Translate this page into:

Microstructure and properties of carbon fiber-H62 brass matrix composites prepared by friction stir processing

⁎Corresponding author at: Institute of Materials Science, Changchun University of Technology, Changchun, Changchun 130012, China. yunfengl0615@163.com (Yunfeng Li)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Carbon fibre (CF) reinforced H62 brass matrix composites were fabricated by friction stir process (FSP). The influence of CF compound amount and welding speed on the microstructure and properties of CF-H62 brass matrix composites was investigated by variable orthogonal experiments by drilling CF filled holes in H62 brass plates. Under the set experimental process parameters, the stirred friction processed composites with good surface formation, all without macroscopic defects, no loosening or holes. Optical microscopy, scanning electron microscopy (SEM) and transmission electron microscopy (TEM) were used to observe the microstructure of the joints. The microstructure is a fine isometric crystal that is the result of dynamic recrystallisation. As the welding speed increased from 20 mm/min to 60 mm/min, the average grain size at the weld in the weld zone decreased from 5 μm to 2 μm. When the hole depth of the filled CF was 1.5 mm and the welding speed was 40 mm/min, the CF was most uniformly distributed in the composite area. This paper uses the orthogonal test method to optimise the formulation design of a variety of reinforcement fibre contents. The friction and wear properties as well as the physical properties of the two friction material samples were tested using a constant speed friction tester, a shear strength tester and a Rockwell hardness tester. The influence of each fibre and content on the friction material properties was investigated by extreme difference analysis; The best fibre ratio formulation was selected by combining a fuzzy comprehensive evaluation method. ANOVA was used to investigate the changes in friction material properties after the addition of graphene.

Keywords

H62 brass matrix composites

Friction stir processing

Carbon fiber

Matrix composites

1 Introduction

H62 brass is a copper-zinc alloy containing 62% copper. Based on retaining the excellent properties of copper, it has better mechanical properties than copper, good electrical and thermal properties. Corrosion resistance is better, plasticity, fatigue resistance is better (Ahmad et al., 2018). And it is more conducive to processing and lower production cost than purple copper (Bennett et al., 2019). Brass is a very important non-ferrous metal due to its good overall performance, so it is widely used in industry and other fields. Numerous industrial parts are prepared from brass. Currently, in the field of friction stir welding, there are more studies on aluminium, magnesium and titanium alloys at home and abroad. Research on copper alloys is still lacking. However, with the development of technology, there are higher requirements for the production and processing of brass in various fields (Carrick, et al., 2018). The current industry also requires functional materials with excellent mechanical properties and outstanding friction and wear properties with excellent electrical conductivity. Due to the lack of wear resistance and mechanical properties of brass, the range of applications is also very limited (da Luz et al., 2018). Therefore, the fabrication of brass composites with greatly improved properties while retaining the excellent properties of brass materials has become an important research direction and development need and has received much attention. CF has many outstanding properties, such as excellent specific strength and specific modulus. In addition, it has many advantages such as deformation resistance, wear resistance and corrosion resistance. In recent years, CF has become one of the new materials of interest (Kosiel and Śmietana, 2020).

Translated with https://www.DeepL.com/Translator (free version).

CF is highly resistant to high temperatures and is stable and is often used as a reinforcing phase to improve the properties of the material by compounding with metals and non-metals. Considering the advantages of brass and CF, this study analyzes CF-reinforced brass matrix composites (Kritika et al., 2021). The new CF-H62 brass composite material is prepared by drilling holes in brass filled with CF and by stirring and friction processing using advanced material preparation techniques, which can bring out the advantageous properties of both the matrix and reinforcing phase materials and has design possibilities and development prospects. One of the most important processes in the production of brass is welding and joining (Li et al., 2021). However, conventional welding processes are not suitable for brass. Firstly, due to the high thermal conductivity of brass, a high heat input is required during the fusion welding process, resulting in the formation of a wide heat affected zone (HAZ) in the joint structure (Mori et al., 2021). Secondly, the melting and solidification of the weld metal leads to macro and micro defects at the joint, such as dendritic structure, porosity, shrinkage, large deformations, residual stresses, inclusions, zinc evaporation, color changes and other defects. FSP is an evolution of Friction Stir Welding (FSW) and is similar to FSW in that the FSP process involves stirring the material by inserting a stirring head tool with downward pressure into the material at a high temperature that does not cause the material to melt (Ramasamy and Palanisamy, 2021). The material is deformed and recrystallized by the stirrer tool with adjustable speed, and the structure of the stirred area is refined. Since FSP can process the material at a temperature below the melting point of the material, problems such as welding defects in fusion welding can be avoided. In resin-based friction materials, friction property modifiers and fillers are generally powder granular filling materials, the main function of such materials is to regulate certain properties of friction material products and production costs (Reddy et al., 2018). It includes, adjusting the hardness, strength, density, dimensional stability of material products and friction properties, reduce friction noise, as well as enhance corrosion and moisture resistance (Saleh and Eskander, 2019).

Friction material formulations are often used with a variety of fillers. Some researchers have studied the effect of three friction reducing fillers, graphite, antimony trisulfide and coke, in combination on the friction wear properties of friction materials, and determined the approximate percentage of the three fillers in resin-based friction materials to be 3%-9%. In this study, the experimental difficulty focuses on the uniformity of CF dispersion in brass base after stirring and friction processing. At present, there is no definite solution to such problem in domestic and international research. So this is a key point and a difficult point at the same time. The stirring and friction processing may adversely affect the electrical conductivity of the composites, and it is also a major difficulty to prepare the composites with improved properties without affecting the electrical conductivity too much. At present, there are few studies on the preparation of brass matrix composites by CF. In this study, CF-H62 brass matrix composites were prepared by stir friction processing method, and the macroscopic and microscopic microstructures and properties of the composites were analyzed at welding speeds of 20 mm/min, 40 mm/min and 60 mm/min, and at hole depths of 1 mm, 1.5 mm and 2 mm for CF addition, respectively. The effects of these two variables on the composites were investigated. The effects of these two variables on the composites were investigated. The experimental and theoretical basis is provided for a more uniform distribution of CF in the brass matrix

2 Related works

The coefficient of thermal expansion of CF-Cu composites can be artificially set and changed. At the same time, it has a relatively high thermal conductivity (Singh et al., 2020). However, this method also has some disadvantages. The CF is easily damaged by this method, and the conductivity of the prepared composites is somewhat lower than by other production methods (Smith et al., 2021). The complex process is also costly and the process is complicated, so the efficiency of preparing the material is also low. The researchers prepared CF-Cu composites by using powder metallurgy method. The friction and wear behavior of the material was also analyzed. The researchers used also used this method to prepare CF-Cu matrix composites (Ustolin et al., 2020). It was found that there are various factors in the process of this method that affect the properties of the prepared material. These include: temperature, pressure, number of sinterings, etc. Because of these uncontrollable factors, the powder metallurgy method is more suitable for the preparation of composites with short CF with low fiber content. Researchers have also used the powder metallurgy method (Wang and Zhu, 2018). CF was used to prepare reinforced Fe-Cu based composites. The composites were also subjected to microscopic observation and hardness and wear resistance tests. After experimental analysis, it was found that the addition of CF did improve the friction and wear properties of the composites. It is a very good reinforcing phase. The researchers also used the method of powder metallurgy (Zaaba, et al., 2021). The effect of different amount of CF compounding on the current-carrying and wear resistance of the composite was studied. After testing and analysis, it was concluded that the higher the amount of CF compound, the higher the friction factor. The wear of the composite increases with increasing current density (Ranganath et al., 2022).

The hot pressing method has its own unique advantages. For example, in the preparation process, it is a pressurized state, which prevents fiber springback. In the powder metallurgy method, fiber springback can occur. Therefore, the hot pressing method does not cause a decrease in the density of the fibers and causes less damage to the fibers. The properties of the composites prepared by this method are good (Unhelkar et al., 2022). However, the hot pressing method has some disadvantages of its own, such as the need to pre-prepare the composite yarn before using this method, which is costly. The equipment is expensive, needs to maintain high temperature and long-term pressurization, not easy to put into production, difficult to promote in industry, there are certain limitations. Moreover, CF is brittle and easy to break when subjected to high pressure (Bauer et al., 2020). Moreover, when preparing CF-Cu composites, CF will be easily distributed unevenly. This is due to the plastic rheology of the copper material. This poor phenomenon will be more serious if it is in a continuous hot pressing process. The focus of the extrusion casting process is the liquid phase penetration step (Bayoumy et al., 2021). There are many factors that can influence this step, such as temperature, pressure, cooling rate, etc. This makes the operation more difficult with more aspects to pay attention to, and the organization and properties of the composite material to be prepared need to be controlled in many ways. However, the cost of this method is also lower compared to the first two preparation methods in the previous section (Boland and Bronlund, 2019). However, there are still some disadvantages, such as the difficulty to control the uniformity of CF distribution. Moreover, under high pressure conditions, it causes high concentration of stress. This can lead to cracks between the fibers, which can cause damage if the cracks expand.

3 Forming and tissue analysis of CF-H62 composites

3.1 CF-H62 composite forming

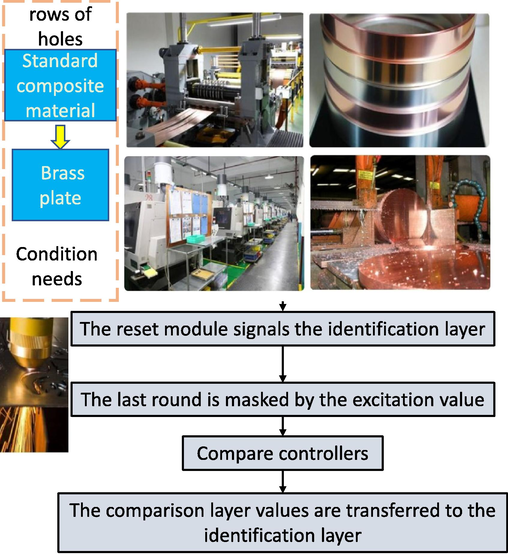

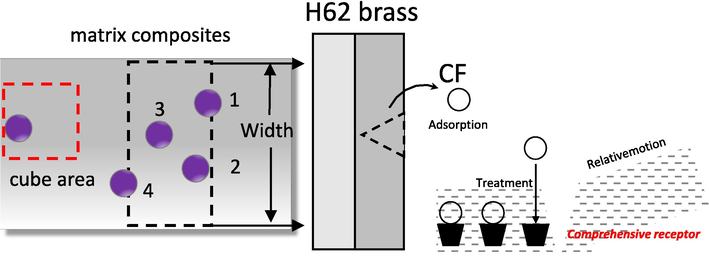

As shown in Fig. 1, three rows of holes are drilled in the H62 brass plate with the dimensions of 350 mm × 120 mm × 4 mm, the diameter of the holes is 2 mm, and the interval between the holes is 0.5 mm. The CF content in the composite material is changed by changing the depth of the holes by filling the holes with CF powder, and each row of holes is divided into three equal sections of the same length, and the depth of the holes in the three sections is 1 mm, 1.5 mm, and 2 mm, respectively. Drilled holes are more anisotropically constrained than slotted holes, so that the CF is not extruded during the stirring friction process. The welding speed of the three rows of holes was 20 mm/min, 40 mm/min and 60 mm/min, respectively, and the rotation speed of the stirring head was fixed at 800 r/min. After filling the holes with CF powder, the brass plate was fixed on the stir friction welding machine with a fixture and stir friction processing was carried out under argon gas to avoid oxidation reaction during the experiment and affect the To avoid the oxidation reaction during the experiment and affect the performance of the composite material. During processing, the stirring head is rotated and inserted into the open area where CF is added, and the stirring friction process is carried out in a straight line along the opening direction at a certain welding speed. During the stir friction process, the stirring head is rotated and inserted into the brass plate to a certain depth. The shoulder of the shaft is in contact with the upper surface of the brass plate, and the stirring needle stirs the brass plate. The grains of the processed material are refined and better dense organization and excellent properties are obtained. In this experiment, CF is dispersed into the base material brass with the stirring of the stirring head, and thus the composite material is obtained.

CF-H62 composite molding.

3.2 Composite material performance testing

The nine experimentally prepared composites were cut into nine specimens of 20 mm × 20 mm × 4 mm at the location containing the welded composite. The cross-section of the specimen perpendicular to the weld direction was ground and polished, and a microhardness test was performed on this cross-section using a Future-tech FM-700 microhardness tester. The test force was 100 gf and the loading time was 15 s. The hardness test line was a horizontal line, chosen to be in the middle of the level containing CF at the stir friction joint. The test points were spaced at 0.5 mm intervals and compared to the average hardness of a stir-fit machined brass with a welding speed of 40 mm/min and a specimen of the same method from the base material. In the CF composite area along the welding direction cut 3 mm diameter, 15 mm length of the cylinder, the nine groups of experimental parameters of the composite material under each group cut three cylindrical specimens, three cylindrical specimens as a group, using the fixture fixed in the vertical universal friction and wear tester MM-W1B friction and wear test, loading pressure of 20 N, wear time of 1 h, before and after the test were weighed, by The wear amount was obtained by calculating the mass difference between the two weighings. The electronic balance model SHANGPING FA2004N was used and compared with the wear of the brass processed by stirring friction at a welding speed of 40 mm/min and the sample of the same method of the base material, as shown in Fig. 2. A field emission scanning electron microscope model ZEISS SUPRA 40 was used to observe the wear surface morphology.

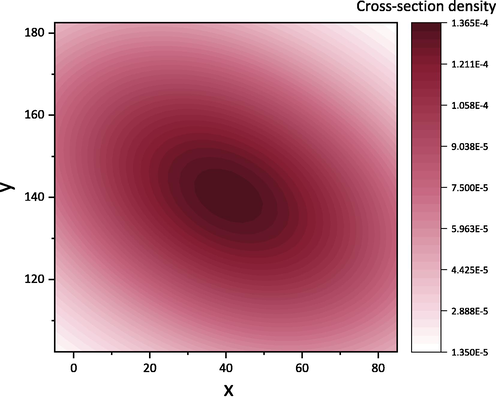

The amount of wear of the specimens with the same method.

Specimens with 5 × 5 mm surface and 1 mm thickness were cut in the CF composite area, and 3 slices of each of the 9 groups of composites under the experimental parameters were cut. The conductivity was measured by a dual electrometric four-probe tester model RTS-9. The average conductivity was calculated for each group of three specimens with a probe spacing of 1 mm and compared with the conductivity of the brass processed by stir friction at a welding speed of 40 mm/min and with that of the base material by the same method. During stir friction machining, the stirring head rotates and the process generates a lot of heat, which causes plastic deformation of the metal and, at the same time, mixing of CF with the brass base by the rotation of the stirring needle. Many factors influence the amount of heat input to the process. For example, the welding parameters such as the welding speed and the rotation speed of the stirring head. On the other hand, friction between the stirrer head shoulder and the brass substrate also occurs, generating a lot of heat. The heat input, in turn, influences the plastic flow of the material during machining and the dispersion of CF in the brass substrate. Adequate stirring and friction generates sufficient heat input for a uniform dispersion of CF in the brass matrix. Fig. 3 corresponds to the cross-sectional morphology of the specimens at the joints of the composite material after stirring and friction processing for nine different experimental parameters, respectively. The results were obtained by metallographic microscopy. The composites were well formed under these sets of process parameters, and no obvious defects such as looseness and holes appeared, which also indicates that the heat input of this experiment is sufficient for the material and the plastic flow of the material is excellent.

Cross-sectional density at the composite joint.

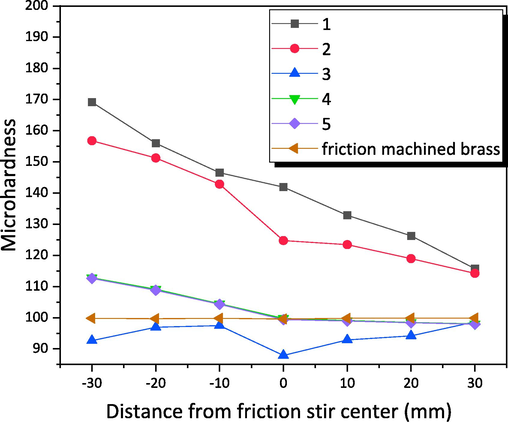

3.3 Hardness of CF-H62 composites

Hardness is one of the mechanical properties of a material. It is a property that measures the softness and hardness of a material. It signifies how easy it is for the object of external force to enter the material when it is subjected to an external force. Hardness testing is an important part of the mechanical properties of materials experiment. Fig. 4 shows the microhardness distribution curve of the stirred friction compound zone of the composite material. It is clear from the graph that the hardness of the brass matrix composite material with CF added for stir friction processing has increased considerably compared to the brass material without CF added for stir friction processing. In addition, it can be observed that when the depth of the hole filled with CF is 1 mm and the welding speed is 20 mm/min (specimen 1), the hardness of the stir friction composite zone of the composite material is maximum.

Microhardness distribution curve in the stirring zone of the composite joint.

The fluctuation of the curves in the figure is due to the unevenness of the hardness at the joints caused by the stir friction processing. After the curves of the brass samples without CF added for the stir friction processing, it can be seen that there are fluctuations and variations, which is due to the grains at the joints being recrystallised by the stir friction processing, and the grains being refined and the hardness being uneven. On the other hand, after stirring friction processing, due to the addition of CF, the organization of the composite material has different uniformity; the hardness is also related to the distribution of CF, which is an excellent material and is used as a reinforcing base in this experiment. When the composite material is subjected to external load, the composite material transfers the external load to CF through the grain bonding interface, and CF can play a role in sharing the load. In addition, the physical properties of CF and brass matrix are different, when the composite material is subjected to external force, the elastic limits of both are different, because CF has high elastic modulus, when the composite material is subjected to external load, when the brass matrix reaches the elastic deformation limit, CF does not reach the elastic deformation limit, CF can play a hindering role for the overall deformation of the composite material, further to improve the composite material Therefore, the composite of CF has a great effect and significance on the improvement of the hardness of the composite material. Therefore, the area with dense distribution of CF can play a more important role in enhancing the hardness of the composite than the area with less distribution, so the hardness value on the curve will be higher, while the curve appears to decrease in the area with sparse distribution.

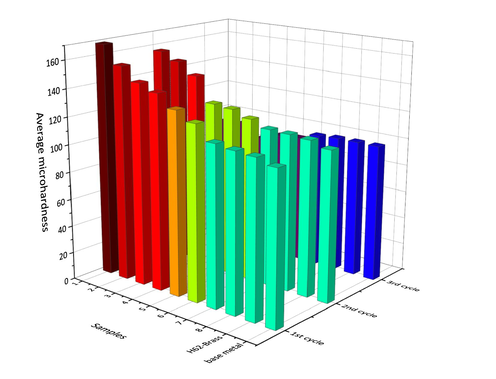

3.4 Hardness test results

As shown in Fig. 5, the average microhardness is the same as that of H62 brass processed by stirring and friction without adding CF. This is due to the heat input generated by the stirring head after the stirring friction process, which refines the grain at the joint and improves the material's ability to withstand external forces. As a result, the hardness of the material is increased. At the same time, the hardness of the base material is lower than that of the brass matrix composite with CF added for stir friction processing. It can be calculated that the hardness of H62 brass without CF added for stir friction processing is about 19.3% higher than that of the base material H62 brass, and the hardness of the composite prepared by adding CF for stir friction processing is about 14.1% to 29.8% higher than that of H62 brass without CF added for stir friction processing, and about 36.1% to 54.9% higher than that of the base material. This also proves that stir friction processing can improve the hardness of H62 brass material, and the addition of CF and stir friction processing can further improve the hardness of the material.

Average microhardness.

It can be seen that after CF compounding, it can play a role in improving the hardness of the material. From the hardness test results, it can be found that when the hole depth is small, i.e., the CF content is small, the hardness of the composite material in the joint composite area is relatively large; when the hole depth is large, the CF content is large, and when stirring friction processing, the CF cannot be well dispersed in the brass matrix, and the CF is unevenly dispersed after stirring, so that the hardness of the composite material is also small. According to this test, it is concluded that the average hardness of the composite decreases as the depth of the hole increases, i.e. the amount of CF compound increases. The analysis shows that it is not the case that the more the CF content is, the stronger the hardness of the material is, but also the uniformity of CF dispersion should be taken into account. CF has two factors affecting the hardness of the composite: on the one hand, the amount of CF compounded and on the other hand, the uniformity of CF dispersion at the joint. When the hole depth is large, the increase of CF in the stirring head for stirring and friction processing will make the stirring insufficient, so that the dispersion of CF in the joint is not uniform, and the situation is that the CF in some parts of the joint is more and some parts are less, so the average hardness is reduced.

4 Experimental results and analysis

4.1 Wear properties of composite materials

Wear of materials is a process that produces a reduction in mass when materials rub against each other. In the frictional wear test, the test force, rotational speed, wear time, the type of ring, the nature of the composite material itself, the composite between the composites, and the roughness of the specimen surface all affect the wear test results. The CF reinforced brass composite material prepared in this paper was found to improve the wear resistance of the material as expected. This is also due to the fact that CF has its own structural characteristics and plays a lubricating role in the material. It forms a protective lubricating film on the friction surface of the material. In this way, it reaches an improved resistance to frictional wear of the material. In this section, the effects of different amounts of CF, different welding speeds, and different pressures on the wear properties of the composite material are discussed. The wear process and mechanism are analyzed by means of wear morphology diagrams.

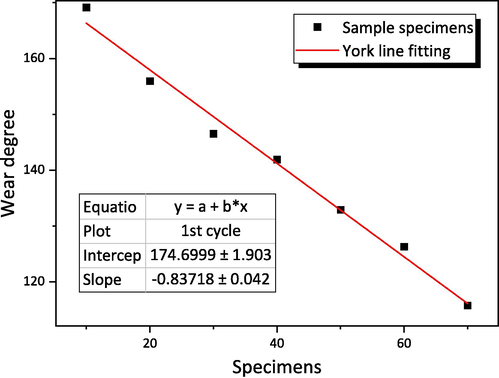

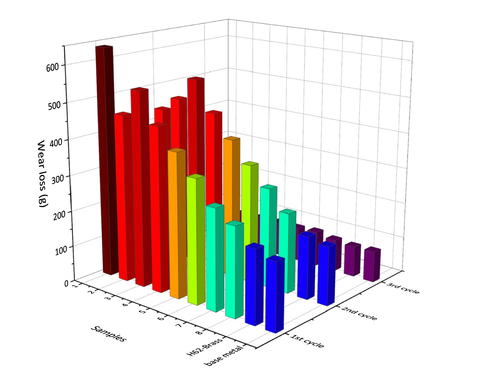

The wear amounts of the composite material, as well as the H62 brass without CF added for stirring friction processing and the base material H62 brass, are shown in Fig. 6 for a friction wear test with a loading pressure of 20 N and a wear time of 1 h. The wear performance is also compared by the amount of wear.

Comparison of specimen wear rates.

The H62 brass specimens processed directly by stir friction without the addition of CF showed more wear than all specimens with the addition of CF, while at the same time showing less wear than the base material H62 brass. It can be seen that stirring friction processing can improve the wear performance of the material, and the CF involvement in the compound, followed by stirring friction processing, further contributes to the improvement of the frictional wear performance of the material. It can be calculated that stir friction processing can reduce the wear of brass specimens by about 37.0%. The specimens processed with the addition of CF showed a reduction in wear of about 15.5%∼41.0% compared to the specimens processed without CF, and a reduction in wear of about 46.7%∼62.8% compared to the base brass specimens. It can be seen that the addition of CF significantly improved the frictional wear performance of the composite. This is due to the high wear resistance of CF itself and the fact that CF can form a solid lubricating film on the friction surface of the material when it is used as a reinforcing base.

4.2 Effect of wear pressure on the wear amount of CF-H62 composite

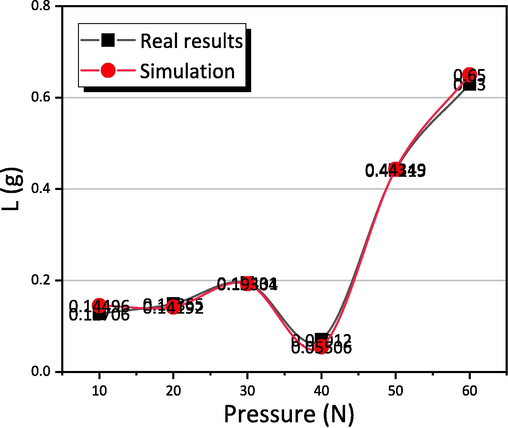

Fig. 7 for specimen 5 (filled with CF hole depth of 1.5 mm, welding speed of 40 mm/min) at different pressures, wear 1 h, the amount of wear at different pressures changes in the line graph. It is clear from the graph that when the pressure is 20 N, the minimum amount of wear of the specimen is 0.0339 g. When the pressure reaches 50 N from 40 N, the growth of the wear volume fold line suddenly increases and a significant increase in the amount of wear occurs. It is analyzed that when the specimen is subjected to frictional wear test, the alternating cutting force is generated on the friction surface between the ring and the specimen under the loaded pressure load, and when the pressure added to the specimen becomes larger, the cutting force also becomes larger, thus leading to an increase in the wear amount of the experiment.

Specimen 5 (filled with CF hole depth of 1.5 mm, welding speed of 40 mm/min) at different pressures.

In the process of friction experiment, the lubricating film formed on the surface of the specimen will also be worn off, the test loading pressure has an important effect on the shedding of self-lubricating film, when the loading pressure is small, i.e. when the pressure is 20 N ∼ 40 N, the pressure is not enough to make the self-lubricating film generated on the friction surface of the material in the process of friction and wear under the alternating cutting force to destroy quickly. When the loading pressure is larger, that is, when the pressure is 40 N ∼ 60 N, the larger alternating cutting force makes the self-lubricating film generated on the friction surface of the material easy to produce fatigue off faster, self-lubricating film off the self-repair, and will fall off under the action of cutting force, the self-lubricating film off the direct frictional wear between the material and the counter-wear ring, at this time the self-lubricating The self-lubricating film can no longer play a timely protective effect on the friction surface of the material, therefore, the amount of material wear increases. When the pressure is 40 N, the folding line growth suddenly increases, indicating that the pressure is just the pressure range that will cause the self-lubricating film to begin to break and fall off.

As seen from the wear morphology diagram, plough grooves can be observed on the wear surface. During the friction process, material particles are dislodged and these particles, under the action of the counter-abrasive ring, cut furrows on the surface of the specimen. The surface of the material specimen and the counter-abrasive ring is not completely smooth, it has very small projections on it, and these factors generate cutting forces along the direction of friction, causing furrows on the friction surface of the specimen. In the early stage of wear, the main shedding is brass matrix, as the counter-abrasive ring continues to rub, CF gradually lose the brass matrix bonding support and adhere to the material friction surface and counter-abrasive ring, forming a lubricating film, the lubricating film protects the matrix directly with the counter-abrasive ring on the micro-convex body or the friction generated by the material particles worn off during the friction experiment, reducing the amount of wear, as shown in Fig. 8 the compound of CF, very good played a role in protecting the material and lubricating the friction. CF is a good choice for improving the frictional wear performance of composite materials. The self-lubricating film formed by CF produces fatigue cracks under the repeated plowing force, and the cracks expand and connect, gradually causing the self-lubricating film to break and fall off, and form abrasive chips, which then reveals the direct frictional wear between the material matrix and the counter-abrasive ring, and the matrix material falls off to form abrasive chips, and then CF will continue to form self-lubricating film to protect the material matrix, and the lubricating film is in the dynamic repair process, and the above process is repeated week after week.

Wear mechanism analysis.

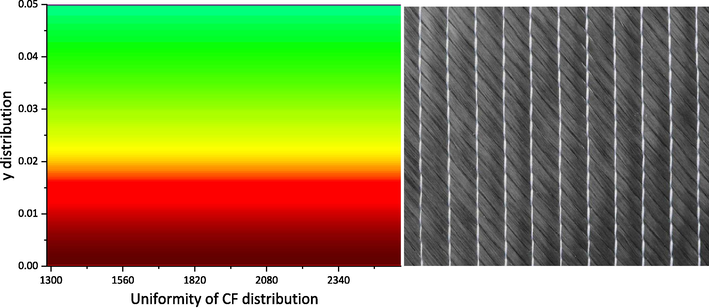

4.3 Effect of grain size and grain boundary area on the properties of CF-H62 composites

Uneven distribution of CF, small amount of CF compound, the coverage area of the formed self-lubricating film is small, not enough to cover the whole wear area, cannot be very effective in protecting the material matrix with the direct wear on the wear ring, so it is easy to form a flaky layer during the wear process, and lead to block off, easy to produce flaking pits, the uniformity of CF distribution has an important impact on the wear resistance of the composite material, as shown in Fig. 9. Abrasive grains cut off many abrasive chips from the surface, and the material on both sides of the plough will produce spalling of the material under the action of repeated motion against the grinding ring, which is called abrasive chips, and this is the principle and process of magic wear. The material on both sides of the plough is hardened by the frictional wear of the hard particles (hardened by the action of repeated deformation) under the action of the shear force, which causes cracks to be produced at a certain depth on the surface of the material, and in the continuous wear, the cracks expand and eventually join together to produce a lamellar layer, and the lamellar layer is turned up in the process of friction, and then flattened under the friction against the grinding ring, so that in the process of repeated friction, fatigue cracks are produced, and fatigue The fatigue cracks expand and join together to form a lamellar layer. The wear mechanism of the specimen processed by stirring friction with CF is mainly the dynamic repair of the lubricating film produced by CF, as well as abrasive wear and adhesive wear.

Uniformity of CF distribution.

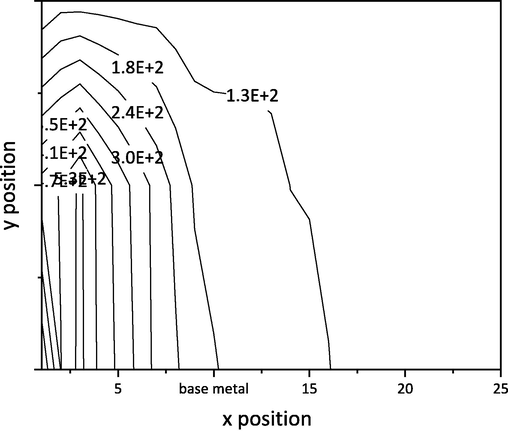

As can be seen in Fig. 10, the conductivity of the H62 brass after stir friction processing decreased compared to the base material H62 brass. However, the conductivity of the composite material with the addition of CF for stirring and friction processing was generally not decreased but increased compared to the base material. The conductivity of specimen 5 was the largest and the conductivity of specimens 7–9 was smaller than that of the other specimens. There are many factors that affect the electrical conductivity of the composites, depending on the specific internal structure of the composite joints. Grain boundaries, twins, and the CF added all have an effect on the conductivity. The number of grains per unit volume is used to reflect the grain size; the higher the number of grains, the smaller the grains. The grain size of a material has a significant impact on many properties of the material. Metals conduct electricity through free electrons, and when free electrons encounter grain boundaries, they move unfavorably, which affects the electrical conductivity. When there are fewer grains, the grain boundary area is small, so the free electrons move more freely and conduct electricity well, and vice versa, the conductivity is poor. So the grain boundary area is large, for the conductivity is not good. After stirring and friction processing, the grain size of H62 brass becomes smaller, so the electrical conductivity decreases compared to the base material. However, at the same time, the twin crystal may also be a high electron migration interface, so the twin crystal may benefit the electrical conductivity of the material and make the conductivity increase. CF has a disordered graphite structure, with graphite lamellae remaining the most basic constituent unit. Graphite lamellae form graphite microcrystals, and graphite microcrystals form the primary fibers, which are at an angle to the fiber axis. The proto-fibers are not straight, but curved and “folded”, and there are pores between the proto-fibers, which affect the electrical conductivity, but the CF has good electrical conductivity along the direction of the monolayer graphite structure. In the direction perpendicular to the monolayer graphite structure, the electrical conductivity is poor.

Conductivity of the H62 brass after stir friction processing.

CF in the composite is bonded to the brass matrix by physical van der Waals forces and the interface is well bonded. The stirring friction processing refines the tissue grain of the material. Deformation twins as well as annealed twins can be observed within the composite. The deformation twins coordinate the deformation of the material and promote the recrystallization of the material. The annealed twin serves to refine the grains, and the refinement of the grains contributes to the improvement of the material properties. Deformation twinning strains are large and may disappear due to the recrystallization process due to the annexation of adjacent grains, or due to the merging of twins with each other and eventually due to dislocation motion. However, the annealed twin strain is smaller and the higher strength of the twin grain boundaries generally makes it difficult to disappear. Dislocations, dislocation entanglements, and dislocation cells can be observed within the composite. The dislocation density increases and dislocation entanglements are formed vertically and horizontally, which come together to form a “wall”, a dislocation wall. The dislocation walls enclose individual “cell-like” regions, dislocation cells.

5 Conclusion

The composite of CF effectively increases the hardness of the material. The hardness of the composite joint was greatest when CF was added at a hole depth of 1 mm and a welding speed of 20 mm/min. The hardness of the composite produced by stir friction processing with CF increased by about 14.1%-29.8% and by 36.1%-54.9% compared to the hardness of the starting material H62 without CF. The more evenly CF was distributed in the joint, the better the average hardness was improved. The welding speed also has an influence on the hardness of the composite, and in this experiment, when the welding speed becomes higher, the hardness of the composite tends to decrease.

There are two competing factors affecting the hardness of the composite, on the one hand, stirring friction processing makes the grain refinement, which is conducive to improving the hardness of the composite, and on the other hand, annealing softening reduces the hardness of the composite, and annealing softening is the dominant factor in this group of experiments. the compound of CF can effectively improve the frictional wear properties of the material. When CF is added to the hole depth of 1.5 mm, the welding speed of 40 mm/min, the wear at the composite joint is the smallest, the best wear resistance of the material. The wear of the composite material prepared by stir friction processing with CF is about 15.5%∼41.0% lower than that of H62 brass without CF, and about 46.7%∼62.8% lower than that of the base material. the more uniform distribution of CF in the composite area, the better the wear resistance of the composite material, and CF can form a solid lubricating film on the surface of the composite material. The hardness of the material also has an effect on the wear resistance, and the higher the hardness, the more it helps the material resist the plowing force. Since the hardness of the joint decreases as the welding speed increases, the wear resistance also decreases as the welding speed becomes larger.

Acknowledgement

The author thankful to the higher authorities for the facilities provided.

Authors’ contribution

This study was done by the author named in this article, and the author accept all liabilities resulting from claims which relate to this article and its contents.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Clay based nanocomposites and their environmental applications. Dev. Prospective Applications Nanosci. Nanotechnol.. 2018;2:166-190.

- [Google Scholar]

- Smartphones in mental health: a critical review of background issues, current status and future concerns. Int. J. Bipolar Disord.. 2020;8(1):1-19.

- [Google Scholar]

- Smart wearable devices in cardiovascular care: where we are and how to move forward. Nat. Rev. Cardiol.. 2021;18(8):581-599.

- [Google Scholar]

- Jolly green MOF: confinement and photoactivation of photosystem I in a metal-organic framework. Nanoscale Adv.. 2019;1(1):94-104.

- [Google Scholar]

- eNutrition-The next dimension for eHealth? Trends Food Sci. Technol.. 2019;91:634-639.

- [Google Scholar]

- A journal for new directions in chemistry rsc. li/njc. New J. Chem. 2018;42(11299):11312-11323.

- [Google Scholar]

- Critical length and interfacial strength of PALF and coir fiber incorporated in epoxy resin matrix. J. Mater. Res. Technol.. 2018;7(4):528-534.

- [Google Scholar]

- Detection in harsh environments. Optical Fibre Sensors: Fundamentals for Development of Optimized Devices 2020:441-476.

- [Google Scholar]

- Incorporation of hydrophobic nanochitosan improves wear resistance of dental sealants. Int. J. Polym. Mater.. 2021;5:309-317.

- [Google Scholar]

- Acrylated Hydroxyazobenzene copolymers in composite-resin matrix inhibits streptococcus mutans biofilms in vitro. Pediatr. Dent.. 2021;43(6):484-491.

- [Google Scholar]

- A review on occurrence, characteristics, toxicology and treatment of nanoplastic waste in the environment. Environ. Sci. Pollut. Res.. 2021;28(32):43258-43273.

- [Google Scholar]

- A study of IOT and its applications on automation and attendance monitoring system. Computer Commun. Informatics (ICCCI), IEEE 2022:4-7.

- [Google Scholar]

- Impact of water flooding on hard cement-recycled polystyrene composite immobilizing radioactive sulfate waste simulate. Constr. Build Mater.. 2019;222:522-530.

- [Google Scholar]

- Effect of alkali treatment on mechanical properties of jute fiber-reinforced partially biodegradable green composites using epoxy resin matrix. Polym. Polym. Compos.. 2020;28(6):388-397.

- [Google Scholar]

- Enhancing supply chain performance using RFID technology and decision support systems in the industry 4.0 -A systematic literature review. IJIM. 2022;2(2):100084

- [Google Scholar]

- Loss of integrity of hydrogen technologies: a critical review. Int. J. Hydrogen Energy. 2020;45(43):23809-23840.

- [Google Scholar]

- Design of radar absorbing structure using SiCf/epoxy composites for X band frequency range. Ind. Eng. Chem. Res.. 2018;57(6):2139-2145.

- [Google Scholar]

- A review: metal filled thermoplastic composites. Polym-Plast Tech Mat. 2021;60(10):1033-1050.

- [Google Scholar]

Further reading

- Bioenergy production on marginal land in Canada: potential, economic feasibility, and greenhouse gas emissions impacts. Appl. Energy. 2017;205:477-485.

- [Google Scholar]

- Evaluation of the latest satellite–gauge precipitation products and their hydrologic applications over the Huaihe River basin. J. Hydrol.. 2016;536:302-319.

- [Google Scholar]

- Closed-loop supply chain coordination strategy for the remanufacture of patented products under competitive demand. App. Math. Model.. 2016;40(13–14):6243-6255.

- [Google Scholar]