Translate this page into:

Mechanical properties of Okuzgozu (Vitis vinifera L. cv.) grapevine canes

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Background

The mechanical properties of Okuzgozu grapevine canes influence pruning and harvesting techniques, grape quality, and the feasibility of using mechanical harvesters.

Methods

This study determined the optimal cutting qualities for the native Okuzgozu grape variety (Vitis vinifera L.) over a range of phenological stages and cane diameters. The cutting tests of canes were performed at different growth periods (veraison, 15 days after veraison and harvesting time). A universal material testing equipment was used to investigate the cutting characteristics of the material.

Results

The results indicate that both phenological stages and diameter significantly impacted measured cutting characteristics of grapevine canes. Cutting strength, cutting force, cutting energy and upper bio-yield force gradually decreased with phenological stages. All average maximum values were obtained during the veraison stage. At this stage, the highest values for cutting strength, cutting force, cutting energy, and upper yield were measured at 13.16 MPa, 774.55 N, 5.94 J, and 631.60 N, respectively. The lowest values were recorded at 9.63 MPa, 568.42 N, 3.33 J, and 513.13 N. A close relationship was observed between cane diameter and cutting energy. The energy requirement decreased linearly with decreasing cane diameter.

Conclusion

The maximum cutting energy and force values were calculated at an internode 5 (IN5) as 7.34 J and 995.49 N respectively, the minimum cutting energy and force values were calculated at internode 1 (IN1) as 1.85 J and 385.52 N, respectively.

Keywords

Cutting energy

Cutting force

Grape

Harvest

Phenological stages

1 Introduction

The importance of agriculture in human life is crucial. Even though grapes have long been a valued and significant crop for Turkey’s economy and human diet, most of the pruning and harvesting tasks are still performed manually in vineyards. Therefore, while the labor productivity is low, the production costs are also very high. In addition, the most important vineyard management tasks include pruning and harvesting. By using a grape harvester and a mechanical pruner, time can be saved while reducing labor and production costs (Morris, 2000). The first step when designing a new pruner and harvester is to determine the cutting energy and force. Reduced harvest and postharvest losses should also be determined. Various physical, mechanical, and ripening properties must be known for each grape cultivar separately. Since the design of the machinery used for pruning, harvesting, sorting, transporting, and grading heavily depends on these qualities. Dimensional size, form, sphericity, surface area, geometric mean diameter, volume, mass, etc. are a few of these characteristics (Kabas et al., 2006; Sessiz et al., 2013). These characteristics are influenced by the diameter, variety, species, maturity, cellular structure, moisture content, and cutting knife type (Amer Eissa et al., 2008; Nowakowski, 2016). The measurement of cutting properties for biological materials is very important when designing a new machine. Knowledge of these properties will be useful for academia, industry, research institutes, machine manufacturers (Nesvadba et al., 2004). In order to develop pruning and harvest machines that are effective at using energy and performing well when cutting equipment is used in these machines, it is crucial to have knowledge of the physical, mechanical, and ripening characteristics of the many grape varietals (Alizadeh et al., 2011). The physical and mechanical characteristics of agriculture products and biological materials including grains, fruits, and seeds have been the subject of several studies up to this point. However, the findings of these research were not directly connected to the cutting characteristics of internodes on grapevine canes. Romano et al. (2010) tested various grapevine branch cutting characteristics. Different grapevines' cutting qualities were described by Sessiz et al. (2015). The cutting qualities of numerous wine grape varieties were described by Ozdemir et al. (2015). The physical features of the Rasa grape were examined by Khodaei and Akhijahani (2012). However, mechanical properties of Okuzgozu grape variety at various development stages and cane diameters remain unexplored.

This study measured the cutting forces and energy values along the internodes of the Okuzgozu grape variety at various development stages and cane diameters.

2 Materials and methods

2.1 Vineyard and test samples

The frequently cultivated indigenous grape variety Okuzgozu (Vitis vinifera L.) was used in this investigation (Fig. 1). The test samples were from a vineyard in Diyarbakr district, Türkiye. Canes from grapevines were randomly selected from the vineyard and used for the test. These samples (Fig. 1) were transported to the laboratory and stored in a refrigerator at 5 °C.

View of vineyard area, Okuzgozu grape variety and grapevine canes.

2.2 Measurement of cane cutting properties

The grapevine cane cutting measurements were made at different growth periods (30 August; 15 days after veraison 15 September; harvesting time 30 September in 2016). The grapevine canes were divided into five groups before the experiments. The grapevine cane internodes were named from the top toward to bottom, from one to five. The cutting characteristics include the cutting energy, specific cutting energy, upper yield, cutting force and cutting strength values were measured along the canes for all internodes in three different phenological stages. Within the scope of this study, five different internodes (IN1, IN2, IN3, IN4, IN5) of the vine cane were examined. The diameters of the samples, which are considered as an internode between two nodes, varied between 6 mm and 11 mm. The mean internode diameters of the samples taken were considered as 6.5, 7.5, 8.5, 9.5, 10.5 mm. The internode diameters of the samples were converted to mm2 depending on their diameter values. Prior to the test, the diameters were measured with a caliper to determine grapevine cane diameters. To minimize the impacts of drying, testing was finished as soon as possible. Moisture determinations of the samples were made based on the ASABE standard (Sessiz et al., 2007; Asabe Standarts, 2009; Ozdemir at al., 2017). Three phenological phases of canes were measured for their average moisture content levels at 39.83 %, 47.61 %, and 50.75 % w.b., respectively.

To determine the correlation between cutting strength and deformation, cutting parameters were measured using the Universal Testing Machine (Lloyd LRX Plus) (Fig. 2). The tests were done by placing the samples flat on the machine platform. During the tests, the loading was done on the vertical axis. The cutter blade was made of steel material, the blade angle is 17°, 6 mm thick, 50 mm wide. All cutting tests were performed at the same loading speed (100 mm/min).

The Lloyd LRX plus materials testing machine and cutting blade.

The peak cutting strength, was calculated using the following equation using the cutting force findings (Mohsenin, 1986; Igathinathane et al., 2010; Kronbergs et al., 2011): where: Fmax is the max. cutting force (N), σs is the max. cutting strength (MPa), A is the cross-sectional area (mm2).

Specific cutting energy, Esc was calculated using the following equation: where: Ec is the cutting energy (J), Esc is the specific cutting energy (Jmm−2).

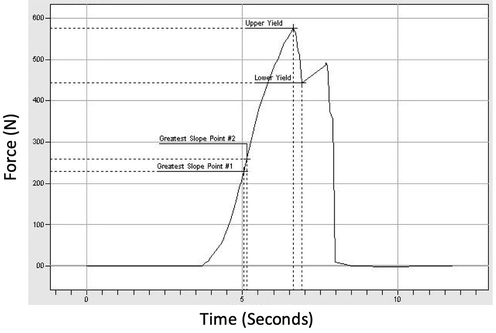

The surface area under the force–deformation curve was measured to calculate the cutting energy (Yore et al., 2002; Amer Eissa et al., 2008; Ekinci et al., 2010; Zareiforoush,et al., 2010; Heidari and Chegini, 2011; Voicu et al., 2011; Nowakowski, 2016). Using a universal testing equipment, the displacement values and cutting energy were calculated. During cutting operations, a computer data collection system captured the force–displacement graphs. A typical force deformation curve for grapevine cane under load is shown in Fig. 3. The first peak point on the graph corresponds to the yield point when the cane damage started. The second peak on the graph represents the maximum compression force. Any more compression results in no increase in applied load at this bio-yield threshold (Lu and Siebenmorgen, 1995; Mohsenin, 1986; Emadi et al., 2004).

Typical force–deformation curve.

2.3 Data analysis

The analysis of variance (ANOVA) approach was used to examine each and every set of data. At the level of P0.05, significant differences in means were analyzed using the least significant difference test (LSD) in JMP software version 11. The results of tests were reported after being repeated at least 15 times. Regression analysis was used in Microsoft Excel (2010) program to determine the relationship between cutting characteristics of grapevine canes and growth periods.

3 Results

Table 1 shows the changes in cutting properties of vine canes at different growth periods. The growth periods have a significant impact on the measured cutting characteristics of grapevine canes, as shown in the Table (P < 0.05). Cutting strength, cutting force, upper yield force and cutting energy gradually decreased with the phenological stages. Maximum values were obtained during the veraison stage. At this stage, while the max. cutting strength, cutting force, bio-yield, specific cutting energy and cutting energy values were determined as 13.16 MPa, 774.55 N, 631.60 N, 0.1 Jmm−2 and 5.94 J, respectively, minimum values were observed as 9.63 MPa, 568.42 N, 513.13 N, 0.072 Jmm−2 and 3.33 J, respectively.

Phenological Stages

Cutting Force

(N)Cutting strength

(Nmm−2)Bio-yield

(N)Cutting energy

(J)Specific cutting energy

(Jmm−2)

Veraison

774.55 a

13.16 a

631.60 a

5.94 a

0.10 a

15 days after Veraison

622.37b

10.87b

526.40b

3.88b

0.065b

Harvest

568.42b

9.63c

513.13b

3.33b

0.051c

Mean

655.11

11.18

557.04

4.38

0.072

LSDz

62.16

0.92

98.39

0.67

0.010

Table 2 shows the mean values of cutting properties at different internodes. Significant differences were observed between the internode diameter of canes at 5 % probability level according to the results obtained via Tukey’s multiple range test. The cutting energy, cutting strength, cutting force and upper yield decreased with a decrease in the internode diameter of the Okuzgozu grapevine canes from 6.5 mm to 10.5 mm. Cutting energy and cane diameter were found to be closely related. The energy required for cutting the canes decreased linearly with decreasing diameter. The max. cutting energy and force values were measured at IN5 as 7.34 J and 995.49 N, respectively. However, while the max. cutting strength was measured at IN1 as 11.63 MPa, the minimum upper yield, cutting energy and force values were measured at IN1 as 355.87 N, 1.85 J and 385.52 N, respectively. From these values, the maximum force decreases from the bottom to the top of the grapevine cane. However, the specific cutting energy increased with increasing internode diameters.

Internode and diameter

Cutting force (N)

Cutting strength (Nmm−2)

Upper Yield

(N)Energy (Nm = Joule)

Specific cutting energy (Jmm−2)

IN1 (6.5)z

385.52 d

11.63

355.87 d

1.85 a

0.056b

IN2 (7.5)

455.04 d

10.31

423.55 cd

2.52b

0.057b

IN3 (8.5)

627.48c

11.06

547.78 bc

4.53c

0.079 a

IN4 (9.5)

810.06b

11.43

646.55b

5.69 d

0.080 a

IN5 (10.5)

995.49 a

11.50

815.11 a

7.34 d

0.084 a

Mean

655.11

11.18

557.77

4.38

0.071

LSDy

95.95

ns

151.88

1.03

0.016

4 Discussion

The current study revealed that the cutting characteristics of grapevine canes were significantly influenced by phenological phases. As the various stages of development advanced, there was a corresponding increase in cutting strength, cutting force, upper bio-yield force, and cutting energy. The maximum point was documented during the veraison stage. Nevertheless, there was an increase in the required cutting energy as the length of the internode increased. The peak yield, cutting strength, cutting force, and cutting energy of Okuzgozu grapevine canes exhibited a decrease as a result of the reduction in their internode diameter. At IN5, the greatest cutting energy recorded was 7.34 J, while the maximum cutting force was 995.49 N. At the IN1 experimental setting, the minimum cutting energy was measured to be 1.85 J, while the minimum cutting force was recorded as 385.52 N.

A comprehensive understanding of grapevine phenology is necessary for effective site evaluation and selection, cultivar and rootstock selection, timing of spraying and fertilization, management of vineyard floor and canopy, and harvesting. The development of efficient pruning procedures, which optimize time and resource use, may be facilitated via an initial understanding of the mechanical characteristics of grapevine canes (Giese et al., 2020). It is necessary to consider the significant variables of cutting force and energy while pruning of grapevines. A study demonstrated significant correlation between the diameter and age of grape canes and the observed cutting force and energy (Esgici et al., 2019). Differential cutting properties have been observed in grapevine canes throughout different phenological stages. A positive correlation has been reported between the increase in internode length and the corresponding rise in shearing force and energy requirement (Esgici et al., 2019). Pruning of vines may lead to alterations in several aspects, including yield, grape composition, storage of non-structural carbohydrates in the trunk and roots, as well as the timing of phenological phases. Regarding Sauvignon blanc grapevines (Falginella et al., 2022), early pruning does not have any significant adverse effects on vine phenology or yield. Previous research has also examined the impact of extensive shoot trimming and crop size management on the composition of berries.

The decrease in cutting energy depends on phenological stages and allows for a proper design of the cutting unit and the prediction of power requirements (Nowakowski, 2016). In particular, the effect of the cane diameter on the cutting energy and force was found to be significant (Ghahraei et al., 2011). The specific cutting energy was observed to be higher at the lower internodes, possibly due to the accumulation of more mature fibers in the canes (Taghijarah et al., 2011). Results of the current study were consistent across studies conducted on sunflower stalk (Ince et al., 2005), rice (Zareiforosh et al., 2010), sugar cane (Taghijarah et al., 2011), and hemp (Kronbergs et al., 2011). Chen et al. (2004) found that the amount of force and energy required to cut a hemp stalk decreased with increasing cross-sectional area. A similar association was found between cutting energy, force, and internode diameter; therefore, this result makes sense. Both Sessiz et al. (2013) and Sessiz et al. (2015) found the same thing for grape and olive suckers. In 2011, Heidari and Chegini investigated the power and cutting energy of a rose petal. In order to generate more cutting energy, the cross-sectional area of kenaf stems should be increased, as stated by Ghahraei et al. (2011). According to Amer Eissa et al., cross-sectional area and moisture content have a major impact on maximum cutting force and cutting energy (2008).

5 Conclusion

The results of the current study revealed that phenological phases significantly affected the measurable cutting properties of grapevine canes. Cutting strength, cutting force, upper bio-yield force and cutting energy gradually decreased with phenological stages. The highest values were obtained at the veraison stage. Nevertheless, specific cutting energy required increased with the increase in internode length. The cutting strength, cutting force, cutting energy, and top yield of Okuzgozu grapevine canes decreased with decrease in the internode diameter. At IN5, the values for maximum cutting energy and force were 7.34 J and 995.49 N, respectively. On the other hand, the values for lowest cutting energy and force were found at IN1 (1.85 J and 385.52 N, respectively).

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Cutting energy of rice stem as influenced by internode position and dimensional characteristics of different varieties. AJCS. 2011;5(6):681-687.

- [Google Scholar]

- Physical and mechanical characteristics for some agricultural residues. In Misr J Ag Eng. 2008;25(1):121-146.

- [Google Scholar]

- Power requirements of hemp cutting and conditioning. Biosyst. Eng.. 2004;87(4):417-424.

- [CrossRef] [Google Scholar]

- Effects of moisture content and compression positions on mechanical properties of carob pod (Ceratonia siliqua L.) Afr. J. Agric. Res.. 2010;5(10):1015-1021.

- [CrossRef] [Google Scholar]

- Relationship between mechanical properties of pumpkin and skin thickness. Int. J. Food Prop.. 2004;8(2):277-287.

- [Google Scholar]

- Cutting parameters of some grape varieties subject to the diameter and age of canes. Fresenius Environ. Bull.. 2019;28:167-170.

- [Google Scholar]

- Effect of early cane pruning on yield components, grape composition, carbohydrates storage and phenology in Vitis vinifera L. cv. Merlot. OENO One. 2022;56(3):19-28.

- [Google Scholar]

- Grapevine Phenology: Annual Growth and Development. Consumer and Environmental Sciences: College of Agricultural; 2020.

- Determining the shear strength and picking force of rose flower. Agricultural Engineering. Ejpau. 2011;14(2):13.

- [Google Scholar]

- Corn stalk orientation effect on mechanical cutting. Syst. Eng.. 2010;107:97-106.

- [CrossRef] [Google Scholar]

- Bending and shearing characteristics of sunflower stalk residue. Biosyst. Eng.. 2005;92(2):175-181.

- [CrossRef] [Google Scholar]

- Physical properties of cactus pear (Opuntia ficus india L.) grown wild in Turkey. J. Food Eng.. 2006;73(2):198-202.

- [CrossRef] [Google Scholar]

- Some physical properties of rasa grape (Vitis vinifera L.) World Appl. Sci. J.. 2012;18(6):818-825.

- [CrossRef] [Google Scholar]

- Mechanical properties of hemp (Cannabis sativa) biomass. Environment. Technology. Resources. 2011;1:184-190.

- [CrossRef]

- Correlation of head rice yield to selected physical and mechanical properties of rice kernels. Transactions of the ASAE. 1995;38(3):889-894.

- [CrossRef] [Google Scholar]

- Physical properties of plant and animals materials (2nd edition). New York, NY: Gordon and Breach Science Publishers; 1986.

- Past, Present, and future of vineyard mechanization. Proceeding ASEV 50 the Anniv. Ann. Mtg Seatle, WA. 2000;51:155-164.

- [Google Scholar]

- Database of physical properties of agro-food materials. J. Food Eng.. 2004;61:497-503.

- [CrossRef] [Google Scholar]

- Empirical model of unit energy requirements for cutting giant miscanthus stalks depending on grinding process parameters. Annals of Warsaw University of Life Sciences – SGGW. Agriculture (agricultural and Forest Engineering). 2016;67:63-70.

- [Google Scholar]

- Cutting properties of wine grape cultivars. Scientific Papers. Series B, Horticulture. 2015;LIX:151-158.

- [Google Scholar]

- Some maturity properties of Okuzgozu (Vitis Vinifera L. CV.) grape berries. Fresen. Environ. Bull.. 2017;28(10):6261-6265.

- [Google Scholar]

- Evaluation of hand forces during manual vine branches cutting. International Conference Ragusa SHWA. Ragusa Ibla Campus- Italy: Work Safety and Risk Prevention in Agro-Food and Forest Systems; 2010.

- Moisture- dependent physical properties of caper fruit. J. Food Eng.. 2007;19:1426-1431.

- [CrossRef] [Google Scholar]

- Cutting Properties of Olive Sucker. Acta Technologica Agriculturae. The Scientific Journal for Agricultural Engineering, the Journal of Slovak University of Agriculture in Nitra.. 2013;16(3):80-84.

- [CrossRef] [Google Scholar]

- Cutting properties of different grape varieties. Agriculture & Forestry. 2015;6(1):211-216.

- [CrossRef] [Google Scholar]

- S358.2 Moisture relationships of plant based agricultural products (52nd edn.). St Joseph MI: American Society of Agricultural Engineers; 2009.

- Shearing characteristics of sugar cane (Saccharum officinarum L.) stalks as a function of the rate of the applied force. AJCS. 2011;5(6):630-634.

- [Google Scholar]

- Voicu, G., Moiceanu, E., Sandu, M., Poenaru, I.C., Voicu, P., 2011. Experiments regarding mechanical behaviour of energetic plant Miscanthus to crushing and shear stress. In Engineering for Rural Development Jelgava, 26.

- Cutting Properties of Rice Straw Paper Number: 026154. ASAE Annual International Meeting / CIGR XVth World Congress 2002

- [CrossRef] [Google Scholar]

- Effect of loading rate on mechanical properties of rice (Oryza sativa L.) straw. Aust. J. Crop Sci.. 2010;4(3):190-195.

- [Google Scholar]