Translate this page into:

Effect of heat treatment on the quality of citrus juices

⁎Corresponding author. binnaik@gmail.com (Bindu Naik)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

The current study was designed to estimate the effect of heat treatment conditions on the quality of the pomelo and kinnow juice. The different temperature–time combination was selected to treat the juices. The quality of the juice was determined based on TSS, acidity, ascorbic acid content, total phenolic content, reducing sugar, antioxidant activity, and sweetness. After the heat treatment to both the juice, the samples showed a significant decrease in total phenolic content, reducing sugars, ascorbic acidity and antioxidant activity of juices as the duration and temperature of the treatment increases. The acidity of the product increases, while sweetness decreases with an increase in the time of treatment. It was also found that there is no significant change in the properties with an increase in the temperature of treatment. It was revealed that low-temperature low time can be used to get a good final quality in terms of ascorbic acid, antioxidant, and total phenolic content of both juices.

Keywords

Heat treatment

Citrus fruits

Kinnow

Pomelo

Quality of juice

Pasteurization

1 Introduction

Juices and whole fruits are consumed all over the world since they are a wonderful source of minerals, vitamins, and fiber. Citrus juices contain intricate combinations of volatile aromatics and non-volatile substances. Aromatic volatile includes aldehydes, alcohols, esters, and ketones, on the other hand non-volatile includes sugars and organic acid (Kader, 2008). The citrus fruit variety known as Kinnow mandarin (Citrus reticulate L.) is a hybrid of Willow leaf and King and is widely grown in India. Kinnow fruits that are fully mature have a rich appealing color and compact skin. It is a plentiful source of nutrients such as vitamin B, β-carotene, vitamin C, phosphorous, and calcium (Purewal and Sandhu, 2020). It is also cherished due to its good natural antioxidant, sensory quality, and physicochemical properties. These plant metabolites help with iron and zinc absorption and improve immunity against various infections, cancer, and coronary heart diseases (Shah et al., 2015). Citrus maxima which is commonly known as pomelo has the appearance of a big grapefruit. It is sweet and slightly acidic with a hint of bitterness. It is a rich source of naringin, which is bitter in flavor, which is responsible for the bitterness of juice, and hence its low commercial value. It contains flavonoids, coumarins, limonoids, antioxidants, and ascorbic acid. It also contains high amount of polyphenolic compound like naringin, hesperidin, P-Coumaric acid, caffeic acid, vanillic acid, and ferulic acid. It has antioxidant activity, analgesic, anti-inflammatory activity, anti-diabetic activity, anti-bacterial activity, and anti-tumor activity (Visakh et al. 2022).

The fruit juice may contain pathogenic microorganisms, or it may be contaminated during the process lines. One of the most used methods to limit microbial risk is heat treatment or pasteurization to kill these microorganisms. This will increase the shelf-life of the juice by increasing the microbial quality and safety. The main target of the heat treatment is to inactivate enzymes and reduce the number of micro-organisms (Yıldız et al., 2022). The quality of the food can be changed after the heat treatment, so proper selection of temperature–time combination is very much important. By using the pasteurization process, the juice-producing sectors seek to preserve juices without sacrificing their nutritional and organoleptic quality (Kumar et al., 2017). A few researchers investigated processing's impact on product quality of juices such as mango juice (Santhirasegaram et al., 2013), tomato juice (Jafari et al., 2017), start fruit juice (Shourove et al., 2020), barberry juice (Farhadi et al., 2017), pineapple (Rattanathanalerk et al., 2005), and orange juice (Scalzo et al., 2004).

The present study aims to treat the extracted juice of kinnow and pomelo in different temperature–time combinations and evaluate the impact of heat treatment on a fruit juice's nutritional value.

2 Material and methods

2.1 Materials

Kinnow and pomelo fruit were procured from the local market of Dehradun, Uttarakhand, India. These were selected based on the visual inspection for any defects and maturity and it is then washed with water to remove any adhering substance. It was then stored in a refrigerator for further usage. All the chemicals used in the study for analysis were procured from Himedia, India It includes 2,2-diphenyl-1-picryl-hydrazyl-hydrate, gallic acid, ascorbic acid, 3,5-Dinitrosalicylic acid, sodium sulphite, NaOH, Potassium sodium tartarate. and Folin Ciocalteau reagent,

2.2 Extraction of juice

Fruits were first peeled and then the segments of the selected citrus fruits were separated. After that, the juice was extracted using the juicer, filtered using a muslin cloth of 1.5–2.0 mm pore size to remove any suspended particles, and stored at 7 ± 1 °C till further usage (Char et al., 2010).

2.3 Heat treatment of juice

The heat treatment was given to the extracted juice by using the water bath at different temperature–time combinations. The juices were treated at temperatures 70 °C, 80 °C, 90 °C, and 100 °C for 15, 30, and 45 min. The sample without any heat treatment was considered a controlled sample.

2.4 Physicochemical properties of juice

The quality of the treated kinnow and pomelo juice was determined based on the change in different physicochemical properties. The titrable acidity of all the samples was estimated by the method explained by Kumar et al. (2019). The total soluble solids (TSS) in the juices were determined by using a hand refractometer as described by Ranganna (1986) and represented in Brix. The sweetness of the juice was determined by calculating the ratio of TSS and titrable acidity and represented in percentage. The reducing sugar was calculated by the DNS method (Srivastava, et al., 2019) and represented in mg/mL of glucose. The total phenolic content (in mg/mL equivalent to gallic acid), antioxidant (in mg/mL equivalent to gallic acid, Himedia, India), and ascorbic acid (in mg/mL equivalent to ascorbic acid, Himedia, India) content of juices were determined by Folin-ciocalteu reagent (Himedia, India) method, DPPH (2,2-diphenyl-1-picryl-hydrazyl-hydrate, Himedia, India) method, and direct colorimetric method respectively (Ranganna, 1986; Srivastava et al., 2019).

2.5 Statistical analysis

All the readings were measured in triplicates and statistical analysis of the data was carried out in Origin 6.0 (Origin Lab Corporation, USA) and values are represented as the mean and bar represents the standard deviations.

3 Results and discussion

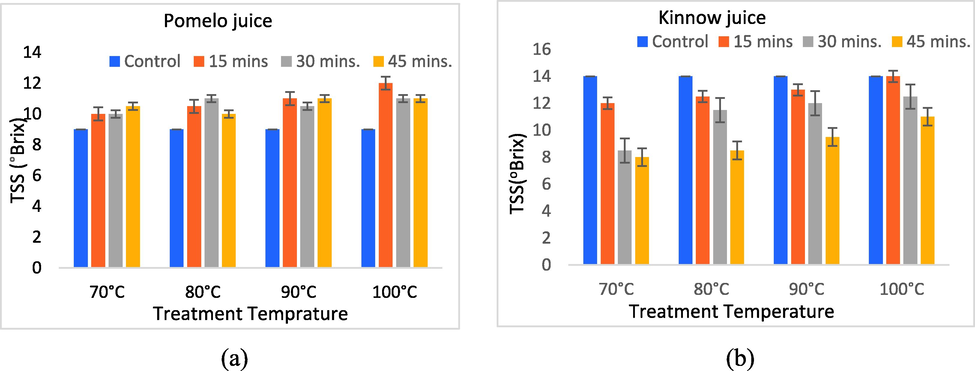

3.1 Effect of heat treatment on total soluble solids (TSS)

One of the most crucial criteria for assessing the quality of a citrus juice is Brix, which is used to represent the percentage of soluble solids in juices (Kohli et al., 2018). Fig. 1 represents the changes in total soluble solids after heat treatment in pomelo and kinnow juice. The TSS of fresh pomelo juice is lower than fresh kinnow juices, which was found to be 9 °Brix and 14 °Brix, respectively. From Fig. 1(a), it can be observed that the TSS of the pomelo juice increases with an increase in the time of treatment from 15 to 45 min for all temperatures, while it doesn’t show any significant effect with an increase in the temperature of treatment at a particular time. The increase in TSS of the juice is may be due to the high evaporation of moisture, which may concentrate the juice by heat treatment for a longer time (Sabanci and Icier, 2017). On the other hand, it can be observed from Fig. 1(b) that the TSS of kinnow juice decreases with an increase in the time for the treatment at a particular temperature. Similar to the pomelo juice, its TSS changes considerably with rise in temperature of treatment. Although, Shourove et al. (2020) noticed that there is no significant change in TSS of star fruit juice after heat treatment.

Changes in TSS after heat treatment in (a) pomelo juice (b) kinnow juice.

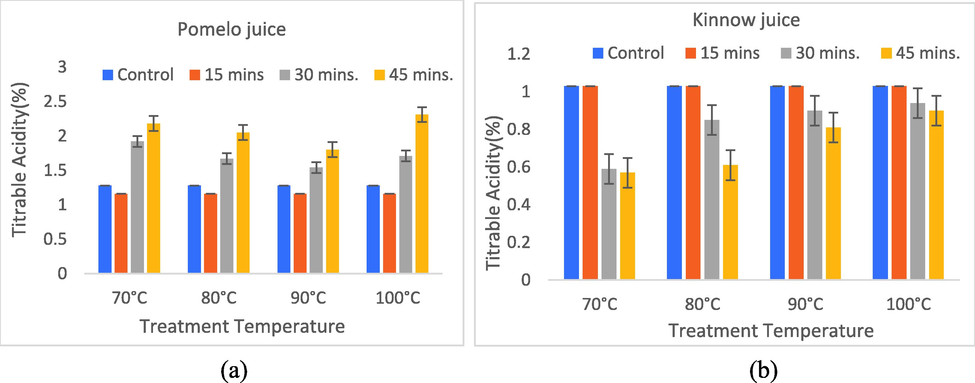

3.2 Effect of heat treatment on titrable acidity

Titrable acidity of fruit beverages is a crucial factor to determine the sourness and maturity of the fruit (Kohli et al., 2019). Fig. 2 shows the effect of heat treatment on the titrable acidity of pomelo and kinnow juice. The titrable acidity of fresh pomelo juice (1.28) was found to be higher than kinnow juice (1.03). From Fig. 2(a), the titrable acidity of pomelo juice increases with an increase in the treatment time from 15 to 45 min for all temperatures and decreases with an increase in treatment temperature. On the other hand, it can be seen from Fig. 2(b) that the titrable acidity of kinnow juice decreases with an increase in the time for the treatment and increases with an increase in treatment temperature. The titrable acidity of fruit juice is very much affected by the method and condition of pasteurization. It also changes during the storage and condition of the storage (Lagnika et al., 2017).

Changes in titrable acidity after heat treatment in (a) pomelo juice (b) kinnow juice.

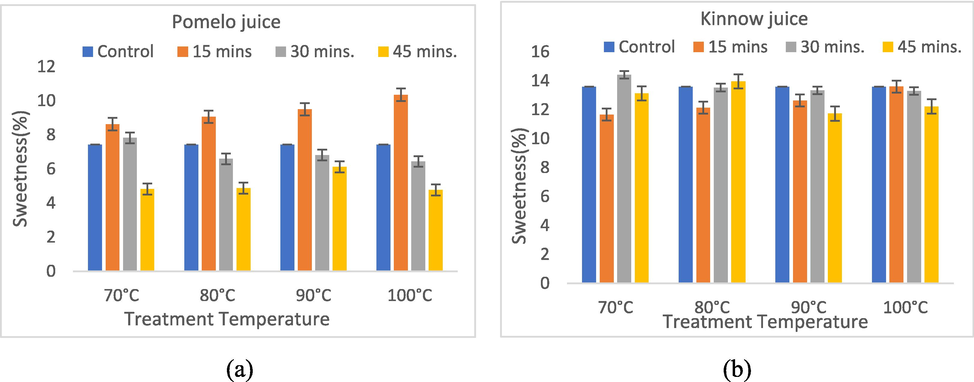

3.3 Effect of heat treatment on sweetness

According to Colaric et al. (2005), the acid and sugar to acid ratio have an impact on sweetness. The changes in the sweetness of fruit juice with heat treatment are shown in Fig. 3. The kinnow fruit juice (13.59 %) is found to be sweeter in comparison to the pomelo (7.43 %). From Fig. 3(a), sweetness of the pomelo juice was found to be higher for the juice treated for 15 min at all temperature ranges as compared to the control. Thereafter, the sweetness was found to be decreased with an increase in the time of heat treatment of the pomelo juice. In continuation, the decrease in sweetness with an increase in the time of treatment may be due to the increase in the acidity of the juice. On the other hand, it was found that there was no significant change in the sweetness of the kinnow juice after heat treatment (Fig. 3(b)).

Changes in the sweetness after heat treatment in (a) pomelo juice (b kinnow juice.

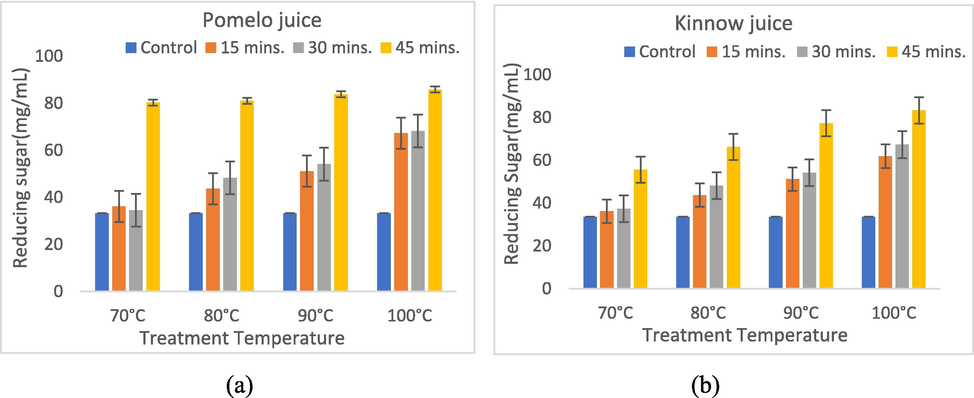

3.4 Effect of heat treatment on reducing sugar

The variations in reducing sugar with heat treatment conditions are shown in Fig. 4. It was found that the reduced sugar of pomelo juice (33.31 mg/mL) is almost the same as the kinnow juice (33.6 mg/mL). It can be observed from Fig. 4(a), that the reducing sugars in the pomelo juice was increases with the increase of temperature and time. So, the highest reducing sugar (85.84 mg/mL) of pomelo juice was found for treated samples at 100 °C for 45 mins. Similar results were found in the case of kinnow (Fig. 4(b)). The reducing sugar of the kinnow juice was found to be increased with the increase in temperature and time for treatment. Therefore, the higher reducing sugar was observed at 83.3 mg/mL for kinnow juice treated at 100 °C for 45 mins. The increase of reducing sugar with the increase in temperature and time could result from the conversion of non-reducing sugar to reducing sugar (Matías et al., 2015). Similar results were also found by other researchers (Kumar et al., 2017; Mehmood et al., 2008; Ricca et al., 2009).

Changes in reducing sugar after heat treatment in (a) pomelo juice (b) kinnow juice.

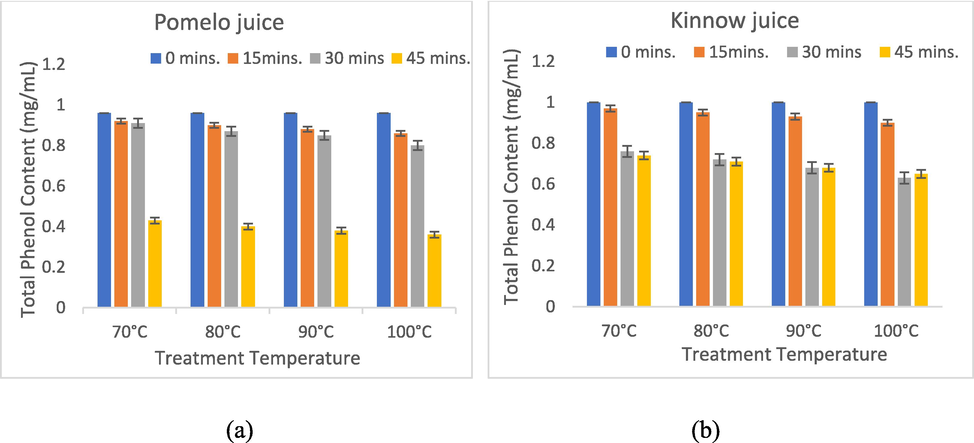

3.5 Effect of heat treatment on total phenol content

Fig. 5 denotes the variations in total phenolic content in pomelo and kinnow juice after heat treatment. The phenolic content of pomelo (0.96 mg/mL) and kinnow (1.00 mg/mL) is found to be almost similar. From Fig. 5(a), it was observed that the total phenolic content of pomelo juice reduces with an increase in treatment temperature as well as the treatment time. The time of treatment has a greater influence on the phenolic content in the pomelo juices. The change is minimum upto the 30 mins of treatment time, while for 45 mins of treatment time, there is a sudden decrease in the values. Therefore, minimum phenols (0.35 mg/mL) in pomelo were obtained in the juice treated at 100 °C for 45 mins. On the other hand, from Fig. 5(b) the phenolic content of the kinnow juice reduces with an increase in temperature and time of treatment, but treatment time has a greater influence. The reduction in the value of phenolic content in the kinnow juice is negligible or minimum up to the treatment time of 15 min, but after that, there is a drastic decrease in the values. However, Su et al. (2019) suggested that after being heat-treated at higher temperatures, the total phenolic content (TPC) of the lychee juice increases as compared to the juices treated at lower temperatures.

Changes in total phenolic content after heat treatment in (a) pomelo juice (b) kinnow juice.

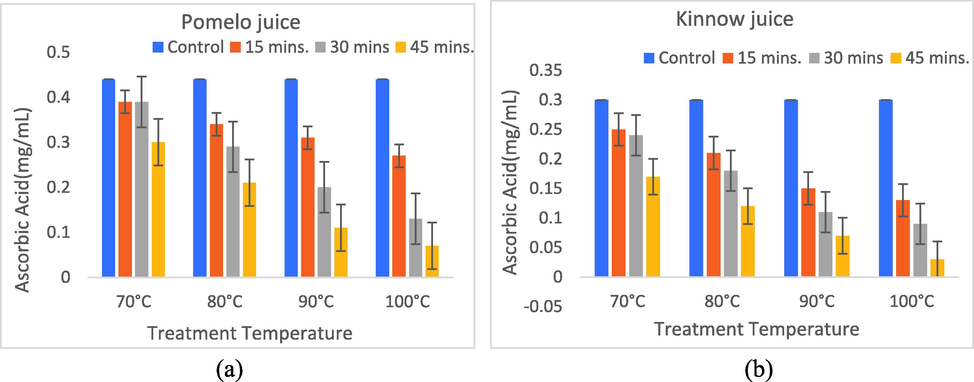

3.6 Effect of heat treatment on ascorbic acid

Vitamin C plays a significant character in antioxidant properties and the browning of juice (Mena et al., 2013). The changes in ascorbic acid in the pomelo and kinnow juice after the heat treatment is represented in Fig. 6. The ascorbic content in the pomelo juice (0.44 mg/mL) is found to be higher than the kinnow juice (0.30 mg/mL). From Fig. 6(a), it can be seen that treatment time and temperature significantly affect the ascorbic acid content in the pomelo juice. The value of the ascorbic acid in pomelo juice decreases with an increase in treatment temperature and time. Similar results were also found for the kinnow juice (Fig. 6(b)). Therefore, the minimum value of the ascorbic content in the pomelo (0.07 mg/mL) and kinnow (0.03 mg/mL) juices was found in samples treated at 100 °C for 45 min. Some researchers suggested that the kind of juice significantly affects the degradation of vitamin C during pasteurization, not the temperature treatment (Mena et al., 2013).

Changes in ascorbic acid after heat treatment in (a) pomelo juice (b) kinnow juice.

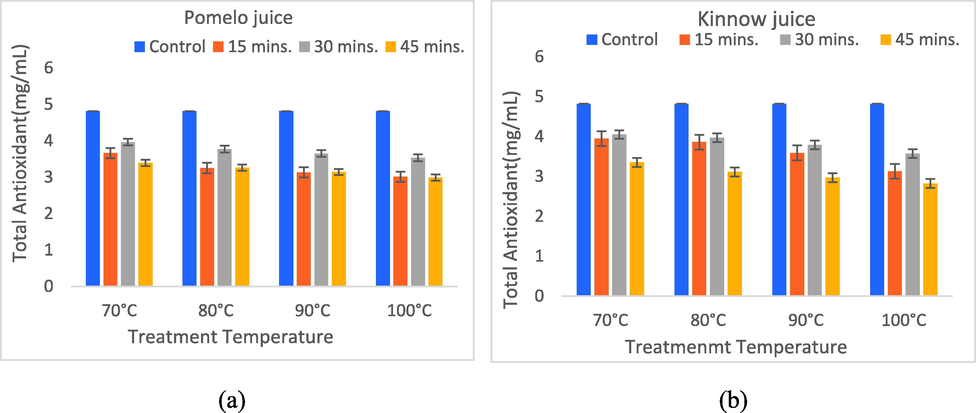

3.7 Effect of heat treatment on antioxidant activity

Fig. 7 represents the changes in antioxidant activity in pomelo and kinnow juice after heat treatment. The antioxidant activity of pomelo (4.81 mg/mL) and kinnow (4.82 mg/mL) is found to be almost similar. From Fig. 7(a), it was observed that the antioxidant activity of pomelo juice reduces with an increase in treatment temperature as well as the treatment time. The maximum change in the antioxidant values was found up to 15 min of treatment time and after that the change in the values is minimal. Similar results were obtained in kinnow juices. Therefore, minimum antioxidant activity in pomelo (0.299 mg/mL) and kinnow (2.82 mg/mL) juice were obtained in the juice treated at 100 °C for 45 mins.

Changes in total antioxidants after heat treatment in (a) pomelo juice (b) kinnow juice.

4 Conclusion

The findings of the study suggest that the selection of a proper temperature–time combination for the heat treatment of citrus juice is a very much important factor in minimally affecting the quality of the juices, as the higher temperature can deteriorate the quality of the juices. The heat sensitive parameters like ascorbic acid, total phenolic content, and antioxidant activity should be considered before selecting the temperature and time for the heat treatment of the product. Based on the results from this study, the low-temperature low time is effective to preserve the heat-sensitive quality. To make this fruit juice on a large scale commercially and for improvements in human health, further study is needed on shelf life, quality enhancement employing stabilizers and packaging, and clinical trials. In future, the effect on quality of the juices with storage and effect of different storage conditions can be studied.

5 Ethics approval and consent to participate

Not applicable.

Funding

Authors are grateful to the Researchers Supporting Project number (RSP2023R360), King Saud University, Riyadh, Saudi Arabia.

CRediT authorship contribution statement

Vijay Kumar: Conceptualization, Validation, Formal analysis, Writing – original draft, Writing – review & editing, Supervision, Project administration. Deepika Kohli: Validation, Formal analysis. Bindu Naik: Conceptualization, Validation, Formal analysis, Writing – original draft, Writing – review & editing, Supervision, Project administration. Ankit Ratore: Validation. Arun Kumar Gupta: Validation, Writing – review & editing. Javed Masood Khan: Validation, Writing – original draft. Mohammad Irfan: Validation, Writing – original draft. Manpreet Singh Preet: Formal analysis, Writing – review & editing. Nidhi Chatterjee: Formal analysis, Writing – review & editing. Sarvesh Rustagi: Writing – original draft, Writing – review & editing.

Acknowledgments

Authors are grateful to the Researchers Supporting Project number (RSP2023R360), King Saud University, Riyadh, Saudi Arabia.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Mild thermal process combined with vanillin plus citral to help shorten the inactivation time for Listeria innocua in orange juice. Food Bioproc. Tech.. 2010;3:752-761.

- [Google Scholar]

- Evaluation of peach and nectarine fruit quality and correlations between sensory and chemical attributes. J. Sci. Food Agric.. 2005;85(15):2611-2616.

- [Google Scholar]

- Comparative study on the effect of heat treatment and sonication on the quality of barberry (Berberis vulgaris) juice. J. Food Process. Preserv.. 2017;41(3):e12956.

- [Google Scholar]

- Effects of thermal processing by nanofluids on vitamin C, total phenolics and total soluble solids of tomato juice. J. Food Sci. Technol.. 2017;54:679-686.

- [Google Scholar]

- Flavor quality of fruits and vegetables. J. Sci. Food Agric.. 2008;88(11):1863-1868.

- [Google Scholar]

- Effect of edible coating on quality of fresh cut sliced papaya. Int. J. Food Sci. Nutr.. 2018;3(2):64-66.

- [Google Scholar]

- Waste utilization of amla pomace and germinated finger millets for value addition of biscuits. Curr. Res. Nutr. Food Sci. J.. 2019;7(1):272-279.

- [Google Scholar]

- Effects of conventional and microwave heating pasteurization on physiochemical properties of pomelo (Citrus maxima) juice. J. Food Process. Technol.. 2017;8(07):8-11.

- [Google Scholar]

- Waste pomelo (Citrus maxima) peels–a natural source of antioxidant and its utilization in peanut oil for suppressing the development of rancidity. Curr. Res. Nutr. Food Sci. J.. 2019;7(3):800-806.

- [Google Scholar]

- Effect of combining ultrasound and mild heat treatment on physicochemical, nutritional quality and microbiological properties of pineapple juice. Food Nutr. Sci.. 2017;8(2):227-241.

- [Google Scholar]

- Optimisation of ethanol fermentation of Jerusalem artichoke tuber juice using simple technology for a decentralised and sustainable ethanol production. Energy Sustain. Dev.. 2015;25:34-39.

- [Google Scholar]

- Effect of pasteurization and chemical preservatives on the quality and shelf stability of apple juice. Am. J. Food Technol.. 2008;3(2):147-153.

- [Google Scholar]

- Combinatory effect of thermal treatment and blending on the quality of pomegranate juices. Food Bioproc. Tech.. 2013;6:3186-3199.

- [Google Scholar]

- Nutritional profile and health benefits of kinnow: an updated review. Int. J. Fruit Sci.. 2020;20(sup3):1385-1405.

- [Google Scholar]

- Handbook of Analysis and Quality Control for Fruit and Vegetable Products. Tata McGraw-Hill Education; 1986.

- Effect of thermal processing on the quality loss of pineapple juice. J. Food Eng.. 2005;66(2):259-265.

- [Google Scholar]

- Optimization of inulin hydrolysis by inulinase accounting for enzyme time-and temperature-dependent deactivation. Biochem. Eng. J.. 2009;48(1):81-86.

- [Google Scholar]

- Applicability of ohmic heating assisted vacuum evaporation for concentration of sour cherry juice. J. Food Eng.. 2017;212:262-270.

- [Google Scholar]

- Effects of thermal treatment and sonication on quality attributes of Chokanan mango (Mangifera indica L.) juice. Ultrason. Sonochem.. 2013;20(5):1276-1282.

- [Google Scholar]

- Effect of thermal treatments on antioxidant and antiradical activity of blood orange juice. Food Chem.. 2004;85(1):41-47.

- [Google Scholar]

- Storage stability of kinnow fruit (Citrus reticulata) as affected by CMC and guar gum-based silver nanoparticle coatings. Molecules. 2015;20(12):22645-22661.

- [Google Scholar]

- Effect of thermal treatment on physicochemical stability and antioxidant properties of locally available underutilized star fruit juice. Asian Food Sci. J.. 2020;14(3):41-53.

- [Google Scholar]

- Quality evaluation of prepared guava-orange fruit bar. Int. J. Chem. Stud.. 2019;7(4):1574-1581.

- [Google Scholar]

- Impact of thermal processing and storage temperature on the phenolic profile and antioxidant activity of different varieties of lychee juice. Lwt. 2019;116:108578.

- [Google Scholar]

- Utilization of Pomelo (Citrus maxima) peel waste into bioactive essential oils: chemical composition and insecticidal properties. Insects. 2022;13(5):480.

- [Google Scholar]

- Heat treatment and microwave applications on homemade sour cherry juice: the effect on anthocyanin content and some physicochemical properties. Curr. Plant Biol.. 2022;29:100242

- [Google Scholar]

Appendix A

Supplementary material

Supplementary data to this article can be found online at https://doi.org/10.1016/j.jksus.2023.102819.

Appendix A

Supplementary material

The following are the Supplementary data to this article: