Translate this page into:

A comparative review of processing methods for graphene-based hybrid filler polymer composites and enhanced mechanical, thermal, and electrical properties

⁎Corresponding author at: Department of Mathematics and Physics, Universit‘a degli Studi della Campania “Luigi Vanvitelli”, 81100 Caserta, Italy. zulfiqar.ali@unicampania.it (Zulfiqar Ali)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Graphene-based hybrid filler polymer composites represent a significant advancement in materials science and engineering due to graphene’s remarkable mechanical, thermal, and electrical properties. This comprehensive review systematically evaluates both traditional (e.g., mechanical and solution mixing) and modern fabrication techniques (e.g., in situ polymerization, chemical modification, electrospinning, and layer-by-layer assembly) employed in the synthesis of these composites, comparing their effectiveness in enhancing material properties such as strength, thermal stability, and conductivity. Emphasizing the synergistic interactions between graphene and other fillers within polymer matrices, the paper discusses mechanisms that lead to superior composite performance. A thorough survey of the literature highlights successful examples where these composites have demonstrated significant advancements in mechanical, thermal, and electrical properties. Three detailed tables summarize findings from published studies, illustrating the enhanced properties and achievements at various filler concentrations across different preparation methods. The review concludes by outlining future research directions aimed at optimizing graphene hybrid filler polymer composites for broader scientific and industrial utilization. By consolidating current knowledge and providing a practical resource, this review aims to guide researchers and practitioners in harnessing the full potential of these advanced materials.

Keywords

Graphene

Hybrid polymer composites

Processing methods

Properties

1 Introduction

Polymer composites, a blend of polymers and reinforcing materials have been pivotal in materials science since their inception in ancient times. Their modern development began in the early 1900 s with the advent of synthetic resins, glass fibers, and nanocomposites (Godara et al., 2021). Due to their strength, corrosion resistance, and design flexibility, they are indispensable in various modern industries such as automotive, aerospace, and electronics (Oladele et al., 2020).

Hybrid filler polymer composites which are formed by combining different types of fillers to achieve superior properties are essential in modern industrial applications due to their improved properties compared to single filler composites. They work together to strengthen mechanically through improved stress transfer and crack resistance, improve thermal conductivity by forming efficient heat transfer networks, enhance electrical conductivity by creating effective conductive pathways, and boost barrier properties by creating complex, tortuous paths that impede gas or liquid diffusion. These synergistic interactions result in composite materials that outperform those with single fillers. (Sallal et al., 2024) developed a promising ZrO2-ZnO nano-powder hybrid polymer nanocomposite for foot prosthetics applications, which showed better mechanical, hydrophobic, and antibacterial properties than the polymer base. Moreover, the integration of various carbon fillers like graphene, carbon nanotubes, carbon fibers, and other fillers (metals, silica, and nano-clays) (Althobaiti et al., 2022) allows for optimized performance, such as improved strength-to-weight ratios, greater thermal stability, and increased conductivity (Yadav et al., 2023).

Due to the high specific surface area (2600 m2g−1), and structure graphene-based polymer composites present great potential for multifunctional materials that reshape heavy industries e.g., aerospace, electronics, energy storage, and automotive (Ali et al., 2024, Abu-Okail et al., 2021). In 3D connected structured hybrid polymer composites, the presence of graphene highly induces mechanical, thermal, and electrical properties due to its intrinsic high mechanical strength, higher Young's modulus ∼ 1 TPa, high thermal conductivity (∼5000 Wm-1K−1), and high electrical conductivity (∼6.6x106 Sm−1). Recent advances in materials science e.g., improving dispersion and manufacturing techniques have improved the performance and cost-effectiveness of graphene-based hybrid polymer composites, underscoring their relevance in next-generation technologies (Sabet 2024). Graphene types like pristine graphene, graphene oxide (GO), and reduced graphene oxide (rGO) offer unique properties for polymer composites. Pristine graphene enhances mechanical strength and conductivity due to its atomic-level thickness and high aspect ratio. GO improves dispersibility and interfacial interactions, enhancing thermal stability. rGO, derived from GO reduction, boosts electrical conductivity and mechanical strength, ideal for sensors and coatings (Tiwari et al., 2018). Other forms like graphene nano-platelets, quantum dots, nanoribbons, and aerogels further tailor properties like strength, conductivity, and thermal stability in composite materials, advancing applications in materials engineering such as heat dissipation (Liu et al., 2021), flexible sensors, and energy storage devices (Ibrahim et al., 2020), Sinha et al., 2020, Jagadeesh et al., 2022, Singh et al., 2022).

This review paper summarized different aspects of graphene-based hybrid filler polymer composites, including the traditional and recent processing techniques, a deep insight into successfully prepared composites reported in different literatures, and mechanical, thermal, and electrical properties.

2 Processing techniques

2.1 Old preparation methods for graphene and hybrid polymer composites

2.1.1 Mechanical mixing

Mechanical mixing is a conventional method used to fabricate graphene-based hybrid polymer composites. This method uses mechanical forces, e.g., high-speed mixers, ball mills, mortar, and pestle, to get a homogeneous mixture of graphene and other fillers with a polymer matrix. However, this method is beneficial due to its low cost, scalability, and suitability for different polymer matrices, but the difficulty in achieving uniform dispersion, the risk of thermal degradation of the polymer and graphene, and limited control over the orientation of the fillers are limitations of this method. Thus, additional methods, e.g., sonication or surface modification, can be adopted to improve dispersion efficacy (Krusenbaum et al., 2022). Mechanical mixing is commonly employed in the creation of conductive composites for electromagnetic interference (EMI) shielding and anti-static packaging, as well as in structural materials for automotive and aerospace components.

(Jing et al., 2021) developed graphene nanoplatelets (GNPs) coated Linear low-density polyethylene (LLDPE) nanocomposites with permeable and complex geometry using a ball-milling technique. The LLDPE/GNPs composite presented superb electromagnetic interference shielding effectiveness (EMI-SE) of ∼ 32.4 dB with a customizable and optimized structure. (Awasthi et al., 2018) produced porous Molybdenum disulfide nanoparticles (MoS2) linked with thin layered reduced graphene oxide (rGO) by ultrasonic chemical method for supercapacitor applications and it was observed that rGO increased the surface area and conductivity of MoS2 resulting in quick transport of electrolyte ions to electrodes and rGO/ MoS2 composites exhibited outstanding electrochemical performance with a specific capacitance 314.5 Fg−1.

2.1.2 Solution mixing

Solution mixing is a widely used method for preparing homogeneous graphene-based hybrid polymer composites with efficient interfacial bonding. In the processing of this technique, graphene and other desired fillers are dissolved in a solvent. Afterward, the polymer matrix is mixed to obtain a homogeneous solution (Ke et al., 2012). Compared to mechanical mixing, solution blending is advantageous to obtain a better filler distribution. The presence of a solvent highly facilitates the interfacial adhesion and control over the interaction, with a higher possibility of fabricating different functional additives between the filler and matrix to get a customized composite (Ismail et al., 2023). However, this method also has certain limitations, such as expensive and harmful solvents, poor dispersion of graphene sheets in the solvent, and solvent removal (Dunlop and Bissessur 2020). Solution mixing is ideal for applications requiring uniform dispersion of graphene within the polymer matrix, such as flexible electronics, energy storage devices like supercapacitors and batteries, and sensitive chemical and biological sensors.

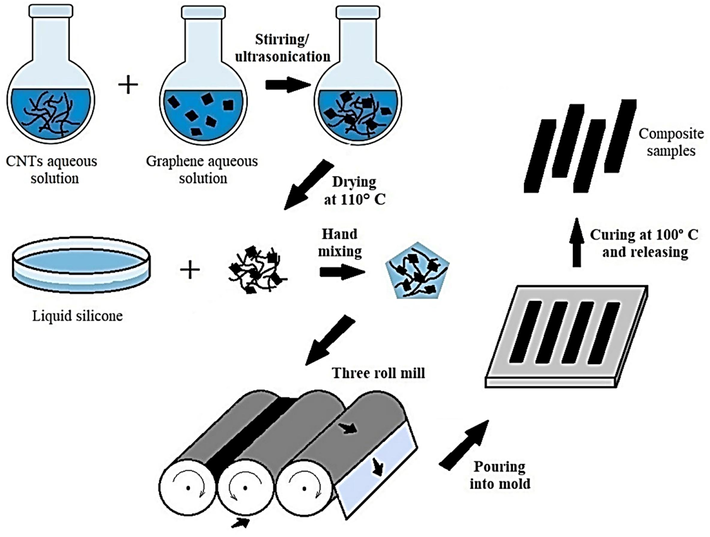

(Barshutina et al., 2021) reported, graphene/CNT/ polydimethylsiloxane (PDMS) hybrid composite via water solution mixing and later calendaring in a three-roll-mill. In processing, CNTs and graphene (G) were homogeneously dispersed in separate solvents, and then both solutions were mixed, stirred, and ultrasonicated for 20 min and dried in a vacuum oven at 110 °C. Later, the dried CNT/G hybrid filler foam was soaked by PDMS and passed through a roll mill. The schematic process of preparation is shown in Fig. 1. It was analyzed that G/CNT/PDMS composites offered excellent synergistic effects at ratio G/CNT (8:2) and exhibited outstanding electrical and mechanical properties.

Schematic procedure for preparing G/CNT/PDMS hybrid composite by solution mixing approach. Reprinted with permission from Ref. (Barshutina et al., 2021).

Overall, Mechanical and solution mixing, both are effective to prepare graphene-based polymer composites. Mechanical mixing is suitable for large-scale production due to its simplicity and compatibility with existing equipment. On the other hand, solution mixing offers improved control over graphene dispersion and composite properties.

2.2 Recent preparation methods for graphene and hybrid polymer composites

The preparation of graphene and hybrid polymer composites faces challenges like agglomeration due to high surface energy and van der Waals forces, impairing composite properties. Dispersion techniques such as high-shear mixing, ultrasonication, and solution-based methods are used to address this but can cause structural damage. Enhancing filler dispersion and interfacial bonding involves using specific compatibilizers and coupling agents, such as maleic anhydride-grafted polymers, which improve compatibility, and silane coupling agents, which form chemical bonds between fillers and the polymer matrix (Roy et al., 2020). Additionally, surface modification of graphene and other fillers through chemical functionalization, such as oxidation to introduce oxygen-containing groups or using surfactants like cetyltrimethylammonium bromide (CTAB), improves their compatibility and distribution, resulting in composites with enhanced mechanical, thermal, and electrical properties (Nanda et al., 2021).

Here are a few modern techniques currently adopted by many researchers:

2.2.1 In-situ polymerization

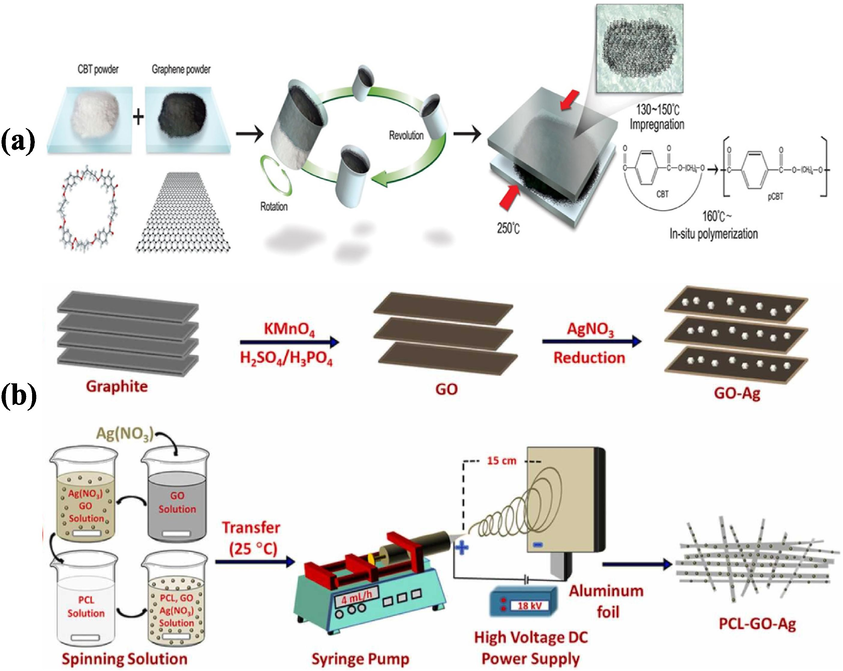

In-situ polymerization is an effective process for fabricating graphene-based hybrid polymer composites. In this method, Graphene oxide (GO) or reduced graphene oxide (rGO) is dispersed in a monomer solution. A polymerization initiator is added to start polymerization, where monomers polymerize and bond with GO/rGO sheets, forming a composite with tailored properties based on monomer choice and conditions. Compared to other mixing methods, in-situ polymerization can provide better control over the dispersion and orientation of graphene within the polymer matrix, making it a promising technique for the development of advanced graphene-based hybrid polymer composites (Dunlop and Bissessur 2020, Tarhini and Tehrani-Bagha 2023). In-situ polymerization is used for high-performance composites in aerospace, defense, and automotive industries due to its ability to create strong interfacial bonds. Moreover, (Noh et al., 2015) developed an excellently dispersed graphene/polymer composite with enhanced electrical conductivity by in situ polymerization of cyclic butylene terephthalate (CBT) oligomers. Before processing, the materials were moisture-freed by heating overnight at 110 °C then CBT and graphene powders were homogeneously mixed at 2000 rpm for 3 min by a high-speed Thinky mixer, and finally, the powder was used to prepare GNP-pCBT, GO-pCBT, and CCG-P-pCBT composites by heat pressing. Fig. 2 (a) Shows a detailed illustration of preparation steps.

Schematic illustration of (a) graphene/polymer composites by in-situ polymerization. (b) graphene surface modification processes and solution mixing by magnetic stirring and later PCL-GO-Ag composite fabrication by electrospinning approach. Reprinted with permission from Ref. (Noh et al., 2015, Sarıipek et al., 2022).

2.2.2 Chemical modification

Chemical modification is an advanced approach to synthesizing graphene-based hybrid polymer composites with heavily modified properties. In this method, GO/rGO is chemically functionalized via covalent (e.g., adding carboxyl, and hydroxyl groups) or non-covalent (e.g., π-π stacking, hydrogen bonding) methods. These modifications enhance compatibility with the polymer matrix, improving dispersion and interaction, thus optimizing mechanical, thermal, and electrical properties of the composite Fig. 2 (b). The process involves different functionalization methods containing covalent functionalization. Herein, molecules are directly introduced onto the surface of graphene, and non-covalent functionalization involves non-bonding interactions to combine functional groups (Paniagua et al., 2014). Covalent functionalization ways are usually followed by reactive functional groups, like epoxides or amines, to bond with the graphene surface. Non-covalent functionalization involves various interactions to attach molecules on the graphene surface, such as π-π stacking, hydrogen bonding, or electrostatic forces. Finally, the chemically surface-modified graphene is introduced in the polymer matrix by solution blending, melt mixing, or in-situ polymerization. As a result, a well-dispersed composite with high mechanical strength and thermal and electrical properties is obtained (Liu et al., 2012). Chemical modification enhances biomedical applications, such as drug delivery systems and tissue engineering scaffolds, as well as environmental applications like water and air purification.

(Jakubczak and Jastrzębska 2021) reported RGO/Al2O3-Ag nanocomposite with surface modification of metal oxide nanoparticles (MxOy) onto graphene family nanomaterials (GFMs) for filtration of drinking water. Compared to other methods, chemical modification ensures uniform dispersion of graphene in the polymer matrix and prevents agglomeration.

2.2.3 Electrospinning

Electrospinning is an outstanding approach to developing graphene-based hybrid polymer composites with desired aspect ratios and improved filler dispersion. During the procedure, (Abdali and Ajji 2017) a uniform graphene-polymer solution is prepared using a compatible solvent. The electrospinning setup involves a high-voltage power source, a sharp-edge spinneret with polymer solution, and a grounded collector. The electric field is applied, and the charged polymer jet with intercalated nanofibers is deposited on the collector. Meanwhile, the solvent is evaporated, and the collected graphene-based hybrid polymer composite undergoes post-curing and thermal annealing. The resulting composites exhibit improved mechanical, thermal, and electrical properties due to the strong interfacial bonding achieved through electrospinning. Compared to traditional methods, this method offers higher control over composite thickness, filler dispersion, nanoscale structure, and fiber orientation, which makes it suitable for applications involving high surface-to-volume ratios (Subramani and Rajiv 2021). Electrospinning produces nanofiber mats for filtration, energy devices, and biomedical scaffolds.

(Sarıipek et al., 2022) successfully prepared the poly(ε-caprolactone) PCL-GO-Ag hybrid composite via electrospinning. Initially, a magnetically stirred solution was prepared containing Ag nanoparticles and graphene oxide (GO), then added to the PCL solution and magnetically stirred to achieve a homogeneous solution. Later, the PCL-GO-Ag composite was obtained by electrospinning, as shown in Fig. 2 (b). The characterization results showed that the PCL-GO- 3.0 % Ag composite achieved higher tensile strength, higher resistance to elastic deformation, and good antibacterial activity.

2.2.4 Layer-by-Layer assembly

The layer-by-layer (LBL) assembly technique is another effective method for fabricating graphene-based hybrid polymer composites. LBL involves the sequential deposition of graphene and polymer layers to create highly ordered multilayer structures. This technique ensures uniform dispersion of graphene within the polymer matrix and strong interfacial interactions, leading to enhanced mechanical, thermal, and electrical properties of the composite. Compared to other methods, LBL assembly is a simple, inexpensive, and versatile process that allows for precise control over the composition and structure of the graphene-polymer composite. The resulting multilayer films exhibit improved performance characteristics that make them suitable for a wide range of applications (Wu et al., 2020). LBL assembly allows for precise control of composite structures, making it ideal for multifunctional coatings, photonic devices, and sensors.

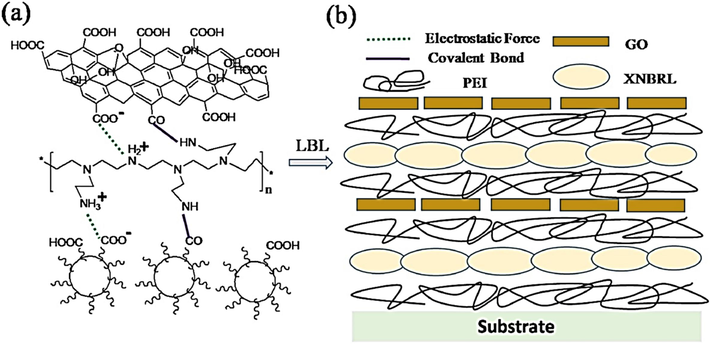

(Wang et al., 2016) adopted LBL approach and developed polyethyleneimine (PEI)/ carboxylic acrylonitrile butadiene rubber (XNBR)/PEI/GO hybrid composite with negatively charged XNBR and GO was positively charged due to amino groups from PEI molecules as shown in Fig. 3. The performed analysis revealed highly ordered GO and XNBR sheets with enhanced mechanical and electrical properties. Fig. 3. (a) shows the assembly process of XNBR latex, PEI, and GO sheets, and Fig. 3. (b) represents the final construction of the composite on a glass slide or silicon substrate.

Schematic representation (a) to develop PEI/XNBR/PEI/GO hybrid composite and (b) final design of composite using LBL approach. Reprinted with permission from Ref. (Wang et al., 2016).

Graphene-Based Hybrid Polymer Composites.

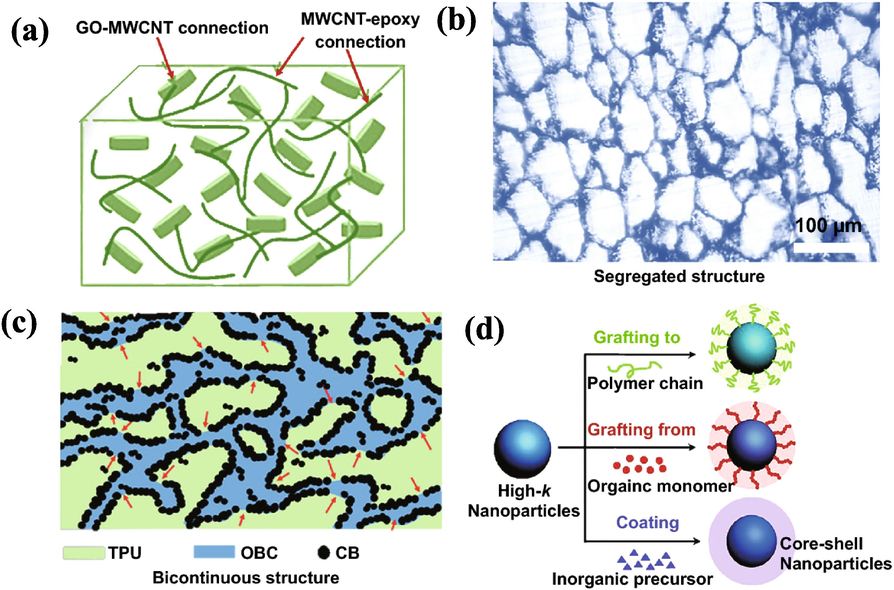

Graphene-based hybrid polymer composites offer a groundbreaking performance due to the exceptional inherent properties of graphene and its synergistic relation with other fillers within a polymer matrix. Synergistic effects in graphene-based hybrid polymer composites arise from the combined properties of graphene with other fillers and the polymer matrix, leading to enhancements that exceed those of the individual components. This synergy results in composites with superior mechanical strength, improved thermal and electrical conductivity, and enhanced durability (Zailan et al., 2024). Different processing techniques impact the dispersion, interfacial bonding, and orientation of graphene within the polymer matrix, thereby influencing the properties. The choice of technique depends on the desired properties and application requirements. (Wei et al., 2022) summarized different processing techniques to produce functional polymer composites and demonstrated that fabrication methods significantly affect the performance, structure, and properties of polymer composites. Fig. 4. (a) shows a connected network structured GO/MWCNT /epoxy composite, Fig. 4. (b) depicts the combination of filler particles localized on corners of the polymer matrix, Fig. 4. (c) shows the connected morphology of olefin block copolymer/carbon black/thermoplastic polyurethane (OBC/CB/TPU) ternary mixture composites and Fig. 4. (d) demonstrates different filler surface modification strategies.

(a) Network structure of GO-MWCNT /epoxy composite. (b) Formation of segregated system by localized filler particles at the boundaries between the polymer grains. (c) Graphical interpretation of network structure of olefin block copolymer/carbon black/thermoplastic polyurethane (OBC/CB/TPU) ternary mixture composites. (d) Typical procedures associated with filler surface modification. Adopted with consent from Ref. (Wei et al., 2022).

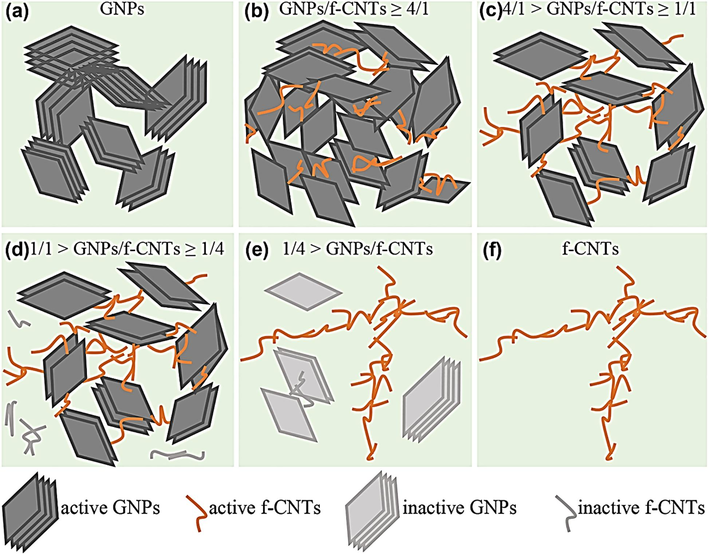

Incorporating GNPs and CNTs into polymer composites enhances electrical conductivity anisotropy. GNPs align in-plane, while CNTs create 3D networks, bridging GNP layers and boosting through-thickness conductivity. (Luo et al., 2022) formed a 3-Dimensional (3-D) hybrid structure at various aspect ratios to achieve a synergistic effect with enhanced conductivity by introducing pristine carbon nanotubes (p-CNTs) and functionalized carbon nanotubes (f-CNTs) into conductive poly (methyl methacrylate)/graphene nanoplatelet (PMMA/GNP) composites. The composites were investigated for in-plane and through-plane electrical properties, and tunable conductivity anisotropy ranging from 0.01 to 1000 was achieved. Moreover, it was observed that, in the in-plane direction the synergies of hybrid fillers are highly dependent on total filler content. while, in the through-plane path, the GNP/CNT or GNP/f-CNT ratio was a key parameter. Fig. 5. Shows the evolution of a micro-structural conductive network with the volume ratio of GNPs/f-CNTs.

Schematic representation of conductive 3D network structure of PMMA/GNP/f-CNT composites as a function of decreasing content of GNPs/f-CNTs to interpret different synergistic behaviors. Conductive polymer composites containing (a) single GNPs (b) GNPs/f-CNTs ≥ 4/1 (c) 4/1 > GNPs/f-CNTs ≥ 1/1 (d) 1/1 > GNPs/f-CNTs ≥ 1/4 (e) 1/4 > GNPs/f-CNTs, and (f) single f-CNTs. Reprinted with permission from Ref. (Luo et al., 2022).

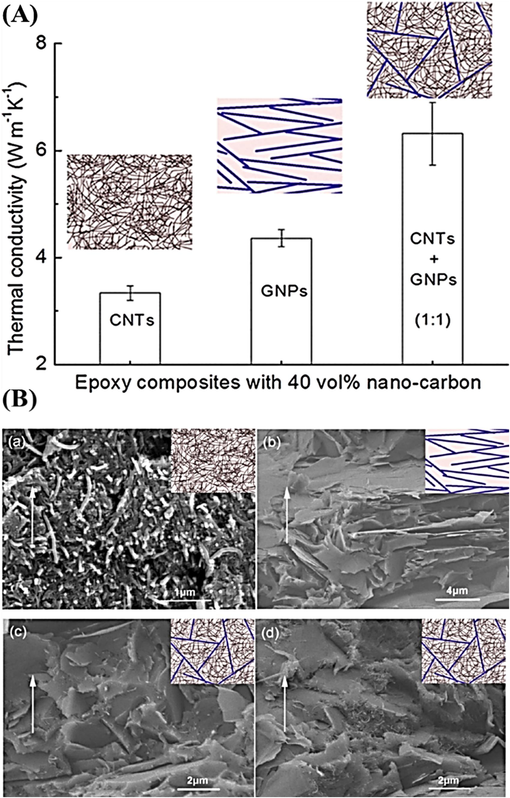

Multi-walled carbon nanotubes (MWCNTs) have a high aspect ratio and can form interconnected 3D conductive networks, while GNPs have large surface areas that facilitate efficient heat transfer. When combined, the MWCNTs can bridge the GNP layers, creating a more effective heat dissipation pathway. This synergistic effect allows for a significant improvement in thermal conductivity. (Huang et al., 2012) designed GNP, MWCNT, and highly loaded epoxy composites and achieved a synergistically enhanced thermal conductivity with 10 − 50 vol% nanocarbon filler, e.g., (the composite with 20 vol% CNTs and 20 vol% GNPs shows a thermal conductivity up to 6.31 Wm−1 K−1). Fig. 6. Represents (A) the thermal conductivity comparison for individual CNTs, GNPs and hybrid CNT+GNP filler at 40 vol% and (B) shows the morphology of the fractured surface of epoxy composites with individual CNT, GNP, and hybrid CNT+GNP fillers at 20 vol% to 40 vol%.

(A) Comparison of thermal conductivity of CNTs/GNPs epoxy composite to individual CNTs and GNPs at 40 vol% (B) SEM images showing the morphology of fracture surface of the epoxy composites: (a) epoxy/CNT50, (b) epoxy/GNP50, and (c,d) epoxy/CNT25/GNP25. The arrows indicate the through-thickness direction of the composite samples, while the insets in the figures exhibit the nanocarbon dispersion in the composites. Reproduced and reprinted with permission from Ref. (Huang et al., 2012).

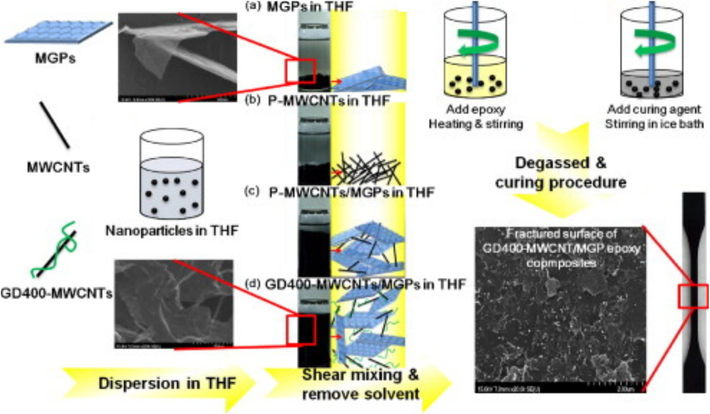

(Yang et al., 2011) designed epoxy composites with multi-graphene platelets (MGPs) and MWCNTs and achieved improved mechanical properties and thermal conductivity due to the synergetic effect. MWCNTs bridge adjacent MGPs and offer a high contact area between the MGP/MWCNT structures. Scanning electron microscope images showed that MWCNT/MGP hybrid nanofillers presented higher solubility and better compatibility than individual MWCNTs and MGPs, and the tensile strength of GD400-MWCNT/MGP/epoxy composites was 35.4 % higher than that of pure epoxy and thermal conductivity increased by 146.9 % using GD400-MWCNT/MGP hybrid fillers. Fig. 7. Demonstrates the preparation process of epoxy composites with different nanofillers.

Preparation of epoxy composites with different nanofillers (a) MGPs (b) P-MWCNTs (c) P-MWCNTs/MGPs and (d) GD400-MWCNTs/MGPs, via solution mixing method. Reprinted with permission from Ref. (Yang et al., 2011).

Graphene-based hybrid filler polymer composites exhibit enhanced mechanical, thermal, and electrical properties compared to pure polymers and single-filler composites, achieved through sophisticated measurement techniques like tensile testing, Dynamic Mechanical Analysis (DMA), four-point probe, laser flash analysis, SEM, TEM, AFM, and XRD. These hybrids combine the strengths of various fillers, resulting in superior tensile strength, Young’s modulus, thermal stability, and electrical conductivity due to improved filler dispersion, load transfer, and conductive network formation. Microstructural analysis using SEM, TEM, and XRD reveals better filler-matrix adhesion and synergistic interactions in hybrid composites, distinguishing them from the simpler structures of pure polymers and single-filler composites. These advanced materials, therefore, hold significant promise for high-performance applications in engineering, electronics, and thermal management.

3 Mechanical and structural properties

The presence of graphene and intercalated fillers through a polymer matrix offers a paradigm shift in material engineering due to its unique structural properties. Graphene-based hybrid polymer composites possess remarkable tensile strength, high Young's modulus, and significant resistance to deformation due to graphene's intrinsic strength, stiffness, and ability to form strong interfacial interactions with other fillers and the polymer matrix (Li et al., 2023). These composites can be customized to achieve specific mechanical properties by handling filler content, orientation, and interactions to fulfill the demands of heavy industries. The filler content and orientation significantly impact the mechanical properties of graphene-based hybrid polymer composites. Increased filler loading enhances moduli and tensile strengths, but this depends on dispersion and interfacial interactions. Proper alignment and synergistic interactions between fillers create a strong network, enhancing structural integrity and load transfer efficiency. Recent advancements in graphene-based polymer composites focus on functionalization to enhance compatibility with polymers, hierarchical structures for optimized load transfer, and hybridization with nanomaterials for synergistic effects. Advanced processing techniques enable precise control over graphene dispersion, tailoring mechanical properties for diverse applications like automotive and aerospace. Table 1. summarizes the recent values obtained for the increased mechanical properties (modulus, tensile strength) of graphene-based polymer composites and percentage % enhancement @ pure polymer matrix prepared by various processing techniques.

Hybrid Filler

Hybrid Filler Content

Matrix

Preparation technique

Young's modulus and enhanced %

Tensile strength

and enhanced %

Ref.

Multi-walled carbon nanotubes/multi-graphene platelets (MWCNTs/MGPs)

0.1/0.9 wt%

Epoxy

Melt-blending

3350 MPa 22.6 %

64.5 MPa 14.5 %

(Yang et al., 2011)

GNP/Carbon black (CB)

2/24 wt%

Ethylene–propylene–diene terpolymer rubber (EPDM)

Roll milling

20 MPa 198.5 %

19.9 MPa ≈17.06 %

(Valentini et al., 2016)

Graphene foam/CF

0.5/10 wt%

PDMS

Chemical vapor deposition (CVD)

3.05 MPa 185 %

2.50 MPa 63 %

(Zhao et al., 2016)

GO/Short glass fibers (GF)

0.5/-wt.%

Polyether-sulphone (PES)

Extrusion compounding and Injection molding

7.3 GPa 25.4 %

119 MPa 10.2 %

(Du et al., 2016)

GO/CFGO

0.1/1 wt%

Polyurethane (PU)

Mechanical mix and

Electrophoretic deposition23.18 MPa −

62.04 MPa 46.4 %

(Jiang et al., 2016)

Reduced graphene oxide/ Silica (rGO/SiO2)

1/99 30 phr (parts per hundred)

Styrene butadiene rubber (SBR)

Electrostatic assembly/ Roll mill

2.7 MPa 170 %

17.34 MPa 1204 %

(Lin et al., 2016)

GNP/GF

5/10 wt%

PP

Melt mixing and injection molding

4.47 GPa −

45.4 MPa −

(Pedrazzoli et al., 2015)

Short CFs /GO

12.5/0.5 wt%

PES

Solution and melt mixing

7.79 GPa 31.7 %

119.09 MPa 12.1 %

(Li et al., 2015)

3-aminopropyltriethoxysilane −functionalized graphene oxide (APTSi-GO)

1.5 wt%

Polyimide (PI)

In situ polymerization and thermal imidization

− 132 %

− 79 %

(Qian et al., 2015)

4 Thermal properties

Graphene, with its high intrinsic thermal conductivity (≈5000 W m −1 K −1 at room temperature) (Ali et al., 2024), is ideal for producing polymer composites with substantial increase in thermal stability. For instance, with a 2 wt% loading of graphene foams, the thermal conductivity of the composite was successfully increased from 0.19 W m −1 K −1 to 0.42 W m −1 K −1 (Zhang et al., 2022). These composites have found applications in high-temperature environments due to their enhanced thermal stability. Furthermore, Thermogravimetric analysis (TGA) is pivotal for evaluating the thermal properties of graphene-based polymer composites. It reveals that graphene enhances thermal stability by acting as a heat transfer barrier, reducing polymer matrix decomposition rates (Kumar et al., 2023). For instance, studies like that by (Farivar et al., 2021) show TGA-derived temperature of maximum mass change rate (Tmax) values increase with graphene particle size, highlighting TGA's role in optimizing these composites' thermal performance. Graphene interplay with various fillers offers synergistic effects within the polymer matrix and produces thermally conductive pathways that provoke heat transmission (Hassanzadeh-Aghdam et al., 2022). Furthermore, the combination of fillers like nanoparticles, carbon fibers, and carbon nanotubes offers more efficient heat transfer mechanisms as each filler contributes to heat transmission. Carbon fibers improve thermal diffusivity, while nanoparticles enhance thermal conductivity through filler dispersion and aspect ratios. The combination of these fillers with graphene leads to synergistic improvements in thermal properties, making these composites highly effective for thermal management applications (Liu et al., 2022). Table 2. reviews the enhanced thermal conductivities of graphene hybrid polymer composites and percentage % enhancement @ pure polymer matrix prepared by different preparation methods reported in published work.

Hybrid Filler

Hybrid Filler Content

Matrix

Preparation method

Thermal conductivity (Wm-1K−1) and % Increase

Ref.

GNPs/MWCNT

20/20 vol%

Epoxy

Melt-blending

6.31 3055 %

(Huang et al., 2012)

MWCNTs/MGPs

0.1/0.9 wt%

Epoxy

Melt-blending

0.321 146.9 %

(Yang et al., 2011)

GNP/CB

2/24 wt%

EPDM

Roll milling

1.2 313.79 %

(Valentini et al., 2016)

GF/CF

0.5/10 wt%

PDMS

CVD

0.55 162 %

(Zhao et al., 2016)

GNP/GF

20/16 wt%

PP

Melt mixing

5 times increase (pure PP)

(Pedrazzoli et al., 2015)

APTSi-GO

1.5 wt%

PI

In situ polymerization and thermal imidization

0.33 100 %

(Qian et al., 2015)

GF+modified hexagonal boron nitride (M−h−BN)

33.8 wt%

PDMS

CVD+Solution mixing

23.45 12928 %

(Fang et al., 2017)

G/Cu nanoparticles

40/35 wt%

Epoxy

Solution method

13.5 6650 %

(Barani et al., 2020)

BN+reduced graphene oxide (rGO)

13.16 vol%

Epoxy

Ice-templated and infiltration

5.05 2425 %

(Yao et al., 2018)

Expanded graphite (EG)/CNTs

20/1 wt%

High density polyethylene (HDPE)

Melt blending

3.10 25 %

(Che et al., 2017)

EG/MWCNT

15/5 wt%

PP

Melting method

1.52 442.86 %

(Wu et al., 2016)

Al2O3/GNP

12 wt%

Epoxy

Solution mixing

1.49 677 %

(Sun et al., 2016)

Boron nitride nanosheets (BNNSs)/ Graphene

1.6/6.8 wt%

Polyamide-6 (PA6)

Solution mixing

0.891 350 %

(Shao et al., 2016)

Functionalized Graphene sheets with nanodiamonds filler (FGS/NDs)

45 wt%

Polyvinylidene fluoride (PVDF)

Solution method

0.66 257.14 %

(Yu et al., 2013)

5 Electrical properties

Graphene’s exceptional electrical properties make it a promising material for polymer nanocomposites. The electrical conductivity of these composites increases sharply with the incorporation of graphene due to its high aspect ratio and ability to form conductive networks for electrons to flow. For example, graphene enables the insulator-to-conductor transition at significantly lower loading by providing percolated pathways for electron transfer. These synergistic networks provide a percolation network with enhanced interfacial interactions and create efficient conductive pathways. These networks significantly boost electron mobility by providing continuous conductive channels and reducing electron scattering (Lalire et al., 2024). Consequently, the composites exhibit improved electrical conductivity making them ideal for advanced sensors, electromagnetic interference shielding, and flexible electronics (Tarhini and Tehrani-Bagha 2023). Furthermore, graphene's two-dimensional structure and high surface area allow for efficient heat dissipation, which is advantageous in electronic packaging and thermal management applications. Graphene-enhanced polymer composites are increasingly being integrated into heat sinks, thermal interface materials, and circuit boards where they effectively dissipate heat generated by high-power electronics, improving overall device performance and reliability in demanding conditions. To further explain Table 3. summarizes the enhanced electrical conductivities of graphene hybrid polymer composites from published research.

Hybrid Filler

Hybrid Filler Content

Matrix

Preparation method

Electrical conductivity

Ref.

APTSi-GO

1.5 wt%

PI

in situ polymerization and thermal imidization

2.6 × 10−3 Sm−1

(Qian et al., 2015)

EG/MWCNT

15/5 wt%

PP

Melting method

159.62 Sm−1

(Wu et al., 2016)

FGS/NDs

10 wt%

PVDF

Solution method

7.1 × 10−7 Scm−1

(Yu et al., 2013)

RGO sheets

10 wt%

Amine-modified nano-fibrillated cellulose (A-NFC)

Solution casting

71.8 Sm−1

(Luong et al., 2011)

Graphene

20 wt%

Polypyrrole (PPy)

In-situ polymerization

7.930 Scm−1

(Bose et al., 2010)

GNP/Short CF

0.02/0.08 vol%

Polymer

Theoretical modeling

103 Sm−1

(Saberi et al., 2023)

GNP

1.0 wt%

Epoxy

3-roll mill

2.6 × 10−6 Sm−1

(Imran and Shivakumar 2019)

Graphene hybrid fillers are revolutionizing various industries due to their superior mechanical, electrical, and thermal properties. In automotive and aerospace industries, graphene-reinforced composites, such as graphene oxide polymers and graphene-nanotube hybrids, provide lightweight, strong, and thermally stable components for improved performance (Ali et al., 2024). In electronics and electrical applications, hybrids like graphene-silver nanowires and graphene-polymer composites offer high conductivity and EMI shielding for flexible electronics and conductive materials (Sahoo et al., 2024). Energy storage devices, including batteries, fuel cells, and supercapacitors, benefit from graphene-metal oxide and graphene-conducting polymer composites for enhanced energy density and stability (Wang et al., 2015). Biomedical applications use graphene-based hydrogels and graphene-silver nanoparticles for biocompatible materials, drug delivery systems, and antimicrobial coatings (Bellier et al., 2022). Environmental applications, such as water purification, leverage graphene-activated carbon and graphene-biopolymer composites for effective pollutant adsorption and sustainability, emphasizing recyclability and biodegradability (Karthik et al., 2021).

Graphene, despite its remarkable properties, faces several technical and economic challenges. The scale-up of production is a significant hurdle, with current methods struggling to produce high-quality graphene in large quantities. Achieving uniform dispersion and reproducibility in graphene production is also challenging (Lou et al., 2024). Economically, the cost of graphene and hybrid fillers, along with processing costs, pose limitations. Advances in large-scale production methods are being explored, but these methods are still expensive and resource-intensive. Cost reduction strategies include the use of cheaper raw materials and process optimization (Ikram et al., 2020). However, Graphene and its fillers pose environmental and health concerns due to their potential toxicity. Studies suggest that graphene's ultrafine particles could pose risks similar to other nanomaterials, including potential respiratory and cellular health impacts if not handled properly. Moreover, the environmental impact of graphene disposal and degradation remains uncertain. Safety measures are crucial and include guidelines for safe handling, such as using protective equipment during production and processing, and establishing protocols for waste disposal to minimize environmental contamination. Strict adherence to these guidelines is essential to mitigate risks associated with graphene and ensure its safe integration into various industries (Lin et al., 2024). Future research in graphene and hybrid fillers should prioritize innovative synthesis techniques to enhance production scalability and quality, such as advanced chemical vapor deposition (CVD) and novel exfoliation methods. Exploration into new hybrid filler combinations will drive the development of materials with enhanced properties and performance, potentially revolutionizing industries like electronics, aerospace, and energy storage. Furthermore, focusing on advanced applications in emerging fields such as flexible electronics, biomedical devices, and environmental remediation holds promise for commercialization, pushing the boundaries of graphene's utility and economic viability in diverse technological landscapes (Sabet 2024, Mombeshora and Muchuweni 2023, Zhang et al., 2022).

6 Conclusion and Outlook

This literature review summarizes the panorama of graphene-based hybrid filler polymer composites involving conventional and advanced preparation techniques, and a detailed analysis of graphene-based hybrid polymer composites related to enhanced mechanical, thermal, and electrical properties reported in different research papers. It was concluded that traditional preparation techniques are beneficial for their simplicity and scalability but show deficits in the homogeneity, surface integrity, and balanced dispersion of fillers through the polymer matrices. However, modern fabrication techniques, e.g., surface functionalization, electrospinning, and additive manufacturing, offer superior dispersion and interfacial bonding and highly facilitate the synthesis of graphene hybrid fillers and introduction to polymers. The synergistic effects of graphene are widely explored, as many studies reported that incorporating graphene hybrid fillers in polymers drastically enhanced the mechanical strength, Young's modulus, and bending strength. Moreover, the thermal ability and electron mobility were highly expanded.

Although many practical and theoretical studies have been proposed, several challenges exist to attain the expected results. Firstly, achieving homogeneous dispersion of fillers is challenging due to the strong van der Waals forces between graphene sheets, which lead to aggregation. Additionally, the difference in surface energies between graphene and the polymer matrix hinders uniform distribution. Secondly, large-scale production is challenging, due to the high cost of high-quality graphene and the complex, energy-intensive processes required for uniform dispersion. Additionally, the need for specialized equipment and precise control over manufacturing parameters further complicates scalability. Lastly, addressing the environmental impact and safety concerns of graphene-based hybrid polymer composites is crucial for their commercial use to ensure sustainable development and regulatory compliance. Potential risks include toxicity to humans and ecosystems, necessitating thorough assessment and mitigation strategies.

CRediT authorship contribution statement

Zulfiqar Ali: Writing – original draft, Methodology, Conceptualization. Saba Yaqoob: Writing – review & editing. Jinhong Yu: Investigation, Formal analysis. Alberto D’Amore: Visualization, Validation, Supervision. M. Fakhar-e-Alam: Visualization, Software, Investigation, Formal analysis.

Acknowledgments

The authors gratefully acknowledge the financial support from the University of Campania Luigi Vanvitelli. The University of Campania Luigi Vanvitelli participates in the transformative national contract managed by CARE-CRUI for access to the electronic journals of the publisher Elsevier.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Preparation of electrospun nanocomposite nanofibers of polyaniline/poly (methyl methacrylate) with amino-functionalized graphene. Polymers. 2017;9(9):453.

- [CrossRef] [Google Scholar]

- Effect of dispersion of alumina nanoparticles and graphene nanoplatelets on microstructural and mechanical characteristics of hybrid carbon/glass fibers reinforced polymer composite. J. Mater. Res. Technol.. 2021;14:2624-2637.

- [CrossRef] [Google Scholar]

- Structural, dielectric and electrical properties of new Ni-dopedcopper/bentonite composite. J. King Saud Univ. Sci.. 2022;34(5):102127

- [CrossRef] [Google Scholar]

- Layer-Structured partially reduced graphene oxide sheathed mesoporous MoS2 particles for energy storage applications. J. Colloid Interface Sci.. 2018;518:234-241.

- [CrossRef] [Google Scholar]

- Thermal properties of the binary-filler hybrid composites with graphene and copper nanoparticles. Adv. Funct. Mater.. 2020;30(8):1904008

- [CrossRef] [Google Scholar]

- Biocompatible, electroconductive, and highly stretchable hybrid silicone composites based on few-layer graphene and CNTs. Nanomaterials. 2021;11(5):1143.

- [CrossRef] [Google Scholar]

- Recent biomedical advancements in graphene oxide-and reduced graphene oxide-based nanocomposite nanocarriers. Biomater. Res.. 2022;26(1):65.

- [CrossRef] [Google Scholar]

- In-situ synthesis and characterization of electrically conductive polypyrrole/graphene nanocomposites. Polymer. 2010;51(25):5921-5928.

- [CrossRef] [Google Scholar]

- Largely improved thermal conductivity of HDPE/expanded graphite/carbon nanotubes ternary composites via filler network-network synergy. Compos. Part A Appl. Sci. Manuf.. 2017;99:32-40.

- [CrossRef] [Google Scholar]

- Tensile and flexural properties of graphene oxide coated-short glass fiber reinforced polyethersulfone composites. Compos. B. Eng.. 2016;99:407-415.

- [CrossRef] [Google Scholar]

- Nanocomposites based on graphene analogous materials and conducting polymers: a review. J. Mater. Sci.. 2020;55(16):6721-6753.

- [CrossRef] [Google Scholar]

- Dense graphene foam and hexagonal boron nitride filled PDMS composites with high thermal conductivity and breakdown strength. Compos. Sci. Technol.. 2017;152:243-253.

- [CrossRef] [Google Scholar]

- Thermogravimetric analysis (TGA) of graphene materials: effect of particle size of graphene, graphene oxide and graphite on thermal parameters. C.. 2021;7(2):41.

- [CrossRef] [Google Scholar]

- Review on history and characterization of polymer composite materials. Mater. Today: Proc.. 2021;44:2674-2677.

- [CrossRef] [Google Scholar]

- Influence of graphene nano-platelets on thermal transport performance of carbon fiber-polymer hybrid composites: overall assessment of microstructural aspects. Int. J. Therm. Sci.. 2022;171:107209

- [CrossRef] [Google Scholar]

- Toward effective synergetic effects from graphene nanoplatelets and carbon nanotubes on thermal conductivity of ultrahigh volume fraction nanocarbon epoxy composites. J. Phys. Chem. C.. 2012;116(44):23812-23820.

- [CrossRef] [Google Scholar]

- Prospects of nanostructured composite materials for energy harvesting and storage. J. King Saud Univ. Sci.. 2020;32(1):758-764.

- [CrossRef] [Google Scholar]

- Advances in synthesis of graphene derivatives using industrial wastes precursors; prospects and challenges. JMR&T.. 2020;9(6):15924-15951.

- [CrossRef] [Google Scholar]

- Graphene-modified carbon/epoxy nanocomposites: electrical, thermal and mechanical properties. J. Compos. Mater.. 2019;53(1):93-106.

- [CrossRef] [Google Scholar]

- Dynamic mechanical and thermal properties of Flax/bio-phenolic/epoxy reinforced hybrid composites. J. King Saud Univ. Sci.. 2023;35(7):102790

- [CrossRef] [Google Scholar]

- Effect of natural filler materials on fiber reinforced hybrid polymer composites: an overview. J. Nat. Fibers.. 2022;19(11):4132-4147.

- [CrossRef] [Google Scholar]

- A review on development of ceramic-graphene based nanohybrid composite systems in biological applications. Front. Chem.. 2021;9:685014

- [CrossRef] [Google Scholar]

- Multiscale graphene oxide–carbon fiber reinforcements for advanced polyurethane composites. Compos. Part A Appl. Sci. Manuf.. 2016;87:1-9.

- [CrossRef] [Google Scholar]

- Facile fabrication of lightweight porous FDM-Printed polyethylene/graphene nanocomposites with enhanced interfacial strength for electromagnetic interference shielding. Compos. Sci. Technol.. 2021;207:108732

- [CrossRef] [Google Scholar]

- Graphene-based materials for environmental applications: a review. Environ. Chem. Lett.. 2021;19(5):3631-3644.

- [CrossRef] [Google Scholar]

- A comparison of melt and solution mixing on the dispersion of carbon nanotubes in a poly (vinylidene fluoride) matrix. Compos. b. Eng.. 2012;43(3):1425-1432.

- [CrossRef] [Google Scholar]

- The mechanochemical synthesis of polymers. Chem. Soc. Rev.. 2022;51(7):2873-2905.

- [CrossRef] [Google Scholar]

- Fabrication and characterization of graphene oxide-based polymer nanocomposite coatings, improved stability and hydrophobicity. Sci Rep.. 2023;13(1):8946.

- [CrossRef] [Google Scholar]

- Electrical properties of graphene/multiphase polymer nanocomposites: a review. Carbon. 2024;225:119055

- [CrossRef] [Google Scholar]

- Microstructure and properties of carbon fiber-H62 brass matrix composites prepared by friction stir processing. J. King Saud Univ. Sci.. 2023;35(5):102652

- [CrossRef] [Google Scholar]

- Enhanced mechanical properties of short carbon fiber reinforced polyethersulfone composites by graphene oxide coating. Polymer. 2015;59:155-165.

- [CrossRef] [Google Scholar]

- Environmental and health impacts of graphene and other two-dimensional materials: a graphene flagship perspective. ACS Nano. 2024;18(8):6038-6094.

- [CrossRef] [Google Scholar]

- The filler–rubber interface and reinforcement in styrene butadiene rubber composites with graphene/silica hybrids: a quantitative correlation with the constrained region. Compos. Part A Appl. Sci. Manuf.. 2016;86:19-30.

- [CrossRef] [Google Scholar]

- Strategies for chemical modification of graphene and applications of chemically modified graphene. J. Mater. Chem.. 2012;22(25):12435-12452.

- [CrossRef] [Google Scholar]

- Significantly enhanced thermal conductivity of polymer composites via establishing double-percolated expanded graphite/multi-layer graphene hybrid filler network. Eur. Polym. J.. 2021;160:110768

- [CrossRef] [Google Scholar]

- 3D expanded graphite frameworks for dual-functional polymer composites with exceptional thermal conductive and electromagnetic interference shielding capabilities. ACS Appl. Electron. Mater.. 2022;4(2):707-717.

- [CrossRef] [Google Scholar]

- Graphene nanoribbons: current status, challenges and opportunities. Quantum Front.. 2024;3(1):3.

- [CrossRef] [Google Scholar]

- Electrically conductive polymer composite containing hybrid graphene nanoplatelets and carbon nanotubes: synergistic effect and tunable conductivity anisotropy. Adv. Compos. Hybrid Mater.. 2022;5:1-13.

- [CrossRef] [Google Scholar]

- Graphene/cellulose nanocomposite paper with high electrical and mechanical performances. J. Mater. Chem.. 2011;21(36):13991-13998.

- [CrossRef] [Google Scholar]

- The current impacts and future prospects of graphene derivatives in polymer-based supercapacitors. Discov Mater.. 2023;3(1):32.

- [CrossRef] [Google Scholar]

- Advancements in multi-scale filler reinforced epoxy nanocomposites for improved impact strength: a review. Crit. Rev. Solid State Mater. Sci.. 2021;46(4):281-329.

- [CrossRef] [Google Scholar]

- Ultra-high dispersion of graphene in polymer composite via solvent freefabrication and functionalization. Sci. Rep.. 2015;5(1):9141.

- [CrossRef] [Google Scholar]

- Polymer-based composites: an indispensable material for present and future applications. Int. J. Polym. Sci.. 2020;1:8834518

- [CrossRef] [Google Scholar]

- Surface-initiated polymerization from barium titanate nanoparticles for hybrid dielectric capacitors. ACS Appl. Mater. Interfaces.. 2014;6(5):3477-3482.

- [CrossRef] [Google Scholar]

- Synergistic effect of graphite nanoplatelets and glass fibers in polypropylene composites. J. Appl. Polym. Sci.. 2015;132(12)

- [CrossRef] [Google Scholar]

- In situ polymerization of polyimide-based nanocomposites via covalent incorporation of functionalized graphene nanosheets for enhancing mechanical, thermal, and electrical properties. J. Appl. Polym. Sci.. 2015;132(44)

- [CrossRef] [Google Scholar]

- A critical review on the utilization of various reinforcement modifiers in filled rubber composites. J. Elastom. Plast.. 2020;52(2):167-193.

- [CrossRef] [Google Scholar]

- Predicting the electrical conductivity of short carbon fiber/graphene nanoplatelet/polymer composites. Mater. Chem. Phys.. 2023;309:128324

- [CrossRef] [Google Scholar]

- Unveiling transformative potential: recent advances in graphene-based polymer composites. Iran. Polym. J.. 2024;1–15

- [CrossRef] [Google Scholar]

- Recent progress in graphene and its derived hybrid materials for high-performance supercapacitor electrode applications. RSC Adv.. 2024;14(2):1284-1303.

- [CrossRef] [Google Scholar]

- Effect of adding (ZrO2-ZnO) nanopowder on the polymer blend (lamination and methyl vinyl silicone) in a hybrid nanocomposite material. J. King Saud Univ. Sci.. 2024;36(2):103061

- [CrossRef] [Google Scholar]

- Preparation of poly (ε-caprolactone) nanofibrous mats incorporating graphene oxide-silver nanoparticle hybrid composite by electrospinning method for potential antibacterial applications. Colloids Surf. A Physicochem. Eng. Asp.. 2022;653:129969

- [CrossRef] [Google Scholar]

- Synergistic effect of BN and graphene nanosheets in 3D framework on the enhancement of thermal conductive properties of polymeric composites. Compos. Sci. Technol.. 2016;135:83-91.

- [CrossRef] [Google Scholar]

- A review on recent development on polymeric hybrid composite and analysis of their enhanced mechanical performance. Mater. Today: Proc.. 2022;56:3692-3701.

- [CrossRef] [Google Scholar]

- Mechanical properties of hybrid polymer composites: a review. J. Braz. Soc. Mech. Sci.. 2020;42:1-13.

- [CrossRef] [Google Scholar]

- Electrospun based polythioaniline/polyvinylalcohol/graphene oxide composite nanofibers for supercapacitor application. Ionics. 2021;27:2203-2218.

- [CrossRef] [Google Scholar]

- Decoration of defect-free graphene nanoplatelets with alumina for thermally conductive and electrically insulating epoxy composites. Compos. Sci. Technol.. 2016;137:16-23.

- [CrossRef] [Google Scholar]

- Advances in preparation methods and conductivity properties of graphene-based polymer composites. Appl. Compos. Mater.. 2023;30:1737-1762.

- [CrossRef] [Google Scholar]

- Evolution of graphene oxide and graphene: from imagination to industrialization. Chem. Nano. Mat.. 2018;4(7):598-620.

- [CrossRef] [Google Scholar]

- Synergistic effect of graphene nanoplatelets and carbon black in multifunctional EPDM nanocomposites. Compos. Sci. Technol.. 2016;128:123-130.

- [CrossRef] [Google Scholar]

- PANI/graphene nanocomposite films with high thermoelectric properties by enhanced molecular ordering. J. Mater. Chem. A.. 2015;3(13):7086-7092.

- [CrossRef] [Google Scholar]

- Enhanced electrical and mechanical properties of rubber/graphene film through layer-by-layer electrostatic assembly. Compos. B. Eng.. 2016;90:457-464.

- [CrossRef] [Google Scholar]

- “Toolbox” for the processing of functional polymer composites. Nanomicro. Lett.. 2022;14(1):35.

- [CrossRef] [Google Scholar]

- Largely enhanced thermal and electrical conductivity via constructing double percolated filler network in polypropylene/expanded graphite–multi-wall carbon nanotubes ternary composites. Compos. Sci. Technol.. 2016;130:28-35.

- [CrossRef] [Google Scholar]

- Layer-by-layer assembled nacre-like polyether amine/GO hierarchical structure on carbon fiber surface toward composites with excellent interfacial strength and toughness. Compos. Sci. Technol.. 2020;198:108296

- [CrossRef] [Google Scholar]

- The role of fillers to enhance the mechanical, thermal, and wear characteristics of polymer composite materials: a review. Compos. - A: Appl. Sci. Manuf.. 2023;175:107775

- [CrossRef] [Google Scholar]

- Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon. 2011;49(3):793-803.

- [CrossRef] [Google Scholar]

- Construction of 3D skeleton for polymer composites achieving a high thermal conductivity. Small. 2018;14(13):1704044

- [CrossRef] [Google Scholar]

- Enhanced thermal conductivity for PVDF composites with a hybrid functionalized graphene sheet-nanodiamond filler. Fibers Polym.. 2013;14:1317-1323.

- [CrossRef] [Google Scholar]

- Synergistic improvement of mechanical, electrical and thermal properties by graphene nanoplatelets in polyaniline incorporated rubbery thermoplastic composites. JMR&T.. 2024;28:4097-4109.

- [CrossRef] [Google Scholar]

- Carbon fibre/graphene foam/polymer composites with enhanced mechanical and thermal properties. Compos. B. Eng.. 2016;94:102-108.

- [CrossRef] [Google Scholar]

Appendix A

Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.jksus.2024.103457.

Appendix A

Supplementary data

The following are the Supplementary data to this article: