Translate this page into:

Adaptive control of inventory systems with unknown deterioration rate

*Corresponding author abdefoul@ksu.edu.sa (A. Foul),

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Available online 15 February 2011

Abstract

In this paper, a continuous-time model of a production inventory system in which a manufacturing firm produces a single product selling some and stocking the remaining is considered. Model reference adaptive control with feedback is applied to track the output of the system (the inventory level) toward the inventory goal level. The theory is illustrated by the presentation of the results of computer simulation studies of this particular system.

Keywords

Production planning

Inventory

Deterioration

Optimal control

Adaptive control

1 Introduction

Applications of optimal control theory to management science, in general, and to production planning, in particular, are proving to be quite fruitful; see Sethi and Thompson (2000). Naturally, with the optimal control theory, optimal control techniques came to be applied to production planning problems. For example,

-

Self-tuning control: Hedjar et al. (2007) study how to use control and identification methods for controlling the system when its parameters are not all a priori known to the designer.

-

Receding-horizon control: Hedjar et al. (2005) applied a discrete-time technique in which the control action is obtained by repeatedly solving on-line open-loop optimization problems at each time step.

-

Predictive control: Hedjar et al. (2004) used a j-step ahead predictor to predict the tracking error. An identification algorithm is incorporated to estimate the model parameters in the case where they are unknown.

In this paper we apply yet another optimal control technique, called model reference adaptive control (MRAC), in which the performance specifications are given in terms of a model (or targets, or goals); see for example Sastry and Bodson (1989). The goals represent the ideal state of the process. Adaptive control is therefore similar to self-tuning control in that it also attempts to overcome unknown or varying system dynamics while achieving adequate tracking performances.

In order to apply the MRAC to the problem of production planning, we will be using another concept from optimal control theory that of feedback control. This concept was first applied by James Watt to control the speed of his steam engine about 200 years ago. Since then, the number of industrial applications has increased to the point that most automatic control systems today include feedback control. As we progress, we will occasionally make use of some notions from the theory of optimal control that may not be familiar to the management scientists. Each time this proves to be necessary, we will be giving, for the novice, the definition of such notions. In the next section we introduce the notation and formally describe the system. We are assuming that the firm of interest to us adopts a continuous-review (instead of a periodic-review) policy. In Section 3 we derive the optimal control variable when all system parameters are known while in Section 4, we derive the optimal control variable when not all system parameters are known. Illustrative examples are provided in both Sections 3 and 4.

2 Model assumptions and notation

We consider the classical production planning problem in which a manufacturing firm producing a single item, selling some and stocking the remaining units. We assume that the firm has set an inventory goal level and a production (or control) goal rate. We also assume that a proportion of the units in stock deteriorate at a constant rate which may be known or unknown. Item deterioration is of great importance in inventory theory see Goyal and Giri (2001). In this paper, we apply an optimal control technique, called model reference adaptive control (MRAC) to the fore cited production planning problem where the firm adopts a continuous-review policy, that is, the inventory level is monitored continuously. To state the model we use the following notation:

I(t): inventory level at time t,

P(t): production rate at time t (P(t) ⩾ 0),

D(t): demand rate at time t,

θ: constant deterioration rate (θ > 0),

Id(t): inventory goal level at time t,

Pd(t): production goal rate at time t (Pd(t) ⩾ 0).

The interpretation of the goal rates is as follows:

-

The inventory goal level Id(t) is a safety stock that the firm wants to keep on hand at time t.

-

The production goal rate Pd(t) is the most efficient rate desired by the firm at time t.

Given a reference model in terms of goals Id for the inventory level I (state variable) and Pd for the production rate P, the objective of the control problem is to choose an appropriate production rate P such that all the functions involved are bounded and I tracks Id.

Since demand occurs at rate D, production occurs at the controllable rate P, and deterioration occurs at a constant rate θ, it follows that the inventory level I evolves at each instant of time t according to the state equation

In the analysis of process dynamics, the process variables and controls are functions of the time t.

Taking the Laplace transform of both sides of (2.3), we have:

The parameter ad, which is chosen to be positive (ad > 0) in order to ensure the stability of the reference model, represents the rate of convergence of the desired inventory level.

Since the final value of the desired inventory level is given by: or . One can choose the parameter bd to tune the gain between the input/output of the reference model. The parameter bd is also chosen to be positive (bd > 0) in order to preserve the sign between the input and the output of the reference model.

Further, the form of Eq. (2.4) allows us to break the transform of the output variable (namely the desired inventory level Id) into the product of two terms: the fraction, known as the transfer function, and the transform of the input variable (namely the desired production rate ud). The transfer function and its parameters characterize the process and determine how the output variable responds to the input variable.

As we mentioned in Section 1, our aim in this paper is to illustrate an application of the MRAC technique by applying it to a management science problem, namely the production planning problem. In Hedjar et al. (2004, 2005, 2007), a reference model is given and the objective is to obtain the state and control (I, u) that minimize a performance index defined as the sum of the penalty costs incurred when (I, u) deviate from their respective goals (Id, ud). In the MRAC technique, no objective function is designed. The reference model (Id, ud) is still given and the goal is to determine the control u so that the state variable I tracks its goal Id.

The next section treats the case where the deterioration rate θ is known. Then, in the following section we will be dealing with the case when θ is unknown.

3 Model reference control

For I to track Id for any goal control ud, the control variable u should be chosen so that the transfer function from the input ud to the output I is equal to that of the reference model. As mentioned in Section 1, we propose the following feedback control

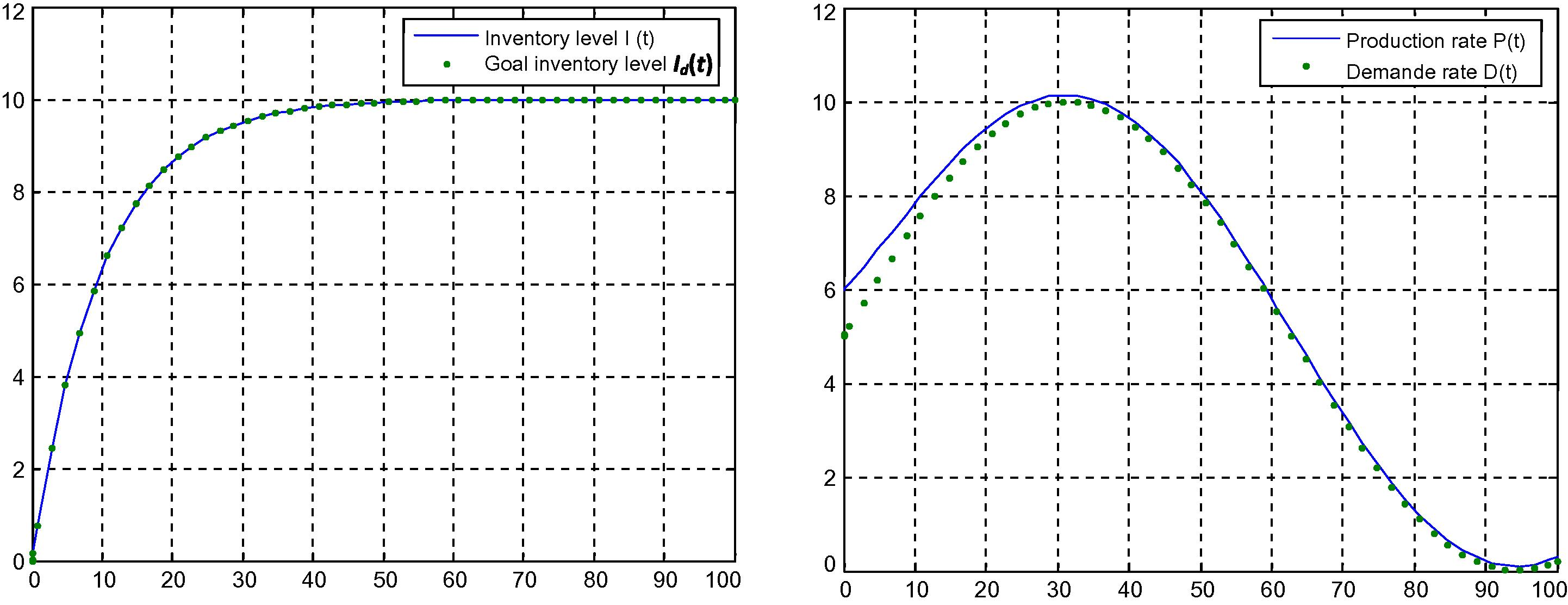

Simulation example: Let us assume, for example, that items in stock deteriorate at a rate of

, so that

Results of model reference control simulation.

4 Model reference adaptive

A situation virtually always met in practice occurs when the deterioration rate is unknown. When the parameter θ is unknown, the control (3.1) cannot be implemented. Therefore, instead of (3.1), we propose the control

4.1 Lyapunov approach

Late in the nineteenth century, Lyapunov (Khalil, 2002; Sastry and Bodson, 1989) developed an approach to stability analysis that is widely used at the present time, known as the direct method. In a nutshell, this method consists of exhibiting a positive scalar function V such that . Such a function is called Lyapunov function and has the origin as a stable equilibrium point. The Lyapunov function is not unique; rather, many different Lyapunov functions may be found for a given system. Likewise, the inability to find a satisfactory Lyapunov function does not mean that the system is unstable. In the context of adaptive control, the use of the Lyapunov approach allows us not only to analyze the stability properties of the system but also to design an adaptive law for k and . First, we recall below, Lyapunov theorem which allows us to differentiate between the stability and asymptotic stability of a system.

Theorem Khalil, 2002

Let x = 0, be an equilibrium point for a general nonlinear system modeled by:

-

If in D, then is stable. This means that given , such that .

-

If in , then is asymptotically stable, i.e., , as .

Using this theorem, we will show that our closed loop system is stable.

Consider the function

4.2 Stability analysis

The inventory system closed by the time varying feedback (4.1) can be represented by: The above closed loop system can be written under matrix form: where represents the state of the inventory system in closed loop and is the state matrix.

The Lyapunov function can be rewritten as: . Since the matrix is positive definite, that is, in where is the equilibrium point or the origin of the closed loop system. We have .

Note that:

-

When , , the state converges toward the equilibrium point provided the tracking error , until the state reaches the origin, in which case , , i.e., and , i.e., .

-

When before x(t) reaches the equilibrium point, and according to the theorem given above, x(t) converges to x0, where , where and are constants. Thus, we have the tracking error , , , i.e., and , i.e., .

This shows that our system is stable and not asymptotically stable. Although in control theory, it is usually preferable to have an asymptotic stability instead of stability, in our case, stability is sufficient since the tracking performance is achieved .

Implementation: The MRAC control law (4.1) and (4.8) is easily implemented. The adaptive gains γ1 and γ2 can be chosen to be any positive real numbers; see Sastry and Bodson (1989). It is to be noted however that these values affect the transient performance of the closed loop system: large γ1, γ2 lead to faster convergence. The initial values are chosen to be a priori guesses of the unknown parameters k and , respectively. Small initial parameter error usually leads to better transient behavior. The reference model and input ud are designed so that Id describes the optimal trajectory to be followed by the state equation.

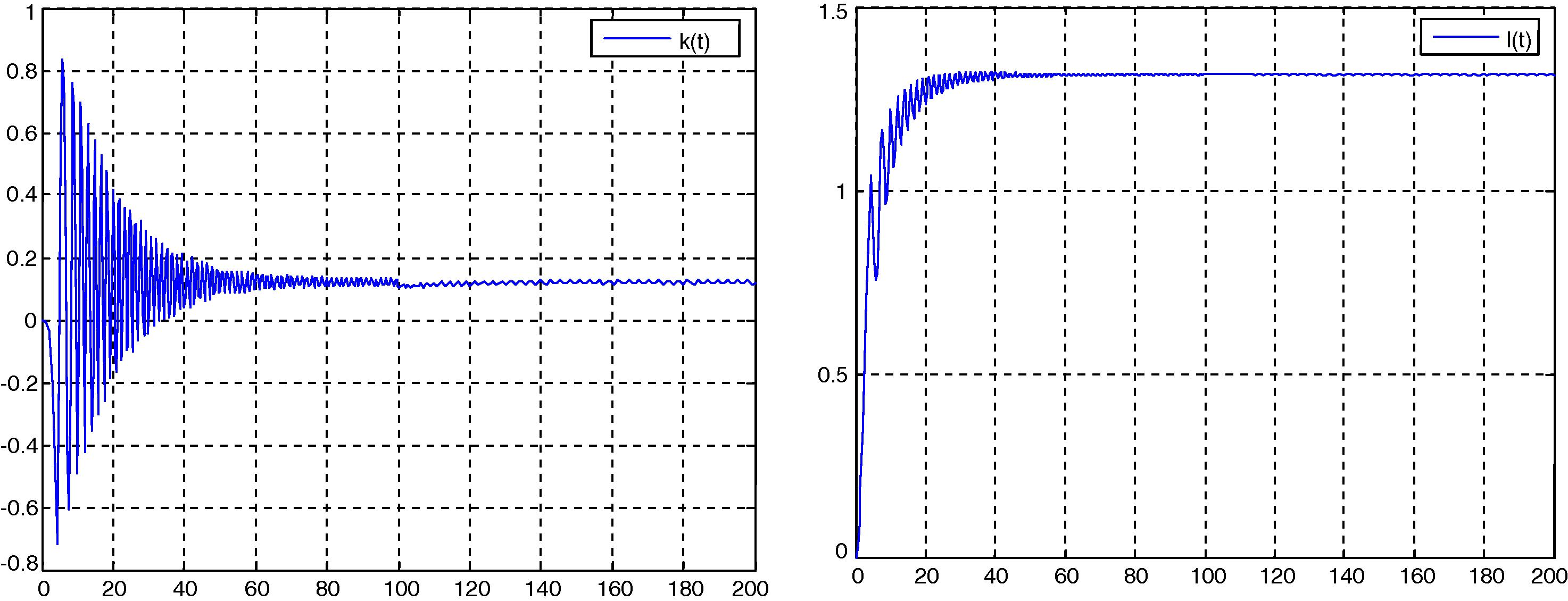

Simulation example: Consider the data of the previous section example, except for the deterioration rate θ that is supposed to be unknown now. We also take

And

. A simulation was conducted for 200 units of time. First we show in Fig. 2 the convergence of k(t) to

(left) and

to

. Note that these results have been expected in the stability analysis.

Convergence results of model reference adaptive control simulation.

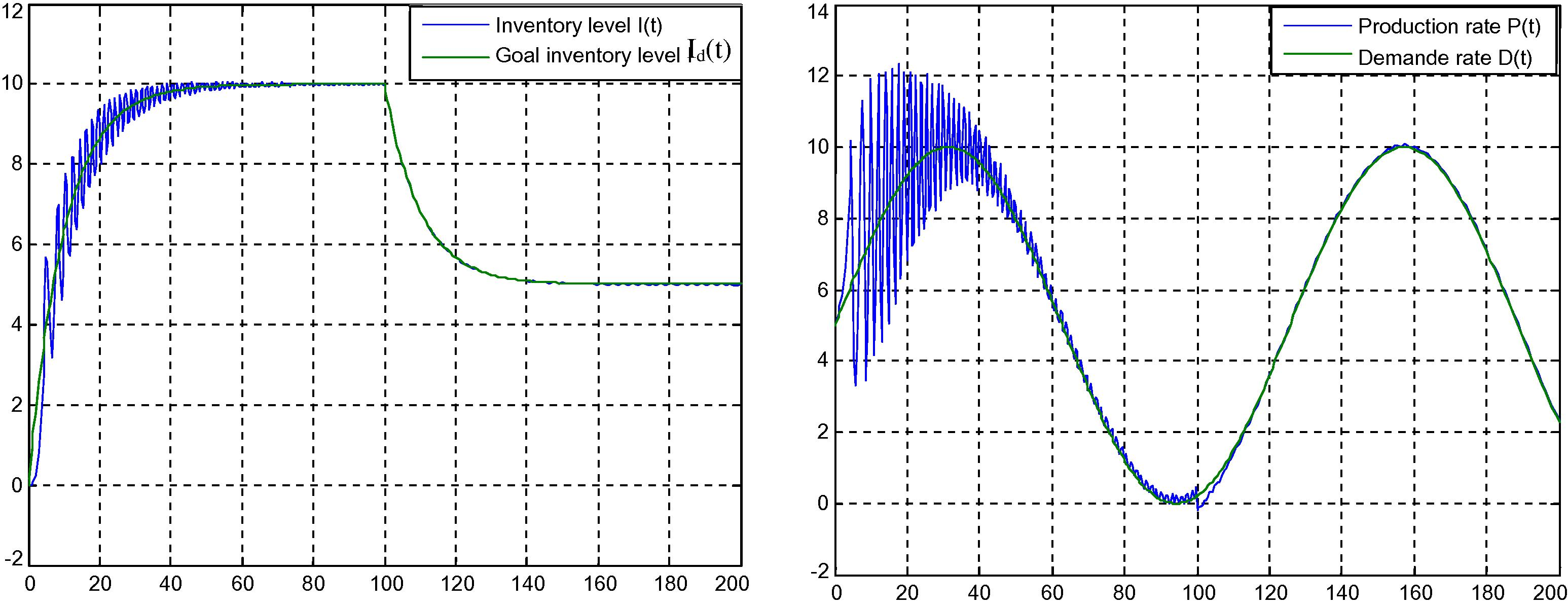

Fig. 3 shows the variations of the inventory level I(t) and the inventory goal level Id (left) and the variations of the production rate P(t) and demand rate D(t) (right). It is depicted that after transient time, the inventory level I(t) tracks perfectly the inventory goal level

.

Variations results of model reference adaptive control simulation.

5 Conclusion

We have shown in this paper how to use an optimal control technique known as ‘Model reference adaptive control with feedback’ to solve a production-inventory planning problem. Simulations have been conducted to validate the results obtained. As a future research direction, we suggest the use of this technique on other inventory models, particularly those involving more than one differential equation, and on problems from other fields, such as economics, finance, etc.

References

- Recent trends in modeling of deteriorating inventory. European Journal of Operational Research. 2001;134:1-16.

- [Google Scholar]

- Predictive control of periodic-review production inventory systems with deteriorating items. TOP. 2004;12(1):193-208.

- [Google Scholar]

- Receding horizon control of a hybrid production system with deteriorating items. Nonlinear Analysis: Special Series on Hybrid Systems and Applications. 2005;63:405-422.

- [Google Scholar]

- Self-tuning optimal control of periodic-review production inventory systems with deteriorating items. Advanced Modeling and Optimization. 2007;9(1):91-104.

- [Google Scholar]

- Nonlinear Systems (third ed.). New Jersey: Prentice-Hall; 2002.

- Adaptive Control: Stability, Convergence, and Robustness. Englewood: Prentice-Hall; 1989.

- Optimal Control Theory: Applications to Management Science and Economics (second ed.). Dordrecht: Kluwer Academic Publishers; 2000.