social cooking styles for capacity. These lustrous leaves won't corrupt the items effectively and hold the dampness in. They additionally can spare its items both in advertise deals and transport of items as snacks with transient nature. Similarly, Thaumatococcus danielli is utilized in towns, yet has huge acknowledgment in towns and urban areas. Various assortments of pockets and packs are made by Palmyra leaves, jute strands, and banana leaves. It is roughly discovered that glass and wood bundling is being utilized for around 5000 years. In the 1900s, paper and cardboard are being utilized as significant bundling materials. The most established re-shapeable packaging material is paper. Mulberry tree barks are utilized to wrap food. The papers which are utilized today are unique to the main papers. Flax filaments and later old material clothes are utilized to make paper in the early periods. Nuts and gourds, the tanned hide is used to store and transport different types of items in early times. An emptied bit of wood may have been utilized with leaves or creature skin to build a containing/putting away gadget. These choices are just hypotheses to what in particular may have been the main bundling material utilized by early people. A long time after the trackers and finders built up the principal type of bundling, the requirement for bundling and containing gadgets turned out to be more significant.

At the point when man started to tame creatures and plants, towns started to spring up. Pack animals or any domesticated animal are utilized to convey cargo, merchandise, or supplies. The ass or jackass is the most established known pack creature, having been being used perhaps as right on time as 3500 BCE. Pack creatures are regularly utilized in the territory where wheeled vehicles would experience trouble. Thus the presentation of networks expanded the requirement for broader stockpiling and transportation devices to flexibly bigger gatherings of individuals. Ancient man produces vessels and containers from natural substances such as leaves, woods, gourds, bamboo, lotus leaves, palm leaves, coconut shells, and animal skin. It led to the arrival of creativity and innovation. People learned how to make crates from wood, pots from clay and found the techniques of weaving. They began to use animal skin, weaving baskets and sacks from plant fibers and leaves to make stronger bags. Later on, like minerals, metals, and synthetic compounds were found, metals and earthenware were created prompting the utilization of new materials including textures, pottery, metals, lacquerware, wood product, jade product, and specific sorts of paper. Steam motors denoted the start of the industrial revolution. With these advancements, the human could store food from antagonistic climate conditions and creatures.

4.2 Modern packaging techniques

4.2.1 Vacuum packaging

This technique primarily involves the elimination of gases within the packaged habitat thus generating vacuum conditions in which food spoiling aerobic organisms fail to thrive. The preservative effect of Vacuum Packaging (VP) is a direct result of the expulsion of oxygen from the packaging environment, oxygen impermeable films, good hygiene, storage temperatures, and low illumination are some of the precautions to be taken for successful VP. VP is a much easier packaging method. The main aspect in the case of the customer's perspective of purchasing meat products remains the colour. Thus commercial methods of packaging are involved in protecting the fresh red color of meat. The stability of color in meat products is decided by the pace of oxymyoglobin oxidation (Faustman, et al., 2010). Strictly anaerobic species like Clostridium may continue to thrive in this environment even though aerobic organisms may not be destroyed but simply inactivated. Vacuum packaged red meat usually is spoiled over a long time by thermosphacta or lactic acid bacteria (Kerry & Tyuftin, 2017). Vacuum packaging became accepted by consumers because its contents were visible and its color was relatively fixed. Usually, in ready-to-eat meat products packaged in VP or MAP, Lactic and acetic acids or their sodium and potassium salts are used as antilisterial agents (McMillin & Belcher, 2012). Vacuum packaging is accepted by a broad range of clients and it helps in creating innovations in the field of packaging of pre-cooked food. The challenges of vacuum packing include its inability to seal delicate foods, post-packing spoilage, plastic intoxication and anaerobic microbial contamination. This can be rectified through proper washing, blanching and precooking.

4.2.2 Modified atmosphere packaging

Modified Atmosphere Packaging (MAP) is a method where meat products are preserved by changing the gas composition enclosing them and it differs from the atmospheric gas composition. The composition of the gas mixture depends on the type of product being packaged more generally carbon dioxide (CO2) nitrogen (N2) and oxygen (O2). Even though oxygen increases the spoilage it preserves the red color of meat. Similarly, CO2 in excess may result in discoloration, and N2 is for displacing O2 and also helps in maintaining the structure of the package by maintaining CO2 levels (Kerry & Tyuftin, 2017). Though MAP helps in preserving the product, microbial action and temperature control of the raw product are necessary. The stability of the colour of cured meat packaged under the MAP method may be determined by lighting quality, and oxygen level product: headspace ratio of volume. One of the most challenging aspects of MAP is the unique atmospheric requirements for the variety of products. In red meats, oxygen is necessary for the bright red colour expected by consumers, but oxygen also contributes to degradative oxidation. Therefore, techniques to control oxygen exposure are of value to red meat products. Respiring fresh produce requires distinct levels of oxygen and carbon dioxide. Typically, oxygen levels lower than atmospheric and carbon dioxide higher than atmospheric are needed.

(Guo et al., 2018) studied that in roast chicken the growth of TVC, molds, and yeast was slower when packed in lesser CO2 MAP. When the gas composition was altered in MAP the fat oxidation, pH, color of the roasted chicken was not significant. (Klein et al., 2017) studied 2-methyl-1-propanol, 2-methyl-1-butanol, 3-methyl-1-butanol, hydroxy-2-butanone, ethyl acetate, 2-butanone, and sulfur-containing compounds were some of the markers for chicken breast fillets contamination under MAP. These volatile organic compounds could act as an indicator for measuring the freshness of a product (Lorenzo & Gomez, 2012).

4.2.3 A comparison between vacuum packaging and modified atmosphere packaging

Djordjevic et al., 2018, studied the impact of Salmonella species on minced meat, where both the vacuum and modified packaging were used, the result proved that the viable and Lactobacillus bacteria counts showed differences, thus proved meat packaged with MAP technology with 50 % of CO2 showed lesser counts. Higher CO2 levels exhibited more antibacterial activity against the pathogens TVC and LAB showing that the most effective control was brought about by MAP. In vacuum packaging, the color stability increased over time and the oxidation of lipid and protein was less, though the redness of meat was affected when the product exposed to air regained the original color. Microbial growth and lipid oxidation were affected by the CO2content in low O2 MAP. Chitosan, Z.multifloraboiss essential oil, Sumac extract were utilized under conditions of MAP with a storage period of 20 days, they showed a strong antimicrobial effect and SE and ZEO together portrayed notable impacts on preventing oxidation of lipid in meat and meat products, and higher amount of O2 in MAP had shown higher oxidation effect (Langroodi et al., 2018). Pork loins packaged in Hi*MAP or VP were studied to determine which packaging was better, the results were displayed and pork loins packaged in HiO*MAP have lesser color and oxidation life span than the latter. Thus the study impacts stress on the effect of HiO*MAP packaged pork loins on eating quality must be considered by the pork industry. (Ortiz et al., 2020) conducted a test on 253 consumer's preferences for packaging over Spanish meat product Iberian dry-cured ham. The sensory test showed 70 % of consumers preferred VP over MAP and the reasons were more eco-friendly packaging, increased appearance, color but in case of odor more scores were received by MAP.

4.2.4 Heat shrink wrapping

Heat shrink wrapping is a technique similar to vacuum packaging but not used for products to increase shelf life. They are simply used for meat transportation. The difference between vacuum packaging and heat shrink wrapping involves increased attractive appearance reduce drip loss and reduce package corners (Kerry & Tyuftin, 2017).

4.2.5 Antimicrobial packaging

Antimicrobial Packaging (AM) may help lower contamination, reduce microbial growth and expand the life span of products. AM includes an antimicrobial agent that is embedded in the packaging material that inhibits the growth of microorganisms. This method can principally be used to strengthen food preservation, influencing the capability to stop or deteriorate the growth or doubling of microbes (Rawdkuen et al., 2016). Antimicrobial chemicals or compounds in a polymer matrix to decrease the growth of spoiled food pathogens by targeting specific bacteria in order to improve food shelf life. Incorporating antimicrobial compounds into edible films for food packaging represents a significant advancement in the realm of biodegradable food packaging. This innovation aims to curtail and impede the growth of microorganisms on the surfaces of food items. The antimicrobial agent is introduced directly either into the food particles themselves or into the packaging material, serving to uphold the quality and safety of the food product. Over time, it gradually releases, leading to an extension of the product's shelf life (Yuvaraj et al., 2021) In comparison with adding AM agents directly onto foods, the use of AM packaging has advantages because additives added on food surfaces through drips or sprays are less powerful to slow down the growth of microorganisms. This is due to the denaturation of active substances by food constituents and higher dispersion of AM agents which diminishes the sensitivity of AM agents. Among the antimicrobial treatments suggested and explored for meat packing are natural biopolymers (chitosan), organic acids or their associated acid anhydrides, alcohols, bacteriocins (nisin and pediocin), chelators, and enzymes (lysozyme).(Fadiji et al., 2023) Nisin which is a primary food constituent has exhibited significant control of microorganism growth exclusively when combined with other antimicrobial techniques (Djenane et al., 2020). Table 2 shows various products packaged using antimicrobial compounds.

Product

Coating Material

Antimicrobial packing material

Target microorganism

Conditions

Results

References

Ready to eat chicken deli meat

Tapioca starch active nanocomposite film

Grape Pomace

Listeria monocytogenesATCC7644 and S.aureusATCC29213

4 °C, 10 days meat covered with starch films

88.7–97.6 % of inhibition on S.aureus than L.monocytogenes with 33.0–627 % inhibition

Xu et.al,2018

Ready to eat deli turkey meat

Polylactic acid films and coating solutions

Chitosan

L.innocua

10 °C, 24 h meat coated with PLA film and coating solution was applied for direct coating treatment

Coating with 1.94 mg/cm2 of chitosan and 0.388 mg/cm2 of LAE reduced L.innocua by 4.5 logs CFU/cm2with flash pasteurization reduced over a 5log reduction

Guo, et al., 2014

Chicken breast meat

Nanocomposite film

ZnO and okra mucilage

S.aureus, Lactic acid bacteria(LAB), Thiobarbituric acid and so on

4°c, 12 days chicken breast covered with films

CMC/OM50%/ZnO film could preserve the breast chicken better

Mohammadi et al., 2019

Raw meat

Chitosan nanoZnO composite film

Chitosan

E.coliandS.aureus

4°c, 6 days kept in C-2 pouches

C-2 bags inhibited the total concentration of bacterial growth

Rahman, et al., 2017

Chicken breast fillets

Edible coating of whey protein isolate

Oregano and clove essential oil

Pseudomonas sp, Aerobic mesophilic bacteria, Aerobic psychotropic bacteria, and Enterbactericea

4°c, 13 days breast fillets coated by dipping, draining, and drying

The High concentration of oregano EO shows 2 log reduction against AMB, 1 log reduction against APB and Enterobacteriaceae, and 1.5 log units against Pseudomonas

Pan, et al., 2014

Chicken meat

Linear low-density polyethylene/ CLO film

Clove essential oil(CLO)

L.monocytogenes, Salmonella Typhimurium

4°c, 28 days chicken samples wrapped with LLDPE films

Oil coated with film destroyed the microorganisms on the 5th day of storage and no further growth occurs.

Mulla et.al, 2016

Ham product

Bioactive starch film

Gallic acid, Chitosan and carvacrol

L.monocytogenes

4°c, 28 days aseptically packed with film

(0.3 g/g starch) of gallic acid, carvacrol and chitosan has destroyed the growth completely

Zhao, et al., 2019

Ground beef patties

Zein film

Lysozyme(LY) (43 mg/g) and Disodium ethylenediaminetetraacetic acid (Na2EDTA, 19 mg/g)

Mesophilic microorganism (TVC) and Coliforms (TCC)

4°c, 7 days films at both sides of each piece wrapped with stretch plastic film and with aluminum foil

After 5 and 7 days, the TVC of patties with LY and Na2EDTA films was significantly lower (0.75–1.9 log CFU/g) than control films. After 5 days, the TCC of patties with LY and Na2EDTA films was significantly lower than control but after 7 days, no significant difference in TCC of patties was found

Sanchez-Ortega, 2014

Minced beef meat

Zein film

ZeitariaMultifloraBoiss essential oil (ZEO), Monolaurin (ML)

L.monocytogenes and E.coli

4°c, 12 days films were placed at both sides of patties and kept in polyethylene bags

The use of ZEO and ML on antimicrobial activity was found to be dose-dependent. Zein film containing the combination of ZEO and ML in meat shows a synergistic effect on the growth of microorganisms

Moradi, et al., 2016

4.2.6 Nanomaterial packaging

Nanotechnology is currently crucial in the field of modern packaging since the customer's satisfaction is met. Nanomaterials enhance the barrier and mechanical characteristics of the materials used in food packaging. Zinc(Zn), iron(Fe), copper(Cu), gold(Au),aluminum(Al), nickel(Ni) and silver(Ag). Titanium, iron, zirconium, and zinc oxides, or talc, mica are some metals used in the manufacturing of nanoparticles.

The process of preparing nano-food packaging encompasses various aspects, including heat and mass transfer, nanoscale reaction engineering, nanobiotechnology, and molecular synthesis, as illustrated in Fig. 1. Polymer nanocomposites find application in nano-food packaging for several purposes:

-

Enhancing packaging barrier properties, such as the prevention of carbon dioxide, moisture, oxygen ingress, and the retention of ethanol and flavour compounds (Mei and Wang, 2020).

-

Facilitating active packaging, which involves the inhibition or retardation of microbial growth and food spoilage (Kim et al., 2020a, 2020b; Pirsa and Shamusi, 2019).

-

Enabling intelligent packaging capable of monitoring the condition of the packaged food (Ding et al., 2020).

-

Utilizing degradable biopolymers to enhance the physical and chemical qualities of biopolymers (Kraśniewska et al., 2020; Sun et al., 2020).

For instance, silver nanoparticles showed fungal death as it breaks the membrane thus showing the anti-fungal property. Similarly, gold particles exhibited disinfectant properties against bacteria (Youssef & Sayed, 2018). Biopolymers are now widely surveyed for bringing innovation in the methods of packaging. The processes involved are after the selection of the compounds they are combined with the solvent material, followed by the addition of plasticizer (Umaraw et al., 2020).

Alzate et al., 2017, created a film utilizing glucose fused along with potassium sorbate, tapioca starch, hydroxypropyl methylcellulose, and carvacrol. This film showed an increased disinfectant effect against Zygosaccharomyces bailii, Lactobacillus plantarum, and Pseudomonas fluorescens and it was also said to increase the storage stability of the product. The reason for nanomaterial-based sensors was since they could bind to target particles and were capable of producing detectable signals, thus helping in the identification of food contaminants and spoilage of food materials. (Souza et al., 2020) successfully produced bio nanocomposite films by using ZnO and chitosan for the packaging of fresh poultry meat. The films used to protect fresh poultry meat presented an extension on its shelf-life time, proving that this technology has a promising potential to be applied by the food industry. They had concluded that the preservation achieved was quite similar between the three levels of ZnO Nanoparticles (0.5 %, 1 %, 2 %) tested. Zinc oxide nanoparticles incorporated at 0.5 % resulted in the highest water vapor permeability and smallest tensile strength, contributing to a facilitated diffusion process of ZnO Nanoparticles.

The detection or identification of nanoparticles in the food matrices or environmental containers poses challenges. In addition, a better clarification is needed to understand if the toxicity is due to the high Zn dose or the ZnO nanoparticles themselves.

Despite tremendous advancements in the use of nanoparticles in food nanotechnology, little is known about nanoparticle toxicity. The two main safety issues when employing nanoparticles are allergens and heavy metal leakage. Nanoparticles are currently being used in food products at a faster rate than desired, with the requisite information or laws in place, posing a risk to the environment and human health (Ranjan et al., 2014). In 2011, the European Food Safety Authority (EFSA) issued a guideline titled “on the Risk Assessment of the Application of Nanoscience and Nanotechnologies in the Food and Feed Chain” (Committee, 2011), requiring manufacturers to give physicochemical data. It requires data from in vitro distribution, absorption, genotoxicity, metabolism, and excretion tests, as well as a 90-day oral toxicity test with repeated doses. If data demonstrate no migration, complete dissolution, or degradation, a chemical may be omitted from these standards (Committee, 2011).

5 Future trends

New advances will be increased, for example, Pascalisation (High-Pressure Processing), utilization of defensive microorganisms, and utilization of explicit phages. HPP gives off an impression of being the ideal key for protection; so far all different processes have had some negative aspects. Since no synthetics are included, there is no contamination or taste adjustment to the food. The microorganisms in the food stay unblemished; anyway, they are inhibited by the pressure-induced disassembly of their DNA structure.

Biopolymers include polysaccharides (cellulose, starch, alginates, chitosan, etc) or proteins which change the hurdles to gas, moisture and also effectively modify the mechanical and physical attributes. An example of this method is Pullulan-alginate-based films which showed properties of water solubility, heat sealable, and oxygen impermeable (Xiao et al., 2014).

Active packaging is a modern technique where the meat products, package, and the environment in which the meat is packaged communicate to give a positive attribute of the product and this is brought about by embedding active compounds that absorb or release substances to prevent the spoilage of product and to extend its shelf life (Mcmillin, 2017).

Emitting packets which contain antimicrobial or antioxidant components, such as essential oil, ethanol may be used. Similarly, absorbent sheets embedded with silver, copper, or copper nanoparticles help in absorbing gases (Otoni et al., 2016). Package film containing nitrite crystals and packaged using the VP method has shown evidence that the red color of meat is retained and it also extends the life span to 10 times higher than other packaged meat. Scavengers when added may help in the removal of odors produced during the process of meat respiration (Mcmillin, 2017).

Intelligent packaging is another technique where sensors or indicators are used to detect changes in product quality (Mcmillin, 2017). Alternative technologies include headspace measurement of headspace gases by the use of fluorescent sensors for O2, package leak indicating sensors, identifying target metabolites, etc. Time-temperature indicators provide knowledge on changes of temperature that may affect the quality or may possess a severe threat to human health. Other techniques such as gas indicators, freshness indicators, and pathogenic microbe detectors are also used. But still the application of biosensors in the packaging of meat products needs to compete with other modern packaging techniques in terms of effectiveness, cost, and reliability (Adley, 2014).

Biodegradable packaging also has attracted consumers to a larger extent but cost and other characteristics restrict its usage in the market. Integrated chips are impregnated in the packaging of food that can send information to the consumer's mobile phone which reads barcoding on the package (Fang, et al., 2017).

Challenges may continue to be posed in terms of efficiency of sensors\indicators, the harmlessness of active and intelligent packaging, cost, the effect on the environment, and integration into prevailing packaging systems. More innovative approaches in the field of detailed information generating packages, intelligent packaging, more accurate and multipurpose sensors, may be undertaken (Mcmillin, 2017).

6 Impact of COVID-19 pandemic on meat industry

The impact of the COVID-19 pandemic is widely spread to various types of sectors. The pandemic which leads to mass shutdown resulted in anguish to billions of poverty-stricken farmers. Rumors of poultry birds posing as a medium for COVID-19 resulted in reduced demand for poultry meat in several parts of India. Even post-COVID-19 the demand for poultry meat declined further as consumers did not show a keen interest in purchasing them. The domestic meat sector as well was interrupted due to the breaking of the market chain. Prices of mutton plunged as high as 50–80 % of the normal price since the reduced availability of mutton. However, lockdown caused the buffalo meat export units to shut down their process resulting in loss accounting about Rs.25000 crores per annum to the country, India. Animal feed availability was reduced initially during the 1st stage of lockdown thus impacting the growth and production of rearing animals which caused the significant economic loss. A survey indicated that consumers preferred fresh meat to processed and ready-to-eat meat products in India. During the lockdown period, 81 % of chicken meat was available whereas only 37.6 % of fish and 24.8 % mutton were available. A wide range of changes was produced in meat consumption patterns among consumers, the quantity of meat purchase was reduced by 60 % whereas in regions where the availability of meat was a satisfactory increase in consumption was found (Biswal et al., 2020).

Global Data's 2021 Q1 Consumer survey depicted that 37 % of consumers in the South Korean population are worried about their physical wellbeing due to COVID-19. Consumers seek plant-based products as an alternative and thus food industry aims in fulfilling their needs in South Korea. Lotte food replaced the conventional meat patty with a vegan burger patty and introduced a sriracha plant burger in the market. There was a sudden decline in the consumption of pork in the year 2020 and about 70 % of South Korea's total meat consumption rate suffered a decline in demand due to pandemic (Food processing-technology, 2021).

WHO predicted that production of meat would increase annually by 376 million tons till 2030 from 218 million tons between the years 1997–1999. But considering the pandemic situation, the U.S. Department of Agriculture has found that global trade of poultry meat in particular chicken has fallen by 4 % accounting for 11.7 million tons from the previous year's stats. About 1 % of the global poultry meat trade will reduce. In India, the consumption rate accounts for 3998 metric tons which are decreased comparing to the previous year's consumption (Data Bridge Market Research, 2021).

7 Conclusion

Various practices have been implemented from ancient times in the meat processing industry. Developments are being made in this field to fulfill the customer's requirements. From curing, chilling techniques to antimicrobial and nanomaterial packaging there have been continuous developments in meat industries but as days progress the consumer's demand such as transportation, storage, shelf life, environmental issues, the market value of the products seems to be a challenging issue. Moreover, Rapid Urbanization has resulted in increased intake of animal-based products in developing countries. In Asian countries, Pork remains a major part of production and consumption in meat industries. Thus more innovative and eco-friendly measures can still be researched to full fill upcoming customer demands.

Acknowledgements

This research was supported by Korea Basic Science Institute (National research Facilities and Equipment Center) grant funded by the Ministry of Education (grant No. 2023R1A6C101A045), and was also supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2022R1A6A1A03055869).

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Crab-meat-isolated psychrophilic spore-forming bacteria inactivation by electron beam ionizing radiation. Food Microbiol.. 2018;76:374-381.

- [CrossRef] [Google Scholar]

- Effect of elementary and advanced glycation products of nisin on its preservative efficacy and digestibility. Food Chem.. 2010;122(4):1043-1046.

- [CrossRef] [Google Scholar]

- Past, present and future of sensors in food production. Foods. 2014;3:491-510.

- [CrossRef] [Google Scholar]

- Effect of the potassium sorbate and carvacrol addition on the properties and antimicrobial activity of tapioca starch -hydroxypropyl methylcellulose edible films. Starch Staerke. 2017;69(5–6):1600261.

- [CrossRef] [Google Scholar]

- Chemical characteristics of fish nugget with mangrove fruit flour substitution. Aquat. Procedia. 2016;7:265-270.

- [CrossRef] [Google Scholar]

- Effect of freezing on the quality of meat. Encyclopedia Food Secur. Sustain.. 2019;2:493-497.

- [CrossRef] [Google Scholar]

- Phytochemical analysis and antibacterial activities extracts of mangrove leaf against the growth of some pathogenic bacteria. Microb. Pathog.. 2018;114:225-232.

- [CrossRef] [Google Scholar]

- Effect of giving mangrove leaf extract (Acanthus Ilicifolius) and Teak Leaf Extract (Tectona grandis) on Iron (Fe) beef exposed to gamma radiation. Int. Res. J. Adv. Eng. Sci.. 2020;5(3):21-23.

- [Google Scholar]

- Impact of COVID-19 and associated lockdown on livestock and poultry sectors in India. Vet. World. 2020;13:1928-1933.

- [CrossRef] [Google Scholar]

- Meat consumption and health outcomes. Vegetarian Plant-Based Diets Health Dis. Prevention. 2017;197–214

- [CrossRef] [Google Scholar]

- Antibacterial activity of some salt marsh halophytes and mangrove plants against methicillin-resistant Staphylococcus aureus. World J. Microbiol. Biotechnol.. 2008;25:155.

- [CrossRef] [Google Scholar]

- Super chilling concepts enabling safe, high quality and long term storage of foods. Procedia Food Sci.. 2011;1:1907-1909.

- [CrossRef] [Google Scholar]

- Influence of different types and proportions of added edible seaweeds on characteristics of low-salt gel/emulsion meat systems. Meat Sci.. 2008;79:767-776.

- [CrossRef] [Google Scholar]

- Committee, E. S, 2011. Guidance on the risk assessment of the application of nanoscience and nanotechnologies in the food and feed chain. EFSA J. 9 https://doi.org/10.2903/j.efsa.2011.2140.

- Data Bridge Market Research. Available online: https://www.databridgemarketresearch.com/covid-19-resources/covid-19-impact-on-meat-in-the-food-and-beverage-industry (accessed on 22-06-2021).

- A naked-eye detection polyvinyl alcohol/cellulose-based pH sensor for intelligent packaging. Carbohydr. Polym.. 2020;233:115859

- [CrossRef] [Google Scholar]

- Improvement of the shelf-life status of modified atmosphere packaged camel meat using Nisin and Olea europaea subsp laperrinei leaf extract. Foods. 2020;9:1336.

- [CrossRef] [Google Scholar]

- Survival of Salmonella spp. in minced meat packaged under vacuum and modified atmosphere. Braz. J. Microbiol.. 2018;49(3):607-613.

- [CrossRef] [Google Scholar]

- Perspectives for chitosan based antimicrobial films in food applications. Food Chem.. 2009;114(4):1173-1182.

- [CrossRef] [Google Scholar]

- Quality changes during superchilled storage of cod (Gadusmorhua) fillets. Food Chem.. 2007;105(3):1067-1075.

- [CrossRef] [Google Scholar]

- Studies on antimicrobial and antioxidant efficiency of glasswort (Salicorniafruticosa) herb juice and methanolic extract in minced beef. Int. J. Mod. Agric.. 2013;2

- [Google Scholar]

- A Review on antimicrobial packaging for extending the shelf life of food. Processes. 2023;11:590.

- [Google Scholar]

- Natural antioxidants against lipid-protein oxidative deterioration in meat and meat products: a review. Food Res. Int.. 2014;64:171-181.

- [CrossRef] [Google Scholar]

- Active and intelligent packaging in meat industry. Trends Food Sci. Technol.. 2017;61:60-71.

- [CrossRef] [Google Scholar]

- Irradiation for better foods. Trends Food Sci. Technol.. 2006;17(4):148-152.

- [CrossRef] [Google Scholar]

- Myoglobin and lipid oxidation interactions: mechanism bases and control. Meat Sci.. 2010;86(1):86-94.

- [CrossRef] [Google Scholar]

- Food processing-technology. Available online: https://www.foodprocessing-technology.com/comment/covid-19-vegan-boom-south-korea/ (accessed on 22-06-2021).

- Biodegradable active food packaging structures based on hybrid cross-linked electrospun polyvinyl alcohol fibers containing essential oils and their application in the preservation of chicken breast fillets. Food Packag. Shelf Life. 2021;27:100613

- [Google Scholar]

- The effects of processing and preservation technologies on meat quality: sensory and nutritional aspects. Foods. 2020;9:1416.

- [CrossRef] [Google Scholar]

- Inclusion of seaweeds as healthy approach to formulate new low-salt meat products. Curr. Opin. Food Sci.. 2020;40:20-25.

- [CrossRef] [Google Scholar]

- Effect of normal and modified atmosphere packaging on shelf life of roast chicken meat. J. Food Saf. 2018

- [CrossRef] [Google Scholar]

- Antimicrobial films and coatings for inactivation of Listeria innocua on ready-to-eat deli turkey meat. Food Control. 2014;40:64-70.

- [CrossRef] [Google Scholar]

- Hammes, W.P., Hertel, C., 2009. The genera Lactobacillus and Carnobacterium. In Ecology of Lactic Acid Bacteria: From Gastrointestinal Tract to the Industrial Fermentation, Vol. 1. Springer, pp. 160-262.

- A new active nanocomposite film based on PLA/ZnO nanoparticle/essential oils for the preservation of refrigerated Otolithes ruber fillets. Food Packag. Shelf Life. 2019;19:94-103.

- [Google Scholar]

- Changes in protein properties and tissue histology of tuna meat as affected by salting and subsequent freezing. Food Chem.. 2018;271:550-560.

- [CrossRef] [Google Scholar]

- Gelatin films with nisin and catechin for minced pork preservation. Food Packag. Shelf Life. 2018;18:173-183.

- [CrossRef] [Google Scholar]

- Storage and preservation of raw meat and muscle-based food products: IV storage and packaging. Lawrie’s Meat Sci. (Eight Ed.). 2017;297–327

- [CrossRef] [Google Scholar]

- Interactions between raw meat irradiated by various kinds of ionizing radiation and transglutaminase treatment in meat emulsion systems. Radiat. Phys. Chem.. 2020;166

- [CrossRef] [Google Scholar]

- ZnO nanostructures in active antibacterial food packaging: preparation methods, antimicrobial mechanisms, safety issues, future prospects, and challenges. Food Rev. Int. 2020:1-29.

- [Google Scholar]

- Detection of volatile organic compounds arising from chicken breast filets under modified atmosphere packaging using TD-GC/MS. Food Anal. Methods. 2017;11:88-98.

- [CrossRef] [Google Scholar]

- Biopolymers-based materials containing silver nanoparticles as active packaging for food applications–A review. Int. J. Mol. Sci.. 2020;21:698.

- [Google Scholar]

- Weight loss in superchilled pork as affected by cooling rate. J. Food Eng.. 2018;219:25-28.

- [CrossRef] [Google Scholar]

- Effects of sumac extract dipping and chitosan coating enriched with Zatariamultiflora Boiss oil on the shelf-life of meat in modified atmosphere packaging. LWT Food Sci. Technol.. 2018;98:372-380.

- [CrossRef] [Google Scholar]

- Effects of Salicornia herbacea powder on quality traits of sun dried Hanwoo Beef jerky during storage. Korean Soc. Food Sci. Animal Resources. 2013;33(2):205-213.

- [CrossRef] [Google Scholar]

- Fresh and cured meat processing and preservation. Sci. Animal Growth Meat Technol. 2019:205-228.

- [CrossRef] [Google Scholar]

- Shelf life of fresh foal meat under MAP, overwrap and vacuum packaging conditions. Meat Sci.. 2012;92(4):610-618.

- [CrossRef] [Google Scholar]

- Essential Oil Composition and Antioxidant Capacity of Carumcopticum and its Antibacterial Effect on Staphylococcus aureus, Enterococcus faecalis and Escherichia coli O157: H7. J. Food Process. Preservation 2017

- [CrossRef] [Google Scholar]

- Bio-based active packaging: carrageenan film with olive leaf extract for lamb meat preservation. Foods. 2020;9:1759.

- [CrossRef] [Google Scholar]

- Advances in the packaging of fresh and processed meat products. Adv. Meat Poultry Seafood Packaging 2012:173-204.

- [CrossRef] [Google Scholar]

- Advances in using nanotechnology structuring approaches for improving food packaging. Ann. Rev. Food Sci. Technol.. 2020;11:339-364.

- [Google Scholar]

- Incorporating essential oils marjoram and rosemary in the formulation of beef patties manufactured with mechanically deboned poultry meat to improve the lipid stability and sensory attributes. Food Sci. Technol. (. 2012;45(1):79-87.

- [CrossRef] [Google Scholar]

- Nanocomposite films with CMC, okra mucilage, and ZnO nanoparticles: extending the shelf-life of chicken breast meat. Food Packag. Shelf Life. 2019;21

- [CrossRef] [Google Scholar]

- Effects of chitosan coating with green tea aqueous extract on lipid oxidation and microbial growth in pork chops during chilled storage. Foods. 2020;9:766.

- [CrossRef] [Google Scholar]

- Antioxidant and antimicrobial effects of zein edible film impregnated with Zatariamultiflora Boiss. essential oil and monolaurin. LWT-Food Sci. Technol.. 2016;72:37-43.

- [CrossRef] [Google Scholar]

- Antimicrobial efficacy of clove essential oil infused into chemically modified LLDPE film for chicken meat packaging. Food Control. 2016;73(B):663-671.

- [CrossRef] [Google Scholar]

- Use of food preservatives and additives in meat and their detection techniques. Meat Quality Anal. 2020:187-213.

- [CrossRef] [Google Scholar]

- Is packaging affecting consumers' preferences for meat products? A study of modified atmosphere packaging and vacuum packaging in Iberian Dry-Cured Ham. J. Sensory Stud. 2020

- [CrossRef] [Google Scholar]

- Trends in antimicrobial food packaging systems: emitting sachets and absorbent pads. Food Res. Int.. 2016;83:60-73.

- [CrossRef] [Google Scholar]

- Antimicrobial efficiency of edible coatings on the preservation of chicken breast fillets. Food Control. 2014;36(1):69-75.

- [CrossRef] [Google Scholar]

- Effect of Ferula goangulata (Chavil) essential oil supplementation on lamb growth performance and meat quality characteristics. Small Rumin. Res.. 2018;167:48-54.

- [CrossRef] [Google Scholar]

- Essential oils as natural additives to prevent oxidation reactions in meat and meat products: a review. Food Res. Int.. 2018;113:156-166.

- [CrossRef] [Google Scholar]

- Intelligent and active packaging of chicken thigh meat by conducting nano structure cellulose-polypyrrole-ZnO film. Mater. Sci. Eng.: C. 2019;102:798-809.

- [Google Scholar]

- Use of lucerne hay in ruminant feeds to improve animal productivity, meat nutritional value and meat preservation under a more variable climate. Meat Sci.. 2020;170

- [CrossRef] [Google Scholar]

- Flexible chitosan-nano ZnO antimicrobial pouches as a new materialfor extending the shelf life of raw meat. Int. J. Biol. Macromol.. 2017;97:382-391.

- [CrossRef] [Google Scholar]

- Nanoscience and nanotechnologies in food industries: opportunities and research trends. J. Nanoparticle Res.. 2014;16(2464)

- [CrossRef] [Google Scholar]

- Antimicrobial packaging for meat products. Antimicrobial Food Packaging 2016:229-241.

- [CrossRef] [Google Scholar]

- Natural antioxidants used in meat products: a brief review. Meat Sci.. 2019;148:181-188.

- [CrossRef] [Google Scholar]

- Antimicrobial edible films and coatings for meat and meat products preservation. Sci. World J. 2014

- [CrossRef] [Google Scholar]

- Eco-friendly ZnO/Chitosan bio nanocomposites films for packaging of fresh poultry meat. Coatings. 2020;10:110.

- [CrossRef] [Google Scholar]

- Multifunctional bionanocomposite films based on konjac glucomannan/chitosan with nano-ZnO and mulberry anthocyanin extract for active food packaging. Food Hydrocoll.. 2020;105942

- [Google Scholar]

- The Food (Control of Irradiation) Regulations 1990, SI 2490, HMSO, 1991.

- The Food Labelling (Amendment) (Irradiated Food) Regulations, 1990, SI 2489, HMSO, 1991.

- Carrageenans and their use in meat products. Crit. Rev. Food Sci. Nutr.. 2009;36(1–2):69-85.

- [CrossRef] [Google Scholar]

- Edible films/coating with tailored properties for active packaging of meat, fish and derived products. Trends Food Sci. Technol.. 2020;98:10-24.

- [CrossRef] [Google Scholar]

- Antimicrobial effect of essential oils of Laurus nobilis L. and Rosmarinus officinallis L. on shelf-life of minced “Maronesa” beef stored under different packaging conditions. Food Packag. Shelf Life. 2016;8:71-80.

- [Google Scholar]

- Bacteriocins from lactic acid bacteria and their applications in meat and meat products. Meat Sci.. 2016;120:118-132.

- [CrossRef] [Google Scholar]

- Barrier properties and microstructure of pullulan alginate-based films. J. Food Process Eng.. 2014;38:155-161.

- [Google Scholar]

- Tapioca starch active nanocomposite films and their antimicrobial effectiveness on ready-to-eat chicken meat. Food Packag. Shelf Life. 2018;16:86-91.

- [CrossRef] [Google Scholar]

- Bionanocomposites materials for food packaging applications: Concepts and future outlook. Carbohydr. Polym.. 2018;193:19-27.

- [CrossRef] [Google Scholar]

- Antimicrobial activity of bioactive starch packaging films against Listeria monocytogenes and reconstituted meat microbiota on ham. Int. J. Food Microbiol.. 2019;305

- [CrossRef] [Google Scholar]

- Preservation technologies for fresh meat – A review. Meat Sci.. 2010;86(1):119-128.

- [CrossRef] [Google Scholar]