Translate this page into:

Antioxidant, physical, and flow properties of dried date paste (Phoenix dactylifera L.) determined using a hybrid convection infrared dryer

⁎Corresponding author at: Chair of Dates Industry and Technology, Department of Agricultural Engineering, College of Food and Agricultural Sciences, King Saud University, PO Box 2460, Riyadh 11451, Saudi Arabia. myounes@ksu.edu.sa (Mahmoud Younis)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Dates are difficult to dry into a powdered material with a specific degree of caramelization. Thus, the evaluation of (IR) drying was performed for various IR intensities (0.076, 0.152, and 0.228 Wcm−2), airflow velocities (0.5, 1.0, and 1.5 m/s), and maltodextrin concentration (MD) (0 %, 20 %, 40 %) on the qualitative properties of ‘Sukkari’ cv. date paste. Data analysis revealed that the shortest drying time was obtained at 0.5 m/s air velocity, which approximated 25–95 min by decreasing the IR intensity from 0.228 W/m2 to 0.076 W/m2 at MD of 40 %. Lower IR intensity at high air velocity and MD% resulted in a higher lightness (L) (82.68), lower visible color change (Δ ) (25.15) from medium light to light red (a) (4.78), and yellowness (b) value of 25.84. However, the bulk density of dried date samples did not significantly change under different operation conditions (0.64–0.77 g/cm3). Flowability properties showed the lowest Hausner’s ratio and cohesion index ranged (0.22–2.53 and 2.89–10.13), respectively, at 1.5 m/s and 40 % MD. However, the sample dried at higher IR intensity levels with 0.5 m/s air velocity and 0 % MD concentration had higher antioxidant properties, viz., phenolic content (14.35 mg GAE/g WD) and DPPH inhibition (63.20 %). The results showed that the infrared drying condition significantly affected numerous quality parameters, and the optimal drying condition for color and flow properties of the Sukkari cultivar is 0.0.076 W/cm2 and 1.5 m/s with 40 % maltodextrin; however, for antioxidant activity is 0.228 W/cm2 and 0.5 m/s without maltodextrin which is suitable for storage powder.

Keywords

Date paste

Infrared drying

Maltodextrin

Antioxidant activities

Flow properties

Physical quality

1 Introduction

Date palm is a widely cultivated crop, spanning over 30 countries. The global annual production of date fruits surpasses eight million tons (Bakouri et al., 2021). Date palm trees are grown all over the Kingdom of Saudi Arabia, which produces approximately 1,610,731 tons annually. Over 156,460 ha are planted with these trees, amounting to 24,446,875 trees across Saudi Arabia (FAOSTAT, 2022). in the Kingdom, approximately 24 million palm trees produce 400 different cultivars of dates, including 60 common varieties (Hobani et al., 2003). Due to the sweetness that ‘Sukkari’ cv. dates possess at the Tamer maturation stage, they are a premium cultivar within the date fruit family that is highly demand. ‘Sukkari’ cv. Date rich in phytochemicals such as phenolic compounds.

The utilization of date fruit losses, including specifically low-quality (second-grade) dates such as ‘Sukkari’ cv., which consumers do not prefer in the present circumstances, is essential for producing secondary products that possess economic value, such as date powder. ‘Sukkari’ cv. is a popular date cultivar that grew primarily in the Qassim region. It is yellow or red and is around 3 cm long (Elsharawy et al., 2019).

Drying is recognized as an effective processing method for food preservation. These processes offer a wide range of preserved foods (Jaya et al., 2006). Currently, the process of dehydrating and transforming a commodity into a fine powder using techniques tailored to specific raw materials is widespread. Milk and egg powder were highly prevalent. The popularity of fruit powder is increasing because it is easy to preserve, handle, transport, and store.

Various techniques for dehydrating dates have been documented in the literature, such as solar drying (Seerangurayar et al., 2019), hot-air drying (Al-Awaadh et al., 2015), and microwave drying (Benamara and Chekroune, 2009). A vacuum dryer was utilized to transform date spread from three distinct types, distinguished by varied degrees of sugar content, into a powdered state. Prior studies have investigated the application of spray drying (Manickavasagan et al., 2015) and foam-mat freeze drying methods for the production of date fruit powder. However, previous studies have not explored the use of IR to dehydrate date paste. Furthermore, infrared heating offers numerous advantages over traditional drying methods under identical conditions.

Anti-caking substances can be used in food to counteract the tendency of fruit powders to absorb moisture at elevated temperatures and humid conditions during dehydration. High molecular weight drying aids such as gum Arabic, and maltodextrin are often used to improve the ability of the powder to absorb moisture and flow smoothly (Jakubczyk et al., 2010).

Various high molecular weight substances, such as (MD), are incorporated into fruit paste or juice to create powders that flow freely and resolve the issue of stickiness (Manickavasagan et al., 2015). MDs are high molecular weight additives widely regarded as the most cost-effective option. Maltodextrin enhances the stability and hygroscopicity of fruit juice, sweeteners, and flavorings that pose challenges in the drying process (Gabas et al., 2007). For example, Jaya et al. showed that tricalcium phosphate, an anti-caking agent, and MD enhanced the ability of mango powder to flow smoothly and absorb moisture. Jakubczyk et al. demonstrated that adding maltodextrin significantly decreased the hygroscopicity of apple purée powder. Additionally, Benedetti et al. found that persimmon pulp powder combined with MD exhibited lower water absorption rates when compared to pure persimmon powder.

Investigations on the effects of drying on date paste's physical, flow, and antioxidant properties are very limited and require further investigation. Therefore, the research aims to study the use of maltodextrin as an anti-caking agent in date paste before infrared drying, under the influence of both radiation intensity and airflow velocity on the physical quality, flow characteristics, and antioxidant activity, and determine the optimal drying conditions for date powder.

2 Materials and methods

2.1 Preparing date paste

The experimental investigation included a variety of low-grade date fruits called ‘Sukkari’ cv., which are categorized as second-grade (Phoenix dactylifera L.) fruits. Samples were obtained from the Al-Qassim and Hail markets in June 2023. The packages were then placed in plastic bags to ensure optimal preservation. The dates were stored at a temperature of 5 °C for one week.

Kernels extracted after washing the dates and wiping them to eliminate excess moisture. The moisture content of the recently picked dates ranged from 20 % to 23.5 % w.b. The procedure entailed grinding date flesh using a mincer at a laboratory scale, namely at the Al Halees Centre in Jeddah, Kingdom of Saudi Arabia. This mincing technique aims to obtain a uniform and smooth paste. Date paste was combined with a specified quantity of MD using a laboratory-scale mixer (KM070, 1100 W; Kenwood, China) for 5 min. The preparation of date powders involved the addition of three different percentages of MD to date paste (0 %, 20 %, and 40 %). The date paste was subsequently molded into a thickness of 0.3 cm, with an accuracy of ± 0.05 cm. The width and length of the paste were kept constant at 2 cm and 8 cm, respectively, with an accuracy of ± 0.2 cm. The paste samples were moved into airtight plastic containers and exposed to freezing conditions. Afterward, they were left at room temperature for two hours to prepare for the drying trials (Images of the preparation of date paste are attached in the supplementary file from S1 to S4).

2.2 Design of dryer & test procedure

Drying was conducted using an IR dryer, as shown in Fig. 1. The drying channel, constructed from a 1.5 mm galvanized metal sheet, had internal dimensions of 35 × 35 cm and a length of 234 cm. The main components of the dryer consisted of electric heaters with a power range of 0–3 kW. These heaters warmed the air used in the drying process. A fan with a power of 0.033 kW was used to generate the required airflow over the samples. The equipment was equipped with a balance that had a capacity range of 0–40000 g. The chamber was furnished with 12 IR halogen lamps (model SOPAR, Germany), each with a power output of 0.5 kW, to emit IR toward the samples during drying. The radiation intensity was measured using a pyrometer sensor (model LS122 IR, China).![[A] Actual view and [B] Schematic of the convection infrared drying system [1] drying channel, [2] drying plates, [3] transparent door, [4] process schematic, [5] air velocity sensor, [6] measuring point for humidity and temperature, [7] digital balance, [8] bracket for drying plates, [9] measuring point with humidity and temperature sensor, [10] switch cabinet with digital displays, [11] fan.](/content/185/2024/36/8/img/10.1016_j.jksus.2024.103283-fig1.png)

[A] Actual view and [B] Schematic of the convection infrared drying system [1] drying channel, [2] drying plates, [3] transparent door, [4] process schematic, [5] air velocity sensor, [6] measuring point for humidity and temperature, [7] digital balance, [8] bracket for drying plates, [9] measuring point with humidity and temperature sensor, [10] switch cabinet with digital displays, [11] fan.

The date paste samples were placed onto a holding tray within the chamber. The tray was placed directly in front of the infrared lamps. The distance between the IR lamps and the date paste samples was adjusted by means of height-adjusting screws. The desired radiation intensity was attained by manipulating the height and voltage of the lamps using a voltage regulator, enabling the attainment of the relevant radiation intensities (0.076, 0.152, and 0.228 Wcm−2). The samples were methodically put in the holding trays in a thin layer. The experiments were carried out at three airflows (0.5, 1.0, and 1.5 m/s) and three varying percentages of maltodextrin added to date paste (0 %, 20 %, and 40 %). The mass of the samples was observed until the moisture content of the samples reached approximately 2.2–2.5 % on a wet basis.

2.3 Surface color change

The color of the date powder was quantified using a CR-400 colorimeter (Konica Minolta, Japan). The colorimeter measured three parameters on the Hunter Lab scale: lightness (L), redness/greenness (a), and blueness/yellowness (b) were recorded (Ghnimi et al., 2017). The white plate functioned as a point of reference for calibrating the equipment.

Calculating the total color change or difference (

) between fresh dates and dried dates was also performed using the following Eq. (Elsharawy et al., 2019):

2.4 Total phenolic contents (TPC)

A 5 g powdered date was subjected to polyphenol extraction using 100 mL of 80 % methanol in a water bath maintained at 60 °C for three hours. Following the filtration process, the resulting liquid, known as the extracts, was stored at a temperature of 4 °C. The extracts' total phenolic content (TPC) was determined using the method described by Singleton and Rossi with minor adjustments. A total of 200 mL of the extracts were mixed with 4.0 mL of distilled water and 400 mL of Folin-Ciocalteu reagents and thoroughly blended. Following thorough mixing and a two-hour incubation period, a 20 % Na2CO3 solution was introduced. The mixture was then permitted to incubate for an additional ten minutes at a temperature of 25 °C. The spectrophotometer (PD-303UV, Apel, Saitama, Japan) was used to detect the absorbance at 765 nm. The total phenolic content (TPC) was expressed as milligrams of gallic acid equivalent per gram (GAE/g) of the extracts.

2.5 DPPH inhibition

The free radical activity of the samples was determined by conducting the polyphenol compounds extracted using 1,1-diphenyl-2-picrylhydrazyl (DPPH), as described in Singleton and Rossi (1965). A 1 mL extract solution was mixed with 2 mL of a 4 mg/100 mL methanolic DPPH solution. For control purposes, an equivalent amount of DPPH and methanol were used. After allowing the combinations to stand at room temperature for five minutes and vigorously shaking them, the optical density (OD) at 517 nm was measured. The % inhibition of free radicals was calculated using the following Eq. (Jaya et al., 2006):

2.6 Bulk density & flowability

The flowability of the powder was assessed by employing the Hausner ratio (Seerangurayar et al., 2017), which quantifies the ratio between the densities of the powder after tapping and its bulk density. Three grams of date powder were placed into a 15 ml measuring cylinder, and the bulk density (g/cm3) was determined as the following Eq. [1] (Seerangurayar et al., 2017):

In order to ascertain the tapped density, the cylinder was repeatedly tapped until a consistent volume was achieved. The tapped density (g/cm3) was determined using the method described by Eq. [3] (Seerangurayar et al., 2017):

2.7 Cohension index

The cohesion index was determined using the powder rheometer method, as previously outlined by Janjatović et al., 2012. A volume of approximately 160 ml of the sample was carefully transferred into a measuring cylinder, then weighed and placed on the base of the TA.HD.Plus Texture Analyzer (StableMicro Systems, Godalming, United Kingdom). The cohesiveness coefficient was determined by the integral of the negative segment of the force/distance curve across three successive downward motions of the blade within the measurement cylinder. The cohesiveness index was calculated by dividing the cohesion coefficient by the sample weight.

2.8 Analysis of statistical data

A completely random design was employed for a factorial experiment with a 3 × 3 × 3 design, including radiation intensities, airflow velocities, and different maltodextrin added to the date paste. The objective of this study was to examine the impact of different levels of radiation intensity (0.076, 0.152, and 0.228 Wcm−2), airflow velocity (0.5, 1.0, and 1.5 m/s), and percentages of maltodextrin added to date paste (0 %, 20 %, and 40 %) on the experimental outcomes. Each combined treatment was replicated three times throughout the experiment, resulting in a total of 27 treatments. The analyses were performed three times unless specified otherwise, and the results were presented as the mean values. The statistical analysis was conducted utilizing SPSS Statistics 21.0 (SPSS, Chicago, IL, USA). The post-hoc analysis employed Tukey's test, presenting the results as the mean values.

3 Results and discussions

3.1 Drying time

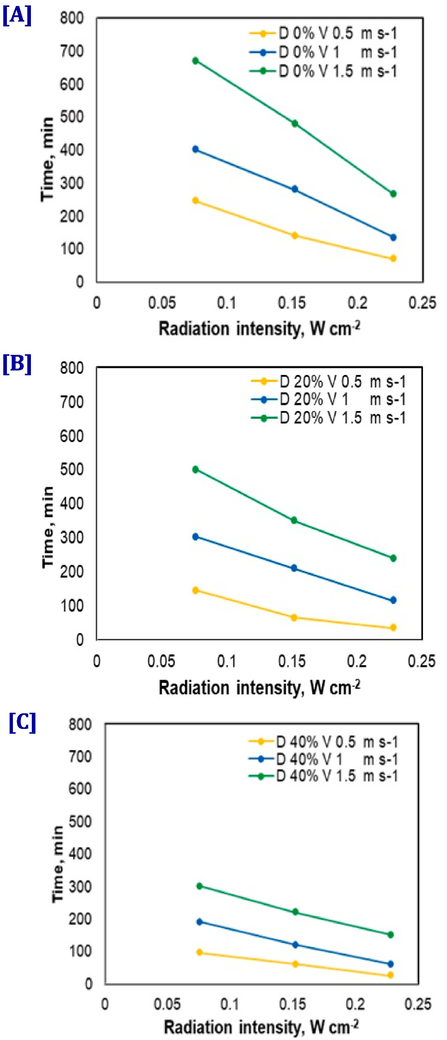

As illustrated in Fig. 2 (A–C), the drying time of date paste samples was reduced with increasing IR intensity and maltodextrin ratio. Lower drying periods were obtained at 0.5 m/s air velocity, which approximated 70–245 min, 35–146 min, and 25–95 min, respectively, by decreasing the IR intensity from 0.228 W/m2 to 0.076 W/m2 at maltodextrin ratios of 0 %, 20 %, and 40 %, respectively. This is consistent with Hajiaghaei and Sharifi (2022), who confirmed a decrease in drying time after adding 20 % of maltodextrin to red beetroot and quince fruit powder under two different drying methods (foam-freezing-heat-air drying).

The Drying time of date paste varies with radiation intensity, air flow velocity, and maltodextrin ratio.

3.2 Surface color change

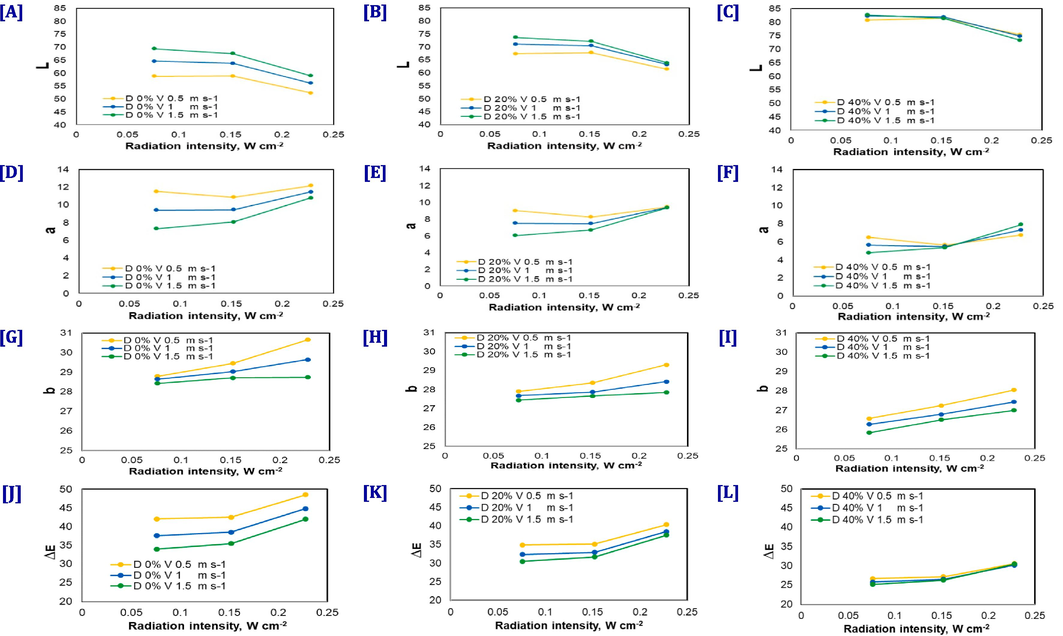

Fig. 3 (A-L) displays the appearance of dried date samples and the outcomes of color analysis, specifically the L, a, b, and ΔE (overall color change) values of dried samples obtained by IR drying at varying air velocities and MD concentrations. Under different air velocities, there was a noticeable change in luminosity, as the “L” value decreased with increasing radiation intensity and thus increasing the temperature. The “L” value also decreased significantly with decreasing air velocity, especially in samples with 0 and 20 % maltodextrin (Fig. 3A and 3B), without any significant changes between IR intensity and air velocity in 40 % maltodextrin (Fig. 3C). Date pastes were much darker at 0.228 W/cm2 and fell to 52.27, 56.13, and 58.98 for 0.5, 1.0, and 1.5 m/s, respectively, with loss percentages of 11.04, 13.07, and 10.41 % for 0 % MD concentration. At the same time, the lightness value was the highest and ranged between (73.36 % and 81.39 %) at 40 % of MD concentration, with no significant change between IR intensity and air velocity (P > 0.05). The dark color in high intensity might be due to the Maillard reaction, a chemical reaction between sugars and proteins. Furthermore, the sugars in dates underwent caramelization as a result of prolonged exposure to heat, leading to a darker effect throughout the drying process (Raza et al., 2019).

Changes in the color parameters L, a, b, and

of date powder at varying radiation intensities, air flow velocity, and maltodextrin ratios.

The existing primary color of the date paste was dark red, and a value of b (yellowness) was utilized to illustrate the variation in color in the resulting date powders. In contrast to the dark red color of the date flesh, the maltodextrin powder was white in hue. As a result, it was anticipated that the proportions of these two mixtures would cause a variation in their color appearance. The whiteness (L value) of the reddish date paste increased as the concentration of white MD in the paste rose, resulting in a corresponding decrease in the redness (L value) of the powder. As indicated by the increased b value, the date paste transformed its initial dark red hue to a yellowish hue upon MD addition in agreement with (Sablani et al., 2008).

The value of a* increased as radiation intensity increased and air velocity decreased (Fig. 3D-3F). The maximum a* value (12.16) was obtained at 0.228 W/cm2 and 0.5 m/s, while the lowest value (4.79) was found at the lowest radiation intensity and the highest air velocity. Furthermore, the b* value was changed significant (p < 0.05), as displayed in Fig. 3G-3I. As the drying temperature increased, the highest value at (0.288 W/cm2, 0.5 m/s, and 0 % MD) decreased significantly (P < 0.05) followed by 27.78 (0.152 W/cm2, 1.0 m/s, and 20 % MD) to 25.84 (0.076 W/cm2, 1.5 m/s, and 40 % MD). Non-enzymatic browning causes an increase in a* and b* values, whereas the breakdown of pigment complexes caused by extreme heating due to increased air velocity causes a drop in a* and b* values. Jogihalli et al (2017). found a similar fluctuation in a* and b* values during chickpea roasting and microwave-roasted black pepper, as indicated in (Desai et al., 2023).

The absence of maltodextrin (0 %) had a substantial impact on the color changes (Δ E) of ‘Sukkari’ cv. dates (41.98–48.54) (Fig. 3J-3L). Furthermore, the rise in Δ E resulting from the increased intensity of infrared radiation (0.228 W/cm2) and reduced air velocity (0.05 m/s) can be attributed to alterations in the specific color attributes (L, a, and b) caused by the browning and caramelization of certain delicate components, such as sugar comprising 78.32 % of the dry weight, and their impact on volatile compounds (Siddeeg et al., 2019). Furthermore, the enzymatic oxidation of phenolic substances during IR drying may also impact the Δ E values of ‘Sukkari’ cv. dates (Doymaz et al., 2016). Overall, low IR heating and high air velocity with 40 % MD concentration could be recommended for keeping the Change color (ΔE) of ‘Sukkari’ cv. dates.

3.3 Total phenolic content (TPC) & DPPH inhibition

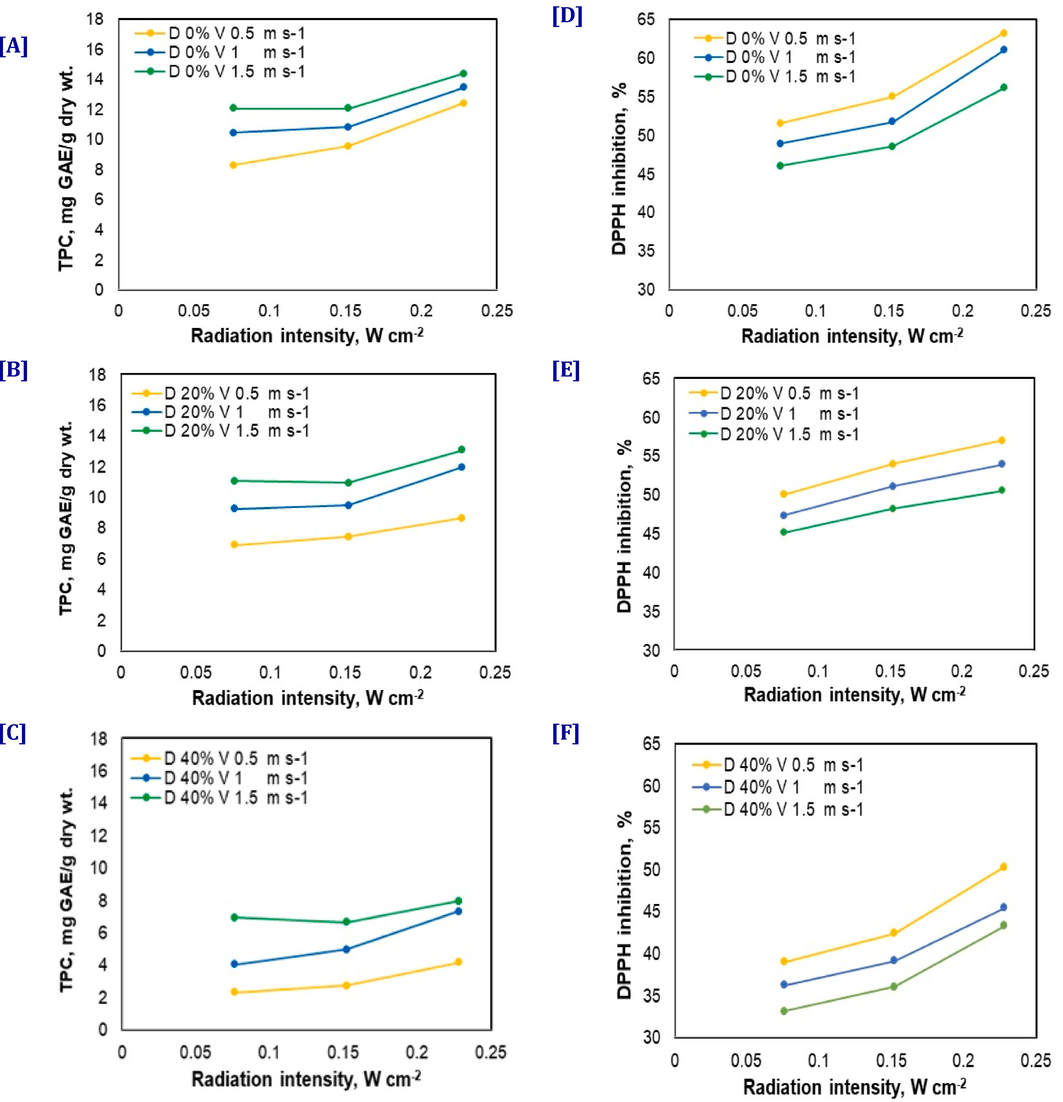

The phenolic contents of a date variety indicate its nutraceutical characteristics due to its antioxidant ability (AlJuhaimi et al., 2020). Fig. 4A-4C demonstrate a notable fluctuation in the total phenolic content of the date paste when subjected to varied intensities of infrared radiation and air velocities at various concentrations of MD. The TPC values peaked at an infrared intensity of 0.228 W/m2, measuring 11.96, 13.44, and 14.44 mg GAE/100 g DW at velocities of 0.5, 1.0, and 1.5 m/s, respectively, in the absence of maltodextrin. A similar observation was made at 20 % and 40 % maltodextrin with lower values compared to 0 % maltodextrin. This finding is consistent with the study of Carranza-Concha et al. (2012), who confirmed a significant rise in the phenolic content of dates as the drying temperature increases. The observed increase might be explained by both tannin degradation and improved extractability, which result from the heat breakdown of lignin-associated phenolic compounds during cellular disintegration (İZLİ, 2016). In contrast, Shahdadi et al. (2015) found that phenolic concentration decreased as temperature increased. Depending on the nature and sensitivity of the phenolic components, dehydration may cause an increase or decrease in phenolic concentration.

Changes in TPC and DPPH inhibition of the date powder at different radiation intensities, air flow velocity, and maltodextrin.

There was no significant difference in phenolic content when comparing 0 % and 20 % of MD concentrations (Fig. 4B and 4C). However, a clear trend of significantly reduced phenolic content (p < 0.05) was seen at a concentration of 40 % MD. This phenomenon may be attributed to the liberation of phenolics from bound constituents (İZLİ, 2016).

The IR intensity significantly positively affected the inhibition of date paste samples. DPPH inhibition of IR-dried ‘Sukkari’ cv. dates ranged from 46.00 % to 63.20 %, from 45.10 % to 57.00 %, and from 33.10 to 50.30 % for 0 %, 20 %, and 40 % MD, respectively, with the highest for those dried at a radiation intensity of 0.076 W/cm2 and air velocity of 0.5 m/s (Fig. 4D-4F). The findings indicate that higher IR intensity led to an increase in the DPPH inhibition of ‘Sukkari’ cv. dates. This is most likely due to increased bioactive chemical release and the formation of Millard reaction products with antioxidant properties (Almusallam et al., 2021). This finding is consistent with the trend observed in TPC (Fig. 4A-4C), suggesting that these compounds significantly enhance the antioxidant capacity. In terms of DPPH inhibition, samples with the highest TPC exhibited the greatest antioxidant capacity.

The interaction between variables (IR*V*MD) did not result in a statistically significant difference (p > 0.05) in the DPPH-free scavenging radical activity of dried samples. This may be attributed to the enhanced preservation of various components, including tocopherols and reducing carbohydrates, which are capable of functioning as antioxidant substances, during infrared drying (Udomkun et al., 2015). These results are consistent with the findings reported by Al-Farsi et al. (2007). The antioxidant activity levels obtained in this study are much greater than those discovered in mango fruit fibers (16.14 mg/g) and guava fiber (26.3–58.7 mg/g) in previous studies (Jiménez-Escrig et al., 2001).

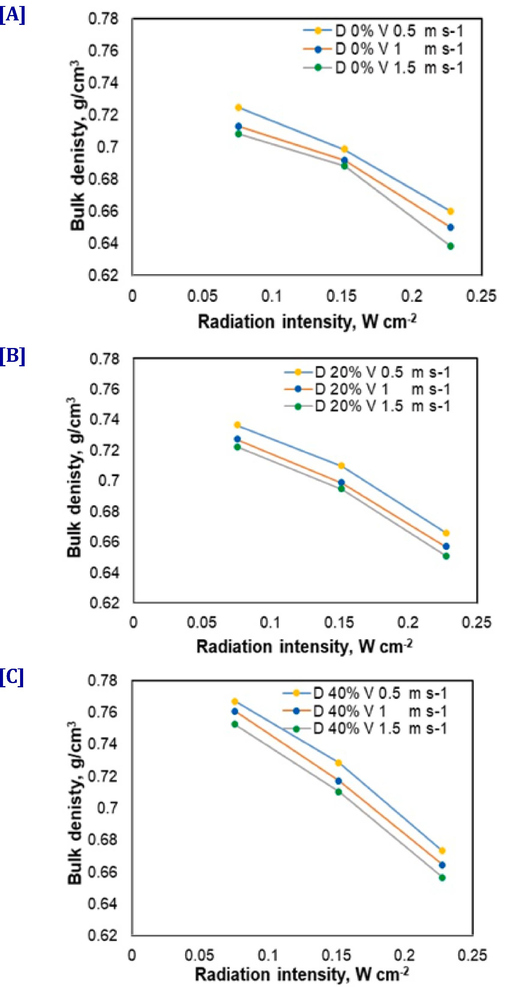

3.4 Bulk density

Bulk density measures the convenience of reconstitution, packaging, transportation, and storage of powdered food (Marques et al., 2014). In addition, the utilization of bulk and particle densities can serve as cost-effective indicators for predicting the quality of particles (Shishir et al., 2014). Fig. 5 (A-C) displays the bulk density of the date powder dried using infrared technology. The powders with 40 % MD exhibited a marginally greater bulk density than those with 0 % and 20 % MD, with no statistically significant disparities (p > 0.05). It was from 0.638 to 0.724 g/cm3, 0.651 to 0.736 g/cm3, and 0.656 to 0.766 g/cm3 for 0 %, 20 %, and 40 % maltodextrin, respectively. Sablani et al. (2008) also observed similar results for oven-dried and drum-dried date powders with MD, respectively. Furthermore, Seerangurayar et al. (2017) demonstrated that the powders produced with MD after drying by foam-mat freeze drying method exhibited a notably greater bulk density. A similar observation was obtained by Bhusari et al. (2014) in their study on spray-dried tamarind powder utilizing MD. The increase in bulk density of date powder at higher concentrations of maltodextrin (higher polymers of glucose) can be attributed to the date powder particles having a reduced characteristic dimension. A denser powder mass was produced by incorporating maltodextrin particulates of a finer (and heavier) consistency into the date paste (Sablani et al., 2008).

Changes in bulk density and flowability of the date powder at different radiation intensities, air flow velocity, and maltodextrin.

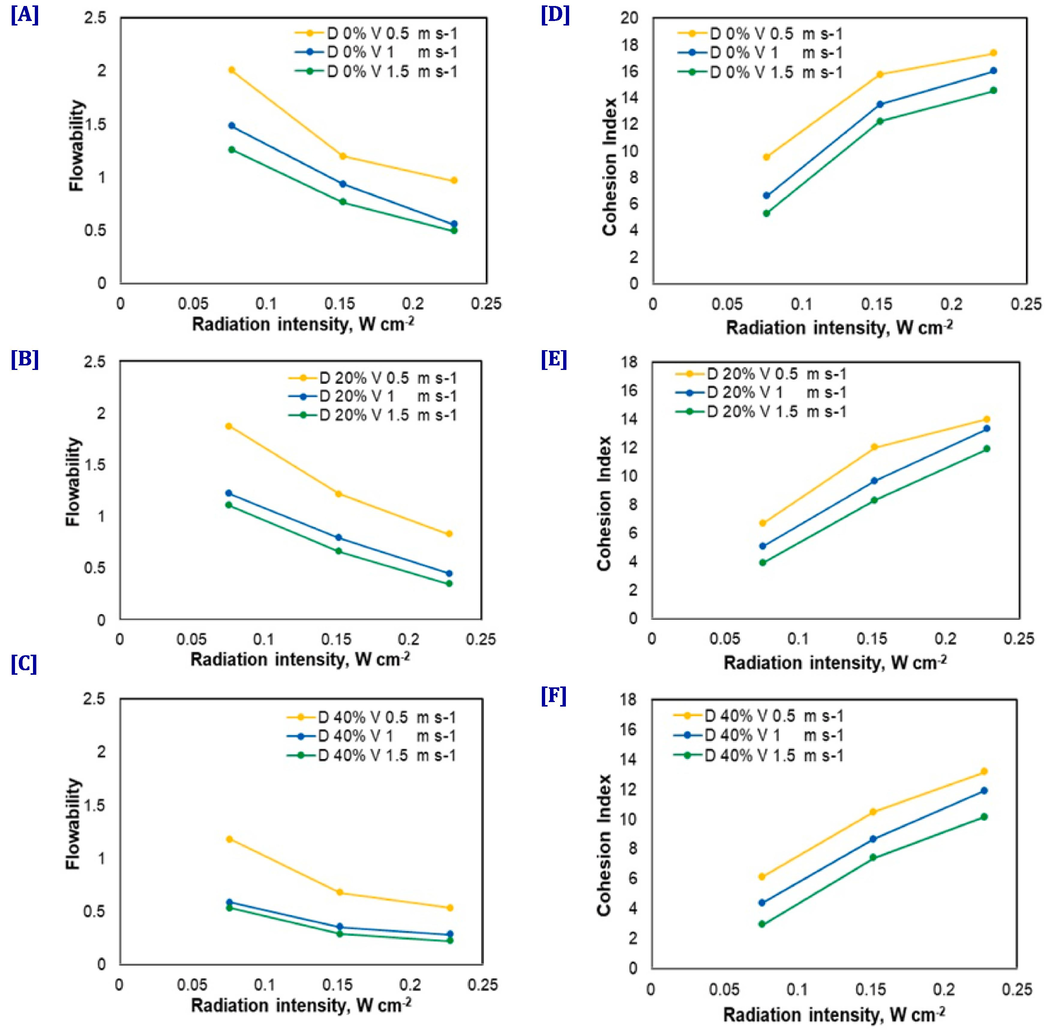

3.5 Flowability & cohesion index

Excellent flowability is an inherent attribute of all powders. A powder exhibiting poor flowability may impede production by causing reduced yields and perhaps causing machine blockages. The powder's flowability was determined by calculating the Hausner Ratio. Fig. 6A-6C demonstrate the changes in flowability in coarse ‘Sukkari’ cv. powders due to variations in IR intensity, air velocity, and MD concentration. With the increase in radiation intensity accompanied by an increase in temperature, the flow properties of date powder decreased. This is in contrast to Hasan et al. (2022), who proved that increasing the temperature from 65 to 75 °C improved the flow properties of Barakawi powder. The variation in flow characteristics of Barakawi and ‘Sukkari’ cv. as temperatures rise may be due to the disparity in their sugar compositions. The study conducted by Wang et al. (2019) found that changes in the levels of fructose, sucrose, and glucose affect the co-melting behavior of these sugars. According to Foster et al. (2006), it is likely that rising temperatures in ‘Sukkari’ cv. result in melting, which encourages the formation of liquid bridges between particles. This, in turn, hinders the movement of substances. The flowability characteristics of a powder are also influenced by several elements, including gravity, friction, cohesion, adhesion, shape, and size of the particles (Dhanalakshmi et al., 2011).

Changes in flowability and cohesion index of the date powder at different radiation intensities, air flow velocity, and maltodextrin.

As shown in Fig. 6A-6C, the Flowability (Hausner ratio) was in the range of 0.49–2.00, 0.346–1.87, and 0.22–1.17 for 0 %, 20 %, and 40 % MD, respectively, added to date paste. Aulton (2002) pointed out that a Hausner ratio greater than 1.25 indicates weak flow; therefore, the percentage achieved by 20 % and 40 % MD was very appropriate in terms of flow. Carr (1965) found that date powder generated with a 50 % concentration of gum arabic in the Khalal stage had good flowability, whereas the other concentrations only showed fair flowability. In addition, Seerangurayar et al. (2017) found that flowability was enhanced when MD was added compared to gum arabic. The rise in MD results in an elevation of the glass transition temperature, leading to a decrease in hygroscopicity and an increase in powder flowability. This is due to the fact that the hygroscopicity of high-sugar amorphous powders is influenced by their glass transition temperature (Bhandari and Howes, 1999).

The powder flow behavior was categorized using the cohesiveness index (Fig. 6D-6F). IR intensity increased particle cohesiveness (from 9.51 to 17.32 mm; 6.66 to 13.94 mm; 6.11 to 13.15 mm) at 0.5 m/s for 0 %, 20 %, and 40 % MD, respectively. These findings indicate that increased air velocity and MD% may lead to a lower cohesion index. The highest (17.32 mm) and lowest (2.89 mm) cohesion indexes were found at 0.228 W/cm2 for 0.5 m/s and 0.076 W/cm2 for 1.5 m/s These findings are consistent with Ribeiro et al. (2020), who confirmed the improvement of powder flow and the reduction of powder cohesion by adding 30 % maltodextrin to cocoa pulp powder samples for both spray and freeze drying. Desai et al. (2023) also found a rise in the cohesiveness index of roasted coffee and black pepper under identical conditions. The increase in cohesion index results from the formation of connections between particles. This occurs when the solid matrix collapses beyond the glass transition temperature, leading to a loss of structure and a decrease in sample volume (Oyinloye and Yoon, 2020).

4 Conclusion

The addition of varying percentages of MD to samples before IR drying induced intricate alterations in the structure and chemistry of the date paste. This led to modifications in the paste color, density, flow quality, and antioxidant characteristics, which were accompanied by a distinct degree of caramelization. The alteration in physical attributes, such as the density of the powder, plays a crucial role in determining the flow properties during the handling and packing of the powder. The antioxidant capabilities of the sample were significantly enhanced by infrared drying. The total phenolic content (TPC) and the DPPH inhibitory activity increased after the drying process. The study's findings offer valuable insights into fundamental characteristics that can be utilized in various food formulations and benefits researchers, processors, and industrial applications. The optimization study revealed that when dried at a power density of 0.076 W/cm2 and an air velocity of 1.5 m/s with 40 % maltodextrin, the date paste exhibited superior color retention and good flow qualities. Additionally, the dried date paste showed enhanced antioxidant capabilities at 0.228 W/cm2 and 0.5 m/s without maltodextrin and may be effectively included in storage powder and food compositions.

Funding: This research was funded by King Abdulazizi City for Science and Technology (KACST), Saudi Arabia, grant number 2–17–04–001–0015.

CRediT authorship contribution statement

Mahmoud Younis: Conceptualization, Data curation, Funding acquisition, Methodology, Project administration, Resources, Validation, Writing – review & editing. Khaled A. Ahmed: Resources, Software, Validation. Isam A. Mohamed Ahmed: Investigation, Methodology, Visualization, Writing – original draft, Writing – review & editing. Hany M. Yehia: Data curation, Methodology. Diaeldin O. Abdelkarim: Conceptualization, Formal analysis, Investigation, Methodology, Resources, Validation. Ahmed Elfeky: Data curation, Writing – original draft.

Acknowledgments

The authors would like to thank King Abdulazizi City for Science and Technology (KACST) for financially supporting this research through project number 2-17-04-001-0015. Thanks are also extended to the Deanship of Scientific Re-search, King Saud University, for the support through the Vice Deanship of Scientific Research Chairs.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- No Title. Int. J. Food Eng.. 2015;11:421-434.

- [CrossRef]

- Compositional and Functional Characteristics of Dates, Syrups, and Their by-Products. Food Chem.. 2007;104:943-947.

- [Google Scholar]

- AlJuhaimi, F.; Özcan, M. M.; Uslu, N.; Ghafoor, K.; Babiker, E. E.; Ahmed, I. A. Mohamed. Bioactive properties, fatty acid compositions, and phenolic compounds of some date palm (Phoenix dactylifera L.) cultivars,“ Journal of Food Processing and Preservation, vol. 44, no. 5, Article ID e14432, 2020.

- Optimization of Ultrasound-Assisted Extraction of Bioactive Properties from Date Palm (Phoenix Dactylifera L.) Spikelets Using Response Surface Methodology. LWT. 2021;140:110816

- [CrossRef] [Google Scholar]

- Colour Change during Hot Air and Microwave Complementary Dehydration of Naturally Dried Date (Phoenix Dactylifera L.) Fruits. World J. Dairy Food Sci.. 2009;4:8-13.

- [Google Scholar]

- Implication of Glass Transition for the Drying and Stability of Dried Foods. J. Food Eng.. 1999;40:71-79.

- [CrossRef] [Google Scholar]

- Effect of Carrier Agents on Physical and Microstructural Properties of Spray Dried Tamarind Pulp Powder. Powder Technol.. 2014;266:354-364.

- [CrossRef] [Google Scholar]

- Effects of Drying and Pretreatment on the Nutritional and Functional Quality of Raisins. Food Bioprod. Process.. 2012;90:243-248.

- [Google Scholar]

- Physico-Functional and Quality Attributes of Microwave-Roasted Black Pepper (Piper Nigrum L.) Int. J. Food Eng.. 2023;19:561-572.

- [Google Scholar]

- Agglomeration of Food Powder and Applications. Crit. Rev. Food Sci. Nutr.. 2011;51:432-441.

- [Google Scholar]

- Effects of Infrared Heating on Drying Kinetics, Antioxidant Activity, Phenolic Content, and Color of Jujube Fruit. J. Food Meas. Charact.. 2016;10:283-291.

- [CrossRef] [Google Scholar]

- Elsharawy, N.T.; Mashael, A.L.; Al-Ayafi, A. Different types of dates in saudi arabia and its most fungal spoilage and its most preservation methods. 2019.

- FAOSTAT, (2022). FAO Statistical Yearbook .Food and Agricultural Organization of the United Nations.

- Glass Transition Related Cohesion of Amorphous Sugar Powders. J. Food Eng.. 2006;77:997-1006.

- [Google Scholar]

- Date Fruit (Phoenix Dactylifera L.): An Underutilized Food Seeking Industrial Valorization. NFS J.. 2017;6:1-10.

- [Google Scholar]

- Physicochemical Properties of Red Beetroot and Quince Fruit Extracts Instant Beverage Powder: Effect of Drying Method and Maltodextrin Concentration. J. Food Qual.. 2022;2022:1-8.

- [Google Scholar]

- Dehydration of Date Fruit (Pheonix Dactylifera L.) for the Production of Natural Sweet Powder. NFS J.. 2022;27:13-20.

- [CrossRef] [Google Scholar]

- Development of a Neural Network Classifier for Date Fruit Varieties Using Some Physical Attributes. King Saud Univ. Res. Cent.. 2003;126:5-18.

- [Google Scholar]

- Total Phenolics, Antioxidant Capacity, Colour and Drying Characteristics of Date Fruit Dried with Different Methods. Food Sci. Technol.. 2016;37:139-147.

- [Google Scholar]

- Moisture Sorption Characteristics and Glass Transition Temperature of Apple Puree Powder. Int. J. Food Sci. Technol.. 2010;45:2515-2523.

- [Google Scholar]

- Assessment of Powder Flow Characteristics in Incoherent Soup Concentrates. Adv. Powder Technol.. 2012;23:620-631.

- [Google Scholar]

- Optimization of Maltodextrin and Tricalcium Phosphate for Producing Vacuum Dried Mango Powder. Int. J. Food Prop.. 2006;9:13-24.

- [Google Scholar]

- Guava Fruit (Psidium Guajava L.) as a New Source of Antioxidant Dietary Fiber. J. Agric. Food Chem.. 2001;49:5489-5493.

- [Google Scholar]

- Physico-Functional and Antioxidant Properties of Sand-Roasted Chickpea (Cicer Arietinum) Food Chem.. 2017;237:1124-1132.

- [Google Scholar]

- V Physicochemical Characteristics of Date Powder Produced in a Pilot-Scale Spray Dryer. Dry. Technol.. 2015;33:1114-1123.

- [Google Scholar]

- Application of Maltodextrin in Green Corn Extract Powder Production. Powder Technol.. 2014;263:89-95.

- [CrossRef] [Google Scholar]

- Effect of Freeze-Drying on Quality and Grinding Process of Food Produce. A Review. Processes. 2020;8

- [CrossRef] [Google Scholar]

- Impact of Drying Methods on Composition and Functional Properties of Date Powder Procured from Different Cultivars. Food Sci. Nutr.. 2019;7:2345-2352.

- [CrossRef] [Google Scholar]

- Flow Behavior of Cocoa Pulp Powder Containing Maltodextrin. Brazilian. J. Food Technol.. 2020;23

- [Google Scholar]

- A New Method of Producing Date Powder Granules: Physicochemical Characteristics of Powder. J. Food Eng.. 2008;87:416-421.

- [CrossRef] [Google Scholar]

- Effect of Carrier Agents on Flowability and Microstructural Properties of Foam-Mat Freeze Dried Date Powder. J. Food Eng.. 2017;215:33-43.

- [Google Scholar]

- Effect of Solar Drying Methods on Color Kinetics and Texture of Dates. Food Bioprod. Process.. 2019;116:227-239.

- [Google Scholar]

- Study of Phenolic Compound and Antioxidant Activity of Date Fruit as a Function of Ripening Stages and Drying Process. J. Food Sci. Technol.. 2015;52:1814-1819.

- [Google Scholar]

- Physical Properties of Spray-Dried Pink Guava (Psidium Guajava) Powder. Agric. Agric. Sci. Procedia. 2014;2:74-81.

- [CrossRef] [Google Scholar]

- Sugar Profile, Volatile Compounds, Composition and Antioxidant Activity of ‘Sukkari’ cv. Date Palm Fruit. J. Food Sci. Technol.. 2019;56:754-762.

- [CrossRef] [Google Scholar]

- Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic.. 1965;16:144-158.

- [Google Scholar]

- Influence of Air Drying Properties on Non-Enzymatic Browning, Major Bio-Active Compounds and Antioxidant Capacity of Osmotically Pretreated Papaya. LWT-Food Sci. Technol.. 2015;60:914-922.

- [Google Scholar]

Appendix A

Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.jksus.2024.103283.

Appendix A

Supplementary data

The following are the Supplementary data to this article: